I-ProLeanHub. Isikhathi sokufunda esilinganisiwe: imizuzu emi-4, imizuzwana emi-4

Izinhlobo Laser Cutting Machines

Izinzuzo kanye nekusasa laser cutting for sheet metal

I-Laser cut material

Ukulinganiselwa Laser Cutting

Amathiphu Wokuklama

Izindleko zokusika i-laser

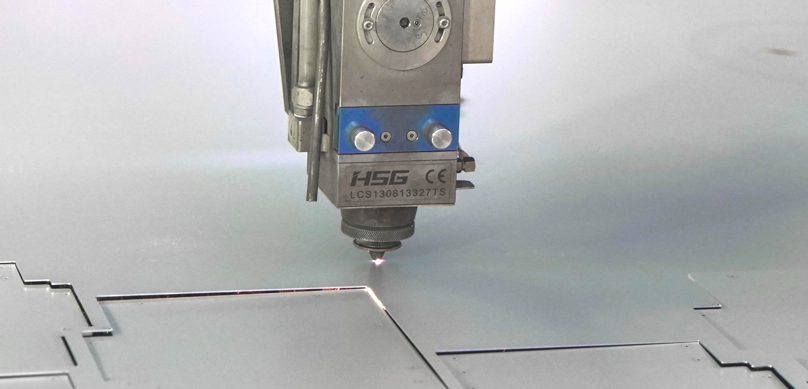

Ukusika i-Laser kuyinqubo yokusika ye-CNC lapho kusetshenziswa i-laser enamandla kakhulu ukusika izinto.Kule nqubo, i-high-intensity beam ikhiqizwa ngokugqugquzela impahla ye-laser ngokukhipha ugesi ngaphakathi komkhumbi ovaliwe.I-Optics isetshenziselwa ukugxilisa i-laser beam ephumayo endaweni yokusebenza, ukuyisika ngokuphumelelayo ngokuyincibilikisa, ukuhwamulisa noma ukuyishisa.Ukunyakaza kwe-laser beam kulawulwa ubuchwepheshe be-CNC.

1 Izinhlobo Zemishini Yokusika I-Laser

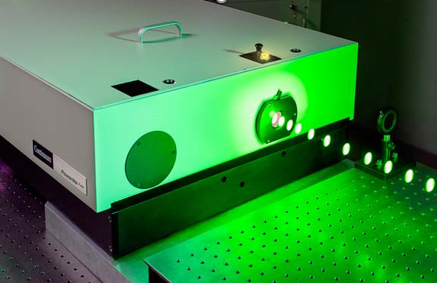

Ama-Lasers asetshenziswa emishinini yokusika i-laser ahlukaniswe ikakhulukazi izinhlobo ezintathu.Ziyi-CO 2, ama-Fiber lasers nama-crystal lasers.Ngayinye inezici ezihlukile eziyenza ilungele ukusetshenziswa okuhlukile.Ezinye zifaneleka kangcono ukusika i-laser yensimbi yeshidi ngoba zinikeza ukushisa okudingekayo.

Ama-laser e-CO2 iyithuluzi elidumile lokusika i-laser elaziswa ngokulawula kwawo kalula nokunemba okuphezulu.I-beam yegesi ye-CO2 egxilile yenziwa isebenze ngogesi ukuze ifuthe ukusika.

Ama-laser we-fiber asebenzisa imicu yengilazi ukwandisa amandla ama-lasers.Umphumela unamandla kakhulu futhi unembe kune-CO2 laser.Ama-laser ama-fiber avame ukusetshenziswa ezinsimbi ngenxa yokugxila kwawo futhi kuqinile.

I-crystal laser ifana ne-fiber laser, ngaphandle kokuthi isebenzisa kokubili i-pump diode nekristalu ukuze ikhiqize ukuqina kwe-beam.Ama-laser e-Crystal anokusebenza namandla okusebenza afana nama-laser fiber.

2 Izinzuzo, ukungalungi kanye nekusasa lokusebenzisa i-laser cutting for sheet metal

| Uhlobo lwe-laser | I-CO 2 (I-Carbon Dioxide) | I-Fiber Lasers | I-Crystal Lasers |

| Inzuzo | • Ukusebenza kahle kwamandla • Isilinganiso esiphezulu sokuphuma kwamandla | • Amandla aphezulu | • Isilinganiso esiphezulu sokuphuma kwamandla |

| Ububi | • Ayilungele insimbi yeshidi eliwugqinsi | • Ukusebenza kahle kokuphindaphinda | • Izindleko eziphansi kunezisika ze-plasma zalolu hlobo lwezinto |

| Isicelo | Le laser ilungele ukubhoboza, ukuqopha nokusika izinto zokwakha ezincanyana | Le laser isetshenziselwa ikakhulukazi ukuqopha nokubhoboza | Le laser ifanele izimboni zokukhiqiza nezezokwelapha |

Kuze kube manje, ngenkathi i-fiber lasers ithola ukuthandwa ngokushesha, ama-CO2 lasers ahlala eyindinganiso yemboni.Yize kubusha, ubuchwepheshe be-fiber laser kulindeleke ukuthi bube yindinganiso phakathi neminyaka eyi-10 kuya kweyi-15 ezayo.Izinkampani eziningi zizoqhubeka nokusebenzisa amalaser azo e-CO2 nama-fiber lasers, okuzinikeza ukukhetha okwengeziwe emiklameni eziyinikeza amakhasimende azo.Ukusika i-laser kungabuye kuhlanganiswe nokuphrinta kwe-3D ukudala imikhiqizo enembile nethembekile yamakhasimende.

3 Laser cutting material

Ukusika i-Laser kungasetshenziswa ukusika izinto ezihlukahlukene, njengephepha, izinkuni, insimbi, idwala, njll., kodwa isetshenziswa kabanzi ekucubunguleni insimbi yensimbi yezinto ezifana:

- I-Aluminium

- Insimbi

- Insimbi engagqwali

- Ithusi nezinye izinsimbi

Ngokuvamile, abasiki be-laser balungele ukusika insimbi yeshidi elincanyana, enogqinsi oluyi-15mm lwe-aluminium no-6mm lwensimbi.Ngokuvamile banokubekezelelana kwe-0.2 kuya ku-0.1 mm

4 Ukulinganiselwa Laser Cutting

Ngenxa yokunemba okuphezulu kokusika kwe-laser, izingxenye zokusika ze-laser zidinga ukuqedwa okuncane.Isistimu ye-laser idala indawo encane ethintekile ekushiseni, inciphisa isidingo sokwelashwa kokushisa kwangemva kokucubungula.Uma kuqhathaniswa nezinye izinqubo zokusika, ukusika kwe-laser kunembe kakhulu futhi kuguquguquka (ubuhlakani bezinto ezibonakalayo) kunokusika i-plasma, kodwa hhayi okuhle njengokusika kwe-waterjet.

5 Amathiphu okuklama

1) Isikhala sibalulekile!

Isikhala sibaluleke kakhulu ekusikeni kwe-laser ukuqeda amaphutha futhi uthole imiphumela engcono kakhulu.Isikhala esincane kufanele silingane nobukhulu bempahla.Isibonelo, ekusikeni kwe-laser yensimbi yeshidi, uma insimbi yeshidi ingu-2mm ubukhulu, igebe phakathi kwezindlela ezimbili liyi-2mm.Lokhu kubalulekile futhi uma usebenza ngemiklamo ehlukene ye-laser cut sheet metal.

2) Khetha ukujiya okulungile

Ukuqina kuyisici esibalulekile okufanele sicatshangelwe emisebenzini yokusika i-laser.Ihlobene ngokuqondile namandla e-laser.Ngakho-ke, ukuphakama kobukhulu, amandla amancane e-laser ukungena nokusika izinto.Kodwa-ke, ngezinye izikhathi ukwandisa amandla e-laser kungase kwandise amathuba okusika izinto ezinjalo.

3) Khumbula ukusika

Ukwakhiwa kwelaser kudonsela ukunaka kulokho abantu abathi ukusika okubalulekile.I-kerf into ehwamukayo lapho i-laser beam ishaya into enqunywe nge-laser.Akukhona nje ekusikeni kwe-laser.Kuyabonakala kwezinye izinqubo zokukhipha imishini.Ngenxa yobukhulu be-laser beam, ukusika kwe-kerf laser kwenzeka.Kubalulekile ukucabangela lokhu ngesikhathi sesigaba sokuklama.

6 Izindleko zokusika nge-laser

Izindleko zokusika i-laser zingahluka kakhulu kuye ngohlobo lwe-laser nezinto ezikhethiwe.Indlela elula yokwazi intengo yephrojekthi yakho yokwenza ishidi lensimbi iwukulayisha ifayela lakho le-CAD ukuze uthole ikhotheshini yamahhala esheshayo.

Umbono ka-Prolean uwukuba umhlinzeki wesixazululo oholayo we-On-Demand Manufacturing.Sisebenza kanzima ukwenza ukukhiqiza kube lula, kusheshe, futhi kongiwe kusuka ku-prototyping kuye ekukhiqizeni.Xhumana nathi mahhalacaphuna.

Isikhathi sokuthumela: Mar-24-2022