ProLeanHub. Kiyasta lokacin karantawa: Minti 4, daƙiƙa 4

Nau'in Injin Yankan Laser

Abũbuwan amfãni da kuma gaba na Laser sabon ga sheet karfe

Laser yanke abu

Iyaka na Laser Yanke

Nasihu Zane

Kudin yankan Laser

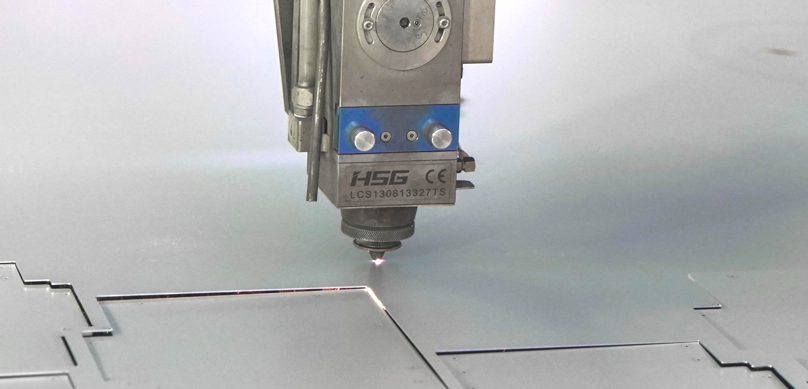

Yanke Laser shine tsarin yankan CNC wanda ake amfani da Laser mai ƙarfi don yanke abu.A cikin wannan tsari, ana samar da katako mai ƙarfi ta hanyar ƙarfafa kayan laser ta hanyar fitar da wutar lantarki a cikin rufaffiyar jirgin ruwa.Ana amfani da na'urorin gani don mayar da hankali ga sakamakon Laser katako a kan workpiece, yadda ya kamata yanke shi ta hanyar narkewa, vaporizing ko kona shi.Ana sarrafa motsi na katako na Laser ta hanyar fasahar CNC.

1 Nau'in Injin Yankan Laser

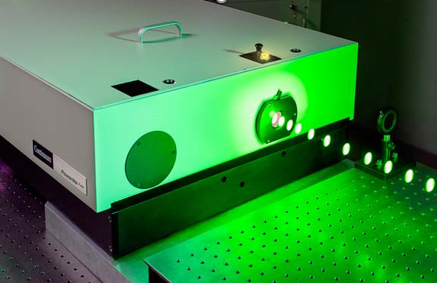

Laser amfani da Laser yankan inji suna yafi zuwa kashi uku iri.Su ne CO 2, Fiber Laser da crystal Laser.Kowannensu yana da kaddarorin daban-daban waɗanda suka sa ya dace don amfani daban-daban.Wasu sun fi dacewa da yankan karfe na Laser saboda suna samar da zafin da ake bukata.

CO2 Laser sanannen kayan aikin yankan Laser ne wanda aka ba da daraja don sauƙin sarrafawa da daidaitattun daidaito.An kunna katako na iskar CO2 mai da hankali ta hanyar lantarki don yin amfani da yanke.

Fiber Laser amfani da gilashin zaruruwa don ƙara m na Laser.Sakamakon ya fi ƙarfi kuma daidai fiye da laser CO2.Sau da yawa ana amfani da Laser na fiber akan karafa saboda mayar da hankali da katako mai ƙarfi.

Laser crystal yayi kama da Laser fiber, sai dai yana amfani da duka famfo diode da crystal don samar da ƙarfin katako.Crystal Laser da yi da aikace-aikace m kwatankwacin fiber Laser.

2 Abũbuwan amfãni, rashin amfani da kuma gaba na yin amfani da Laser yankan ga sheet karfe

| Nau'in Laser | CO 2 (Carbon Dioxide) | Fiber Lasers | Crystal Lasers |

| Amfani | • Babban ƙarfin makamashi • Babban ƙarfin fitarwa rabo | • Babban makamashi | • Babban ƙarfin fitarwa rabo |

| Hasara | • Bai dace da ƙarfe mai kauri ba | • Ƙarfin maimaituwa yadda ya dace | • Ƙananan farashi fiye da masu yankan plasma don irin wannan kayan |

| Aikace-aikace | Wannan Laser ne manufa domin hakowa, engraving da yankan in mun gwada da bakin ciki kayan | Ana amfani da wannan Laser galibi don sassaƙawa da hakowa | Wannan Laser ya dace da masana'antu da masana'antu na likita |

Ya zuwa yanzu, yayin da fiber Laser ke da sauri samun shahararsa, CO2 Laser zama masana'antu misali.Ko da yake gaskiya sabuwa, fiber Laser fasahar ana sa ran zama misali a cikin 10 zuwa 15 shekaru masu zuwa.Yawancin kamfanoni za su ci gaba da yin amfani da laser CO2 da fiber lasers, suna ba su ƙarin zaɓi a cikin ƙirar da suke ba abokan ciniki.Hakanan za'a iya haɗa yankan Laser tare da bugu na 3D don ƙirƙirar samfuran daidai kuma abin dogaro ga abokan ciniki.

3 Kayan yankan Laser

Ana iya amfani da yankan Laser don yanke abubuwa iri-iri, kamar takarda, itace, ƙarfe, dutse, da sauransu, amma ana amfani da shi sosai wajen sarrafa ƙarfe na kayan kamar:

- Aluminum

- Karfe

- Bakin karfe

- Copper da sauran karafa

Gabaɗaya, masu yankan Laser suna da kyau don yankan ƙaramin ƙarfe na bakin ciki, tare da matsakaicin kauri na 15mm don aluminum da 6mm don ƙarfe.Suna yawanci suna da juriya na 0.2 zuwa 0.1 mm

4 Iyakoki na Yankan Laser

Saboda babban madaidaicin yankan Laser, sassan yanke Laser yana buƙatar ƙarancin ƙarewa.Tsarin Laser yana haifar da ƙaramin yanki da ya shafa zafi, yana rage buƙatar jiyya mai zafi bayan aiwatarwa.Idan aka kwatanta da sauran matakai na yanke, Laser yankan ne mafi daidai da m (material-hikima) fiye da plasma yankan, amma ba da kyau kamar yadda waterjet yankan.

5 Nasihun ƙira

1) Tazara yana da mahimmanci!

Tazara yana da mahimmanci a yankan Laser don kawar da kurakurai da samun sakamako mafi kyau.Ya kamata mafi ƙarancin tazara ya zama daidai da kaurin kayan.Misali, a yankan karfen karfen Laser, idan karfen takardar yana kauri 2mm, tazarar dake tsakanin hanyoyin biyu shine 2mm.Wannan kuma yana da mahimmanci idan kuna aiki akan ƙirar ƙirar ƙirar Laser daban-daban.

2) Zabi kauri mai kyau

Kauri abu ne mai mahimmanci wanda dole ne a yi la'akari da shi a cikin ayyukan yankan Laser.Yana da alaƙa kai tsaye da ikon laser.Sabili da haka, mafi girman kauri, ƙarancin ikon laser don shiga da yanke ta cikin kayan.Duk da haka, wani lokacin ƙara ƙarfin laser na iya ƙara yiwuwar yanke irin waɗannan kayan.

3) Tuna yanke

Zane na Laser yana jawo hankali ga abin da mutane ke cewa shine yanke da ke da mahimmanci.Kerf shine kayan da ke ƙafewa lokacin da katakon Laser ya buga kayan da aka yanke.Ba wai kawai a yankan Laser ba.Ana ganin shi a cikin sauran hanyoyin sarrafa mashin ɗin.Saboda kauri daga cikin Laser katako, kerf Laser yankan faruwa.Yana da mahimmanci a yi la'akari da wannan a lokacin tsarin zane.

6 Kudin yankan Laser

Kudin yankan Laser na iya bambanta yadu dangane da nau'in Laser da kayan da aka zaɓa.Hanya mafi sauƙi don sanin farashin aikin ƙirƙira ƙarfe na takarda ita ce loda fayil ɗin CAD ɗin ku don samun fa'ida nan take kyauta.

Prolean's hangen nesa shine ya zama jagorar samar da mafita na Masana'antar Buƙatu.Muna aiki tuƙuru don sanya masana'anta cikin sauƙi, sauri, da adana farashi daga samfuri zuwa samarwa.Tuntube mu kyautazance.

Lokacin aikawa: Maris 24-2022