Inkqubo yokukhupha imali: Kutheni kubalulekile kwimveliso?

Uhlaziyo lokugqibela 09/14, ixesha lokufunda: 8 imiz

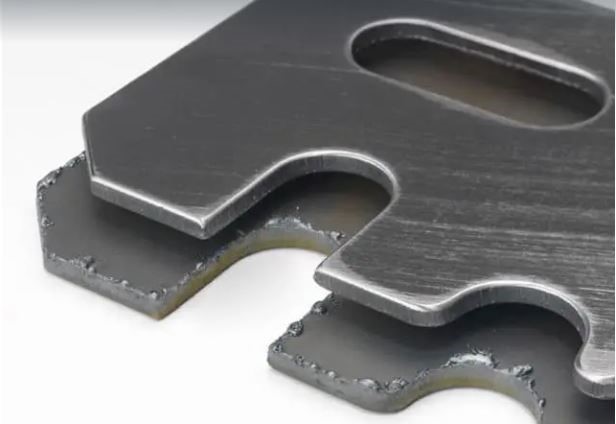

Inxalenye yesinyithi kunye ne-burr kwaye emva kokuchithwa

Xa sigrumba umngxuma kwaye sinqumlesheet metalngexesha lenkqubo yokwenziwa, umngxuma kunye nemiphetho ishiya into encinci efana ne-volcano eyongezelelweyo edityaniswe macala omabini, eyaziwa ngokuba yi-bur.Phantse zonke iindlela zokuvelisa, kubandakanywaukusika, ukugaya, ukugrumba, ukukrola,ukujika, kunye nokubetha amagqabi, i-burr kwiindawo zentsimbi emva kokuhlinzwa.Le bur ichaphazela umlinganiselo, ukudibanisa, amandla, kunye nobuhle bobuhle bemveliso.Ke ngoko, iDeburring kufuneka ithathelwe ingqalelo kuyo yonke iprojekthi yokuvelisa.

Iintlobo zeBurr

Iimpawu zomatshini kunye nezixhobo zokusebenza zibandakanya uhlobo lwesixhobo, ukuqhelaniswa nesixhobo, iipropathi zezinto zokusebenza, kwaye okona kubaluleke kakhulu,indlela isixhobo esingena kwaye siphuma ngayo ngelixa sisenza umsebenzi wokuvelisa simisela uhlobo lwe-burr kumphezulu.

Nazi iintlobo eziqhelekileyo ze-burrekwafuneka isuswe kwimveliso

| Uhlobo lweBurr | Imeko |

| Poisson Burr | Xa intsimbi ifumana uxinzelelo olugqithisileyo kumphezulu, imiphetho yayo ikhubazeka kwaye yolulwe. |

| I-burr yokusika | I-burr ikwicandelo elisikiweyo le-workpiece ngelixa lihlulwe kwindawo ephakathi. |

| Qengqela ngaphaya | i-burr eyenziwe ekuphumeni kwesixhobo kwisixhobo sokusebenza: Ithatha imathiriyeli ngelixa isondla |

| krazula i-burr | UBurr wahlala kunye necala lokusikwa ngexesha lomsebenzi wokubethelwa. |

Iintlobo zokuhlawulela

Ukuchithwa kungenziwa ngeendlela ezahlukeneyo kuxhomekeke kwinxalenye yentsimbi kunye ne-burr.Ezona ndlela zidumileyo zokuqhawula zibandakanyaincwadi,CNC machining, i-vibratory, i-electrochemical, i-thermal, kunye ne-abrasive.

1. Ukucima ngomatshini we-CNC

Njengoko usazi, yonke inkqubo yomatshini kwiUmatshini weCNCinezixhobo ezithile zokwenza, kwaye ukuhlawula kungaphunyezwa ngokutshintsha isixhobo, nangona inokongeza kwixesha lomjikelo.Uhlobo lwesixhobo sokukhupha ixhomekeke kwinto oya kuyisusa, umngxuma, imingxunya enqamlezileyo, imiphetho, okanye umphezulu osicaba.Unokukhetha isixhobo esijolise kakhulu kweso sicelo ngokusekelwe koku.

Imiphetho:Izixhobo ze-Chamfer okanye i-CNC cutter yokucima izinto eziphakanyisiweyo kunye nokugudisa umphezulu

Imingxuma:Izixhobo zokujikeleza ezijikelezayo

Imiphezulu ethe tyaba: Iibhrashi zokususa ngokulula zinokuxhonywa kwi-bit

Imisonto:Imisonto ayinayo i-giant burr.Khetha ibrashi efanelekileyo.

Ukucima ngomatshini we-CNC

Aemva kokukhetha izixhobo, landela la manyathelo alandelayo

1. Cwangcisa inkqubo ye-CNC yokuhlawula imali

2. Qinisekisa ulungelelwaniso lokuqala lwesixhobo (X, Y, Z), emva koko yitsalele kwiqhekeza.Ungayicwangcisa ukuya kwisiqingatha soluhlu lwesixhobo.

3. Faka izinto eziguquguqukayo zegalelo ezifana namandla okuthobela kunye nesantya sesondlo esisekwe kubungakanani beburr.Emva koko, lungisa indawo, kwaye uqalise isenzo.

Iimpawu zeCNC Deburring

· I-Deburring CNC Machining Components yinkqubo ekhawulezayo enokwenziwa kwiyunithi enye kunye nemodeli yeeyunithi ezininzi zamacandelo ezenziweyo.

· Xa kuthelekiswa nobuchule obuqhelekileyo, isantya salo sokuqhawula siphezulu;ingade ifikelele kwiimitha ezi-3 ngomzuzu omnye.

· Ukuphindaphinda kunye nezinye igalelo Iiguquguquko zinokuhlengahlengiswa ngokwedijithali ngokweemfuno zokusetyenzwa.

· Ayichaphazeli ukugudiswa kwendawo yangaphambili kwaye ayilimazi inxalenye.

· Ayichaphazeli ukuchaneka kwe-dimensional okanye ukomelela kwamalungu, kwaye inceda ukomeleza imveliso xa sele ifakelwe amanye amacandelo.

2. Uxinzelelo oluphezulu- ukuchithwa kwejethi yamanzi

Enye indlela edumileyo yokususa uthuli, iitshiphusi, kunye ne-burr kwiindawo ukuze zigudiswe kukukhupha ijethi yamanzi ngoxinzelelo oluphezulu.I-burr kunye ne-chunks yecandelo lecandelo elichaziweyo lichithwa ngamanzi oxinzelelo oluphezulu (35 ukuya kwi-60 MPa) ukusuka kwijethi.Le ndlela yokucima inokuphinda ifezekise indawo ecocekileyo kunye nentsalela.Ngelishwa, izixhobo zokuhlawulela ngokubanzi azikwazi ukufezekisa le nkqubo yokuhlawula isetyenziselwa iindawo ezinzima.

3. Ukuchithwa kwemali ngesandla

I-Manual deburring yindlela ehloniphekileyo yexesha lokulungisa kunye nokunciphisa umphezulu ngokususa i-residu eqhotyoshelweyo eshiywe kwindawo yomatshini wenxalenye.Ingaqhutywa kusetyenziswa izixhobo ezahlukeneyo zeemilo kunye nobukhulu obahlukeneyo.Izixhobo zezandla zisetyenziselwa ukukrazula imiphetho ebukhali kunye nemingxuma ecofelweyo kwaye ibonelele ngokufana komphezulu.Uninzi lweenkqubo zokuvelisa eziqhutywa kwiindibano zocweyo ezingazenzekelanga zixhomekeke ekuhlawuleni ngesandla ngamagcisa anezakhono.

Umqheba kunye neblade enokutshintshwa ngamacandelo amabini aphambili ezixhobo zokucima ngesandla.Umsebenzi wokuqhawula emngxunyeni udinga isandla esizinzileyo ekubambeni kunye nokujikeleza kwee-blades ezihlanjululwayo kwicandelo lecandelo, Nangona ukuchithwa kwemisebenzi kwimida yokusika kunye neendawo ezinqamlekileyo zingenziwa ngokusebenzisa ifayile yesandla okanye isixhobo esiqhelekileyo se-chamfering.Ngokohlobo, inkqubo yesibini, kunye nosetyenziso lweenxalenye, iiblade ezinoluhlu lweemilo zinokusetyenziswa kwisiphatho esinye ngokutshintsha sangaphambili.

Ukuhlawula ngesandla

4. Ukuchithwa kwe-Electrochemical

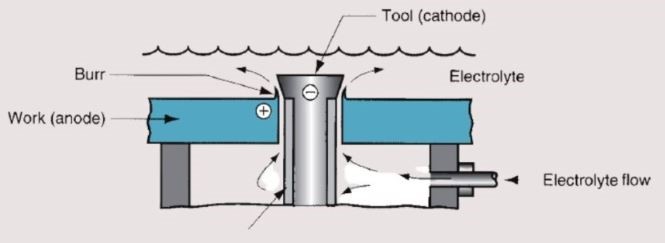

IiBurrs kwijiyometri entsonkothileyo kunzima ukuyisusa usebenzisa i-CNC, manual, abrasive, vibratory, kunye nezinye iindlela.Ngenxa yoko, kusetyenziswa i-electrochemical deburring.I-electrochemical deburring isekelwe kumgaqo we-electrolysis.

Inkqubo yokuchithwa kwe-Electrochemical

Umsebenzi uqhagamshelwe kwitheminali elungileyo yomthombo wamandla (i-anode).Isixhobo se-electrochemical deburring kunye ne-insulation ixhunyiwe kwi-terminal engafanelekanga (i-cathode), kunye ne-glycol okanye isisombululo setyuwa njenge-electrolyte.I-electrolyte idlula kwisithuba soyilo phakathi kwe-burr kunye nesixhobo.Iyinyibilikisa i-burrs ngokudlulisa i-ion yensimbi ye-workpiece, ivelise i-hydroxide slurry njenge-byproduct.

5. I-Abrasive deburring

Kusetyenziswa izixhobo ezicolekileyo zokurhawuzelela kobu buchule ukususa izitenxo ezingephi ukusuka kumphezulu wento eyenziwe ngoomatshini kunye nokudala ukuthungwa komphezulu ogudileyo.Intsimbi ephezulu, i-aluminium oxide, kunye ne-glass blades zizinto eziqhelekileyo ezisetyenziselwa ukwenza i-jet elawulwayo yokukhupha i-jet ekwazi ukususa ngokukhawuleza i-burrs ngokuqondisa i-jet kubo.IMicro-abrasive blasting lelinye igama layo elisetyenziswa ngabavelisi.Ukusukela ukuba le ndlela yokucima isusa ii-microns kumphezulu, iyenza ilungele iindawo ezifuna ukuchaneka okugqithisileyo, njengeebhloko ze-injini, i-aerospace, kunye nezinto zerobhothi.

IiNzuzo zokuSebenzisa imali

Ukulinganisa izibonelelo zokuhlawula, ukudibanisa, amandla, ubuhle bobuhle, kunye nomgangatho wemveliso wokugqibela.

Nazi iingenelo eziphambili;

· I-Deburring isusa isinyithi esincanyathiselwe kumngxunya kunye nomphezulu, ngoko ke iyenza igudise kwaye incede ukudala amandla adityanisiweyo kakuhle ngelixa ujoyina amacandelo akhutshiweyo.

· Imingxuma ecocekileyo yenza ukukhwelana ngokugqibeleleyo kwindibano.

· I-flatness yamacandelo iyanda ngokuchithwa, okuya kwenza kube lula kwimisebenzi yesibini.

· I-Burr inokujika icala elinye lenxalenye ngelixa idibanisa nabanye, ibangele ulungelelwaniso olungalunganga phakathi kwabo.Ngenxa yoko, i-Misalignment idala amandla okwenza ukuba imveliso ingaphumeleli.Lo mngcipheko wokungaphumeleli unokuncitshiswa ngokutshiswa ngokufanelekileyo kwamacandelo.

· Xa umlinganiselo uthathwa kwaye usetyenziswe ngexesha lezigaba zokuvelisa, indawo engalinganiyo yephepha lesinyithi kunye ne-burr eqhotyoshelweyo iya kuchaphazela ukuchaneka.Ubungakanani obungalunganga bunokukhokelela ekungaphumelelini kwiimpawu zemveliso kwaye bunokuba yimveliso enganelisiyo kubathengi.

· I-smooth, i-deburred surface iphucula i-aesthetics yenxalenye kwaye incedisa kwinkqubo yokuhlobisa ngakumbi.

· Imiphetho emininzi esandula kusikwa inencam ebukhali;ukukhupha i-deburring kunokugudisa ubukhali, ukwenza abasebenzi kunye nabathengi bazive bekhuselekile.

Unyino lokuSebenzisa imali

Ngaphandle kwamathandabuzo, i-Deburring yeyona ndlela ilungileyo yokugudisa umphezulu weendawo zentsimbi, kodwa inemida ethile ekusebenzeni kwiimeko ezimbalwa.

1. Iikona ezibukhali kunye neencam

Ukukhupha iikona ezibukhali kunye neekona ezisezantsi kunzima kakhulu.Iyakwazi ukususa isitokhwe esininzi kunye ne-burrs encinci, okukhokelela kwimiphetho engafezekanga kunye nokulahleka kobukhulu becala lentsimbi.

2. Amagumbi atywiniweyo

Ukudilizwa kwamagumbi atywiniweyo kunzima kakhulu ukuqhubeka nako.Ukususa i-burrs kwiincam zegumbi kunokuphelisa ubukhulu obubalulekileyo begumbi.

3. Iijometri ezintsonkothileyo

Onke amalungu awakwazi ukukhutshwa ngezixhobo ezijikelezayo, njengegiya ye-bevel, kunye namanye amacandelo othumelo, kuba ezi jiyometri zinzima zishiya i-burr ende nengqindilili.

4. Ukukrwela umphezulu

Ngexesha lokugungxulwa komphezulu ngokuchithwa, ukuba iingcali aziphathi izixhobo, kukho umngcipheko wokukrazula ukusuka phezulu ngaphandle kokuqwalaselwa okufanelekileyo, okuchaphazela ubukhulu becala lentsimbi, ukuthoba amandla emveliso yokugqibela.

Iingcamango zokugqibela

Ukugqitywa komphezulu ligama elibanzi elibandakanya imisebenzi eyahlukeneyo yomatshini, ukucola, ukupolisha, ukugquma, kunye nezinye iinkqubo zokugudisa iindawo zentsimbi.Nangona kunjalo, inokuba bubuhle bobuhle kubathengi ngokubanzi.Kodwa ukugqiba kunempembelelo ebalulekileyo kubomi kunye nomgangatho wemveliso yokugqibela.

Ukungafezeki okuncinci kumphezulu wesinyithi kunokukhokelela kwingxaki efanelekileyo ngelixa udibanisa iindawo.Njengoko umgangatho wokufaneleka uchaphazela amandla okudibanisa kunye nokudibanisa, ukugqitywa kwendawo kufuneka kube yinto ephambili ephezulu kubenzi.I-Deburring kukuqala kokusebenza ukugudisa kuba enye inkqubo, enjengokukhanya, ukupeyinta, kunye nokugquma, igqibelela kuphela emva kokususa intsalela encinci encanyathiselwe phezulu.Inkampani yethu ibisebenza kuzo zonke iinkonzo zokuvelisa ukusuka kwiprototype yoyilo ukuya ekugqityweni kwemveliso phantsi kophahla olufanayo.CNC machining, isitofu sokubumba, kwayeIAluminiyam Extrusionzikwayingcali yethu onokuthi uthembele kuthi.

Siye sabonelela ngomgangatho wokuchithwa kwezixhobo zetsimbi kungakhathaliseki ukuba luhlobo luni lokugqiba olufunekayo ngokuxhomekeke kumatshini osetyenziswa kwizinto.Zive ukhululekile ukubafikelela kuthiukuba ufuna naziphi na iinkonzo ezinxulumene nemveliso.

Ii-FAQ's

Ngaba deburring isisombululo esona sigudileyo umphezulu?

Ewe, yeyona ndlela ilungileyo.I-Deburring isusa i-Metal Extension eqhotyoshelweyo kunye nentsalela phezu komhlaba emva komatshini.Kwakhona, inokulawulwa ukuthintela ukukhuhla okungadingekile kumphezulu ngelixa ulula.

Loluphi uhlobo lokuhlawula olona lungcono?

Akukho mpendulo yokwenyani;kuxhomekeke kwimfuno yemveliso yokugqibela ekufuneka yenziwe.Ukuba imveliso yokugqibela ayifuni ukuchaneka okuphezulu, inokwenziwa ngesandla ngezixhobo ezilula.Nangona kunjalo, i-electrochemical iya kuba yeyona ndlela ilungileyo ukuba izinto zifuna ukuchaneka okuphezulu.

Yeyiphi indlela yokukhupha imali ngokukhawuleza?

I-Electrochemical Deburring ikhawuleza xa ithelekiswa nabanye kwaye inokwenziwa ngaphakathi komzuzu.Umatshini we-CNC kwakhona yinkqubo ekhawulezayo nelula ukuba i-workpiece inkulu (Iyakwazi ukucima ukuya kwi-3 yeemitha kwintsebenzo enye).

Ixesha lokuposa: May-30-2022