Sheet Metal Welding: Duk abin da kuke Bukatar Ku sani

Sabuntawa ta ƙarshe:09/02, lokacin karantawa: 6 mins

Aikin walda

Sheet karfe walditsari ne mai mahimmanci na ƙirƙira saboda yana ɗaya daga cikin mafi sauƙi hanyoyin haɗin gwanon sassaƙaƙe na zanen ƙarfe don ƙirƙirar siffar da ake so.A cikin walda, saman mating ɗin suna fuskantar zafi mai tsanani don haɗa su ta hanyar narkar da ƙarfe a wurin da aka keɓe.A wasu lokuta, ana amfani da matsa lamba don shiga sassan sassan, amma Spark shine mafi mashahuri tsakanin masana'antun da aikace-aikacen masana'antu.

Wannan talifin zai ɗan tattauna a taƙaiceDabarun walda na takarda daban-daban, Aikace-aikace, abubuwan da za a yi la'akari da su, da wasu shawarwarin walda masu taimako.

1. MIG

MIG waldi aiki

Wani suna na MIG waldi shine Gas Metal Arc Welding (GMAW).A waldi tsari a cikin abin da consumable m waya lantarki halitta narke pool a cikin shiga matsayi.Tushen cajin lantarki yana dumama wurin da aka yi niyya kuma yana narkar da karfe.Ta wannan hanyar, bindigar walda tana amfani da iskar kariya (helium, argon, nitrogen) don hana tafkin weld kamuwa da gurɓacewar yanayi.Ya dace da zanen karfe na bakin karfe, Carbon karfe, da Aluminum.

A cikin walda na MIG, ana buƙatar kwararar iskar gas ta ciki daga silinda mai ba da wutar lantarki da wutar lantarki tare da wutar lantarki akai-akai don ƙirƙirar baka na lantarki don narkar da ƙarfe da ciyar da wayar lantarki.

Gudun walda a cikin MIG ya bambanta daga 20 zuwa 30 inci a cikin minti daya dangane da wurin walda ( saman ciki ko na waje) & abu.Koyaya, MIG ya zama mafi atomatik kuma yana iya walda har zuwa 100"a minti daya.

2. TIG

TIG waldi aiki

waldi na TIG yana ba da zafi zuwa takamaiman yanki na ƙananan ƙarfe inda haɗawa ya zama dole ta amfani da na'urorin tungsten mara amfani.Kamar walda MIG, ana amfani da garkuwar iskar gas don hana gurɓata tafkin walda.Tun da ba za a iya cinye wutar lantarki ba, ana ƙarfafa haɗin gwiwa tare da kayan filler.Don haka, ana buƙatar ciyar da sandar filler ci gaba a cikin matsayin walda a duk lokacin aiwatarwa.

A cewar hukumarkarfen takardakauri, za ka iya zaɓar diamita na tungsten lantarki don aikin walda.Misali, na'urar tungsten 2.4mm zai fi kyau idan karfen takarda yana kusa da 3mm lokacin farin ciki.1.6 mm zai zama mafi kyawun zaɓi idan takardar ta kasance mai rauni.

Domin ya haifar da karfi gidajen abinci a steeliness karfe & ba ferrous sheet karfe kamar Aluminum, jan karfe, titanium, magnesium, da Chromium, TIG waldi ne yadu amfani a cikin sararin samaniya & mota masana'antu masana'antu ban da furniture ƙirƙira.Duk da cewa waldar TIG na hannu yana motsawa a hankali (4 zuwa 6"a cikin minti daya), walda ta amfani da sarrafa kansa ko tsarin mutum-mutumi na iya hanzarta aiwatarwa.

3. Al'adar sanda

Aikin walda na sanda

Waldawar sanda ita ce hanya ta gama gari kuma ta al'ada ta haɗa farantin karfe, wanda ke amfani da walda mai kariya ta ƙarfe.Hanya ce ta walƙiya ta hannun hannu wacce ke amfani da sandar da aka lulluɓe cikin juyi azaman lantarki.Wutar lantarki tana ɗaukar mummunan halin yanzu inda aka haɗa takardar aikin tare da tabbataccen tasha na tushen wutar AC.

Hanya ce madaidaiciya.Haɗa sandar lantarki zuwa bindigar walda kuma taɓa wurin walda don ci gaba.Ko da yake yana ajiye ƙarfe da yawa a cikin matsayi na walda kuma yana buƙatar babban matakin ƙwarewa, ya dace da ƙananan karafa kamar carbon karfe da zanen ƙarfe tare da kauri ƙasa da 3.2 mm.

4. Plasma Arc Welding

Plasma Arc walda aiki

A cikin waldawar arc na plasma, ana samar da haɗin gwiwar ƙarfe ta hanyar ƙuƙƙwarar baka da aka yi da babban magudanar ruwa na iskar gas mai ionized da ake kira plasma.A mafi yawan ayyukan waldawar baka na plasma, ana samar da jet ɗin plasma ta hanyar dumama iskar gas a cikin ɗakin polenta na tocilan da kuma tilastawa plasma ta hanyar bututun ƙarfe.Ana samun garkuwar ɓarna ta hanyar plasma kuma ana ƙara ta da iskar kariya ta taimako.Gas ɗin kariya na taimako suna amfani da argon, helium, ko cakuda argon tare da hydrogen ko helium.

Ƙarfin zafin zafi na rafin plasma yana mai da hankali sosai kuma yana da ƙarfi sosai saboda ƙaƙƙarfan baka, yana ba da damar shiga mai zurfi.A sakamakon haka, yana samar da barga, kunkuntar, da walƙiya mai sauri a cikin takarda.Za'a iya haɗa karafa na takarda ta amfani da waldawar al'ada ta plasma tare da ko ba tare da kayan filler ba.Ƙarfe na ƙarfe da mara ƙarfe, gami da zanen gado masu rauni, ana iya haɗa su ta amfani da waldawar al'ada ta plasma.

5. Laser-bim waldi

Laser katako walda aiki

A cikin waldawar katako na Laser, katako mai tsawo na photon da aka nuna a wurin waldi yana dumama zanen karfe kuma ya haɗa su ta hanyar ƙirƙirar tafkin walda.Babban fa'idar wannan tsarin walda shine cewa za a sami ƙaramin yanki da zafi ya shafa saboda tarin hasken hasken wuta mai ƙarfi.

Laser waldasun dace da ƙarfe na takarda tare da babban zafin jiki mai narkewa da ƙarfin zafi, kamar Carbon & bakin karfe, titanium, da Aluminum.Saboda kunkuntar waldi ana iya samun sauƙi, ana amfani da shi don ƙirƙira sassan kayan aiki, jakunkunan iska, hannun riga, da na'urorin bugun zuciya.

Akwai biyu misali inji for Laser waldi ayyuka a kan takardar karfe, da gajere da kuma dogon-wavelength iri.Maɓuɓɓugar tsayi mai tsayi sune laser nau'in CO2, yayin da injunan tsayin tsayi sune YAG, faifai, ko katako na fiber.Babban bambanci shine injinan da ke da ɗan gajeren zangon narke kayan da sauri fiye da na dogon lokaci.

Yanzu bari mu kwatanta kowane tsarin walda don kyakkyawar fahimta;

| SN | Nau'in | Gudun walda | Kayayyakin takarda |

| 1 | MIG | 20 zu30″/minti atomatik: har zuwa 1oo ″ / minti | Carbon & Bakin Karfe, Aluminum |

| 2 | TIG | 4 zu10″/minti sarrafa kansa: Har zuwa 80 ″ / minti | Karfe, chromium, titanium, jan karfe, magnesium |

| 3 | Sanda | 3 zu6″/minti | karafa masu wuya kamar carbon karfe da zanen ƙarfe na ƙarfe |

| 4 | Laser katako | 40 zuwa 140″/minti(ya danganta da manual ko ta atomatik) | Abubuwan da ke da babban wurin narkewa, Carbon & bakin karfe, titanium |

| 5 | Plasma Arc | 10 zuwa 20″/minti, sarrafa kansa: har zuwa 125 ″ / min | Dukansu ferrous da maras ƙarfe |

Kwatanta tsakanin hanyoyin walda

Nau'in matsayin walda & Alamomi

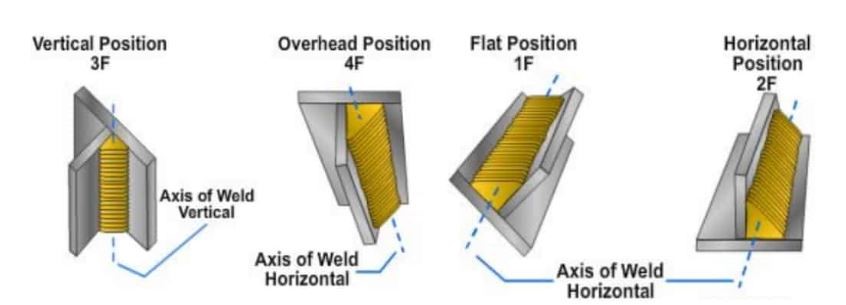

Akwai nau'ikan nau'ikan walda guda huɗu Flat (1), Horizontal (2), A tsaye (3), da Sama (4).Lambar da ke cikin madaidaicin tana wakiltar alamar nau'in.Hakanan, ana iya amfani da fillet (F) da walƙiya mai tsagi (G) a cikin duka azuzuwan huɗu.Bari mu fahimci waɗannan alamomin ta misalin;

i. 3 F: Fillet walda a tsaye matsayi

ii. 4 G: welding na tsagi a cikin matsayi na sama

iii. 2 F: Fillet waldi a tsaye

Matsayi daban-daban na walda

A cikin waldawar fillet, ƙarshen saman saman kwance ana sanya shi a kan saman tsaye a cikin matsayi mai siffar L.Duk da yake a cikin tsagi waldi, yayin da a cikin tsagi waldi, duka karfen da za a welded ya kwanta a kan jirgin sama guda (A tsaye).

Abubuwan da za a yi la'akari da su yayin waldi na karfe

Don kwanciyar hankali da ƙarfafa bikin aure, ya kamata a yi la'akari da dalilai daban-daban.Bari mu fayyace wasu muhimman abubuwa daki-daki;

1. Kayan filler

Zabi abin da zai iya hana lalata da tsatsa daga ƙarshe.Har ila yau, ku tuna cewa sandan filler ya kamata ya zama bakin ciki fiye da kauri na takarda.Misali, sandar filler ya kamata ya kasance tsakanin 0.7 da 1 mm idan kuna shirin walda karfen da ke cikin kauri 1.5 mm.

2. Girman Electrode

Ya kamata a zaɓi girman lantarki bisa ga zafin (lantarki) da ake amfani da shi da kuma matakin walda da ake buƙata.Misali, na'urar lantarki mai diamita na inci 0.125 tana aiki mafi kyau don kunkuntar walda da yanayin zafi mara nauyi.

3. Matsa a kan takardar aiki

Yin amfani da matse don daidaita matsayin walda yana da mahimmanci don cimma daidaiton walda da ƙarfi.Bugu da ƙari, takardar tana buƙatar danne daidai don hana zanen gadon aiki daga motsi yayin walda.

Tips don fuskantar matsaloli yayin walda

· Zai fi kyau a yi amfani da na'urar lantarki mai nuni don kiyaye baka da kududdu ƙanƙanta da sarrafawa gwargwadon yuwuwar walda a cikin matsatsun wurare tsakanin guntun karfen don wannan yana kiyaye yankin zafi a cikin wuraren da ba su da ƙarfi.

· Gwada walda a kan samfura kafin fara aiwatar da aikin walda na ƙarfe don tabbatar da inganci da gamawa.

· Lokacin yin walda na MIG, matsar da bindigar walda a madaidaiciyar hanya tare da saurin tafiye-tafiye mafi sauri lokacin da yankin baka ya yi zafi.Zai kare daga kunar wuta.

· Ka guji barin kowane ramuka a wurin walda domin za su yi aiki azaman ɗigon ruwa kuma suna ƙarfafa samuwar lalata.

· Don ɓatar da zafi, kawo wurin da zafin ya shafa cikin hulɗa da sandar sanyi da aka yi da jan karfe ko Aluminum.

Kammalawa

Zaɓin dabarar walda da ta dace dangane da ƙarfen takarda da ƙayyadaddun samfur da ake buƙata yana da mahimmanci.Bayan zabar nau'in walda, ya kamata a yi la'akari da dalilai da yawa, gami da girman lantarki, kayan filler, matsayi, da ƙari.A Prolean, muna ba da ƙwararrushawarwari da sabis na walda takarda karfedaga zayyana sigogin walda zuwa yankan Laser da walda wanda ya dace da bukatun ku.Tuntuɓi injiniyan mukai tsaye don ƙarin bayani.

FAQ's

Wadanne hanyoyi ne mafi kyawun hanyoyin walda tare da duka AC & DC?

Hanyoyi daban-daban na walda suna aiki akan nau'ikan biyu.Koyaya, walda MIG zai zama mafi kyau idan kun yi amfani da tushen AC & DC guda biyu.

Menene gama gari nau'ikan walda don karafa?

Akwai hanyoyin walda guda biyar gama-gari don karfen takarda, gami da TIG, MIG, Stick, Laser beam & waldawar plasma.

Menene iyakar kauri don walƙiya karfen takarda?

O.8 mm shine ƙananan kauri mai iyaka don walƙiya karfe.Koyaya, idan kuna buƙatar walda zanen gado ƙasa da waccan, zaku iya amfani da walda na MIG tare da waldar MIG, amma ku tabbata tip ɗin lantarki yana da kaifi sosai.

Wadanne abubuwa ne masu mahimmanci da ya kamata a yi la'akari yayin aiwatar da ayyukan walda?

Girman sandar Electrode & Filler, kauri na takardar aiki, da ake amfani da shi don zafi, matsa lamba, da aminci sune mafi yawan abubuwan da ake buƙata.

Lokacin aikawa: Jul-08-2022