Deburring txheej txheem: Vim li cas nws tseem ceeb hauv kev tsim khoom?

Xeem tshiab 09/14, lub sij hawm los nyeem: 8 mins

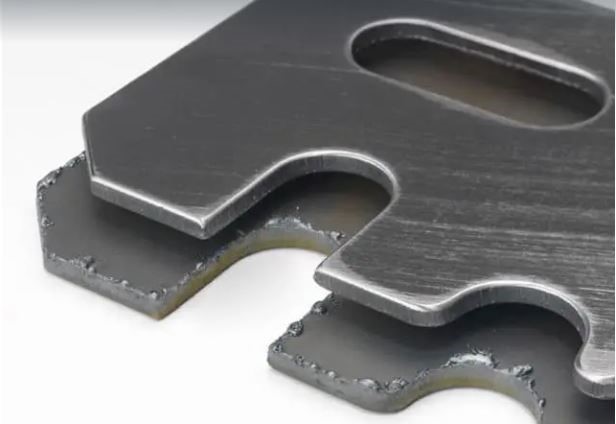

Hlau ib feem nrog burr thiab tom qab deburring

Thaum peb khawb ib lub qhov thiab txiav lubdaim hlauThaum lub sij hawm tsim cov txheej txheem, lub qhov thiab cov npoo tawm ib qho me me volcano-zoo li cov khoom ntxiv txuas rau ntawm ob sab, hu ua bur.Yuav luag txhua txoj kev tsim khoom, suav nrogtxiav, milling, Drilling , engraving ,tig, thiab xuas nrig ntaus nplooj, burr ntawm cov hlau qhov chaw tom qab ua haujlwm.Qhov burr no cuam tshuam rau kev ntsuas, sib dhos, lub zog, thiab txawm tias qhov zoo nkauj ntawm cov khoom.Li no, Deburring yuav tsum tau txiav txim siab hauv txhua qhov kev tsim khoom.

Hom Burr

Cov yam ntxwv ntawm machining thiab workpieces muaj xws li hom cuab yeej, cov cuab yeej taw qhia, cov khoom ua haujlwm, thiab qhov tseem ceeb tshaj plaws,Yuav ua li cas lub cuab yeej nkag mus thiab tawm thaum ua tiav kev tsim khoom txiav txim siab hom burr ntawm qhov chaw.

Ntawm no yog cov hom burruas yuav tsum tau muab tshem tawm hauv kev tsim khoom

| Burr hom | Scenario |

| Poisson Burr | Thaum cov hlau tau txais kev ntxhov siab ntau dhau ntawm qhov chaw, nws cov npoo tau txais cov yas deformed thiab elongated. |

| Txiav tawm burr | Lub burr yog nyob rau ntawm ntu ntu ntawm lub workpiece thaum nws yog cais los ntawm qhov nruab nrab. |

| Roll-over | burr ua rau ntawm qhov tawm ntawm lub cuab yeej los ntawm lub workpiece: Nws yuav siv qee yam khoom thaum pub mis |

| Kua muag burr | Burr tseem nrog rau kev txiav-sab thaum lub sijhawm xuas nrig ntaus. |

Hom kev deburring

Deburring tuaj yeem ua tau ntau yam nyob ntawm qhov hlau thiab burr.Txoj kev deburring nrov tshaj plaws suav nrogphau ntawv qhia,CNC machining, vibratory, electrochemical, thermal, thiab abrasive.

1. Deburring nrog lub tshuab CNC

Raws li koj paub, txhua txoj kev machining hauv ibCNC tshuabmuaj cov cuab yeej tshwj xeeb los ua, thiab deburring kuj tuaj yeem ua tiav los ntawm kev hloov cov cuab yeej, txawm hais tias nws yuav ntxiv rau lub sijhawm voj voog.Cov cuab yeej deburring yog nyob ntawm seb koj yuav deburr, qhov, cross-qhov, npoo, los yog tiaj tus.Koj tuaj yeem xaiv lub hom phiaj tseem ceeb rau daim ntawv thov ntawd raws li qhov no.

Ntug:Cov cuab yeej Chamfer lossis CNC cutter kom tshem tawm cov khoom tsim thiab du nto

Qhov:Cov cuab yeej rotatory deburring

Cov chaw tiaj tus: Deburring Txhuam yooj yim tuaj yeem ntsia tau rau ntawm me ntsis

Xov:Xov tsis muaj burr loj heev.Xaiv ib qho txhuam hniav uas tsim nyog.

Deburring nrog CNC tshuab

Atom qab xaiv cov cuab yeej, ua raws li cov kauj ruam hauv qab no

1. Teeb lub CNC programming rau deburring

2. Txiav txim siab lub cuab yeej pib ua haujlwm (X, Y, Z), tom qab ntawd rub nws mus rau daim.Koj tuaj yeem teeb tsa nws mus txog ib nrab ntawm cov cuab yeej ntau yam.

3. Nkag mus rau input variables xws li kev ua raws cai thiab pub tus nqi raws li burr loj.Tom qab ntawd, kho qhov chaw, thiab pib qhov kev txiav txim.

Cov yam ntxwv ntawm CNC Deburring

· Deburring CNC Machining Cheebtsam yog txheej txheem ceev uas tuaj yeem ua tiav ntawm ib chav tsev thiab ntau chav ua qauv ntawm cov khoom tsim.

· Piv nrog rau cov txheej txheem ib txwm, nws qhov deburring ceev yog superior;nws tuaj yeem deburr txog 3 meters hauv ib feeb.

· Ntau zaus thiab lwm yam kev hloov pauv hloov pauv tuaj yeem hloov kho digitally raws li kev ua tiav.

· Nws tsis cuam tshuam qhov smoothness ntawm pem hauv ntej nto thiab tsis ua mob rau ib feem.

· Nws tsis cuam tshuam rau qhov tseeb qhov tseeb lossis lub zog ntawm cov khoom, thiab nws yuav pab ntxiv dag zog rau cov khoom lag luam thaum nws tau haum nrog lwm cov khoom.

2. Kev kub siab - dej dav hlau deburring

Lwm txoj hauv kev zoo rau tshem tawm plua plav, chips, thiab burr los ntawm qhov chaw kom ua rau lawv du yog qhov siab-siab dej dav hlau deburring.Cov burr thiab chunks ntawm cov ntu ntu tau muab tshem tawm los ntawm cov dej kub siab (35 txog 60 MPa) los ntawm lub dav hlau.Txoj hauv kev ntawm kev deburring no tuaj yeem ua tiav qhov huv thiab tsis muaj qhov seem.Hmoov tsis zoo, cov cuab yeej deburring dav dav tsis tuaj yeem ua tiav cov txheej txheem deburring siv rau qhov nyuaj.

3. Phau ntawv Deburring

Kev tuav deburring yog ib lub sij hawm-honored txoj kev ntawm smoothing thiab flattening nto los ntawm kev tshem tawm cov txuas residue sab laug nyob rau hauv lub machining cheeb tsam ntawm ib feem.Nws tuaj yeem ua haujlwm siv ntau yam cuab yeej ntawm cov duab sib txawv thiab qhov ntau thiab tsawg.Cov cuab yeej tes yog siv rau chamfering ntse npoo thiab tapping qhov thiab muab qhov sib xws.Feem ntau cov txheej txheem tsim tau ua nyob rau hauv kev cob qhia uas tsis yog automated cia siab rau phau ntawv deburring los ntawm cov kws tshaj lij.

Tus kov thiab lub tshuab hloov tau yog ob qho tseem ceeb ntawm cov cuab yeej siv deburring.Kev ua haujlwm deburring nyob rau hauv lub qhov yuav tsum tau ib tug ruaj khov txhais tes ntawm tuav thiab kev sib hloov ntawm lub deburring hniav nyob rau hauv lub seem ntawm ib feem, Thaum deburring kev khiav hauj lwm ntawm tej npoo thiab tiaj tus nto yuav ua tau siv ib tug tes ntaub ntawv los yog ib tug niaj hnub chamfering cuab yeej.Raws li hom, txheej txheem thib ob, thiab cov ntawv thov, cov hniav uas muaj ntau yam duab tuaj yeem siv rau hauv ib leeg los ntawm kev hloov qhov dhau los.

Phau ntawv deburring

4. Electrochemical deburring

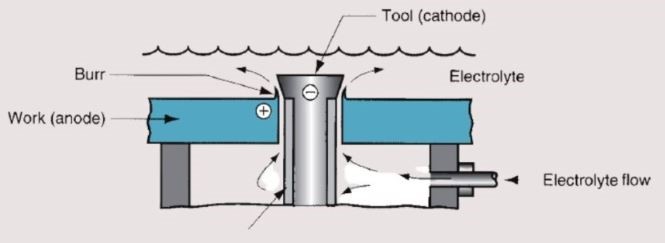

Burrs nyob rau hauv complex geometry yog nyuaj rau tshem tawm siv CNC, phau ntawv, abrasive, vibratory, thiab lwm yam.Li no, electrochemical deburring yog siv.Electrochemical deburring yog raws li txoj cai electrolysis.

Electrochemical deburring txheej txheem

Lub workpiece yog txuas mus rau lub hwj chim qhov chaw nres nkoj zoo (anode).Cov cuab yeej electrochemical deburring nrog rwb thaiv tsev yog txuas nrog lub davhlau ya nyob twg tsis zoo (cathode), nrog glycol lossis ntsev tov raws li cov electrolyte.Ib qho electrolyte dhau los ntawm kev tsim qhov sib txawv ntawm cov burr thiab cov cuab yeej.Nws dissolves cov burrs los ntawm kev hloov cov hlau ion ntawm lub workpiece, ua ib tug hydroxide slurry raws li ib tug byproduct.

5. Abrasive deburring

Cov ntaub ntawv zoo abrasive yog siv nyob rau hauv cov txheej txheem no kom tshem tawm me me irregularities ntawm nto ntawm cov khoom machined thiab tsim ib tug du nto zoo nkauj.Cov hlau muaj zog, aluminium oxide, thiab iav hniav yog cov khoom siv sib tsoo uas siv los tsim lub dav hlau tswj tau uas tuaj yeem tshem tawm cov burrs los ntawm kev coj lub dav hlau mus rau lawv.Micro-abrasive blasting yog lwm lub npe rau nws uas manufacturers siv.Txij li qhov no deburring mus kom ze tshem tawm microns los ntawm qhov chaw, nws ua rau nws zoo tagnrho rau cov khoom uas yuav tsum tau ceev precision, xws li cav blocks, aerospace, thiab robotics hais.

Cov txiaj ntsig ntawm Deburring

Deburring cov txiaj ntsig ntsuas, sib dhos, lub zog, kev zoo nkauj zoo nkauj, thiab tag nrho cov khoom zoo kawg nkaus.

Nov yog cov txiaj ntsig tseem ceeb;

· Deburring tshem tawm cov hlau txuas rau ntawm qhov tapping thiab saum npoo, yog li nws feem ntau smooths lawv thiab pab tsim kom muaj zog sib xyaw ua ke thaum koom nrog cov khoom tawg.

· Cov qhov huv huv ua kom zoo meej mating ntawm kev sib dhos.

· Qhov flatness ntawm qhov chaw nce nrog deburring, uas yuav ua rau nws yooj yim dua rau kev ua haujlwm theem nrab.

· Burr tuaj yeem skew ib sab ntawm ib feem thaum koom nrog lwm tus, ua rau Misalignment ntawm lawv.Yog li ntawd, Misalignment tsim lub peev xwm ua rau cov khoom lag luam tsis ua haujlwm.Qhov kev pheej hmoo ntawm kev ua tsis tiav no tuaj yeem raug txo nrog kev ua kom zoo ntawm cov khoom.

· Thaum qhov ntsuas tau muab coj los siv thiab siv thaum lub sijhawm tsim khoom, qhov tsis sib xws ntawm cov ntawv hlau nrog txuas burr yuav cuam tshuam qhov raug.Qhov loj me tsis raug tuaj yeem ua rau tsis ua haujlwm ntawm cov khoom nta thiab tuaj yeem yog cov khoom tsis txaus siab rau cov neeg siv khoom.

· Qhov du, deburred nto txhim kho qhov zoo nkauj ntawm ib feem thiab pab hauv kev kho kom zoo nkauj ntxiv.

· Feem ntau cov txiav tshiab muaj cov npoo ntse;deburring tuaj yeem du tawm qhov ntse, ua rau cov neeg ua haujlwm thiab cov neeg siv khoom muaj kev nyab xeeb.

Kev txwv ntawm Deburring

Tsis muaj qhov tsis ntseeg, Deburring yog txoj hauv kev zoo tshaj plaws kom du nto ntawm cov hlau, tab sis nws muaj qee qhov kev txwv hauv kev khiav hauj lwm hauv ob peb qhov xwm txheej.

1. Ntse ces kaum thiab ntug

Deburring ntse thiab qis kaum sab xis yog qhov nyuaj heev.Nws tuaj yeem tshem tawm cov khoom lag luam ntau dhau nrog me me burrs, ua rau cov npoo tsis zoo thiab qhov loj me ntawm cov hlau tsis zoo.

2. Cov chav kaw kaw

Deburring ntawm cov thawv kaw yog qhov nyuaj heev los mus nrog.Tshem tawm burrs los ntawm chav tsev cov npoo tuaj yeem tshem tawm lub chamber lub thickness tseem ceeb.

3. Complex geometry

Tag nrho cov khoom tsis tuaj yeem raug tshem tawm nrog cov cuab yeej tig, xws li bevel iav, thiab lwm yam khoom sib kis, vim tias cov geometry nyuaj no tawm ntawm qhov ntev thiab tuab burr.

4. Nto scraping

Thaum lub sij hawm smoothing ntawm nto los ntawm deburring, yog hais tias cov tub txawg tsis tuav cov cuab yeej, muaj kev pheej hmoo ntawm scraping ntawm lub nto yam tsis muaj kev saib xyuas kom zoo, uas cuam tshuam rau lub thickness ntawm cov hlau, txo lub zog ntawm cov khoom kawg.

Kev xav kawg

Deg xov yog ib lo lus dav uas suav nrog ntau yam kev ua haujlwm, sib tsoo, Deburring polishing, txheej, thiab lwm yam txheej txheem ntawm cov hlau.Txawm li cas los xij, nws tsuas yog qhov kev zoo nkauj zoo nkauj rau cov neeg siv khoom.Tab sis kev ua tiav muaj qhov cuam tshuam loj rau lub neej thiab qhov zoo ntawm cov khoom kawg.

Kev tsis zoo me ntsis ntawm cov hlau saum npoo tuaj yeem ua rau muaj teeb meem haum thaum sib dhos cov khoom.Raws li qhov zoo ntawm kev sib haum xeeb cuam tshuam rau lub zog ntawm cov pob qij txha thiab haum, qhov chaw tiav yuav tsum yog qhov tseem ceeb tshaj plaws rau cov tuam ntxhab.Deburring yog qhov pib ua haujlwm rau smoothing vim tias lwm cov txheej txheem, xws li ci ntsa iab, pleev xim, thiab txheej, tsuas yog tau zoo tag nrho tom qab tshem tawm cov seem me me txuas rau saum npoo.Peb lub tuam txhab tau ua haujlwm ntawm txhua qhov kev tsim khoom tsim los ntawm kev tsim qauv los ua kom tiav cov khoom hauv tib lub ru tsev.CNC machining, txhaj tshuaj molding, thiabAluminium Extrusionkuj yog peb cov kws tshaj lij uas koj tuaj yeem tso siab rau peb.

Peb tau muab qhov zoo tshaj plaws deburring rau cov hlau tsis muaj teeb meem dab tsi ntawm kev ua tiav yog xav tau nyob ntawm cov machining siv rau cov khoom.Xav tias dawb rauhu rau pebyog tias koj xav tau kev pabcuam kev tsim khoom.

FAQ's

Yog deburring qhov zoo tshaj plaws tov kom du nto?

Yog, nws yog txoj hauv kev zoo tshaj plaws.Deburring tshem tawm cov hlau txuas txuas ntxiv thiab qhov seem ntawm qhov chaw tom qab machining.Tsis tas li ntawd, nws tuaj yeem tswj tau los tiv thaiv qhov tsis tsim nyog scraping ntawm qhov chaw thaum smoothing.

Hom kev deburring twg yog qhov zoo tshaj?

Tsis muaj lus teb tiag;nws nyob ntawm qhov yuav tsum tau ntawm cov khoom kawg yuav tsum tau tsim.Yog tias cov khoom kawg tsis xav tau siab precision, nws tuaj yeem ua manually nrog cov cuab yeej yooj yim.Tseem, electrochemical yuav yog txoj kev zoo tshaj plaws yog tias cov khoom xav tau siab precision.

Cov txheej txheem deburring twg yog ceev?

Electrochemical Deburring yog nrawm piv rau lwm tus thiab tuaj yeem ua tiav hauv ib feeb.CNC tshuab kuj yog ib tug ceev thiab yooj yim txheej txheem yog hais tias lub workpiece yog loj (Nws muaj peev xwm deburr mus txog 3 meters nyob rau hauv ib lub lag luam).

Post lub sij hawm: May-30-2022