Sheet Metal Welding: Konke Odinga Ukukwazi

Isibuyekezo sokugcina:09/02, isikhathi sokufunda: 6 imiz

Ukusebenza kwe-Welding

Ishidi lensimbi yokushiselakuyinqubo yokwenziwa ebalulekile ngoba ingenye yezindlela ezilula zokuhlanganisa izingcezu ezisikiwe zamashidi ensimbi ukuze wakhe umumo oyifunayo.Ekushiseleni, izindawo zokukhwelana zingaphansi kokushisa okunamandla ukuze zixube ngokuncibilikisa insimbi endaweni ekhethiwe.Kwezinye izimo, ingcindezi iphinde isetshenziselwe ukujoyina izingxenye zeshidi, kepha i-Spark idume kakhulu phakathi kwabakhiqizi nezicelo zezimboni.

Lesi sihloko sizoxoxa kafushaneAmasu okushisela amashidi ensimbi ahlukene, Izicelo, izici okufanele zicatshangelwe, kanye neseluleko sokushisela esiwusizo.

1. I-MIG

Umsebenzi wokushisela we-MIG

Elinye igama le-MIG welding yi-Gas Metal Arc Welding (GMAW).Inqubo yokushisela lapho i-electrode yocingo eqinile esebenzisekayo idala ichibi lokuncibilika endaweni yokujoyina.Ithiphu ye-electrode yokushaja kagesi ishisa indawo eqondiwe futhi incibilikisa insimbi.Kule ndlela, isibhamu sokushisela sisebenzisa igesi evikelayo (i-helium, i-argon, i-nitrogen) ukumisa i-weld pool ukuthi ingangenwa ukungcoliswa komoya.Ilungele amashidi ensimbi ensimbi engagqwali, i-Carbon steel, ne-Aluminium.

Ekushiseleni kwe-MIG, ukugeleza kwegesi kwangaphakathi kusuka kusilinda sokuhlinzeka kanye nokunikezwa kwamandla okunomthamo ongashintshi kuyadingeka ukuze kwakhiwe i-arc kagesi yokuncibilikisa insimbi nokondla intambo ye-electrode.

Ijubane lokushisela ku-MIG liyahlukahluka kusuka kumayintshi angama-20 kuye kwangama-30 ngomzuzu kuye ngendawo yokushisela (Indawo yangaphakathi noma yangaphandle) nezinto ezibonakalayo.Kodwa-ke, i-MIG isizenzekele kakhulu futhi ingashisela ifike ku-100″ngomzuzu.

2. I-TIG

Ukusebenza kwe-TIG Welding

I-TIG yokushisela iletha ukushisa endaweni ethile yeshidi lezinsimbi lapho ukuhlanganisa kuyadingeka kusetshenziswa ama-electrode e-tungsten angasebenziseki.Njengokushisela kwe-MIG, ukuvikela igesi ye-inert kusetshenziselwa ukuvimbela ukungcoliswa kwechibi lokushisela.Njengoba i-electrode ayikwazi ukudliwa, inhlanganisela iqiniswa ngezinto zokugcwalisa.Ngakho-ke, ukuphakela induku yokugcwalisa ngokuqhubekayo endaweni yokushisela kuyo yonke inqubo kuyadingeka.

Ngokusho kweishidi lensimbiukujiya, ungakhetha ububanzi be-electrode ye-tungsten yenqubo yokushisela.Isibonelo, i-electrode ye-tungsten engu-2.4mm izoba ngcono uma insimbi yeshidi iwugqinsi ongu-3mm.I-1.6 mm iyoba inketho engcono kakhulu uma ishidi libuthakathaka.

Ngenxa yokuthi idala amajoyinti aqinile kunsimbi yensimbi & neshidi leshidi elingeyona insimbi njenge-Aluminium, ithusi, i-titanium, i-magnesium, ne-Chromium, ukushisela kwe-TIG kusetshenziswa kabanzi embonini ye-aerospace neyokukhiqiza izimoto ngaphandle kokwenziwa kwefenisha.Noma i-TIG welding ihamba kancane (4 kuya ku-6″ngomzuzu), ukushisela usebenzisa i-automation noma indlela yerobhothi kungasheshisa inqubo.

3. I-Stick Welding

Ukusebenza kwe-Stick Welding

Ukushisela induku kuyindlela evamile futhi evamile yokuhlanganisa amapuleti ensimbi eshidi, esebenzisa ukushisela i-arc yensimbi evikelekile.Kuyindlela yokwenza i-arc welding esebenzisa induku embozwe ku-flux njenge-electrode.I-electrode iphethe i-negative current lapho ishidi lokusebenzela lixhunywe khona netheminali ephozithivu yomthombo wamandla we-AC.

Kuyindlela eqondile kakhulu.Namathisela induku ye-electrode kusibhamu sokushisela bese uthinta indawo yokushisela ukuze uqhubeke.Nakuba ifaka insimbi eningi kakhulu endaweni yokushisela futhi idinga izinga eliphezulu lobuchwepheshe, ifanele izinsimbi eziqinile njenge-carbon steel namashidi ensimbi anogqinsi olungaphansi kuka-3.2 mm.

4. I-Plasma Arc Welding

Ukusebenza kwe-Plasma arc Welding

Ku-plasma arc welding, i-metal coalescence ikhiqizwa i-arc ehlanganisiwe eyenziwe ngesivinini esiphezulu segesi ionized ebizwa ngokuthi i-plasma.Emisebenzini eminingi yokushisela i-arc ye-plasma, ijethi ye-plasma ikhiqizwa ngokushisisa igesi ye-orifice ekamelweni le-torch polenta nokuphoqelela i-plasma ngombhobho obambayo.Isivikelo esiyingxenye sitholwa nge-plasma futhi sengezwe igesi eliyisivikelo.Amagesi ayisivikelo asebenzisa i-argon, i-helium, noma ingxube ye-argon ne-hydrogen noma i-helium.

Amandla okushisa omfudlana we-plasma agxilile futhi anamandla kakhulu ngenxa ye-arc ehlanganisiwe, okuvumela ukungena okujulile.Ngenxa yalokho, ikhiqiza ukushisela okuzinzile, okuncane, futhi okusheshayo ensimbi yeshidi.Izinsimbi zeshidi zingahlanganiswa kusetshenziswa i-plasma arc welding noma ngaphandle kwezinto zokugcwalisa.Izinsimbi ezisansimbi nezingeyona insimbi, okuhlanganisa namashidi antekenteke, zingahlanganiswa kusetshenziswa i-plasma arc welding.

5. I-laser-beam welding

Ukusebenza kwe-laser beam welding

Ku-laser beam welding, i-photon beam ende ekhonjwe endaweni yokushisela ishisa amashidi ensimbi futhi iwahlanganise ngokwakha idamu lokushisela.Inzuzo eyinhloko yale nqubo yokushisela ukuthi kuzoba nendawo encane ethinteke ekushiseni ngenxa ye-concentrated high-density photons beam.

Ama-lasers weldzilungele izinsimbi zeshidi ezinezinga lokushisa eliphezulu elincibilikayo kanye nokushisa kokushisa, njenge-Carbon & insimbi engagqwali, i-titanium, ne-Aluminium.Ngenxa yokuthi izinto zokushisela eziwumngcingo zifinyeleleka kalula, zisetshenziselwa ukwenza izingxenye zegiya, ama-airbag, imikhono, nama-pacemaker.

Kunemishini emibili ejwayelekile yokusebenza kwe-laser welding eshidini lensimbi, izinhlobo ezimfushane nezinde zamaza.Imithombo yamaza amade ama-laser ohlobo lwe-CO2, kanti imishini yamaza amafushane i-YAG, idiski, noma imishayo yefiber.Umehluko omkhulu wukuthi imishini enobude obufushane obungamaza incibilikisa impahla ngokushesha kunemide.

Manje ake siqhathanise ngayinye yezinqubo zokushisela ukuze siqonde kangcono;

| SN | Uhlobo | Isivinini sokushisela | Izinto zeshidi |

| 1 | I-MIG | 20 kuya ku-30″ / iminithi okuzenzakalelayo : kufika ku-1oo ″ / iminithi | I-Carbon nensimbi engagqwali, i-Aluminium |

| 2 | I-TIG | 4 ku10″ / iminithi okuzenzakalelayo: Kufika ku-80″ / iminithi | Insimbi, i-Chromium, i-titanium, ithusi, i-magnesium |

| 3 | Induku | 3 ku6″ / iminithi | izinsimbi eziqinile njenge-carbon steel namashidi ensimbi |

| 4 | I-Laser beam | 40 kuya ku-140″ / iminithi (kuya ngemanuwali noma ngokuzenzakalelayo) | Izinto ezinezinga eliphezulu lokuncibilika, Ikhabhoni nensimbi engagqwali, i-titanium |

| 5 | I-Plasma arc | 10 kuya ku-20″ / iminithi, okuzenzakalelayo : kufika ku-125 ″ / iminithi | Kokubili i-ferrous kanye ne-non-ferrous |

Ukuqhathanisa phakathi kwezinqubo zokushisela

Izinhlobo zezikhundla zokushisela & Izimpawu

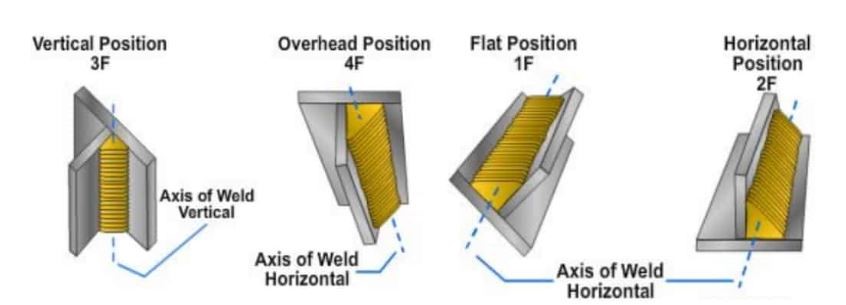

Kunezinhlobo ezine eziyisisekelo zezikhundla zokushisela I-Flat (1), Evundlile (2), Eqondile (3), ne-Overhead (4).Inombolo ekubakaki imele uphawu lohlobo.Futhi, kokubili i-fillet (F) kanye ne-groove welding (G) ingasetshenziswa kuwo wonke amakilasi amane.Masiziqonde lezi zimpawu ngesibonelo;

i. I-3 F: I-fillet welding endaweni eqondile

ii. 4 G: i-groove welding endaweni engaphezulu

iii. 2 F: I-fillet welding endaweni evundlile

Izikhundla ezihlukahlukene zokushisela

Ku-welding ye-fillet, umkhawulo ongaphezulu wendawo evundlile ubekwe endaweni eqondile endaweni ye-perpendicular efana no-L.Ngenkathi i-groove welding, ngenkathi i-groove welding, kokubili ishidi lensimbi okufanele lishiselwe libeka endizeni efanayo (Iqondile).

Izinto okufanele zicatshangelwe ngesikhathi sokushisela i-sheet metal

Ukuze uthole umshado ozinzile futhi oqinile, izici ezihlukahlukene kufanele zicatshangelwe.Ake sibukeze ezinye zezici ezibalulekile ngokuningiliziwe;

1. Izinto zokugcwalisa

Khetha okokugcwalisa okukwazi ukuvimbela ukugqwala nokugqwala ekugcineni.Futhi, khumbula ukuthi induku yokugcwalisa kufanele ibe mncane kunobukhulu beshidi lensimbi.Isibonelo, induku yokugcwalisa kufanele ibe phakathi kuka-0.7 no-1 mm uma uhlela ukushisela insimbi yeshidi engu-1.5 mm ubukhulu.

2. Usayizi we-Electrode

Usayizi we-electrode kufanele ukhethwe ngokusekelwe ekushiseni (ugesi) osetshenzisiwe kanye nezinga lokushisela elidingekayo.Isibonelo, i-electrode enobubanzi obungamayintshi angu-0.125 isebenza kangcono ekushiseleni okuncane nezimo zokushisa eziphansi.

3. Izinsimbi eshidini lokusebenza

Ukusebenzisa i-clamp ukulungisa indawo yokushisela kubalulekile ekuzuzeni ukushisela okuzinzile namandla.Ngaphezu kwalokho, ishidi lidinga ukuboshelwa ngendlela efanele ukuze kuvinjelwe amashidi okusebenza ukuthi angagudluki ngesikhathi sokushiselwa.

Amathiphu okubhekana nezinkinga ngesikhathi sokushisela

· Kungcono ukusebenzisa ithiphu ye-electrode ecijile ukuze ugcine i-arc ne-puddle kukuncane futhi kulawulwa ngangokunokwenzeka lapho kushiselwa ezindaweni eziqinile phakathi kwezingcezu zensimbi ngoba lokhu kugcina indawo yokushisa isendaweni ecindezeleke kakhulu.

· Hlola i-welding kuma-prototypes ngaphambi kokuqala izinqubo zokushisela zensimbi ukuze uqinisekise ikhwalithi nokuqedwa kwendawo.

· Lapho wenza i-MIG yokushisela, hambisa isibhamu sokushisela ngendlela eqondile ngesivinini sokuhamba esisheshayo ngangokunokwenzeka lapho indawo ye-arc ishisa kakhulu.Izovikela ekutubekeni.

· Gwema ukushiya noma yiziphi izimbobo endaweni yokushisela ngoba zizosebenza njengemigodi yomswakama futhi zikhuthaze ukwakheka kokugqwala.

· Ukuze uchithe ukushisa, hlanganisa indawo ethinteke ukushisa nge-coll bar eyenziwe ngethusi noma nge-Aluminum.

Isiphetho

Ukukhetha indlela yokushisela efanele esekelwe eshidini lensimbi kanye nemininingwane edingekayo yomkhiqizo kubalulekile.Ngemuva kokukhetha uhlobo lwe-welding, izici eziningana, kufaka phakathi usayizi we-electrode, impahla yokugcwalisa, isikhundla se-clamp, nokuningi, kufanele kucatshangelwe.Kwa-Prolean, sihlinzeka ngochwepheshesheet metal welding ukubonisana kanye nezinsizakalokusukela ekuklameni imingcele yokushisela kuya ekusikeni kwe-laser nokushisela okuhambisana nezidingo zakho.Xhumana nonjiniyela wethungokuqondile ukuze uthole ulwazi olwengeziwe.

Imibuzo Evame Ukubuzwa

Yiziphi izindlela ezingcono kakhulu zokushisela ngazo zombili i-AC & DC?

Izindlela ezahlukahlukene zokushisela zisebenza kuzo zombili izinhlobo.Kodwa-ke, ukushisela kwe-MIG kungaba okungcono kakhulu uma usebenzisa yomibili imithombo ye-AC&DC.

Yiziphi izinhlobo ezijwayelekile zokushisela amashidi ensimbi?

Kunezindlela ezinhlanu ezijwayelekile zokushisela zeshidi lensimbi, okuhlanganisa i-TIG, i-MIG, iStick, i-Laser beam & plasma welding.

Ungakanani umkhawulo wokujiya wokushisela i-sheet metal?

U-O.8 mm umkhawulo wokujiya ophansi wokushisela insimbi yeshidi.Nokho, uma udinga ukushisela amashidi aphansi kunalokho, ungasebenzisa i-MIG yokushisela nge-MIG, kodwa qiniseka ukuthi ithiphu le-electrode licijile kakhulu.

Yiziphi izici ezibalulekile okufanele zicatshangelwe ngenkathi kwenziwa imisebenzi yokushisela?

Usayizi wenduku ye-Electrode & Filler, ubukhulu beshidi lokusebenza, elifakelwa ukushisa, indawo yokubopha, nokuphepha yikona okucatshangwayo okudingeka kakhulu.

Isikhathi sokuthumela: Jul-08-2022