Njira yochotsera ndalama: Chifukwa chiyani ndikofunikira pakupanga?

Kusintha komaliza 09/14, nthawi yowerenga: 8 mins

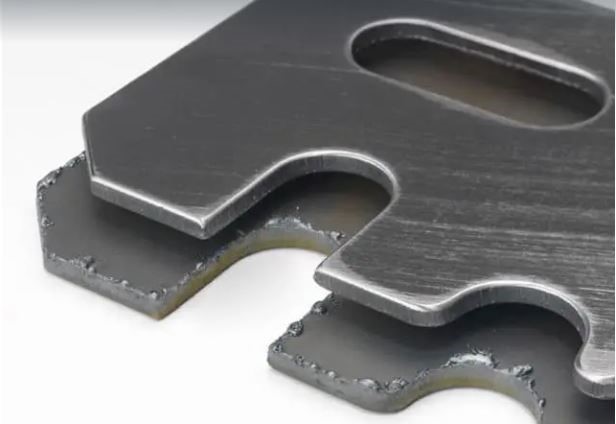

Chitsulo mbali ndi burr ndi pambuyo deburring

Pamene ife kubowola dzenje ndi kudula thepepala lachitsulopopanga, dzenje ndi m'mbali mwake zimasiya kachidutswa kakang'ono kooneka ngati phiri lophulika, komwe kamalumikizidwa mbali zonse ziwiri, yotchedwa bur.Pafupifupi njira zonse zopangira, kuphatikizakudula, mphero, kubowola, kujambula,kutembenuka, ndi kubaya masamba, burr pazigawo zachitsulo pambuyo opareshoni.Bur iyi imakhudza muyeso, kusonkhanitsa, mphamvu, komanso kukongola kwa chinthucho.Chifukwa chake, Deburring iyenera kuganiziridwa muntchito iliyonse yopanga.

Mitundu ya Burr

The Machining ndi workpiece makhalidwe monga chida mtundu, kutengerapo chida, katundu workpiece, ndipo chofunika kwambiri,momwe chida chimalowera ndikutuluka pamene chikugwira ntchito yopanga chimatsimikizira mtundu wa burr pamwamba.

Nayi mitundu yodziwika bwino ya burrzomwe zimayenera kuchotsedwa pakupanga

| Mtundu wa Burr | Zochitika |

| Poisson Burr | Chitsulochi chikakhala ndi nkhawa kwambiri pamtunda, m'mphepete mwake mumapunduka komanso amatalikirana. |

| Kudula kwa burr | Burr ili pa gawo lodulidwa la workpiece pamene imasiyanitsidwa ndi gawo lapakati. |

| Gubuduzani | burr wopangidwa pakutuluka kwa chida kuchokera ku chogwirira ntchito: Zimatengera zinthu zina podyetsa |

| misozi burr | Burr adakhalabe limodzi ndi mbali yodulidwa panthawi yomwe amawombera. |

Mitundu ya deburing

Deburring ikhoza kuchitika m'njira zosiyanasiyana kutengera gawo lachitsulo ndi burr.Njira zodziwika kwambiri zochotsera ndalama zikuphatikizapobuku,CNC makina, vibratory, electrochemical, thermal, and abrasive.

1. Kuwotcha ndi makina a CNC

Monga mukudziwa, njira iliyonse yopangira makina aCNC makinaili ndi zida zapadera zogwirira ntchito, ndipo kubweza kumathanso kutheka posintha chida, ngakhale chitha kuwonjezera nthawi yozungulira.Mtundu wa chida chochotsera zimadalira zomwe mungachotsere, kubowola, mabowo opingasa, m'mphepete, kapena pamtunda.Mutha kusankha chida chomwe chili ndi cholinga cha pulogalamuyi potengera izi.

M'mphepete:Zida za Chamfer kapena CNC cutter kuti afufute zomwe zidakwezedwa ndikusalaza pamwamba

Mabowo:Zida zozungulira zozungulira

Malo athyathyathya: Maburashi a Deburring mosavuta amatha kuyikapo pang'ono

Ulusi:Ulusi ulibe giant burr.Sankhani burashi yoyenera.

Kuwotcha ndi makina a CNC

Amukasankha zida, tsatirani izi

1. Khazikitsani pulogalamu ya CNC yolipira

2. Dziwani momwe chidachi chikugwirizanira (X, Y, Z), kenako chikokereni ku chidutswacho.Mutha kuyiyika mpaka theka lachidacho.

3. Lowetsani zosintha monga kukakamiza kutsatira ndi kuchuluka kwa chakudya kutengera kukula kwa burr.Kenako, ingolani malowo, ndikuyamba kuchitapo kanthu.

Makhalidwe a CNC Deburring

· Deburring CNC Machining Components ndi njira yofulumira yomwe ingatheke pamagulu amodzi ndi mitundu yambiri yamagawo opangidwa.

· Poyerekeza ndi njira wamba, liwiro lake deburring ndi apamwamba;imatha kuwononga mpaka 3 metres mphindi imodzi.

· Kawirikawiri ndi zolowetsa zina Zosintha zitha kusinthidwa mwa digito malinga ndi zofunikira pakukonza.

· Sichimakhudza kusalala kwa kutsogolo komanso sikuvulaza gawolo.

· Sizikhudza kulondola kwa mbali kapena mphamvu za zigawozo, ndipo zimathandiza kulimbitsa mankhwalawo atayikidwa ndi zigawo zina.

2. High pressure-water jet deburing

Njira ina yodziwika bwino yochotsera fumbi, tchipisi, ndi ma burr m'zigawo kuti zikhale zosalala ndi kuthamanga kwambiri kwa jet yamadzi.Ma burr ndi ma chunks a gawo lomwe latchulidwalo amachotsedwa ndi madzi othamanga kwambiri (35 mpaka 60 MPa) kuchokera ku jet.Njira yochotsera izi imathanso kupeza malo oyera komanso opanda zotsalira.Tsoka ilo, zida zonse zowonongera sizingakwaniritse izi zomwe zimagwiritsidwa ntchito pazinthu zovuta.

3. Kuchotsera pamanja

Kuwotcha pamanja ndi njira yolemekezeka yanthawi yayitali yosalala komanso yosalala pamwamba pochotsa zotsalira zomwe zatsalira pagawo la makina a gawolo.Itha kugwiritsidwa ntchito pogwiritsa ntchito zida zosiyanasiyana zamawonekedwe ndi makulidwe osiyanasiyana.Zida zam'manja zimagwiritsidwa ntchito pokopa nsonga zakuthwa ndi mabowo okhomedwa ndikupereka mawonekedwe ofanana.Njira zambiri zopangira zomwe zimachitika m'ma workshop omwe sali odzipangira okha amadalira kubweza pamanja ndi akatswiri aluso.

Chogwirizira ndi tsamba losinthika ndi zigawo ziwiri zazikulu za zida zowotchera pamanja.Kuchotsa ntchito mu dzenje kumafuna dzanja lokhazikika pakugwira ndi kuzungulira kwazitsulo zowonongeka pa gawo la gawolo, Pamene ntchito zowonongeka pamphepete mwazitsulo ndi malo osasunthika zingatheke pogwiritsa ntchito fayilo yamanja kapena chida chokhazikika chamfering.Malingana ndi mtundu, ndondomeko yachiwiri, ndi magawo ogwiritsira ntchito, masamba omwe ali ndi mawonekedwe osiyanasiyana angagwiritsidwe ntchito pa chogwirira chimodzi posintha choyambirira.

Kuchotsera pamanja

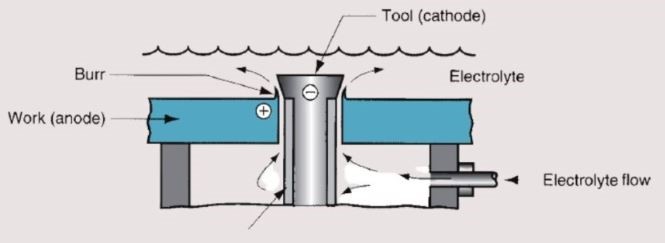

4. Electrochemical deburring

Ma Burrs mu geometry yovuta ndizovuta kuchotsa pogwiritsa ntchito CNC, manual, abrasive, vibratory, ndi njira zina.Chifukwa chake, electrochemical deburring imagwiritsidwa ntchito.Electrochemical deburring imachokera pa mfundo ya electrolysis.

Electrochemical deburring process

Chogwirira ntchitocho chimalumikizidwa ndi terminal yabwino yamagetsi (anode).Chida cha electrochemical deburring ndi kutchinjiriza chimalumikizidwa ku terminal yoyipa (cathode), yokhala ndi glycol kapena mchere monga electrolyte.Electrolyte imadutsa pampata wamapangidwe pakati pa burr ndi chida.Imasungunula ma burrs posamutsa ion yachitsulo ya chogwirira ntchito, ndikupanga hydroxide slurry ngati chopangira.

5. Abrasive deburring

Zida zonyezimira bwino zimagwiritsidwa ntchito m'njira imeneyi kuchotsa zolakwika zazing'ono pamwamba pa chinthu chopangidwa ndi makina ndikupanga mawonekedwe osalala.Chitsulo champhamvu kwambiri, aluminium oxide, ndi magalasi amagalasi ndi zida zomwe zimagwiritsidwa ntchito popanga jeti yowongoka yomwe imatha kuchotsa ma burrs powalozera ndegeyo.Kuphulika kwa Micro-abrasive ndi dzina lina lomwe opanga amagwiritsa ntchito.Popeza njira yowonongekayi imachotsa ma microns pamwamba, imapangitsa kuti ikhale yabwino kwa ziwalo zomwe zimafuna kulondola kwambiri, monga midadada ya injini, mlengalenga, ndi zinthu za robotics.

Ubwino wa Deburring

Deburring phindu muyeso, kusonkhanitsa, mphamvu, kukongola kokongola, ndi mtundu wonse wazinthu zomaliza.

Nazi mapindu ofunikira;

· Deburring imachotsa zitsulo zomwe zimamangiriridwa pa dzenje loponyedwa ndi pamwamba, choncho zimawatsitsimutsa ndikuthandizira kupanga mphamvu zophatikizana bwino ndikulowa nawo zigawo zowonongeka.

· Mabowo oyera amapanga makwerero abwino pamisonkhano.

· Kutsika kwa magawo kumawonjezeka ndi kubweza, zomwe zimapangitsa kuti ntchito zachiwiri zikhale zosavuta.

· Burr amatha kusokonekera mbali imodzi ya gawo ndikulumikizana ndi ena, zomwe zimapangitsa kusamvana pakati pawo.Zotsatira zake, Kusalongosoka kumapanga kuthekera kopangitsa kuti chinthucho chilephereke.Chiwopsezo cholephera ichi chikhoza kuchepetsedwa ndi kuwotcha koyenera kwa zigawo.

· Muyeso ukatengedwa ndikugwiritsidwa ntchito panthawi yopanga, pamwamba pa pepala lachitsulo lokhala ndi burr lophatikizidwa lidzakhudza kulondola.Kukula kolakwika kungayambitse kulephera kwazinthu zamalonda ndipo kungakhale chinthu chosakhutira kwa makasitomala.

· Malo osalala, owonongeka amawongolera kukongola kwa gawolo ndikuthandizira kukongoletsa kwina.

· Mphepete zambiri zomwe zangodulidwazo zimakhala ndi nsonga zakuthwa;deburing akhoza kusalaza chakuthwa, kupangitsa ogwira ntchito ndi makasitomala kumva otetezeka.

Zochepa Zowononga

Mosakayikira, Deburring ndiyo njira yabwino kwambiri yosalala pamwamba pazigawo zachitsulo, koma ili ndi zofooka zina pakugwira ntchito muzochitika zingapo.

1. Ngodya zakuthwa ndi m'mbali

Kudulira makona akuthwa komanso ocheperako kumakhala kovuta kwambiri.Ikhoza kuchotsa katundu wochuluka ndi ma burrs ang'onoang'ono, zomwe zimapangitsa kuti m'mphepete mwake mukhale opanda ungwiro ndi kutayika kwa gawo lachitsulo.

2. Zipinda zosindikizidwa

Kuwotcha kwa zipinda zosindikizidwa kumakhala kovuta kwambiri kupitiriza.Kuchotsa zotchingira m'mphepete mwa chipindacho kumatha kubweza makulidwe ofunikira a chipindacho.

3. Ma geometries ovuta

Magawo onse sangathe kuchotsedwa ndi zida zozungulira, monga zida za bevel, ndi zida zina zopatsirana, chifukwa ma geometri ovutawa amasiya burr yayitali komanso yokhuthala.

4. Kukwapula pamwamba

Pa kusalaza pamwamba ndi deburring, ngati akatswiri sagwiritsa ntchito zida, pali chiopsezo kukanda kuchokera pamwamba popanda kusamala bwino, zomwe zimakhudza makulidwe a chitsulo gawo, kuchepetsa mphamvu ya chomaliza mankhwala.

Malingaliro omaliza

Kutsirizitsa pamwamba ndi mawu otakata omwe amaphatikizapo machitidwe osiyanasiyana a makina, kugaya, Kupukuta, Kupukuta, ndi njira zina zosalala zazitsulo.Komabe, zitha kukhala zokongola zokha kwa makasitomala wamba.Koma kumaliza kumakhudza kwambiri moyo ndi khalidwe la chinthu chomaliza.

Kupanda ungwiro pang'ono pazitsulo kungayambitse vuto loyenera pamene mukusonkhanitsa zigawozo.Monga momwe kuyikako kumakhudzira mphamvu ya olowa ndi kukwanira, kumaliza pamwamba kuyenera kukhala kofunikira kwambiri kwa opanga.Deburring ndi ntchito yoyambira yosalala chifukwa njira ina, monga kunyezimira, kujambula, ndi zokutira, zimakhala zangwiro pambuyo pochotsa zotsalira zazing'ono pamwamba.Kampani yathu wakhala akugwira ntchito zonse zopangira kuyambira pakupanga mapangidwe mpaka kumapeto kwa denga lomwelo.CNC makina, jekeseni akamaumba,ndiAluminium Extrusionndi ukatswiri wathu kuti mungadalire pa ife.

Takhala tikupereka ma deburring abwino kwa zigawo zachitsulo mosasamala kanthu kuti ndi mtundu wanji womaliza womwe ukufunika malinga ndi makina omwe amagwiritsidwa ntchito pazinthu.Khalani omasukakufikira kwa ifengati mukufuna ntchito zilizonse zokhudzana ndi kupanga.

FAQs

Ndi deburring njira yabwino yosalala pamwamba?

Inde, ndiyo njira yabwino kwambiri.Deburring amachotsa Ufumuyo zitsulo Extension ndi zotsalira pamwamba pambuyo Machining.Komanso, imatha kuwongoleredwa kuti ipewe kukanda kosafunikira kuchokera pamwamba pomwe ikusalala.

Ndi mtundu wanji wa deburing wabwino kwambiri?

Palibe yankho lenileni;zimatengera kufunikira kwa chinthu chomaliza kuti chipangidwe.Ngati chomaliza sichifuna kulondola kwambiri, chikhoza kuchitidwa pamanja ndi zida zosavuta.Komabe, electrochemical ingakhale njira yabwino kwambiri ngati zigawo zikufunika kulondola kwambiri.

Ndi njira iti yochotsera ndalama mwachangu?

Electrochemical Deburring ndi yofulumira poyerekeza ndi ena ndipo imatha kuchitika mkati mwa mphindi imodzi.CNC makina ndi njira yachangu ndi yosavuta ngati workpiece ndi lalikulu (Iwo akhoza deburr mpaka 3 mamita mu ntchito imodzi).

Nthawi yotumiza: May-30-2022