Deburring process: Sei yakakosha mukugadzira?

Yekupedzisira update 09/14, nguva yekuverenga: 8 mins

Metal chikamu ne burr uye mushure mekubvisa

Patinoboora gomba tocheka thesheet metalpanguva yekugadzira, gomba nemacheto zvinosiya chinhu chidiki chakaita segomo rinoputika chakabatanidzwa pamativi ese, chinozivikanwa sebur.Anenge ese nzira dzekugadzira, kusanganisirakucheka, kugaya, kuchera, kunyora,kutendeuka, uye kurova mashizha, burr pane zvikamu zvesimbi mushure mekuvhiyiwa.Iyi bur inokanganisa kuyerwa, kusangana, simba, uye kunyangwe kunaka kwekunaka kwechigadzirwa.Nekudaro, Deburring inofanirwa kutariswa mune yega yega chirongwa chekugadzira.

Mhando dzeBurr

Iwo machining uye workpiece maitiro anosanganisira chishandiso mhando, chishandiso chekutarisa, workpiece zvivakwa, uye zvakanyanya kukosha,kuti chishandiso chinopinda sei uye chinobuda sei paunenge uchiita basa rekugadzira rinotarisa rudzi rweburr pamusoro.

Heano mhando dzakajairika dzeburriyo yaifanira kubviswa mukugadzira

| Burr mhando | Scenario |

| Poisson Burr | Kana Iyo simbi ikawana yakawandisa kushushikana pamusoro pepamusoro, mipendero yayo inowana mapurasitiki akaremara uye akareba. |

| Kucheka-kubvisa burr | Iyo burr iri pachikamu chakachekwa cheworkpiece apo ichiparadzaniswa kubva pakati pepakati. |

| Roll-over | burr yakagadzirwa pakubuda kwechishandiso kubva kune workpiece: Zvinotora zvimwe zvinhu paunenge uchidyisa kure |

| Tear burr | Burr akaramba ari pamwe neakachekwa-parutivi panguva yekuvhiya. |

Mhando dzekubvisa

Deburring inogona kuitwa nenzira dzakasiyana zvichienderana nesimbi chikamu uye burr.Iyo inonyanya kufarirwa nzira dzekubvisa dzinosanganisirabhuku,CNC machining, vibratory, electrochemical, thermal, uye abrasive.

1. Kubvisa neCNC muchina

Sezvaunoziva, ese machining process mune aCNC muchinaine maturusi chaiwo ekuita, uye kubvisa kunogonawo kuwanikwa nekushandura chishandiso, kunyangwe ichigona kuwedzera kunguva yekutenderera.Iyo deburring tool type inoenderana nezvauchabvisa, gomba, maburi-maburi, mipendero, kana nzvimbo yakati sandara.Iwe unogona kusarudza iyo inonyanya kunangwa chishandiso cheiyo application zvichienderana neizvi.

Edges:Chamfer zvishandiso kana CNC cutter kudzima iyo yakasimudzwa zvinhu uye kutsvedzerera pamusoro

Makomba:Rotatory deburring zvishandiso

Nzvimbo dzakatsetseka: Deburring Brushes zviri nyore anogona kuisirwa pabhiti

Threads:Mathreads haana giant burr.Sarudza bhurasho rakakodzera.

Deburring neCNC muchina

Amushure mekusarudza maturusi, tevera matanho anotevera

1. Seta iyo CNC hurongwa hwekubvisa

2. Sarudza yekutanga kurongeka kwechishandiso (X, Y, Z), wobva waikwevera kuchidimbu.Unogona kuimisa kusvika pahafu yemhando yemidziyo.

3. Pinda mabhii ekuisa senge simba rekutevedzera uye chiyero chekudya zvinoenderana nehukuru hweburr.Zvadaro, gadzirisa nzvimbo, uye tanga chiito.

Hunhu hweCNC Deburring

· Deburring CNC Machining Components inzira inokurumidza inogona kuitwa pane imwechete-uniti uye akawanda-mayuniti emhando dzezvikamu zvakagadzirwa.

· Kuenzaniswa nemaitiro akajairwa, kukurumidza kwayo kwekubvisa kwakakwirira;inogona deburr kusvika mamita matatu muminiti imwe chete.

· Frequency uye kumwe kupinza Variables inogona kugadziridzwa digitaalinen maererano nekugadzirisa zvinodiwa.

· Iyo haina kukanganisa kutsetseka kwechiso chepamberi uye haikuvadzi chikamu.

· Izvo hazvikanganise kurongeka kwedimensional kana kusimba kwezvikamu, uye zvinobatsira kusimbisa chigadzirwa kana chaiswa zvimwe zvikamu.

2. High pressure- mvura jet deburring

Imwe nzira yakakurumbira yekubvisa guruva, machipisi, uye burr kubva kune zvikamu kuti zviite zvinyoro-inomanikidza mvura jet deburring.Iyo burr uye chunks yechikamu chakatsanangurwa chikamu chinodonhedzwa nepamusoro-kudzvanywa mvura (35 kusvika 60 MPa) kubva mujeti.Iyi nzira yekubvisa inogona zvakare kuwana yakachena uye yakasara-isina nzvimbo.Nehurombo, maturusi ekubvisa akajairwa haakwanise kuita iyi nzira yekubvisa inoshandiswa kune yakaoma zvikamu.

3. Manual Deburring

Manual deburring inguva-inoremekedzwa nzira yekutsvedzerera uye kutsetseka kwepamusoro nekubvisa zvakanamirwa zvakasara pane machining nzvimbo yechikamu.Inogona kushandiswa uchishandisa maturusi akasiyana emhando dzakasiyana uye saizi.Maturusi emaoko anoshandiswa kukwenya mipendero yakapinza uye maburi akateyiwa uye inopa kufanana kwepamusoro.Mazhinji maitiro ekugadzira anoitwa mumashopu asina otomatiki anotsamira pakubviswa kwemaoko nenyanzvi dzine hunyanzvi.

Mubato uye blade inotsiviwa ndizvo zvikamu zviviri zvakakosha zvematurusi ekubvisa maturusi.Basa rekubvisa mugomba rinoda ruoko rwakadzikama pakubata uye kutenderera kwemashizha ekubvisa pachikamu chechikamu, Nepo mashandiro ekubvisa pamicheto yekucheka uye nzvimbo dzakatsetseka zvinogona kuitwa uchishandisa ruoko faira kana chenguva dzose chamfering chishandiso.Zvinoenderana nerudzi, yechipiri maitiro, uye zvikamu zvekushandisa, mablades ane huwandu hwemaumbirwo anogona kushandiswa mubato rimwe chete nekutsiva yapfuura.

Manual deburring

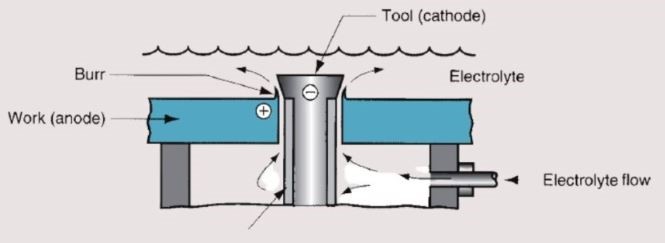

4. Electrochemical deburring

Mabura mune yakaoma geometry yakaoma kubvisa uchishandisa CNC, manyorero, abrasive, vibratory, uye dzimwe nzira.Saka electrochemical deburring inoshandiswa.Electrochemical deburring inobva pane electrolysis musimboti.

Electrochemical deburring process

Iyo workpiece yakabatana kune iyo magetsi sosi yakanaka terminal (anode).Electrochemical deburring tool ine insulation yakabatana kune negative terminal (cathode), ine glycol kana salt solution se electrolyte.Electrolyte inopfuura nepamukaha wekugadzira pakati peburr nechishandiso.Iyo inonyungudutsa maburrs nekuendesa iyo simbi ion yeworkpiece, ichigadzira hydroxide slurry seyakagadzirwa.

5. Abrasive deburring

Abrasive materials akanakisa anoshandiswa muhunyanzvi uhu kubvisa zvikanganiso zvidiki kubva pamusoro pechinhu chakagadzirwa uye kugadzira kutsetseka kwepasi.Iyo yakakwirira-yakasimba simbi, aluminium oxide, uye magirazi mablades akajairika abrasive zvinhu zvinoshandiswa kugadzira inodzoreka deburring jet inokwanisa kubvisa nyore maburrs nekunangisa jet kwairi.Micro-abrasive blasting ndiro rimwe zita rayo rinoshandiswa nevagadziri.Sezvo iyi nzira yekubvisa inobvisa mamicrons kubva pamusoro, inoita kuti ive yakakodzera kune zvikamu zvinoda kunyatsojeka, senge mabhuroko einjini, aerospace, uye marobhoti zvinhu.

Benefits of Deburring

Deburring mabhenefiti kuyerwa, kusangana, simba, runako rwekunaka, uye yakazara yekupedzisira chigadzirwa mhando.

Heano mabhenefiti akakosha;

· Deburring inobvisa simbi yakanamirwa pagomba uye pamusoro, saka inonyanya kutsetseka uye inobatsira kugadzira yakanyatsobatanidzwa simba uchijoinha zvinhu zvakabviswa.

· Makomba akachena anoita kukwirana kwakakwana pakusangana.

· Iyo flatness yezvikamu inowedzera ne deburring, izvo zvichaita kuti zvive nyore kune yechipiri mashandiro.

· Burr inogona kutsveta rumwe rutivi rwechikamu ichibatana nevamwe, zvichikonzera Misalignment pakati pavo.Nekuda kweizvozvo, Misalignment inogadzira mukana wekuita kuti chigadzirwa chikundikane.Iyi njodzi yekukundikana inogona kuderedzwa nekuputirwa kwakakodzera kwezvikamu.

· Kana kuyerwa kuchitorwa uye kushandiswa panguva dzekugadzira nhanho, iyo isina kuenzana pamusoro pesimbi simbi ine yakasungirirwa burr inokanganisa iko kurongeka.Saizi isiriyo inogona kutungamira mukukundikana mune zvigadzirwa uye inogona kuve isingagutsikane chigadzirwa kune vatengi.

· Iyo yakatsetseka, yakasvibiswa nzvimbo inovandudza aesthetics yechikamu uye inobatsira mune imwezve yekushongedza maitiro.

· Micheto mizhinji ichangobva kutemwa ine micheto yakapinza;deburring inogona kupfavisa kupinza, kuita kuti vashandi nevatengi vanzwe vakachengeteka.

Kuganhurirwa kweKubvisa mari

Pasina kupokana, Deburring ndiyo yakanakisa nzira yekutsvedzerera pamusoro pezvikamu zvesimbi, asi ine zvimwe zvipimo mukushanda mune mashoma mashoma.

1. Makona akapinza nemicheto

Deburring yakapinza uye yakaderera-angle makona inotyisa.Inogona kubvisa stock yakawandisa ine mabhura madiki, zvichikonzera kusakwana kwemicheto uye kurasikirwa kwechikamu chesimbi chikamu.

2. Dzimba dzakavharwa

Kubvisa makamuri akavharwa kwakaoma kuenderera mberi.Kubvisa mabhura kubva kumapendero ekamuri kunogona kudzoreredza ukobvu hwekamuri.

3. Complex geometries

Zvese zvikamu hazvigone kubviswa nemidziyo inotenderera, senge bevel giya, uye zvimwe zvinhu zvekutapurirana, nekuti aya akaomarara geometries anosiya refu uye gobvu burr.

4. Surface scraping

Panguva yekunyorovesa kwepamusoro nekubvisa, kana nyanzvi dzisingabatanidzi zvishandiso, kune njodzi yekukwenya kubva kumusoro pasina kunyatsotarisisa, iyo inokanganisa kuwanda kwesimbi chikamu, kudzikisa simba rechigadzirwa chekupedzisira.

Pfungwa dzekupedzisira

Kupedzisa kwepamusoro ishoko rakafara rinosanganisira akasiyana machining mashandiro, kugaya, Deburring polishing, coating, uye mamwe maitiro ekutsvedzerera ezvikamu zvesimbi.Nekudaro, zvinogona kungove runako rwekunaka kune vese vatengi.Asi kupedzisa kune zvakakosha pahupenyu uye kunaka kwechigadzirwa chekupedzisira.

Kusakwana kudiki pamusoro pesimbi kunogona kutungamirira kune dambudziko rakakodzera panguva yekuunganidza zvikamu.Sezvo kunaka kwekukodzera kunokanganisa kusimba kwemajoini uye kuenderana, kupedzisa kwepamusoro kunofanirwa kuve kwekutanga kwevagadziri.Deburring ndiyo yekutanga mashandiro ekutsvedzerera nekuti imwe nzira, senge kupenya, kupenda, uye kupotera, inongove yakakwana mushure mekubvisa diki diki rakasara rakanamirwa pamusoro.Femu yedu yanga ichishanda pane ese ekugadzira masevhisi kubva kune prototype dhizaini kusvika kupedzisa chigadzirwa pasi pedenga rimwechete.CNC machining, jekiseni kuumba,uyeAluminium Extrusionihwowo hunyanzvi hwedu hwaunogona kuvimba nesu.

Isu tanga tichipa kunaka kwekugadzirisa kwezvikamu zvesimbi zvisinei kuti rudzii rwekupedzisa runodiwa zvichienderana nemachining anoshandiswa kune zvinhu.Inzwa wakasunungukasvika kwatirikana iwe uchida chero masevhisi ane chekuita nekugadzira.

FAQ's

Is deburring ndiyo yakanakisa mhinduro yekutsvedzerera pamusoro?

Hungu, ndiyo nzira yakanakisisa.Deburring inobvisa iyo yakanamatira simbi Extension uye yakasara pamusoro pepamusoro mushure mekugadzira.Zvakare, inogona kudzorwa kudzivirira kukwesha kusingakoshi kubva pamusoro paunenge uchitsvedzerera.

Ndeupi rudzi rwekubvisa rwakanyanya kunaka?

Hapana mhinduro chaiyo;zvinoenderana nezvinodiwa zvechigadzirwa chekupedzisira kugadzirwa.Kana chigadzirwa chekupedzisira chisingadi kurongeka kwepamusoro, chinogona kuitwa nemaoko nezvishandiso zviri nyore.Zvakadaro, electrochemical ingave yakanakisa nzira kana zvikamu zvinoda kurongeka kwakanyanya.

Ndeipi nzira yekubvisa inokurumidza?

Electrochemical Deburring inokurumidza kuenzaniswa nevamwe uye inogona kuitwa mukati meminiti.CNC muchina zvakare inokurumidza uye nyore maitiro kana workpiece yakakura (Inogona deburr kusvika 3 metres mune imwechete oparesheni).

Nguva yekutumira: May-30-2022