Kuwotcherera Mapepala: Zonse Zomwe Muyenera Kudziwa

Kusintha komaliza: 09/02, nthawi yowerenga: 6 min

Kuwotcherera ntchito

Kuwotcherera zitsuloNdi njira yofunika kwambiri yopangira zinthu chifukwa ndi imodzi mwa njira zosavuta zolumikizira mapepala achitsulo kuti apange mawonekedwe omwe mukufuna.Powotcherera, malo okwerera amatenthedwa kwambiri kuti asungunuke zitsulo pamalo osankhidwa.Nthawi zina, kukakamiza kumagwiritsidwanso ntchito kujowina zigawo za pepala, koma Spark ndiye wotchuka kwambiri pakati pa opanga ndi mafakitale.

Nkhaniyi ifotokoza mwachiduleNjira zosiyanasiyana zowotcherera zitsulo, Ntchito, zinthu zofunika kuziganizira, ndi malangizo othandizira kuwotcherera.

1. MIG

Kuwotcherera kwa MIG

Dzina lina la kuwotcherera kwa MIG ndi Gas Metal Arc Welding (GMAW).The kuwotcherera ndondomeko consumable olimba waya elekitirodi amalenga Sungunulani dziwe mu kujowina udindo.Mphamvu ya elekitirodi yamagetsi imatenthetsa malo omwe mukufuna ndikusungunula chitsulocho.Mwanjira iyi, mfuti yowotcherera imagwiritsa ntchito mpweya wotchinga (helium, argon, nayitrogeni) kuletsa dziwe la weld kuti lisatengedwe ndi kuipitsidwa kwamlengalenga.Ndi oyenera mapepala zitsulo zosapanga dzimbiri, Carbon zitsulo, ndi Aluminium.

Mu kuwotcherera kwa MIG, mpweya wamkati umatuluka kuchokera ku silinda yoperekera ndi magetsi okhala ndi voteji nthawi zonse amafunikira kuti apange arc yamagetsi yosungunula chitsulo ndi kudyetsa waya wa electrode.

Liwiro la kuwotcherera mu MIG limasiyanasiyana mainchesi 20 mpaka 30 pamphindi kutengera malo owotcherera (Mkati kapena kunja) & zinthu.Komabe, MIG yakhala yokhazikika ndipo imatha kuwotcherera mpaka 100″pamphindi.

2. TIG

TIG ntchito kuwotcherera

Kuwotcherera kwa TIG kumapereka kutentha kudera linalake lazitsulo zazitsulo komwe kujowina kuli kofunikira pogwiritsa ntchito ma elekitirodi a tungsten osagwiritsidwa ntchito.Monga kuwotcherera kwa MIG, chitetezo cha gasi cha inert chimagwiritsidwa ntchito kuteteza kuipitsidwa kwa dziwe lowotcherera.Popeza ma elekitirodi sangathe kudyedwa, cholumikizira chimalimbikitsidwa ndi zida zodzaza.Chifukwa chake, kudyetsa ndodo ya filler mosalekeza pamalo owotcherera munthawi yonseyi ndikofunikira.

Malinga ndipepala lachitsulomakulidwe, mutha kusankha makulidwe a electrode ya tungsten pakuwotcherera.Mwachitsanzo, electrode ya tungsten ya 2.4mm idzakhala yabwino ngati chitsulo chachitsulo chili pafupi ndi 3mm wandiweyani.1.6 mm idzakhala njira yabwino ngati pepala ndi lofooka.

Chifukwa imapanga zolumikizira zolimba muzitsulo zachitsulo & zitsulo zopanda chitsulo monga Aluminiyamu, mkuwa, titaniyamu, magnesium, ndi Chromium, kuwotcherera kwa TIG kumagwiritsidwa ntchito kwambiri muzamlengalenga & mafakitale opanga magalimoto kuphatikiza kupanga mipando.Ngakhale kuwotcherera pamanja kwa TIG kumayenda pang'onopang'ono (4 mpaka 6″pamphindi), kuwotcherera pogwiritsa ntchito makina opangira okha kapena njira ya robotic imatha kufulumizitsa ntchitoyi.

3. Kuwotcherera Ndodo

Ntchito kuwotcherera ndodo

Kuwotcherera ndodo ndi njira yodziwika bwino komanso yachikhalidwe yolumikizira mbale zachitsulo, zomwe zimagwiritsa ntchito kuwotcherera zitsulo zotetezedwa.Ndi njira yowotcherera ya arc yomwe imagwiritsa ntchito ndodo yophimbidwa ndi flux ngati electrode.Elekitirodi imanyamula mphamvu yamagetsi pomwe tsamba logwirira ntchito limalumikizidwa ndi terminal yabwino ya gwero lamagetsi a AC.

Ndi njira yolunjika kwambiri.Gwirizanitsani ndodo ya elekitirodi pamfuti yowotcherera ndikukhudza powotcherera kuti mupitilize.Ngakhale imayika chitsulo chochuluka pamalo owotcherera ndipo imafunikira ukadaulo wapamwamba, ndiyoyenera zitsulo zolimba monga zitsulo za carbon ndi zitsulo zokhala ndi makulidwe ochepera 3.2 mm.

4. Kuwotcherera kwa Plasma Arc

Kuwotcherera kwa Plasma arc

Mu kuwotcherera kwa plasma arc, coalescence yachitsulo imapangidwa ndi arc yopingasa yopangidwa ndi mtsinje wothamanga kwambiri wa mpweya wa ionized wotchedwa plasma.Nthawi zambiri kuwotcherera kwa plasma arc, jet ya plasma imapangidwa powotcha mpweya wa orifice muchipinda cha torch polenta ndikukakamiza madzi a m'madzi a m'magazi kudzera pamphuno yotsekereza.Chishango chaching'ono chimapezedwa kudzera mu plasma ndikuwonjezeredwa ndi mpweya wothandizira woteteza.Mipweya yothandizira yoteteza imagwiritsa ntchito argon, helium, kapena kusakaniza kwa argon ndi hydrogen kapena helium.

Mphamvu ya kutentha kwa mtsinje wa plasma imakhala yokhazikika komanso yamphamvu kwambiri chifukwa cha arc yochepetsetsa, yomwe imalola kulowa mkati mozama.Chotsatira chake, chimapanga chowotcherera chokhazikika, chopapatiza, komanso chofulumira mu pepala lachitsulo.Zitsulo zamasamba zitha kulumikizidwa pogwiritsa ntchito kuwotcherera kwa plasma arc kapena popanda zinthu zodzaza.Zitsulo zachitsulo komanso zopanda chitsulo, kuphatikiza mapepala osalimba, zitha kulumikizidwa pogwiritsa ntchito kuwotcherera kwa plasma arc.

5. Kuwotcherera kwa laser-mtengo

Kuwotcherera kwa laser laser

Mu kuwotcherera kwa laser, mtengo wautali wa photon woloza pamalo owotcherera umatenthetsa zitsulo ndikuziphatikiza popanga dziwe lowotcherera.Ubwino waukulu wa njira yowotcherera iyi ndikuti padzakhala malo ang'onoang'ono omwe amakhudzidwa ndi kutentha chifukwa cha chitsulo champhamvu kwambiri cha photons.

laser kuwotchererandi oyenera zitsulo pepala ndi mkulu kusungunuka kutentha ndi madutsidwe kutentha, monga Carbon & zitsulo zosapanga dzimbiri, titaniyamu, ndi Aluminium.Chifukwa zowotcherera zopapatiza zimakhala zosavuta kuzipeza, zimagwiritsidwa ntchito popanga zida, ma airbags, manja, ndi pacemaker.

Pali makina awiri muyezo wa laser kuwotcherera ntchito pa pepala zitsulo, yaifupi ndi yaitali wavelength mitundu.Magwero autali-wavelength ndi ma laser amtundu wa CO2, pomwe makina atali-wavelength ndi YAG, disk, kapena fiber matanda.Kusiyana kwakukulu ndikuti makina okhala ndi kutalika kwafupipafupi amasungunula zinthuzo mwachangu kuposa zazitali.

Tsopano tiyeni tifanizire aliyense wa njira kuwotcherera kuti kumvetsa bwino;

| SN | Mtundu | Kuwotcherera liwiro | Zida za pepala |

| 1 | MIG | 20 mpaka 30″ / mphindi zokha : mpaka 1oo ″ / miniti | Mpweya & chitsulo chosapanga dzimbiri, Aluminium |

| 2 | TIG | 4 ku10″ / mphindi makina: Kufikira 80 ″ / mphindi | Zitsulo, chromium, titaniyamu, mkuwa, magnesium |

| 3 | Ndodo | 3 ku 6″ / mphindi | zitsulo zolimba monga zitsulo za carbon ndi zitsulo |

| 4 | Mtundu wa laser | 40 mpaka 140″ / mphindi (kutengera pamanja kapena makina) | Zida zokhala ndi malo osungunuka kwambiri, Carbon & chitsulo chosapanga dzimbiri, titaniyamu |

| 5 | Plasma arc | 10 mpaka 20″ / miniti, zokha: mpaka 125 ″ / mphindi | Zonse zachitsulo komanso zopanda ferrous |

Kuyerekeza njira kuwotcherera

Mitundu ya malo owotcherera & Zizindikiro

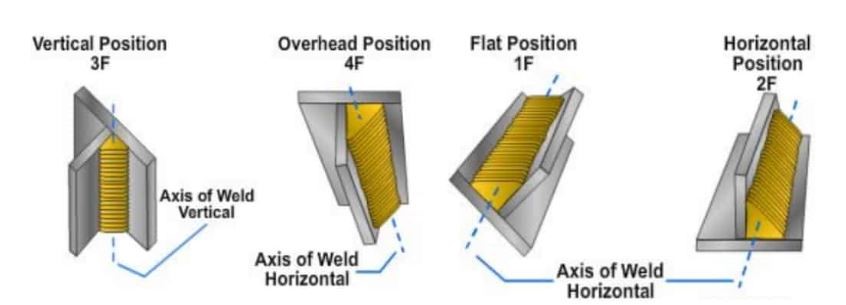

Pali mitundu inayi yoyambira yowotcherera (1), Yopingasa (2), Yoyimirira (3), ndi Pamwamba (4).Nambala mu bulaketi imayimira chizindikiro cha mtunduwo.Komanso fillet (F) ndi groove welding (G) zitha kugwiritsidwa ntchito m'makalasi onse anayi.Tiyeni timvetse zizindikiro izi mwa chitsanzo;

i. 3 F: kuwotcherera fillet pamalo ofukula

ii. 4 G: kuwotcherera groove pamalo apamwamba

iii. 2 F: kuwotcherera fillet pamalo Opingasa

Malo osiyanasiyana owotcherera

Mu kuwotcherera kwa fillet, kumtunda kwa malo opingasa kumayikidwa molunjika pamalo owoneka ngati L.Pamene kuwotcherera poyambira, pamene poyambira kuwotcherera poyambira, onse zitsulo pepala kuti welded wagona pa ndege yomweyo (Oima).

Zinthu zomwe ziyenera kuganiziridwa panthawi yowotcherera zitsulo

Kuti ukwati ukhale wokhazikika komanso wolimba, payenera kuganiziridwa zinthu zosiyanasiyana.Tiyeni tiwone zina mwazinthu zofunika mwatsatanetsatane;

1. Filler zakuthupi

Sankhani chodzaza chomwe chimatha kuteteza dzimbiri komanso dzimbiri.Komanso, kumbukirani kuti ndodo yodzaza iyenera kukhala yowonda kuposa makulidwe achitsulo.Mwachitsanzo, ndodo yodzazayo iyenera kukhala pakati pa 0.7 ndi 1 mm ngati mukufuna kuwotcherera zitsulo zachitsulo zomwe ndi 1.5 mm wandiweyani.

2. Kukula kwa electrode

Kukula kwa elekitirodi kuyenera kusankhidwa potengera kutentha (magetsi) omwe amagwiritsidwa ntchito komanso kuchuluka kwa kuwotcherera komwe kumafunikira.Mwachitsanzo, electrode yokhala ndi mainchesi 0.125 m'mimba mwake imagwira ntchito bwino pakuwotcherera pang'ono komanso kutentha pang'ono.

3. Zokongoletsera pa pepala logwira ntchito

Kugwiritsa ntchito chotchinga kuti musinthe momwe kuwotcherera ndikofunikira kuti mukwaniritse zowotcherera ndi mphamvu.Kuphatikiza apo, pepalali liyenera kumangidwa bwino kuti mapepala ogwirira ntchito asasunthike panthawi yowotcherera.

Malangizo kukumana ndi mavuto pa kuwotcherera

· Ndi bwino kugwiritsa ntchito nsonga yosongoka kuti arc ndi thambi likhale laling'ono komanso lowongolera momwe mungathere powotcherera m'mipata yothina pakati pa zidutswa zachitsulo chifukwa izi zimapangitsa kuti kutentha kuzikhala m'malo ovuta kwambiri.

· Yesani kuwotcherera pa prototypes musanayambe njira zowotcherera zachitsulo kuti muwonetsetse kuti zili bwino komanso zimamaliza.

· Mukamawotcherera MIG, sunthani mfuti yowotchera m'njira yowongoka ndi liwiro laulendo lomwe lingatheke pamene dera la arc likutentha kwambiri.Zidzateteza ku kutopa.

· Pewani kusiya mabowo aliwonse m'malo owotcherera chifukwa adzakhala ngati mapini a chinyezi ndikulimbikitsa kupanga dzimbiri.

· Kuti muthe kutentha, bweretsani malo omwe akhudzidwa ndi kutentha agwirizane ndi chozizira chopangidwa ndi mkuwa kapena Aluminium.

Mapeto

Kusankha njira yoyenera yowotcherera potengera chitsulo chachitsulo ndi zomwe zimafunikira ndikofunikira.Mukasankha mtundu wa kuwotcherera, zinthu zingapo, kuphatikiza kukula kwa ma elekitirodi, zinthu zodzaza, malo otchingira, ndi zina zambiri, ziyenera kuganiziridwa.Ku Prolean, timapereka akatswirikukambirana ndi ntchito zowotcherera zitsulokuchokera pakupanga magawo owotcherera mpaka laser kudula ndi kuwotcherera mogwirizana ndi zosowa zanu.Lumikizanani ndi injiniya wathumwachindunji kuti mudziwe zambiri.

FAQs

Kodi njira zabwino zowotcherera ndi AC & DC ndi ziti?

Njira zosiyanasiyana zowotcherera zimagwira ntchito pamitundu yonseyi.Komabe, kuwotcherera kwa MIG kungakhale kwabwino kwambiri ngati mutagwiritsa ntchito magwero onse a AC&DC.

Ndi mitundu iti yowotcherera yazitsulo zamapepala?

Pali njira zisanu zowotcherera zachitsulo, kuphatikiza TIG, MIG, Ndodo, mtengo wa Laser & kuwotcherera kwa plasma.

Kodi makulidwe apakati pa kuwotcherera zitsulo zamasamba ndi chiyani?

O.8 mm ndiye malire otsika makulidwe a kuwotcherera kwachitsulo.Komabe, ngati mukufuna kuwotcherera mapepala pansi kuposa pamenepo, mutha kugwiritsa ntchito kuwotcherera kwa MIG ndi kuwotcherera kwa MIG, koma onetsetsani kuti nsonga ya elekitirodi ndi yakuthwa kwambiri.

Kodi ndi zinthu ziti zofunika kuziganizira pochita ntchito zowotcherera?

Kukula kwa ndodo ya Electrode & Filler, makulidwe a pepala logwira ntchito, lopaka kutentha, malo otchinga, ndi chitetezo ndizofunikira kwambiri.

Nthawi yotumiza: Jul-08-2022