Inqubo yokukhipha imali: Kungani ibalulekile ekukhiqizeni?

Isibuyekezo sokugcina ngo-09/14, isikhathi sokufunda: 8 imiz

Ingxenye yensimbi ene-burr nangemva kokukhishwa

Lapho sibhoboza umgodi bese usikeishidi lensimbiphakathi nenqubo yokukhiqiza, imbobo namaphethelo kushiya into eyengeziwe emise okwentaba-mlilo enamathiselwe nhlangothi zombili, eyaziwa ngokuthi i-bur.Cishe zonke izindlela zokukhiqiza, kuhlanganiseukusika, ukugaya, ukumba, ukuqopha,ukuphenduka, kanye namahlamvu ahlabayo, i-burr ezingxenyeni zensimbi ngemva kokuhlinzwa.Le bhula ithinta ukukalwa, ukuhlanganisa, amandla, ngisho nobuhle bobuhle bomkhiqizo.Ngakho-ke, i-Deburring kufanele ibhekwe kuwo wonke amaphrojekthi wokukhiqiza.

Izinhlobo ze-Burr

Izici zomshini nezokusebenza zihlanganisa uhlobo lwamathuluzi, umumo wamathuluzi, izakhiwo ze-workpiece, futhi okubaluleke kakhulu,ukuthi ithuluzi lingena futhi liphuma kanjani ngenkathi lenza umsebenzi wokukhiqiza inquma uhlobo lwe-burr endaweni.

Nazi izinhlobo ezijwayelekile ze-burrokwakudingeka isuswe ekukhiqizeni

| Uhlobo lwe-Burr | Isimo |

| Poisson Burr | Lapho Insimbi ithola ingcindezi eyeqile ngaphezulu, imiphetho yayo ikhubazeka futhi ibe mide. |

| I-burr yokusika | I-burr isesigabeni esisikiwe se-workpiece ngenkathi ihlukaniswa nengxenye emaphakathi. |

| Phenduka | i-burr eyenziwe ekuphumeni kwethuluzi kusuka kucezu lokusebenza: Kuthatha okuthile ngenkathi kuphakelwa |

| Bhubhu izinyembezi | U-Burr wahlala kanye ne-cut-side ngesikhathi sokusebenza ngokushaya. |

Izinhlobo zokukhipha imali

Ukuqothula kungenziwa ngezindlela ezihlukahlukene kuye ngokuthi ingxenye yensimbi kanye ne-burr.Izindlela ezidume kakhulu zokukhipha imali zihlanganisaimanuwali,CNC imishini, i-vibratory, i-electrochemical, i-thermal, ne-abrasive.

1. Ukuhlanza ngomshini we-CNC

Njengoba wazi, yonke inqubo machining in aUmshini we-CNCinamathuluzi athile okusebenza, futhi ukukhipha imali kungazuzwa ngokushintsha ithuluzi, nakuba kungase kwengeze esikhathini somjikelezo.Uhlobo lwethuluzi lokususa luncike ekutheni uzokhipha ini, umboboze, unqamule izimbobo, imiphetho, noma indawo eyisicaba.Ungakhetha ithuluzi elihloselwe kakhulu lolo hlelo lokusebenza ngokusekelwe kulokhu.

Imiphetho:Amathuluzi e-Chamfer noma i-CNC cutter yokusula izinto eziphakanyisiwe futhi bushelelezi ubuso

Izimbobo:Amathuluzi okukhipha imali ajikelezayo

Izindawo eziyisicaba: Amabhulashi eDeburring kalula angafakwa kubhithi

Imicu:Imicu ayinayo i-giant burr.Khetha ibhulashi elifanele.

Ukuhlanza ngomshini we-CNC

Angemva kokukhetha amathuluzi, landela lezi zinyathelo ezilandelayo

1. Setha uhlelo lwe-CNC ukuze kukhokhelwe imali

2. Nquma ukudidiyela kokuqala kwethuluzi (X, Y, Z), bese ulihudulela ocezwini.Ungayisetha ifike kuhhafu webanga lethuluzi.

3. Faka okuguquguqukayo okokufaka okufana namandla okuthobela kanye nezinga lokuphakela elisekelwe kusayizi we-burr.Bese, shuna indawo, bese uqala isenzo.

Izici ze-CNC Deburring

· I-Deburring CNC Machining Components kuyinqubo esheshayo engenziwa kumamodeli eyunithi eyodwa kanye namayunithi amaningi ezingxenye ezikhiqiziwe.

· Uma kuqhathaniswa namasu avamile, ijubane layo lokususa liphakeme;ingakwazi ukuqeda amamitha afinyelela ku-3 ngomzuzu owodwa.

· Imvamisa nokunye okokufaka Okuguquguqukayo kungalungiswa ngokwedijithali ngokwezidingo zokucubungula.

· Akuthinti ukushelela kwendawo yangaphambili futhi ayilimazi ingxenye.

· Akuthinti ukunemba kwe-dimensional noma amandla ezingxenye, futhi isiza ukuqinisa umkhiqizo uma usufakwe ezinye izingxenye.

2. Umfutho ophakeme - ukuchithwa kwejethi yamanzi

Enye indlela edumile yokukhipha uthuli, ama-chips, nama-burr ezingxenyeni ukuze azenze zibushelelezi i-high-pressure water jet deburring.I-burr kanye nezingcezu zengxenye eshiwo yengxenye zikhishwa ngamanzi anomfutho ophezulu (35 kuya ku-60 MPa) kusuka kujethi.Le ndlela yokususa ingaphinda ifinyelele indawo ehlanzekile nengenazinsalela.Ngeshwa, amathuluzi ajwayelekile okukhipha imali awakwazi ukufeza le nqubo yokukhipha imali esetshenziselwa izingxenye eziyinkimbinkimbi.

3. Ukukhishwa Kwemali Manuwali

I-Manual deburring kuyindlela ehlonishwayo yesikhathi yokushelela nokululaza ingaphezulu ngokususa izinsalela ezinamathiselwe ezisele endaweni yomshini wengxenye.Ingasetshenziswa kusetshenziswa amathuluzi ahlukahlukene anomumo nosayizi abahlukahlukene.Amathuluzi ezandla asetshenziselwa ukushaya imiphetho ebukhali kanye nezimbobo ezicijile futhi anikeze ukufana kwendawo.Izinqubo eziningi zokukhiqiza ezenziwa kuma-workshops angazenzeki zincike ekukhishweni kwemali okwenziwa ngochwepheshe abanamakhono.

Isibambo neblade eshintshwayo yizici ezimbili eziyinhloko zamathuluzi okukhipha ngesandla.Ukusebenza kokukhipha emgodini kudinga isandla esiqinile ekubambeni nasekujikelezweni kwama-deburring blades engxenyeni yengxenye, Ngenkathi imisebenzi yokukhipha emikhawulweni yokusika kanye nezindawo eziyisicaba zingenziwa ngokusebenzisa ifayela lesandla noma ithuluzi elivamile le-chamfering.Ngokuya ngohlobo, inqubo yesibili, kanye nezinhlelo zokusebenza zezingxenye, ama-blade anezinhlobonhlobo zomumo angasetshenziswa kusibambo esisodwa ngokufaka esikhundleni sangaphambilini.

Ukukhipha imali mathupha

4. Ukukhishwa kwe-Electrochemical

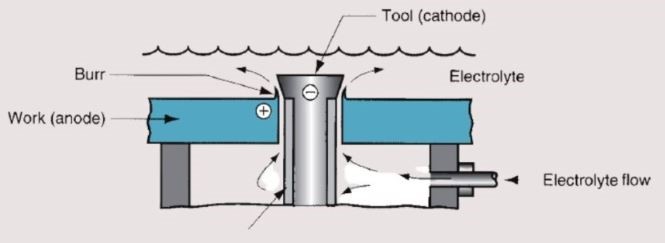

Ama-Burrs kujometri eyinkimbinkimbi kunzima ukuwasusa usebenzisa i-CNC, manual, abrasive, vibratory, nezinye izindlela.Ngakho-ke, kusetshenziswa i-electrochemical deburring.I-Electrochemical deburring isekelwe kumgomo we-electrolysis.

Inqubo ye-Electrochemical deburring

Indawo yokusebenza ixhunywe kutheminali ephozithivu yomthombo wamandla (i-anode).Ithuluzi le-electrochemical deburring eline-insulation lixhunywe ku-terminal negative (cathode), ne-glycol noma isixazululo sikasawoti njenge-electrolyte.I-electrolyte idlula igebe lokuklama phakathi kwe-burr nethuluzi.Incibilikisa ama-burrs ngokudlulisa i-ion yensimbi ye-workpiece, ikhiqize i-hydroxide slurry njenge-byproduct.

5. Ukukhishwa kwe-Abrasive

Izinto ezicolekayo ezicolekile zisetshenziswa kule nqubo ukuze kususwe ukungalungi kahle okuncane endaweni emshinini nokudala ukuthungwa kwendawo okubushelelezi.Insimbi enamandla amakhulu, i-aluminium oxide, nezindwani zengilazi kuyizinto ezivamile zokuhuzuka ezisetshenziselwa ukwakha indiza ekwazi ukucisha ekwazi ukususa ama-burrs ngokuqondisa ijethi ngakuzo.I-Micro-abrasive blasting elinye igama layo elisetshenziswa abakhiqizi.Njengoba le ndlela yokususa ikhipha ama-microns phezulu, iyenza ifaneleke izingxenye ezidinga ukunemba okwedlulele, njengamabhulokhi enjini, i-aerospace, nezinto zerobhothi.

Izinzuzo Zokukhipha Imali

Isilinganiso sezinzuzo zokudonsa, ukuhlanganisa, amandla, ubuhle bobuhle, kanye nekhwalithi yomkhiqizo wokugcina.

Nazi izinzuzo ezibalulekile;

· I-Deburring isusa insimbi enamathiselwe embobeni nangaphezulu, ngakho-ke ibenza bushelelezi futhi kusize ukudala amandla ahlanganiswe kahle ngenkathi kujoyina izingxenye ezikhishiwe.

· Izimbobo ezihlanzekile zenza ukukhwelana okuphelele ekuhlanganiseni.

· I-flatness yezingxenye iyanda ngokukhipha, okuzokwenza kube lula ukusebenza kwesibili.

· U-Burr angakwazi ukusonta uhlangothi olulodwa lwengxenye ngenkathi ejoyina nabanye, okuholela ekungaqondani kahle phakathi kwabo.Ngenxa yalokho, ukungaqondi kahle kudala amandla okwenza umkhiqizo ungaphumeleli.Le ngozi yokwehluleka ingancishiswa ngokushiswa kahle kwezingxenye.

· Lapho isilinganiso sithathwa futhi sisetshenziswa phakathi nezigaba zokukhiqiza, indawo engalingani yeshidi lensimbi eline-burr enamathiselwe izothinta ukunemba.Usayizi ongalungile ungaholela ekuhlulekeni ezicini zomkhiqizo futhi kungaba umkhiqizo ongagculiseki wamakhasimende.

· Indawo ebushelelezi, eboshiwe ithuthukisa ubuhle bengxenye futhi isiza enqubweni yokuhlobisa eyengeziwe.

· Imiphetho eminingi esanda kusikwa inemiphetho ebukhali;ukudabula kungashelela ubukhali, kwenze abasebenzi namakhasimende bazizwe bephephile.

Imikhawulo yokukhipha imali

Ngaphandle kokungabaza, i-Deburring iyindlela engcono kakhulu yokushelela ingaphezulu lezingxenye zensimbi, kodwa inemikhawulo ethile ekusebenzeni ezimeni ezimbalwa.

1. Amakhona acijile nemiphetho

Ukukhipha amakhona acijile futhi ane-engeli ephansi kunzima kakhulu.Ingasusa isitoko esiningi kakhulu esinama-burrs amancane, okuholela ekulahlekelweni kobukhulu bengxenye yensimbi.

2. Amakamelo avaliwe

Ukuchithwa kwamakamelo avaliwe kunzima kakhulu ukuqhubeka nakho.Ukukhipha ama-burrs emaphethelweni egumbi kungahoxisa ukujiya okubalulekile kwegumbi.

3. Amajiyometri ayinkimbinkimbi

Zonke izingxenye azikwazi ukukhishwa ngamathuluzi azungezayo, njengegiya le-bevel, nezinye izinto zokudlulisela, ngoba lezi geometries eziyinkimbinkimbi zishiya i-burr ende newugqinsi.

4. Ukukhuhla ebusweni

Ngesikhathi sokubushelelezi kobuso ngokudiliza, uma ochwepheshe bengabambi amathuluzi, kunengozi yokukhipha phezulu ngaphandle kokunakwa okufanele, okuthinta ubukhulu bengxenye yensimbi, ukwehlisa amandla omkhiqizo wokugcina.

Imicabango yokugcina

Ukuqedwa kwendawo yigama elibanzi elihlanganisa imisebenzi ehlukahlukene yokwenza imishini, ukugaya, ukupholisha i-Deburring, ukunamathela, nezinye izinqubo zokushelela zezingxenye zensimbi.Nokho, kungase kube ubuhle bobuhle kuphela kumakhasimende avamile.Kodwa ukuqeda kunomthelela omkhulu empilweni nasezingeni lomkhiqizo wokugcina.

Ukungapheleli okuncane endaweni yensimbi kungaholela enkingeni efanelekile ngenkathi kuhlanganiswa izingxenye.Njengoba izinga lokufaka lithinta amandla amalunga nokulingana, ukuqedwa kwendawo kufanele kube okuhamba phambili kubakhiqizi.Ukukhipha i-deburring kuwumsebenzi wokuqala wokushelela ngoba enye inqubo, njengokucwebezela, ukudweba, nokunamathiswa, iba yinhle kuphela ngemva kokukhipha izinsalela ezincane ezinamathiselwe phezulu.Inkampani yethu ibisebenza kuzo zonke izinsizakalo zokukhiqiza kusukela ekuklameni kwe-prototype kuya ekuqedeni umkhiqizo ngaphansi kophahla olufanayo.CNC imishini, ukubumba umjovo, futhiI-Aluminium Extrusionnazo ziyingcweti yethu ongathembela kithi.

Besihlinzeka ngokukhipha ikhwalithi yezingxenye zensimbi kungakhathaliseki ukuthi hlobo luni lokuqedela oludingekayo kuye ngomshini osetshenziswa ezintweni.Zizwe ukhululekile ukufinyelela kithiuma udinga noma yimaphi amasevisi ahlobene nokukhiqiza.

Imibuzo Evame Ukubuzwa

Ingabe i-deburring isisombululo esingcono kakhulu sokushelela phezulu?

Yebo, kuyindlela engcono kakhulu.I-Deburring isusa Isandiso sensimbi esinamathiselwe kanye nezinsalela endaweni ngemuva komshini.Futhi, ingalawulwa ukuze kuvinjwe ukukhuhla okungadingekile phezulu ngenkathi ibushelelezi.

Iluphi uhlobo lokususa imali olungcono kakhulu?

Ayikho impendulo yangempela;kuya ngesidingo somkhiqizo wokugcina okufanele wenziwe.Uma umkhiqizo wokugcina ungadingi ukunemba okuphezulu, ungenziwa ngesandla ngamathuluzi alula.Noma kunjalo, i-electrochemical ingaba yindlela engcono kakhulu uma izingxenye zidinga ukunemba okuphezulu.

Iyiphi indlela yokukhipha imali esheshayo?

I-Electrochemical Deburring iyashesha uma iqhathaniswa nezinye futhi ingenziwa phakathi nomzuzu.Umshini we-CNC nawo uyinqubo esheshayo futhi elula uma i-workpiece inkulu (Ingakwazi ukuqeda amamitha angu-3 ekusebenzeni okukodwa).

Isikhathi sokuthumela: May-30-2022