Kaʻina hana deburring: No ke aha he mea nui i ka hana ʻana?

Hoʻohou hope 09/14, manawa e heluhelu ai: 8 min

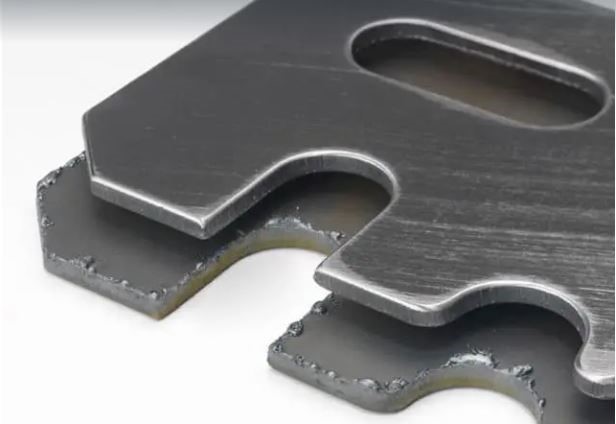

ʻāpana metala me ka burr a ma hope o ka deburring

Ke wili mākou i lua a ʻoki i kapepa metalai ka wā o ka hana ʻana, waiho ka lua a me nā ʻaoʻao i kahi mea ʻē aʻe i hoʻopaʻa ʻia ma nā ʻaoʻao ʻelua, i kapa ʻia ʻo bur.Kokoke i nā ʻano hana hana, meʻoki ʻoki, wili palaoa, wili, kalai,huli ana, a me ke kuʻi ʻana i nā lau, ʻānai i nā ʻāpana metala ma hope o ka hana ʻana.Hoʻopili kēia bur i ke ana, hui, ikaika, a me ka nani aesthetic o ka huahana.No laila, pono e noʻonoʻo ʻia ka Deburring i kēlā me kēia papahana hana.

ʻAno Burr

ʻO nā hiʻohiʻona o ka mīkini a me ka mea hana e pili ana i ke ʻano mea hana, ka hoʻonohonoho ʻana i nā mea hana, nā waiwai o ka mea hana, a ʻo ka mea nui loa,pehea ke komo a puka ʻana o ka mea hana i ka wā e hoʻokō ai i ka hana hana e hoʻoholo ai i ke ʻano burr ma ka ʻili.

Eia nā ʻano burr maʻamaui pono e wehe ʻia i ka hana ʻana

| ʻAno Burr | Hōʻikeʻike |

| Poisson Burr | Ke koʻikoʻi nui ka metala ma luna o ka ʻili, hoʻoheheʻe ʻia kona ʻaoʻao i ka plastic a elongated. |

| Burr ʻoki ʻoki | Aia ka burr ma ka ʻāpana ʻoki o ka mea hana i ka wā e hoʻokaʻawale ʻia mai ka ʻāpana waena. |

| ʻO ka ʻōwili ʻia | burr i hana ʻia ma ka puka ʻana o kahi mea paahana mai ka mea hana: Lawe ia i kekahi mea i ka wā e hānai ai |

| Haehae burr | Noho pū ʻo Burr me ka ʻaoʻao ʻoki i ka wā o ka hana kuʻi. |

Nā ʻano o ka deburring

Hiki ke hana ʻia ka deburring ma nā ʻano like ʻole e pili ana i ka ʻāpana metala a me ka burr.ʻO nā ala deburring kaulana loamanual,ʻO ka mīkini CNC, vibratory, electrochemical, thermal, and abrasive.

1. Hoʻopau me ka mīkini CNC

E like me kāu e ʻike ai, kēlā me kēia kaʻina hana machining i kahimīkini CNCLoaʻa iā ia nā mea hana pono e hana ai, a hiki ke hoʻokō ʻia ka deburring ma ka hoʻololi ʻana i ka hāmeʻa, ʻoiai hiki ke hoʻohui i ka manawa pōʻai.ʻO ke ʻano mea hana deburring e pili ana i ka mea āu e hoʻopau ai, ka lua, nā lua keʻa, nā ʻaoʻao, a i ʻole ka ʻili palahalaha.Hiki iā ʻoe ke koho i ka mea hana i manaʻo nui ʻia no kēlā noi ma muli o kēia.

Nā kihi:ʻO nā mea hana Chamfer a i ʻole ka mea ʻoki CNC e holoi i nā mea i hoʻokiʻekiʻe ʻia a hoʻomaʻamaʻa i ka ʻili

Puka:ʻO nā mea hana hoʻoheheʻe rotatory

Nā ʻili palahalaha: Hiki ke kau ʻia nā Brushes Deburring ma ka bit

Nā Loko:ʻAʻole loaʻa i nā milo kahi burr nunui.E koho i kahi pulupulu kūpono.

Hoʻopau me ka mīkini CNC

Ama hope o ke koho ʻana i nā mea hana, e hahai i kēia mau ʻanuʻu

1. E hoʻonohonoho i ka papahana CNC no ka hoʻopau ʻana

2. E hoʻoholo i ka hoʻonohonoho mua o ka mea hana (X, Y, Z), a laila e kauo i ka ʻāpana.Hiki iā ʻoe ke hoʻonohonoho iā ia i ka hapalua o ka laulā o ka mea hana.

3. E hoʻokomo i nā mea hoʻololi e like me ka ikaika hoʻokō a me ka helu hānai e pili ana i ka nui burr.A laila, hoʻokani i ke kūlana, a hoʻomaka i ka hana.

Nā hiʻohiʻona o CNC Deburring

· ʻO ka Deburring CNC Machining Components kahi kaʻina wikiwiki e hiki ke hana ʻia ma nā ʻāpana hoʻokahi a me nā ʻāpana he nui o nā ʻāpana i hana ʻia.

· Ke hoʻohālikelike ʻia me nā ʻenehana maʻamau, ʻoi aku ka maikaʻi o kona wikiwiki deburring;hiki iā ia ke hoʻopau i ka 3 mika i hoʻokahi minuke.

· Hiki ke hoʻololi ʻia nā ʻano like ʻole a me nā mea hoʻokomo ʻē aʻe e like me nā koi hoʻoili.

· ʻAʻole pili ia i ka maʻalahi o ka ʻili o mua a ʻaʻole e hōʻeha i ka ʻāpana.

· ʻAʻole pili ia i ka pololei a i ʻole ka ikaika o nā ʻāpana, a kōkua ia i ka hoʻoikaika ʻana i ka huahana i ka wā i hoʻopili ʻia me nā mea ʻē aʻe.

2. Pumi kiʻekiʻe- wai jet deburring

ʻO ke ala kaulana ʻē aʻe no ka wehe ʻana i ka lepo, nā ʻāpana, a me nā burr mai nā ʻāpana e hoʻomaʻamaʻa iā lākou, ʻo ia ka deburring wai jet kiʻekiʻe.Hoʻokuʻu ʻia ka burr a me nā ʻāpana o ka ʻāpana i kuhikuhi ʻia e ka wai kiʻekiʻe (35 a 60 MPa) mai ka mokulele.Hiki i kēia ala o ka deburring ke loaʻa i kahi ʻili maʻemaʻe a koena ʻole.ʻO ka mea pōʻino, ʻaʻole hiki i nā mea hana deburring maʻamau ke hoʻokō i kēia kaʻina hana deburring i hoʻohana ʻia no nā ʻāpana paʻakikī.

3. Hoʻopau lima lima

ʻO ka deburring manual kahi ʻano hana i hoʻomaʻamaʻa ʻia a palahalaha i ka ʻili ma ka wehe ʻana i ke koena i hoʻopili ʻia i waiho ʻia ma ka wahi mīkini o ka ʻāpana.Hiki ke hoʻohana ʻia me ka hoʻohana ʻana i nā mea hana like ʻole o nā ʻano like ʻole a me nā nui.Hoʻohana ʻia nā mea hana lima no ka chamfering ʻaoʻao ʻoi a me nā lua paʻi a hāʻawi i ka like ʻana o ka ʻili.ʻO ka hapa nui o nā kaʻina hana hana i hana ʻia i loko o nā papa hana i hana ʻole ʻia e hilinaʻi i ka deburring manual e nā ʻenehana akamai.

ʻO ka paʻa a me ka ʻili hiki ke hoʻololi ʻia nā mea nui ʻelua o nā mea hana deburring manual.Pono ka hana deburring i loko o ka lua i ka lima paʻa i ka paʻa a me ka hoʻololi ʻana o nā ʻāpana deburring ma ka ʻāpana o ka ʻāpana, ʻOiai e hiki ke hana ʻia nā hana deburring ma nā kihi ʻoki a me nā papa pālahalaha me ka hoʻohana ʻana i kahi faila lima a i ʻole kahi mea hana chamfering maʻamau.E like me ke ʻano, ke kaʻina hana lua, a me nā noi ʻāpana, hiki ke hoʻohana ʻia nā lau me nā ʻano like ʻole i hoʻokahi lima ma ka hoʻololi ʻana i ka mea mua.

Hoʻopau lima lima

4. Electrochemical deburring

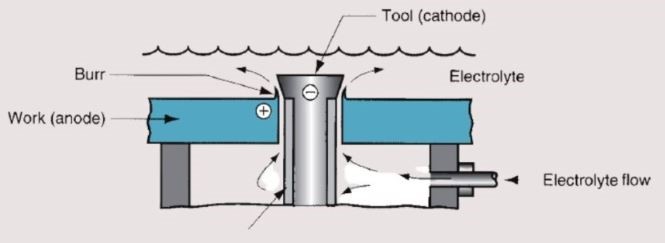

He paʻakikī ka wehe ʻana i nā burrs i loko o ka geometry paʻakikī me ka hoʻohana ʻana i ka CNC, manual, abrasive, vibratory, a me nā ʻano hana ʻē aʻe.No laila, hoʻohana ʻia ka electrochemical deburring.Hoʻokumu ʻia ka deburring electrochemical ma ke kumu electrolysis.

Kaʻina deburring electrochemical

Hoʻopili ʻia ka mea hana i ka hopena maikaʻi o ke kumu mana (anode).Hoʻopili ʻia ka mea hana deburring electrochemical me ka insulation i ka hopena maikaʻi ʻole (cathode), me ka glycol a i ʻole ka paʻakai e like me ka electrolyte.Ke hele nei kekahi electrolyte i ka ʻāpana hoʻolālā ma waena o ka burr a me ka mea hana.Hoʻopau ia i nā burrs ma ka hoʻoili ʻana i ka ion metala o ka mea hana, e hana ana i kahi slurry hydroxide ma ke ʻano he hopena.

5. ʻO ka deburring abrasive

Hoʻohana ʻia nā mea abrasive maikaʻi i kēia ʻenehana e hoʻoneʻe i nā hemahema liʻiliʻi mai ka ʻili o ka mea i hana ʻia a hana i kahi ʻano maʻalahi.ʻO ke kila ikaika kiʻekiʻe, ka alumini oxide, a me nā lau aniani he mau mea abrasive maʻamau i hoʻohana ʻia no ka hana ʻana i kahi jet deburring controllable hiki ke wehe koke i nā burrs ma ke kuhikuhi ʻana i ka jet iā lākou.ʻO ka micro-abrasive blasting kekahi inoa e hoʻohana ai nā mea hana.No ka mea e hoʻoneʻe ana kēia ala deburring i nā microns mai ka ʻili, ua kūpono ia no nā ʻāpana e koi ana i ka pololei loa, e like me nā poloka engine, aerospace, a me nā mea robotics.

Nā Pōmaikaʻi o ka Deburring

ʻO ke ana ʻana i nā pōmaikaʻi Deburring, hui, ikaika, nani nani, a me ka maikaʻi o ka huahana hope loa.

Eia nā pōmaikaʻi nui;

· Hoʻopau ka Deburring i ka metala i hoʻopili ʻia ma ka lua a me ka ʻili, no laila e hoʻomaʻamaʻa mua iā lākou a kōkua i ka hoʻokumu ʻana i ka ikaika i hui pū ʻia me ka hoʻohui ʻana i nā ʻāpana deburred.

· ʻO nā puka maʻemaʻe e hana maikaʻi i ka male ma ka hui.

· Hoʻonui ka palahalaha o nā ʻāpana me ka deburring, e maʻalahi ia no nā hana lua.

· Hiki iā Burr ke skew i kekahi ʻaoʻao o ka ʻāpana i ka wā e hui pū ai me nā mea ʻē aʻe, e hopena i ka Misalignment ma waena o lākou.ʻO ka hopena, hana ʻo Misalignment i ka hiki ke hoʻopau i ka huahana.Hiki ke hōʻemi ʻia kēia pilikia o ka hāʻule ʻole me ka hoʻopili pono ʻana o nā ʻāpana.

· Ke lawe ʻia ke ana a hoʻohana ʻia i ka wā o ka hana ʻana, ʻo ka ʻili ʻole o ka ʻili metala me ka burr i hoʻopili ʻia e pili i ka pololei.Hiki i ka nui hewa ke alakaʻi i ka hemahema o nā hiʻohiʻona huahana a hiki ke lilo i huahana ʻoluʻolu ʻole no nā mea kūʻai.

· Hoʻomaikaʻi ka ʻili maʻemaʻe, deburred i ka aesthetics o ka ʻāpana a kōkua i ke kaʻina hana hoʻonaninani.

· ʻO ka hapa nui o nā ʻaoʻao hou i ʻoki ʻia he ʻoi ʻoi;hiki i ka deburring ke hoʻomaʻemaʻe i ka ʻoi, e ʻoi aku ka palekana o nā limahana a me nā mea kūʻai aku.

Ka palena o ka Deburring

Me ka kānalua ʻole, ʻo Deburring ke ala maikaʻi loa e hoʻomaʻemaʻe i ka ʻili o nā ʻāpana metala, akā aia kekahi mau palena i ka hana ʻana i kekahi mau hiʻohiʻona.

1. Nā kihi ʻoi a me nā kihi

He paʻakikī loa ka wehe ʻana i nā kihi ʻoi a me nā kihi haʻahaʻa.Hiki iā ia ke hoʻoneʻe i ka nui o nā waihona me nā burrs liʻiliʻi, e hopena i nā ʻaoʻao kūpono ʻole a me ka nalowale ana o ka ʻāpana metala.

2. Nā keʻena i hoʻopaʻa ʻia

ʻO ka wehe ʻana i nā keʻena i hoʻopaʻa ʻia he paʻakikī ke hoʻomau.ʻO ka wehe ʻana i nā burrs mai nā ʻaoʻao o ka lumi hiki ke hoʻopau i ka mānoanoa koʻikoʻi o ke keʻena.

3. Nā geometries paʻakikī

ʻAʻole hiki ke hoʻokuʻu ʻia nā ʻāpana āpau me nā mea hana wili, e like me ka bevel gear, a me nā mea hoʻoili ʻē aʻe, no ka mea, haʻalele kēia mau geometries i ka burr lōʻihi a mānoanoa.

4. ʻili ʻili ʻili

I ka wā o ka hoʻomaʻamaʻa ʻana o ka ʻili ma ka deburring, inā ʻaʻole mālama ka poʻe loea i nā mea hana, aia ka pilikia o ka ʻoki ʻana mai ka ʻili me ka nānā ʻole pono ʻana, e pili ana i ka mānoanoa o ka ʻāpana metala, e hoʻohaʻahaʻa i ka ikaika o ka huahana hope.

Nā manaʻo hope

ʻO ka hoʻopau ʻana i ka ʻili he huaʻōlelo ākea e pili ana i nā hana machining like ʻole, wili, Deburring polishing, coating, a me nā kaʻina hana hoʻoluʻu ʻē aʻe o nā ʻāpana metala.Eia nō naʻe, he nani aesthetic wale nō ia no nā mea kūʻai maʻamau.Akā he hopena koʻikoʻi ka hoʻopau ʻana i ke ola a me ka maikaʻi o ka huahana hope.

Hiki i ka hemahema iki ma ka ʻili metala ke alakaʻi i kahi pilikia kūpono i ka wā e hui pū ai i nā ʻāpana.E like me ka hopena o ka maikaʻi o ka hoʻopili ʻana i ka ikaika o nā hono a kūpono, ʻo ka hoʻopau ʻana i ka ʻili he mea nui ia no nā mea hana.ʻO ka Deburring ka hana hoʻomaka no ka hoʻomaʻamaʻa ʻana no ka mea, ʻo ke kaʻina hana ʻē aʻe, e like me ka ʻālohilohi, ka pena, a me ka uhi ʻana, e maikaʻi wale nō ma hope o ka wehe ʻana i ke koena liʻiliʻi i hoʻopili ʻia i ka ʻili.ʻO kā mākou paʻa ua hana ʻo ia i nā lawelawe hana a pau mai ka hoʻolālā prototype a hiki i ka hoʻopau ʻana i ka huahana ma lalo o ka hale hoʻokahi.ʻO ka mīkini CNC, hoʻoheheʻe ʻia, aAluminum Extrusionʻo kā mākou ʻike pū kekahi e hiki ai iā ʻoe ke hilinaʻi iā mākou.

Ke hoʻolako nei mākou i ka deburring maikaʻi no nā ʻāpana metala ʻaʻohe ʻano o ka hoʻopau ʻana e pono ai ma muli o ka mīkini i hoʻopili ʻia i nā mea.E ʻoluʻolu ee launa mai ia makouinā makemake ʻoe i nā lawelawe e pili ana i ka hana.

FAQ

ʻO ka deburring ka hopena maikaʻi loa e hoʻomāmā i ka ʻili?

ʻAe, ʻo ia ke ala maikaʻi loa.Hoʻopau ka Deburring i ka Extension metala i hoʻopili ʻia a me ke koena ma ka ʻili ma hope o ka mīkini ʻana.Eia kekahi, hiki ke hoʻomalu ʻia i mea e pale aku ai i ka ʻōpala pono ʻole mai ka ʻili i ka wā e hoʻomaʻamaʻa.

He aha ke ʻano o ka deburring ʻoi aku ka maikaʻi?

ʻAʻohe pane maoli;pili ia i ka koi o ka huahana hope e hana ʻia.Inā ʻaʻole pono ka huahana hope i ka pololei kiʻekiʻe, hiki ke hana me ka lima me nā mea hana maʻalahi.Eia nō naʻe, ʻo ka electrochemical ke ala maikaʻi loa inā pono nā ʻāpana i ka pololei kiʻekiʻe.

ʻO ka ʻenehana deburring ka wikiwiki?

He wikiwiki ka Electrochemical Deburring i nā mea ʻē aʻe a hiki ke hana ʻia i loko o hoʻokahi minuke.ʻO ka mīkini CNC he hana wikiwiki a maʻalahi hoʻi inā nui ka mea hana (hiki iā ia ke deburr a hiki i 3 mika i ka hana hoʻokahi).

Ka manawa hoʻouna: Mei-30-2022