Tsarin yanke hukunci: Me yasa yake da mahimmanci a masana'anta?

Sabuntawar ƙarshe 09/14, lokacin karantawa: 8 mins

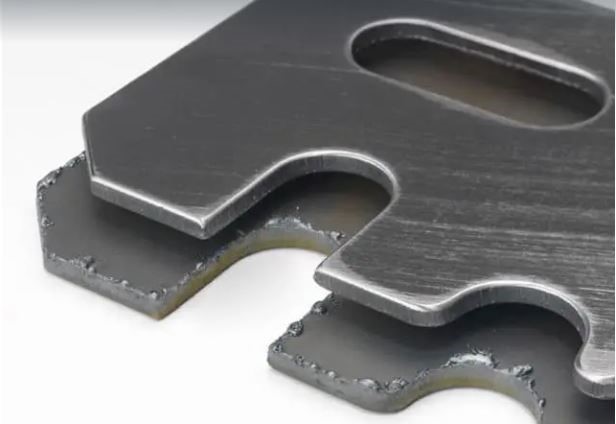

Bangaren ƙarfe tare da burr da bayan deburring

Lokacin da muka huda rami da yankekarfen takardaa lokacin aikin masana'antu, ramin da gefuna suna barin wani ƙaramin abu mai siffar dutsen mai aman wuta da aka haɗe a bangarorin biyu, wanda aka sani da bur.Kusan duk hanyoyin masana'antu, gami dayankan, niƙa, hakowa, zane-zane,juyawa, da naushi ganye, burr a kan sassan karfe bayan aikin.Wannan buraguni yana shafar ma'auni, haɗuwa, ƙarfi, har ma da kyawun kyawun samfurin.Saboda haka, ya kamata a yi la'akari da Deburring a kowane aikin masana'antu.

Nau'in Burr

Halayen machining da workpiece sun haɗa da nau'in kayan aiki, daidaitawar kayan aiki, kaddarorin aiki, kuma mafi mahimmanci,yadda kayan aiki ke shiga da fita yayin aiwatar da aikin masana'anta yana ƙayyade nau'in burr a saman.

Anan akwai nau'ikan burar gama gariwanda dole ne a cire a cikin masana'anta

| Nau'in Burr | Halin yanayi |

| Poisson Burr | Lokacin da ƙarfen ya sami damuwa mai yawa a saman, gefunansa suna samun gurɓataccen filastik da elongated. |

| Cut-off burr | Burr yana kan sashin yanke na aikin aiki yayin da aka raba shi daga tsakiya. |

| Mirgine | burr da aka yi akan fitowar kayan aiki daga kayan aiki: Yana ɗaukar wasu abubuwa yayin ciyarwa |

| Yaga burar | Burr ya kasance tare da yanke-gefen yayin aikin naushi. |

Nau'in yanke hukunci

Ana iya yin ɓarna ta hanyoyi daban-daban dangane da ɓangaren ƙarfe da burr.Shahararrun hanyoyin yanke hukunci sun haɗa damanual,Injin CNC, vibratory, electrochemical, thermal, da abrasive.

1. Deburing tare da CNC inji

Kamar yadda ka sani, kowane machining tsari a cikin waniInjin CNCyana da takamaiman kayan aikin da za a yi, kuma ana iya samun ɓarna ta hanyar canza kayan aiki, kodayake yana iya ƙara zuwa lokacin zagayowar.Nau'in kayan aikin ɓarna ya dogara da abin da zaku lalata, rami, ramukan giciye, gefuna, ko ƙasa mai lebur.Kuna iya zaɓar kayan aiki na farko da aka yi niyya don wannan aikace-aikacen bisa ga wannan.

Gefuna:Chamfer kayan aikin ko CNC abun yanka don shafe tashe kayan da santsi da surface

Ramuka:Kayan aikin jujjuyawa

Lebur saman: Za'a iya shigar da goge goge cikin sauƙi akan bit

Zaren:Zaren ba su da katuwar burar.Zaɓi goga mai dacewa.

Ci gaba tare da injin CNC

Abayan zabar kayan aikin, bi matakai masu zuwa

1. Saita shirye-shiryen CNC don ɓarna

2. Ƙayyade haɗin gwiwar farko na kayan aikin (X, Y, Z), sannan ja shi zuwa yanki.Kuna iya saita shi zuwa rabin kewayon kayan aiki.

3. Shigar da masu canjin shigarwa kamar ƙarfin yarda da ƙimar ciyarwa bisa girman burr.Sa'an nan, kunna matsayi, kuma fara aikin.

Halayen CNC Deburring

· Ƙaddamar da Kayan aikin Injin CNC shine tsari mai sauri wanda za'a iya yi akan nau'ikan raka'a ɗaya da nau'ikan nau'ikan sassa da aka kera.

· Idan aka kwatanta da dabaru na al'ada, saurin ɓatawar sa ya fi;zai iya lalata har zuwa mita 3 a cikin minti daya.

· Za'a iya daidaita mitoci da sauran abubuwan shigar da Maɓallai ta hanyar lambobi gwargwadon buƙatun sarrafawa.

· Ba ya shafar santsi na gaban gaba kuma baya cutar da sashin.

· Ba ya shafar daidaiton girman ko ƙarfin sassan, kuma yana taimakawa wajen ƙarfafa samfurin da zarar an haɗa shi da wasu abubuwan haɗin gwiwa.

2. Babban matsa lamba - ruwa jet deburring

Wata shahararriyar hanya don cire ƙura, guntu, da burr daga sassa don sanya su santsi shine lalata jet mai matsa lamba.Burr da chunks na ɓangaren ɓangaren da aka ƙayyade ana kashe su ta hanyar ruwa mai ƙarfi (35 zuwa 60 MPa) daga jet.Wannan hanyar cirewa kuma tana iya cimma tsaftataccen wuri mara saura.Abin takaici, kayan aikin ɓarna gabaɗaya ba za su iya cim ma wannan aikin ɓata lokaci da ake amfani da su don hadaddun sassan ba.

3. Deburing na Manual

Deburing da hannu hanya ce mai daraja ta lokaci don sassautawa da daidaita saman ta hanyar cire ragowar haɗe-haɗe da aka bari a yankin injinan sashin.Ana iya sarrafa shi ta amfani da kayan aiki daban-daban na siffofi da girma dabam dabam.Ana amfani da kayan aikin hannu don chamfer gefuna masu kaifi da ramukan da aka buga da samar da daidaiton saman.Yawancin hanyoyin masana'antu da ake gudanarwa a cikin tarurrukan da ba a sarrafa su ba sun dogara da ƙwararrun ƙwararrun ƙwararrun ƙwararru.

Hannun hannu da ruwan wukake da za a iya maye gurbinsu sune manyan abubuwan farko guda biyu na kayan aikin lalata da hannu.Ayyukan ƙaddamarwa a cikin ramin yana buƙatar hannu mai tsayi a kan riƙewa da juyawa na ɓangarorin ɓarna a ɓangaren ɓangaren, Yayin da ake yin aiki a kan yankan gefuna da saman saman za a iya yin amfani da fayil ɗin hannu ko kayan aikin chamfer na yau da kullum.Dangane da nau'in, tsari na sakandare, da aikace-aikacen sassa, ana iya amfani da ruwan wukake da kewayon siffofi a cikin hannu ɗaya ta maye gurbin na baya.

Deburing da hannu

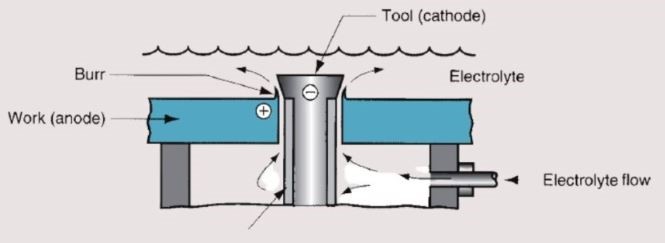

4. Electrochemical deburring

Burrs a cikin hadadden lissafi yana da wahalar cirewa ta amfani da CNC, manual, abrasive, vibratory, da sauran hanyoyin.Don haka ana amfani da lalatawar electrochemical.Deburring Electrochemical dogara ne a kan electrolysis ka'idar.

Tsarin deburring na Electrochemical

Aikin aikin yana da alaƙa da ingantaccen tashar wutar lantarki (anode).Kayan aiki na lalata kayan aikin lantarki tare da rufi an haɗa shi zuwa mummunan tashar (cathode), tare da maganin glycol ko gishiri azaman electrolyte.Electrolyte yana wucewa ta ratar ƙira tsakanin burr da kayan aiki.Yana narkar da burrs ta hanyar canja wurin karfe ion na workpiece, samar da wani hydroxide slurry a matsayin byproduct.

5. Abrasive deburring

Ana amfani da kayan abrasive masu kyau a cikin wannan fasaha don cire ƙananan kurakurai daga saman abin da aka ƙera da kuma haifar da laushi mai laushi.Ƙarfe mai ƙarfi, aluminum oxide, da gilashin gilashin abubuwa ne na yau da kullun da ake amfani da su don ƙirƙirar jet mai lalacewa wanda zai iya cire burrs cikin hanzari ta hanyar jagorantar jet zuwa gare su.Ƙunƙarar iska mai ƙura da ƙura wani suna ne nasa wanda masana'antun ke amfani da shi.Tun da wannan hanyar ɓata lokaci tana cire microns daga saman, yana sa ya zama mai dacewa ga sassan da ke buƙatar matsananciyar daidaito, kamar tubalan injin, sararin samaniya, da abubuwan robotics.

Amfanin Deburring

Deburring fa'idodin ma'auni, haɗawa, ƙarfi, kyawun kwalliya, da ingancin samfurin gabaɗaya.

Ga mahimman fa'idodin;

· Deburring yana cire ƙarfen da aka haɗe akan ramin da aka buga da saman, don haka da farko yana sassauƙa su kuma yana taimakawa ƙirƙirar ƙarfi mai kyau yayin haɗa abubuwan da aka lalata.

· Tsabtace ramuka suna yin cikakkiyar mating akan taro.

· Ƙaƙƙarfan sassa yana ƙaruwa tare da ɓarna, wanda zai sauƙaƙa don ayyukan sakandare.

· Burr na iya karkatar da gefe ɗaya na ɓangaren yayin haɗuwa tare da wasu, wanda ke haifar da Misalignment a tsakanin su.Sakamakon haka, Misalignment yana haifar da yuwuwar sa samfurin ya gaza.Ana iya rage wannan haɗarin gazawar tare da ƙona abubuwan da suka dace.

· Lokacin da aka ɗauki ma'auni kuma aka yi amfani da shi a lokacin matakan masana'antu, rashin daidaituwa na takarda na karfe tare da burar da aka haɗe zai shafi daidaito.Girman da ba daidai ba zai iya haifar da gazawa a cikin fasalulluka na samfur kuma yana iya zama samfur mara gamsuwa ga abokan ciniki.

· Filaye mai santsi, wanda aka lalatar yana inganta kyawun sashin kuma yana taimakawa wajen ci gaba da yin ado.

· Yawancin sabbin gefuna da aka yanke suna da kaifi;deburring na iya sassauta kaifi, sa ma'aikata da abokan ciniki su ji aminci.

Iyaka na Deburring

Ba tare da wata shakka ba, Deburring ita ce hanya mafi kyau don santsi saman sassan ƙarfe, amma yana da iyakancewa a cikin aiki a cikin ƴan yanayi.

1. Kusurwoyi masu kaifi da gefuna

Deburring kaifi da ƙananan kusurwa yana da wahala sosai.Zai iya cire haja mai yawa tare da ƙananan bursu, yana haifar da gefuna mara kyau da asarar girman ɓangaren ƙarfe.

2. Rufe ɗakuna

Deburing na rufaffiyar ɗakunan yana da wuya a ci gaba da shi.Cire burs daga gefuna na ɗakin na iya soke kauri mai mahimmancin ɗakin.

3. Complex geometries

Ba za a iya cire duk sassan da kayan aikin jujjuya ba, kamar gear bevel, da sauran abubuwan watsawa, saboda waɗannan hadadden geometries suna barin burar mai tsayi da kauri.

4. Zazzage saman

A lokacin smoothing na farfajiyar ta hanyar lalatawa, idan masu sana'a ba su kula da kayan aiki ba, akwai haɗarin zubar da hankali daga saman ba tare da kulawa mai kyau ba, wanda ke rinjayar kauri na ɓangaren ƙarfe, rage ƙarfin samfurin ƙarshe.

Tunani na ƙarshe

Ƙarshen saman ƙasa wani lokaci ne mai faɗi wanda ya haɗa da ayyukan mashin ɗin daban-daban, niƙa, goge goge, shafi, da sauran hanyoyin sassauƙa na sassan ƙarfe.Koyaya, yana iya zama kyakkyawan kyan gani ga abokan cinikin gaba ɗaya.Amma ƙarewa yana da tasiri mai mahimmanci akan rayuwa da ingancin samfurin ƙarshe.

Ƙananan ajizanci akan saman ƙarfe zai iya haifar da matsala mai dacewa yayin haɗa sassan.Kamar yadda ingancin dacewa ya shafi ƙarfin haɗin gwiwa da kuma dacewa, kammalawa ya kamata ya zama babban fifiko ga masana'antun.Deburring shine farkon aiki don smoothing saboda wani tsari, kamar haskakawa, zanen, da sutura, kawai yana samun cikakke bayan cire ɗan ƙaramin abin da aka makala a saman.Kamfaninmu ya kasance yana aiki akan duk ayyukan masana'antu tun daga ƙirar samfuri har zuwa kammala samfurin a ƙarƙashin rufin ɗaya.Injin CNC, allura gyare-gyare, kumaAluminum Extrusionsu ne kuma gwanintar mu da za ku iya dogara da mu.

Mun kasance muna samar da ingancin deburring ga sassa na karfe ko da wane irin ƙare da ake bukata dangane da machining da aka yi amfani da su a kan abubuwa.Jin kyauta donkai gare muidan kuna buƙatar kowane sabis da ke da alaƙa da masana'anta.

FAQ's

Shin deburring mafi kyawun bayani don santsin saman?

Ee, ita ce hanya mafi kyau.Deburring yana kawar da Ƙarfe da aka haɗe da shi da ragowar a saman bayan yin injin.Har ila yau, ana iya sarrafa shi don hana zubar da ba dole ba daga saman yayin da ake yin laushi.

Wanne nau'in cirewa ne ya fi kyau?

Babu ainihin amsa;ya dogara da buƙatun samfurin ƙarshe da za a kera.Idan samfurin ƙarshe ba ya buƙatar babban madaidaici, ana iya yin shi da hannu tare da kayan aiki masu sauƙi.Duk da haka, electrochemical zai zama hanya mafi kyau idan aka gyara na bukatar high daidaito.

Wanne dabarar cirewa ke da sauri?

Deburing Electrochemical yana da sauri idan aka kwatanta da wasu kuma ana iya yin shi a cikin minti daya.CNC inji shi ne kuma mai sauri da kuma sauki tsari idan workpiece ne babba (Yana iya deburr har zuwa 3 mita a guda aiki).

Lokacin aikawa: Mayu-30-2022