Sheet Hlau Vuam: Txhua Yam Koj Yuav Tsum Paub

Xeem tshiab: 09/02, sij hawm nyeem: 6 mins

Vuam ua haujlwm

Sheet hlau weldingyog ib qho tseem ceeb fabrication txheej txheem vim hais tias nws yog ib tug ntawm cov yooj yim txoj kev los koom nrog txiav-tawm daim hlau los tsim cov yam xav tau.Nyob rau hauv vuam, cov mating nto yog raug rau kub siab los fuse lawv los ntawm melting cov hlau nyob rau hauv ib tug xaiv cheeb tsam.Qee zaum, lub siab kuj tseem siv los koom nrog cov ntawv, tab sis Spark yog qhov nrov tshaj plaws ntawm cov tuam ntxhab thiab cov ntawv thov kev lag luam.

Kab lus no yuav tham luv luvCov txheej txheem sib txawv ntawm cov ntawv hlau vuam, Cov Ntawv Thov, yam xav tau, thiab qee cov lus qhia siv vuam zoo.

1. MIG

MIG vuam kev ua haujlwm

Lwm lub npe rau MIG vuam yog Gas Metal Arc Vuam (GMAW).Cov txheej txheem vuam nyob rau hauv uas cov khoom siv hluav taws xob siv hluav taws xob tsim lub pas dej yaj hauv qhov sib koom ua ke.Tus nqi hluav taws xob electrode taub hau ua rau thaj chaw tsom thiab yaj cov hlau.Nyob rau hauv txoj kev no, cov phom vuam siv cov roj tiv thaiv (helium, argon, nitrogen) kom txwv tsis pub lub pas dej ua ke los ntawm kev sib kis ntawm huab cua.Nws yog tsim rau cov ntawv hlau stainless, Carbon steel, thiab Aluminium.

Hauv MIG welding, ib qho roj av sab hauv los ntawm lub tog raj kheej thiab lub zog hluav taws xob nrog qhov hluav taws xob tas li yuav tsum tsim kom muaj hluav taws xob arc rau melting cov hlau thiab pub cov hlau electrode.

Qhov vuam ceev hauv MIG txawv ntawm 20 mus rau 30 ntiv tes ib feeb nyob ntawm qhov chaw vuam (Inner lossis sab nrauv) & cov khoom siv.Txawm li cas los xij, MIG tau dhau los ua tsis siv neeg thiab tuaj yeem txuas mus txog 100″ib feeb.

2. TIG

TIG welding operation

TIG vuam xa cov cua sov mus rau thaj chaw tshwj xeeb ntawm cov ntawv hlau uas sib koom ua ke yog tsim nyog siv cov khoom siv tsis siv tungsten electrodes.Zoo li MIG welding, inert gas shielding yog siv los tiv thaiv kev sib kis ntawm lub pas dej welding.Txij li cov electrode tsis tuaj yeem noj tau, qhov sib koom ua ke yog ntxiv nrog cov ntaub ntawv muab tub lim.Yog li, pub cov pas nrig tsis tu ncua rau hauv txoj haujlwm vuam thoob plaws hauv cov txheej txheem yog xav tau.

Raws li covdaim hlauthickness, koj tuaj yeem xaiv txoj kab uas hla ntawm tungsten electrode rau cov txheej txheem vuam.Piv txwv li, 2.4mm tungsten electrode yuav zoo tshaj yog tias cov ntawv hlau nyob ib ncig ntawm 3 hli tuab.1.6 hli yuav yog qhov kev xaiv zoo tshaj plaws yog tias daim ntawv tsis yooj yim.

Vim tias nws tsim cov pob qij txha muaj zog hauv steeliness steel & non-ferrous sheet hlau xws li Aluminium, tooj liab, titanium, magnesium, thiab Chromium, TIG vuam yog dav siv nyob rau hauv aerospace & automotive manufacturing kev lag luam nrog rau cov rooj tog fabrication.Txawm hais tias phau ntawv TIG vuam txav qeeb (4 txog 6″ib feeb), vuam siv automation los yog robotic mus kom ze yuav ua kom cov txheej txheem.

3. Vuam Vuam

Kev ua haujlwm welding

Kev siv cov nplaum nplaum yog feem ntau thiab ib txwm siv ntawm kev sib koom ua ke ntawm cov ntawv hlau, uas siv cov hlau thaiv arc vuam.Nws yog phau ntawv arc vuam txoj hauv kev uas siv ib lub pas uas muaj nyob rau hauv flux li electrode.Cov electrode nqa qhov tsis zoo tam sim no qhov chaw ua haujlwm txuas nrog lub davhlau ya nyob twg zoo ntawm AC lub zog.

Nws yog ib txoj hauv kev yooj yim heev.Txuas cov electrode lo rau ntawm rab phom vuam thiab kov lub vuam taw tes mus txuas ntxiv.Txawm hais tias nws tso cov hlau ntau dhau rau hauv txoj haujlwm vuam thiab yuav tsum muaj kev txawj ntse, nws yog qhov tsim nyog rau cov hlau tawv xws li carbon steel thiab hlau los xij nrog thicknesses qis dua 3.2 hli.

4. Plasma Arc Vuam

Plasma arc vuam ua haujlwm

Hauv plasma arc vuam, hlau coalescence yog tsim los ntawm constricted arc ua los ntawm ib tug high-ceev kwj ntawm ionized roj hu ua plasma.Nyob rau hauv feem ntau plasma arc vuam kev ua haujlwm, lub plasma dav hlau yog tsim los ntawm cua sov cov pa roj nyob rau hauv lub teeb polenta chamber thiab yuam cov plasma los ntawm constricting nozzle.Ib feem ntaub thaiv npog yog tau los ntawm cov ntshav plasma thiab ntxiv los ntawm ib qho kev pab tiv thaiv roj.Cov khoom siv tiv thaiv hluav taws xob siv argon, helium, lossis sib xyaw ntawm argon nrog hydrogen lossis helium.

Lub tshav kub lub zog ntawm cov plasma kwj yog concentrated thiab khaus heev vim yog constricted arc, tso cai rau kev nkag mus tob.Raws li qhov tshwm sim, nws ua kom ruaj khov, nqaim, thiab nrawm nrawm hauv cov ntawv hlau.Cov ntawv hlau tuaj yeem koom nrog siv plasma arc vuam nrog lossis tsis muaj cov khoom muab tub lim.ferrous thiab non-ferrous hlau, nrog rau cov nplooj ntawv tsis yooj yim, tuaj yeem koom nrog siv plasma arc vuam.

5. Laser-beam vuam

Laser beam welding ua haujlwm

Nyob rau hauv laser beam welding, ib tug ntev photon beam taw tes ntawm lub vuam chaw heats cov hlau los xij thiab koom nrog lawv los ntawm kev tsim lub vuam pas dej ua ke.Qhov zoo tshaj plaws ntawm cov txheej txheem vuam no yog tias yuav muaj qhov chaw me me uas cuam tshuam rau qhov kub thiab txias vim yog lub zog muaj zog-density photons beam.

Lasers weldyog tsim rau cov ntawv hlau nrog lub siab melting kub thiab kub conductivity, xws li carbon & stainless hlau, titanium, thiab Aluminium.Vim tias cov vuam nqaim tau yooj yim ua tiav, nws yog siv los tsim cov iav qhov chaw, airbags, lub tes tsho, thiab cov pacemakers.

Muaj ob lub tshuab txheem rau laser vuam ua haujlwm ntawm cov ntawv hlau, hom luv luv thiab ntev wavelength.Qhov chaw ntev wavelength yog CO2-hom lasers, thaum lub tshuab luv luv yog YAG, disk, lossis fiber ntau.Qhov sib txawv tseem ceeb yog tias cov cav tov nrog luv-yoj yaj cov khoom sai dua li ntev.

Tam sim no cia peb muab piv rau txhua qhov txheej txheem vuam kom nkag siab zoo dua;

| SN | Hom | Vuam ceev | Cov ntaub ntawv ntawm daim ntawv |

| 1 | MIG | 20 rau 30″ / feeb automated: mus txog 1oo ″ / feeb | Carbon & stainless hlau, Aluminium |

| 2 | TIG | 4 rau 10″ / feeb automated: Mus txog 80 ″ / feeb | Hlau, Chromium, titanium, tooj liab, magnesium |

| 3 | stick | 3 rau 6″ / feeb | hard hlau zoo li carbon steel thiab hlau los xij |

| 4 | Laser nqaj | 40 rau 140″ / feeb (nyob ntawm phau ntawv lossis automated) | Cov ntaub ntawv nrog lub siab melting point, Carbon & stainless hlau, titanium |

| 5 | Plasma arc | 10 rau 20″ / feeb, automated: mus txog 125 ″ / feeb | Ob leeg ferrous thiab non-ferrous |

Kev sib piv ntawm cov txheej txheem vuam

Hom vuam txoj hauj lwm & Cov Cim

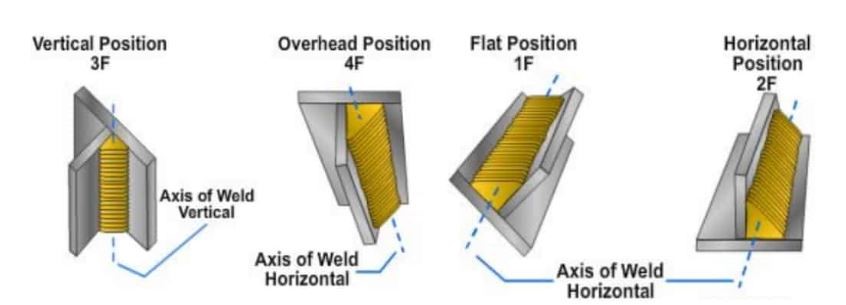

Muaj plaub yam yooj yim ntawm vuam txoj hauj lwm Flat (1), Kab rov tav (2), Ntsug (3), thiab nyiaj siv ua haujlwm (4).Tus lej nyob rau hauv lub bracket sawv cev rau lub cim ntawm hom.Tsis tas li ntawd, ob qho tib si fillet (F) thiab groove vuam (G) tuaj yeem siv rau hauv plaub chav kawm.Cia peb nkag siab cov cim no los ntawm qhov piv txwv;

i. 3 F: Fillet vuam nyob rau hauv txoj hauj lwm ntsug

ii. 4 G: zawj vuam nyob rau hauv ib tug overhead txoj hauj lwm

iii. 2 F: Fillet vuam nyob rau hauv txoj hauj lwm Kab rov tav

Ntau yam vuam txoj haujlwm

Nyob rau hauv lub welding fillet, lub Upper kawg ntawm ib tug kab rov tav nto yog muab tso rau ib tug ntsug nto nyob rau hauv ib tug L-shaped perpendicular txoj hauj lwm.Thaum nyob rau hauv groove welding, thaum nyob rau hauv zawj vuam, ob daim hlau yuav tsum tau welded lays rau tib lub dav hlau (Vertical).

Cov yam tseem ceeb yuav tsum tau xav txog thaum lub caij nplooj ntoos hlav vuam

Rau kev ruaj khov thiab muaj zog tshoob, ntau yam yuav tsum tau xav txog.Cia peb saib qee qhov tseem ceeb hauv kev nthuav dav;

1. Cov khoom siv filling

Xaiv ib tug muab tub lim uas muaj peev xwm kawg tiv thaiv corrosion thiab xeb tsim.Tsis tas li ntawd, nco ntsoov tias cov pas nrig muab tub lim yuav tsum nyias dua li cov ntawv hlau tuab.Piv txwv li, lub pas nrig muab tub lim yuav tsum nyob nruab nrab ntawm 0.7 thiab 1 hli yog tias koj npaj yuav vuam daim hlau uas yog 1.5 hli tuab.

2. Electrode loj

Qhov loj ntawm electrode yuav tsum raug xaiv raws li qhov kub thiab txias (hluav taws xob) thov thiab qib ntawm vuam xav tau.Piv txwv li, ib qho electrode nrog ib txoj kab uas hla ntawm 0.125 ntiv tes ua haujlwm zoo tshaj plaws rau cov vuam nqaim thiab cov cua sov tsawg.

3. Clamps ntawm daim ntawv ua haujlwm

Siv lub clamp los kho txoj haujlwm vuam yog qhov tseem ceeb rau kev ua tiav vuam ruaj khov thiab lub zog.Tsis tas li ntawd, daim ntawv yuav tsum raug clamped kom raug los tiv thaiv cov nplooj ntawv ua haujlwm los ntawm kev hloov pauv thaum vuam.

Cov lus qhia kom ntsib teeb meem thaum vuam

· Nws yog qhov zoo tshaj plaws los siv lub taw tes electrode-ntsis kom lub arc thiab puddle kom me me thiab tswj tau li sai tau thaum vuam nyob rau hauv nruj qhov chaw ntawm daim hlau daim hlau vim qhov no ua rau lub tshav kub cheeb tsam nyob rau hauv heev constrained.

· Kuaj cov vuam ntawm cov qauv ua ntej pib cov txheej txheem hlau vuam kom paub meej qhov zoo thiab qhov chaw tiav.

· Thaum ua MIG vuam, txav rab phom vuam mus rau hauv txoj kev ncaj nrog txoj kev mus los sai tshaj plaws thaum thaj tsam arc kub dua.Nws yuav tiv thaiv los ntawm burnout.

· Tsis txhob tawm hauv qhov chaw hauv qhov chaw vuam vim tias lawv yuav ua raws li cov pinholes noo noo thiab txhawb kev tsim ntawm corrosion.

· Txhawm rau dissipate lub tshav kub, nqa qhov chaw uas muaj cua sov rau hauv kev sib cuag nrog lub chill bar ua los ntawm tooj liab lossis Aluminium.

Xaus

Xaiv cov txheej txheem vuam kom zoo raws li cov ntawv hlau thiab cov khoom siv tshwj xeeb yog qhov tseem ceeb.Tom qab xaiv qhov vuam hom, ntau yam, suav nrog electrode loj, muab tub lim, clamp txoj hauj lwm, thiab lwm yam, yuav tsum tau txiav txim siab.Ntawm Prolean, peb muab kev tshaj lijsheet hlau vuam kev sab laj thiab kev pabcuamlos ntawm kev tsim cov vuam tsis zoo rau laser txiav thiab vuam tailored raws li koj xav tau.Hu rau peb tus engineerncaj qha rau cov lus qhia ntxiv.

FAQ's

Dab tsi yog txoj hauv kev zoo tshaj plaws rau kev vuam nrog AC & DC?

Ntau yam kev siv vuam ua haujlwm ntawm ob hom.Txawm li cas los xij, MIG vuam yuav yog qhov zoo tshaj yog tias koj siv ob qho tib si AC & DC qhov chaw.

Dab tsi yog hom welding rau cov ntawv hlau?

Muaj tsib txoj kev sib txuas rau cov ntawv hlau, suav nrog TIG, MIG, Stick, Laser beam & plasma vuam.

Dab tsi yog qhov thickness txwv rau sheet hlau vuam?

O.8 hli yog qhov tsawg dua thickness txwv rau cov ntawv hlau vuam.Txawm li cas los xij, yog tias koj xav tau vuam cov ntawv qis dua qhov ntawd, koj tuaj yeem siv MIG vuam nrog MIG vuam, tab sis nco ntsoov tias cov hlua electrode yog qhov ntse heev.

Dab tsi yog qhov tseem ceeb uas yuav tsum tau xav txog thaum ua haujlwm vuam?

Electrode & Filler pas nrig loj, qhov tuab ntawm daim ntawv ua haujlwm, thov rau cua sov, txoj haujlwm clamp, thiab kev nyab xeeb yog qhov xav tau tshaj plaws.

Lub sij hawm xa tuaj: Plaub Hlis-08-2022