Sheet Metal Welding: Yonke into ekufuneka uyazi

Uhlaziyo lokugqibela: 09/02, ixesha lokufunda: 6 imiz

Ukusebenza kweWelding

Ishiti lentsimbi ukuweldaYinkqubo yokwenza into ebalulekileyo kuba yenye yeendlela ezilula zokudibanisa amaqhekeza esikiweyo amacwecwe esinyithi ukwenza imilo efunekayo.Kwi-welding, iindawo zokukhwelana ziphantsi kobushushu obukhulu ukuze zidibanise ngokunyibilikisa isinyithi kwindawo echongiweyo.Kwezinye iimeko, uxinzelelo lukwasetyenziselwa ukujoyina iinxalenye zeshiti, kodwa i-Spark yeyona idumileyo phakathi kwabavelisi kunye nezicelo zamashishini.

Eli nqaku liza kuxubusha ngokufutshaneezahlukeneyo sheet metal ukuwelda Techniques, Izicelo, imiba ekufuneka iqwalaselwe, kunye neengcebiso eziluncedo welding.

1. MIG

Umsebenzi we-MIG welding

Elinye igama le-MIG welding yi-Gas Metal Arc Welding (GMAW).Inkqubo ye-welding apho i-electrode yocingo oluluqilima olusetyenziswayo idala i-melt pool kwindawo yokudibanisa.I-electrode yentlawulo yombane ithiphu itshisa indawo ekujoliswe kuyo kwaye inyibilikisa isinyithi.Kule ndlela, umpu we-welding usebenzisa i-gas yokukhusela (i-helium, i-argon, i-nitrogen) ukumisa i-weld pool ekusulelekeni kukungcoliswa kwe-atmospheric.Ifanelekile kumaphepha esinyithi entsimbi, intsimbi yeCarbon, kunye neAluminiyam.

Kwi-MIG welding, ukuhamba kwegesi yangaphakathi ukusuka kwi-cylinder yokubonelela kunye nokunikezelwa kwamandla kunye ne-voltage eqhubekayo iyadingeka ukudala i-arc yombane yokunyibilikisa isinyithi kunye nokondla ucingo lwe-electrode.

Isantya se-welding kwi-MIG sihluka ukusuka kwi-20 ukuya kwi-intshi ye-30 ngomzuzu ngokuxhomekeke kwindawo ye-welding (Ingaphakathi okanye ngaphandle kwendawo) & izinto eziphathekayo.Nangona kunjalo, i-MIG iye yazenzekela ngakumbi kwaye inokuweld ukuya kuthi ga kwi-100″ngomzuzu.

2. TIG

Ukusebenza kwe-TIG welding

I-TIG ye-welding ihambisa ubushushu kwindawo ethile yesinyithi seshiti apho ukudibanisa kuyimfuneko usebenzisa i-electrodes ye-tungsten engasetyenziswanga.Njengokuwelda kwe-MIG, ukukhuselwa kwerhasi ye-inert kusetyenziselwa ukuthintela ukungcoliseka kwechibi le-welding.Ekubeni i-electrode ayinakudliwa, idibeneyo iqiniswa ngezinto zokuzalisa.Ke, ukondla intonga yokuzalisa ngokuqhubekayo kwindawo yokuwelda kuyo yonke inkqubo iyafuneka.

Ngokutsho kwesheet metalubukhulu, unokukhetha ububanzi be-electrode ye-tungsten kwinkqubo ye-welding.Umzekelo, i-electrode ye-tungsten eyi-2.4mm iya kuba ngcono ukuba i-sheet metal ijikeleze i-3mm ubukhulu.I-1.6 mm iya kuba yinto engcono kakhulu ukuba iphepha libuthathaka.

Kuba isenza amaqhina awomeleleyo kwintsimbi yentsimbi kunye nentsimbi yentsimbi engasebenziyo njengeAluminiyam, ubhedu, i-titanium, i-magnesium, kunye neChromium, ukuwelda kwe-TIG kusetyenziswa ngokubanzi kwi-aerospace kunye neshishini lokwenziwa kweemoto ngaphandle kokwenziwa kwefenitshala.Nangona imanuwali TIG welding ihamba kancinci (4 ukuya 6″ngomzuzu), i-welding usebenzisa i-automation okanye indlela yerobhothi inokukhawulezisa inkqubo.

3. Intonga yokuWelding

Umsebenzi welding intonga

I-Stick welding yeyona ndlela ixhaphakileyo neqhelekileyo yokudibanisa iipleyiti zentsimbi, esebenzisa ukuwelda kwentsimbi ekhuselweyo.Yindlela yokwenza i-arc welding manual esebenzisa intonga egqunywe kwi-flux njenge-electrode.I-electrode ithwala i-negative current apho i-worksheet idityaniswe ne-terminal e-positive yomthombo wamandla we-AC.

Yindlela ecacileyo kakhulu.Namathisela intonga ye-electrode kwi-welding gun kwaye uthinte indawo ye-welding ukuze uqhubeke.Nangona ibeka isinyithi eninzi kakhulu kwindawo ye-welding kwaye ifuna umgangatho ophezulu wobuchule, ifanelekile kwiintsimbi ezinzima njenge-carbon steel kunye ne-iron sheets ezinobunzima obungaphantsi kwe-3.2 mm.

4. I-Plasma Arc Welding

Ukusebenza kwePlasma arc welding

Kwi-plasma arc welding, i-metal coalescence iveliswa yi-arc ethintelweyo eyenziwe ngesantya esiphezulu segesi ye-ionized ebizwa ngokuba yi-plasma.Kwiinkqubo ezininzi ze-arc welding ye-plasma, ijethi ye-plasma iveliswa ngokufudumeza irhasi ye-orifice kwigumbi le-torch polenta kunye nokunyanzelisa i-plasma ngokusebenzisa umbhobho obambayo.Isikhuselo esingaphelelanga sifunyanwa ngeplasma kwaye songezwa yigesi encedisayo yokukhusela.Iigesi ezincedisayo zokukhusela zisebenzisa i-argon, i-helium, okanye umxube we-argon kunye ne-hydrogen okanye i-helium.

Amandla okushisa omlambo we-plasma agxininiswe kwaye agxininise kakhulu ngenxa ye-arc edibeneyo, evumela ukungena okunzulu.Ngenxa yoko, ivelisa i-weld ezinzileyo, emxinwa, kwaye ekhawulezayo kwi-sheet metal.Iishidi zesinyithi zinokudityaniswa kusetyenziswa i-plasma arc welding kunye okanye ngaphandle kwezinto zokuzalisa.Isinyithi esine-ferrous kunye ne-non-ferrous, kubandakanywa namaphepha athambileyo, anokuhlanganiswa kusetyenziswa i-plasma arc welding.

5. Laser-beam welding

Ukusebenza kwe-laser beam welding

Kwi-laser beam welding, i-photon beam ende ekhonjwe kwindawo ye-welding ifudumeza amaphepha esinyithi kwaye iwadibanise ngokwenza i-welding pool.Inzuzo ephambili yale nkqubo ye-welding kukuba kuya kubakho indawo encinci echaphazelekayo ukushisa ngenxa ye-concentrated high-energy-density photons beam.

I-Lasers idibanisazilungele iintsimbi zeshiti ezinobushushu obunyibilikayo obuphezulu kunye nokuhanjiswa kobushushu, njengeCarbon & steel stainless, titanium, kunye neAluminiyam.Ngenxa yokuba iiweldings ezimxinwa zifikeleleka ngokulula, zisetyenziselwa ukwenza izixhobo zegiya, ii-airbags, imikhono, kunye ne-pacemakers.

Kukho oomatshini ababini abaqhelekileyo bokusebenza kwe-laser welding kwiphepha lesinyithi, iintlobo ezifutshane kunye nobude obude.Imithombo yobude obude zii-CO2-type lasers, ngelixa oomatshini bobude obufutshane be-YAG, idiski, okanye imiqadi yefiber.Umahluko ophambili kukuba oomatshini abanobude obufutshane banyibilikisa imathiriyeli ngokukhawuleza kunobude.

Ngoku makhe sithelekise nganye inkqubo welding ukuqonda ngcono;

| SN | Uhlobo | Isantya sokuwelda | Izinto zephepha |

| 1 | MIG | 20 ukuya ku-30" / mzuzu ezenzekelayo : ukuya kuthi ga kwi-1oo ″ / ngomzuzu | Ikhabhoni & intsimbi engatyiwa, iAluminiyam |

| 2 | TIG | 4 ukuya kwi-10" / mzuzu ezenzekelayo: Ukuya kuthi ga kwi80″ / ngomzuzu | Intsimbi, i-Chromium, i-titanium, ubhedu, i-magnesium |

| 3 | Intonga | 3 ukuya ku6" / mzuzu | iintsimbi ezinzima njengentsimbi yekhabhoni kunye namaphepha entsimbi |

| 4 | Umqa weLaser | 40 ukuya kwi-140″ / umzuzu (kuxhomekeke kwincwadana okanye ezenzekelayo) | Izixhobo ezinendawo ephezulu yokunyibilika, iCarbon & nentsimbi engatyiwa, titanium |

| 5 | I-Plasma arc | 10 ukuya ku-20" / mzuzu, izenzekelayo: ukuya kuthi ga kwi-125 ″ / ngomzuzu | Zombini i-ferrous kunye ne-non-ferrous |

Ukuthelekisa phakathi kweenkqubo ze-welding

Iintlobo zezikhundla ze-welding & Iimpawu

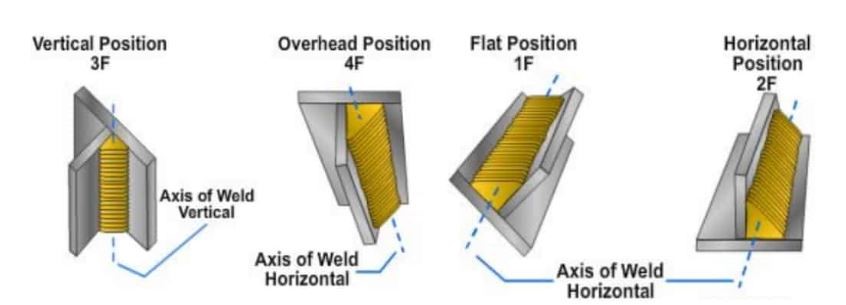

Kukho iintlobo ezine ezisisiseko zezikhundla zokuwelda iFlat (1), iHorizontal (2), iQoqo (3), kunye ne-Overhead (4).Inani elikwisibiyeli limele isimboli yohlobo.Kwakhona, zombini i-fillet (F) kunye ne-groove welding (G) ingasetyenziswa kuzo zonke iiklasi ezine.Masiyiqonde le miqondiso ngomzekelo;

i. I-3 F: I-welding ye-Fillet kwindawo ethe nkqo

ii. 4 G: i-groove welding kwindawo ephezulu

iii. I-2 F: I-Fillet ye-welding kwi-Horizontal position

Izikhundla ezahlukeneyo ze-welding

Kwi-welding ye-fillet, isiphelo esiphezulu somgangatho othe tye sibekwe ngokubhekiselele kumphezulu othe nkqo kwindawo ye-L-shaped perpendicular position.Ngelixa i-welding ye-groove, ngelixa i-welding ye-groove, zombini i-metal sheet ekufuneka idityaniswe ilala kwinqwelo-moya enye (Ngokuthe nkqo).

Izinto eziza kuqwalaselwa ngexesha le-welding sheet metal

Ngomtshato ozinzileyo nowomeleziweyo, kufuneka kuqwalaselwe iinkalo ezahlukahlukeneyo.Makhe sijonge ezinye zezinto ezibalulekileyo ngokweenkcukacha;

1. Izinto zokugcwalisa

Khetha into yokugcwalisa ekwaziyo ukuthintela umhlwa kunye nokwakheka komhlwa.Kwakhona, khumbula ukuba intonga yokuzalisa kufuneka ibe ncinane kunobunzima beshiti.Umzekelo, intonga yokuzalisa kufuneka ibe phakathi kwe-0.7 kunye ne-1 mm ukuba uceba ukuwelda isinyithi esine-1.5 mm ubukhulu.

2. Ubungakanani be-electrode

Ubungakanani be-electrode kufuneka bukhethwe ngokusekelwe kubushushu (umbane) osetyenzisiweyo kunye nomlinganiselo we-welding efunekayo.Umzekelo, i-electrode enobubanzi obuyi-intshi ezi-0.125 isebenza kakuhle kwi-welding emxinwa kunye neemeko zobushushu obuphantsi.

3. Iiclamps kwiphepha lokusebenza

Ukusebenzisa i-clamp ukulungisa indawo ye-welding kubalulekile ekufezekiseni i-welding ezinzileyo kunye namandla.Ukongezelela, ishidi kufuneka linyanzeliswe ngokuchanekileyo ukukhusela amaphepha okusebenza ekutshintsheni ngexesha le-welding.

Iingcebiso zokuhlangabezana neengxaki ngexesha le-welding

· Kungcono ukusebenzisa i-electrode tip ukugcina i-arc kunye ne-puddle incinci kwaye ilawulwa ngokusemandleni xa udibanisa kwizithuba ezixineneyo phakathi kwamaqhekeza esinyithi kuba oku kugcina indawo yobushushu kwiindawo ezixinene kakhulu.

· Ukuvavanya i-welding kwiiprototypes ngaphambi kokuba uqalise iinkqubo ze-welding metal sheet ukuqinisekisa umgangatho kunye nokugqitywa komphezulu.

· Xa usenza i-MIG welding, hambisa umpu we-welding ngendlela ethe tye ngesantya esikhawulezayo sokuhamba xa indawo ye-arc ishushu.Kuya kukhusela ekudinweni.

· Gwema ukushiya nayiphi na imingxuma kwindawo ye-welding kuba iya kusebenza njengemibhobho yomswakama kwaye ikhuthaze ukubunjwa kwe-corrosion.

· Ukuphelisa ubushushu, zisa indawo echatshazelwe bubushushu ukuba idibane nentsimbi ebandayo eyenziwe ngobhedu okanye iAluminiyam.

Ukuqukumbela

Ukukhetha ubuchule bokuwelda obufanelekileyo obusekwe kwiphepha lesinyithi kunye nemilinganiselo yemveliso efunekayo kubalulekile.Emva kokukhetha uhlobo lwe-welding, izinto ezininzi, kubandakanywa ubungakanani be-electrode, izinto zokuzalisa, indawo ye-clamp, kunye nokunye, kufuneka kuthathelwe ingqalelo.KwaProlean, sibonelela ngobuchwepheshasheet metal welding ukubonisana kunye neenkonzoukusuka ekuyileni iiparamitha ze-welding ukuya kwi-laser cutting kunye ne-welding ehambelana neemfuno zakho.Qhagamshelana nenjineli yethungokuthe ngqo ngolwazi oluthe kratya.

Ii-FAQ's

Zeziphi ezona ndlela zilungileyo zokuwelda ngazo zombini iAC & DC?

Iindlela ezahlukeneyo ze-welding zisebenza kuzo zombini iindidi.Nangona kunjalo, ukuwelda kwe-MIG kuya kuba yeyona nto ilungileyo ukuba usebenzisa yomibini imithombo ye-AC&DC.

Zeziphi iintlobo eziqhelekileyo zokuwelda kwishidi lesinyithi?

Zintlanu iindlela eziqhelekileyo zokuwelda kwishiti lesinyithi, kubandakanywa i-TIG, i-MIG, intonga, i-Laser beam kunye ne-plasma welding.

Uthini umda wokutyeba kwiwelding yentsimbi?

I-O.8 mm ngumlinganiselo osezantsi wokutyeba kwiwelding yentsimbi.Nangona kunjalo, ukuba ufuna ukuwelda amashiti angaphantsi kunoko, ungasebenzisa i-MIG welding kunye ne-MIG welding, kodwa qiniseka ukuba incam ye-electrode ibukhali kakhulu.

Zeziphi izinto ezibalulekileyo ekufuneka ziqwalaselwe ngelixa usenza imisebenzi ye-welding?

I-Electrode & Filler ubungakanani bentonga, ubukhulu bephepha lokusebenza, isicelo sokushisa, indawo ye-clamp, kunye nokhuseleko lwezona zinto zifunekayo.

Ixesha lokuposa: Jul-08-2022