ProLeanHub. Ixesha lokufunda eliqikelelweyo: imizuzu emi-4, imizuzwana emi-4

Iintlobo zoomatshini bokusika iLaser

Izinto eziluncedo kunye nekamva lokusika i-laser kwishiti lesinyithi

Izinto zokusika iLaser

Unyino Laser Cutting

Iingcebiso zokuyila

Iindleko zokusika i-laser

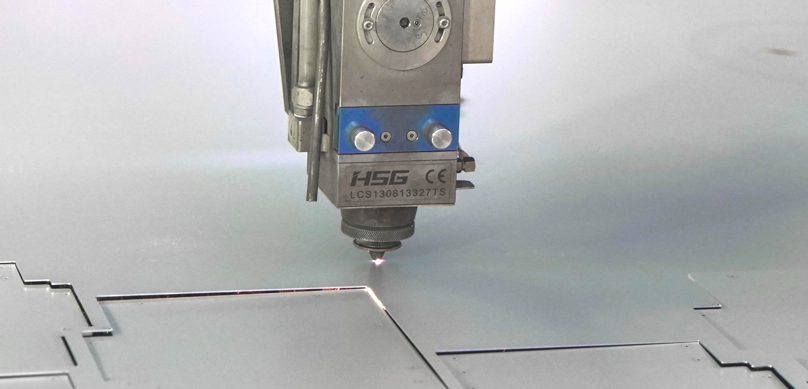

Ukusika i-Laser yinkqubo yokusika i-CNC apho i-laser ephezulu isetyenziselwa ukusika izinto.Kule nkqubo, i-high-intensity beam iveliswa ngokuvuselela izinto ze-laser ngokukhutshwa kombane ngaphakathi kwenqanawa evaliweyo.I-Optics isetyenziselwa ukujolisa i-laser beam kwisiphumo somsebenzi, ukuyisika ngokuyinyibilikisa, ukufunxa okanye ukuyitshisa.Ukuhamba kwe-laser beam kulawulwa yiteknoloji ye-CNC.

Iindidi ezi-1 zoomatshini bokusika iLaser

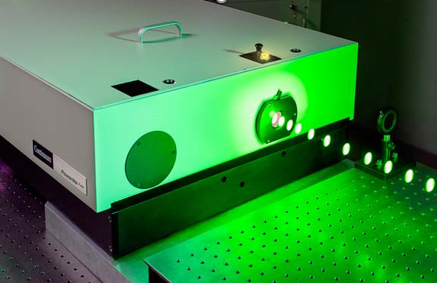

I-Lasers esetyenziswe kumatshini wokusika i-laser ihlulwe ngokukodwa kwiindidi ezintathu.Ziyi-CO 2, i-Fiber lasers kunye ne-crystal lasers.Ngamnye uneempawu ezahlukeneyo ezenza ukuba zilungele ukusetyenziswa okwahlukeneyo.Ezinye zifaneleke ngcono ukusika i-laser ye-sheet metal kuba zibonelela ngobushushu obufunekayo.

I-CO2 lasers sisixhobo esithandwayo sokusika i-laser esixabiswa ngokulula kwabo ukulawula kunye nokuchaneka okuphezulu.Umqadi wegesi ye-CO2 egxininisiweyo ivulwe ngombane ukutshisa ukusika.

Iifiber lasers zisebenzisa iifiber zeglasi ukunyusa amandla e-laser.Isiphumo sinamandla ngakumbi kwaye sichanekile kune-CO2 laser.Iilaser zeFiber zihlala zisetyenziswa kwiintsimbi ngenxa yokugxila kunye nentsimbi eyomeleleyo.

I-crystal laser ifana ne-fiber laser, ngaphandle kokuba isebenzisa zombini i-diode yepompo kunye nekristale ukuvelisa ubuninzi be-beam.Iilaser zeCrystal zinokusebenza kunye nokusetyenziswa okunokwenzeka okuthelekiswa nefiber lasers.

2 Izinto ezilungileyo, ezingeloncedo kunye nekamva lokusebenzisa i-laser cut for sheet metal

| Uhlobo lweLaser | CO 2 (iCarbon Dioxide) | IFayibha Lasers | IiLaser zeCrystal |

| Inzuzo | • Ukusebenza kakuhle kwamandla • Umlinganiselo ophezulu wokuphuma kwamandla | • Amandla aphezulu | • Umlinganiselo ophezulu wokuphuma kwamandla |

| Ukusilela | • Ayifanelekanga kwishiti elishinyeneyo lesinyithi | • Ukuphinda-phinda okuphantsi | • Amaxabiso aphantsi kunee-plasma cutters kolu hlobo lwemathiriyeli |

| Isicelo | Le laser ilungele ukomba, ukukrola kunye nokusika izinto ezibhityileyo | Le laser isetyenziselwa ikakhulu ukukrola kunye nokugrumba | Le laser ifanelekile kwimveliso kunye namashishini ezonyango |

Ukuza kuthi ga ngoku, ngelixa i-fiber lasers ifumana ukuthandwa ngokukhawuleza, ii-CO2 lasers zihlala zisemgangathweni weshishini.Nangona intsha ngokufanelekileyo, itekhnoloji yefiber laser kulindeleke ukuba ibe ngumgangatho phakathi kweminyaka eli-10 ukuya kweli-15 ezayo.Iinkampani ezininzi ziya kuqhubeka nokusebenzisa i-CO2 lasers kunye ne-fiber lasers, zibanika ukhetho olungakumbi kuyilo abalunika abathengi babo.Ukusika kweLaser kunokudibaniswa nokuprintwa kwe-3D ukwenza iimveliso ezichanekileyo nezithembekileyo kubathengi.

3 Izinto zokusika iLaser

Ukusika kweLaser kungasetyenziselwa ukusika izinto ezahlukeneyo, njengephepha, umthi, isinyithi, ilitye, njl.

- Aluminiyam

- Intsimbi

- Yenziwe ngentsimbi eshayinayo

- Ubhedu kunye nezinye iintsimbi

Ngokubanzi, abasiki be-laser balungele ukusika isinyithi esicekethekileyo ngokwentelekiso, esinobukhulu obukhulu be-15mm ye-aluminiyam kunye ne-6mm yentsimbi.Ngokuqhelekileyo banokunyamezela kwe-0.2 ukuya kwi-0.1 mm

4 Unyino Laser Cutting

Ngenxa yokuchaneka okuphezulu kokusika kwe-laser, iinxalenye zokusika i-laser zifuna ukugqitywa okuncinci.Inkqubo ye-laser idala indawo encinci echaphazelekayo yokushisa, ukunciphisa imfuno yonyango lokufudumala emva kokulungiswa.Xa kuthelekiswa nezinye iinkqubo zokusika, ukusika kwe-laser kuchaneke ngakumbi kwaye kuguquguqukayo (izinto eziphathekayo) kunokusika i-plasma, kodwa kungekhona njenge-waterjet cutting.

5 Iingcebiso zokuyila

1) Izithuba zibalulekile!

Izithuba zibaluleke kakhulu ekusikeni kwe-laser ukuphelisa iimpazamo kunye nokufumana iziphumo ezilungileyo.Ubuncinci bezithuba kufuneka bulingane nobukhulu bezinto eziphathekayo.Ngokomzekelo, kwi-sheet metal laser cutting, ukuba i-sheet sheet i-2mm ubukhulu, isithuba phakathi kweendlela ezimbini yi-2mm.Oku kukwabalulekile ukuba usebenza kwiidizayini ezahlukeneyo ze-laser cut sheet metal.

2) Khetha ubukhulu obufanelekileyo

Ukutyeba yinto ebalulekileyo ekufuneka ithathelwe ingqalelo kwimisebenzi yokusika i-laser.Inxulumene ngokuthe ngqo namandla e-laser.Ke ngoko, ukuphakama kobunzima, amandla amancinci e-laser ukungena kunye nokusika izinto.Nangona kunjalo, ngamanye amaxesha ukwandisa amandla e-laser kunokonyusa amathuba okusika izixhobo ezinjalo.

3) Khumbula ukusika

Uyilo lwelaser lutsalela ingqalelo kwinto abayithethayo abantu kukusikwa okubalulekileyo.I-kerf yinto ephuphumayo xa i-laser beam ibetha i-laser-cut material.Akunjalo kuphela ekusikeni kwe-laser.Ibonwa kwezinye iinkqubo zokukhupha oomatshini.Ngenxa yobunzima be-laser beam, ukusika kwe-kerf laser kwenzeka.Kubalulekile ukuqwalasela oku ngexesha lesigaba soyilo.

6 Iindleko zokusika i-laser

Iindleko zokusika i-laser zinokuhluka ngokubanzi kuxhomekeke kuhlobo lwe-laser kunye nezinto ezikhethiweyo.Eyona ndlela ilula yokwazi ixabiso leprojekthi yakho yokwenziwa kwentsimbi kukulayisha ifayile yakho yeCAD ukufumana ikowuti yasimahla kwangoko.

Umbono kaProlean kukuba ngumboneleli wesisombululo okhokelayo kwi-On-Demand Manufacturing.Sisebenza nzima ukwenza imveliso ibe lula, ikhawuleza, kunye neendleko-zokonga ukusuka kwiprototyping ukuya kwimveliso.Qhagamshelana nathi simahlacaphula.

Ixesha lokuposa: Mar-24-2022