Insert molding chikamu

Workingnheyo yekuisa kuumba

Insert molding inzira yekugadzira inosanganisira kuisa preformed component, inozivikanwa seyekupinza, muforoma isati yabaya majekiseni epolymer.Iyo yekuisa inozoputirwa nepolymer, ichigadzira imwechete, yakabatanidzwa chikamu.Iyi nzira inoshandiswa zvakanyanya mumaindasitiri akasiyana akadai semotokari, zvemagetsi, uye zvekurapa kugadzira akawanda ezvigadzirwa.

Tiye anoshanda maitiro eIsert molding

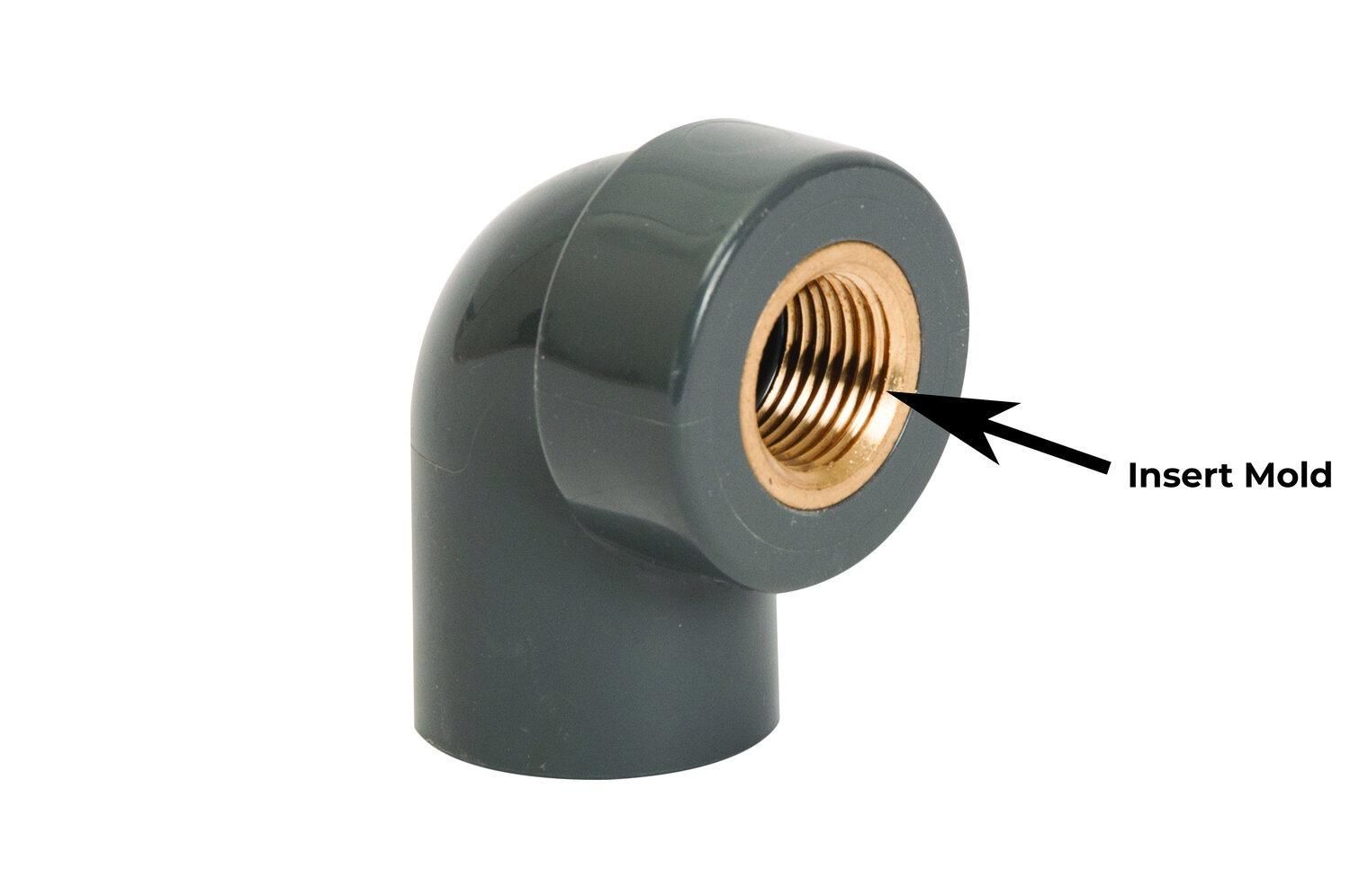

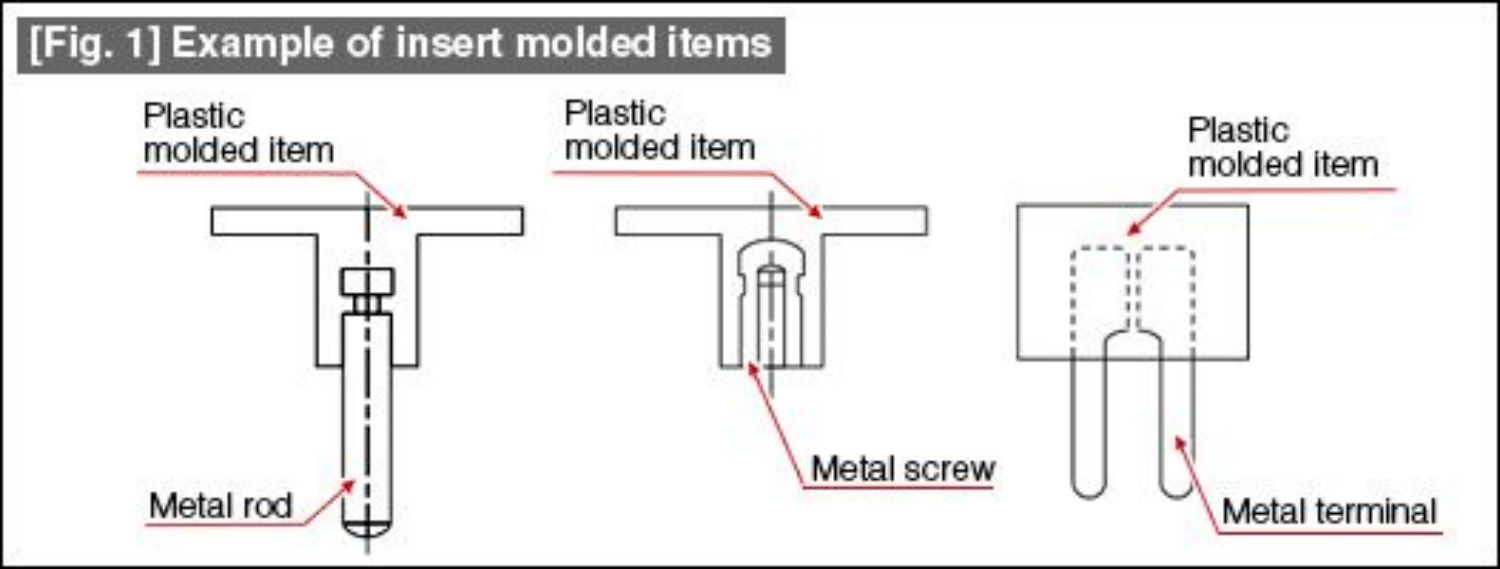

Emuenzaniso wekuisa zvinhu zvekuumba

Emuenzaniso wekuisa zvinhu zvekuumba

Maitiro acho anotanga nekugadzira iyo yekuisa, iyo inogona kugadzirwa kubva kwakasiyana zvinhu zvakaita sesimbi, plastiki, kana ceramics.Iyo yekuisa inozoiswa mu mold, iyo yakagadzirirwa kubata inoisa panzvimbo panguva yekuumba jekiseni.Iyo polymer zvinhu, kazhinji iyo thermoplastic senge polypropylene kana polyethylene, yobva yapinzwa mumold, kwainotenderedza kupinza.Iyo mold inobva yatonhodzwa, uye chigadzirwa chakapedzwa chinobviswa.

Tanobatsirwa neInsert molding

Imwe yemabhenefiti makuru ekuisa molding ndeyekuti inobvumira kugadzirwa kwechinhu chimwe chete, chakabatanidzwa chinosanganisa zvinhu zvekuisa uye iyo polymer.Izvi zvinogona kupa akati wandei mabhenefiti akadai sekuvandudza simba, conductivity, kana insulation.Iyo zvakare inobvumira kune yakakura dhigirii yedhizaini kuchinjika, sezvo iyo yekuisa inogona kushandiswa kugadzira akasiyana mhedzisiro senge mavara gradients, mapatani, kana kunyange kugadzira akasiyana zvinhu zvinhu pachikamu chimwe chete.

Imwe mukana weiyi nzira ndeyekuti inogona kuchengetedza nguva nemari nekubvisa kudiwa kwechipiri maoperation senge welding kana gluing.Izvi zvinogona zvakare kuvandudza huwandu hwese hwechigadzirwa nekudzikisa njodzi yekukanganisa kana kutadza kunokonzerwa nekuita uku.

Maitiro acho zvakare ari nyore kuita otomatiki, izvo zvinoita kuti ive yakakodzera kune yakakwira-vhoriyamu yekugadzira inomhanya.Pamusoro pezvo, inogoneka uye inogona kushandiswa kune dzakasiyana siyana zvigadzirwa, kubva kudiki diki zvidimbu kusvika kumagungano makuru.

Tkumisa nzira iyi

Zvisinei, maitiro anewo zvimwe zvisingakwanisi.Zvimiro zvechigadzirwa chekupedzisira zvinoenderana nerudzi rwekupinza uye polymer inoshandiswa, saka zvakakosha kuti unyatso kusarudza zvigadzirwa kuti uve nechokwadi chekuti chigadzirwa chekupedzisira chine zvimiro zvinodikanwa zvechishandiso chaicho.Pamusoro pezvo, maitiro anogona kunetsa kuwana anowirirana mavara mechi pakati pekuisa uye polymer, kunyanya kana uchishanda nemhando dzakasiyana dzezvinhu.

Ckubatanidza

Mukupedzisa, kuisa molding inzira yekugadzira inosanganisira kuisa preformed component muforoma usati wabaya jekiseni repolymer.Iyo nzira inobvumira kugadzirwa kwechinhu chimwe chete, chakabatanidzwa chinosanganisa zvimiro zvekuisa uye iyo polymer, ichipa akati wandei mabhenefiti akadai sekuvandudza simba, conductivity, kana insulation.Maitiro acho akakodzera kukwirisa-vhoriyamu yekugadzira inomhanya uye inopa yakakura dhizaini kuchinjika, asi zvakare ine painogumira sekuda yakasarudzika michina uye mold uye zvinogona kunetsa kuwana inowirirana ruvara mechi pakati pekuisa uye polymer.Maitiro aya ari kuwedzera kushandiswa mumaindasitiri akasiyana uko kubatanidzwa kwezvinhu zvakasiyana uye zvivakwa zvakakosha, senge mumaindasitiri emotokari nemagetsi, uye anotarisirwa kuramba achishanduka, achipa mimwe mikana yekuvandudza chigadzirwa.Kana uri kutsvagamutengesi wekuisa molding, ndapota inzwa wakasunungukataura nesu.

Nguva yekutumira: Jan-19-2023