Sheet Metal Welding: Zvese Zvaunoda Kuziva

Yekupedzisira update:09/02, nguva yekuverenga: 6 mins

Welding kushanda

Sheet metal weldinginzira yakakosha yekugadzira nekuti ndiyo imwe yedzakareruka nzira dzekubatanidza dzakachekwa-kunze zvidimbu zvesimbi mashizha kugadzira chimiro chaunoda.Muwelding, nzvimbo dzekubatanidza dzinoiswa pasi pekupisa kwakanyanya kuti dzisanganise nekunyungudutsa simbi munzvimbo yakatarwa.Mune zvimwe zviitiko, kudzvanywa kunoshandiswawo kujoinha mapepa, asi Spark ndiyo inonyanya kufarirwa pakati pevagadziri uye maindasitiri ekushandisa.

Nyaya ino ichakurukura muchidimbuakasiyana sheet simbi welding Techniques, Applications, zvinhu zvokufunga nezvazvo, uye mamwe mazano anobatsira welding.

1. MIG

MIG welding operation

Rimwe zita reMIG welding iGas Metal Arc Welding (GMAW).Iyo welding process umo iyo inobatika yakasimba waya electrode inogadzira dziva rekunyungudika munzvimbo yekubatanidza.Iyo yemagetsi charge electrode tip inopisa nzvimbo yakanangwa uye inonyungudutsa simbi.Nenzira iyi, pfuti yemoto inoshandisa gasi rekudzivirira (helium, argon, nitrogen) kumisa dziva re weld kubva pakusvibiswa nekusvibiswa kwemhepo.Inokodzera simbi mashizha esimbi isina tsvina, Carbon simbi, uye Aluminium.

MuMIG welding, gasi remukati rinoyerera kubva kune cylinder yekugovera uye magetsi ane voltage anoramba aripo anodiwa kugadzira arc yemagetsi yekunyungudutsa simbi uye kudyisa waya ye electrode.

Iyo yekumhanyisa kumhanya muMIG inosiyana kubva pa20 kusvika 30 inches paminiti zvichienderana nenzvimbo yewelding (Inner kana yekunze pamusoro) & zvinhu.Nekudaro, MIG yave otomatiki uye inogona weld kusvika ku100″paminiti.

2. TIG

TIG welding kushanda

TIG welding inoendesa kupisa kune chaiyo nzvimbo yepepa simbi uko kujoinha kunodiwa uchishandisa isingabatike tungsten electrodes.Kufanana neMIG welding, inert gasi kudzivirira kunoshandiswa kudzivirira kusvibiswa kwedziva rewelding.Sezvo electrode isingagoni kupedzwa, mubatanidzwa unosimbiswa nezvinhu zvekuzadza.Saka, kudyisa tsvimbo yekuzadza nguva dzose munzvimbo yewelding mukati mekuita kunodiwa.

Maererano nesheet metalukobvu, unogona kusarudza dhayamita ye tungsten electrode yewelding process.Semuenzaniso, 2.4mm tungsten electrode ichave yakanyanya kunaka kana sheet simbi yakatenderedza 3mm gobvu.1.6 mm ichava sarudzo yakanakisisa kana pepa racho risina kusimba.

Nekuti inogadzira majoini akasimba musimbi yesimbi & isiri-ferrous sheet simbi seAluminium, mhangura, titanium, magnesium, uye Chromium, TIG welding inoshandiswa zvakanyanya muaerospace & indasitiri yekugadzira mota kunze kwekugadzira fenicha.Kunyangwe bhuku reTIG welding inofamba zvishoma nezvishoma (4 kusvika 6″paminiti), welding uchishandisa otomatiki kana nzira yerobhoti inogona kukurumidza kuita.

3. Stick Welding

Stick welding operation

Stick welding ndiyo yakajairika uye yechinyakare nzira yekubatanidza mapepa esimbi mahwendefa, ayo anoshandisa shielded metal arc welding.Iyo inyore arc welding nzira inoshandisa tsvimbo yakavharwa mukuyerera se electrode.Iyo electrode inotakura iyo yakaipa ikozvino apo pepa rebasa rakabatana neiyo yakanaka terminal ye AC magetsi sosi.

Inzira yakatwasuka.Batanidza chimuti che electrode kupfuti yewelding uye bata poindi yewelding kuti uenderere mberi.Kunyangwe ichiisa simbi yakawandisa panzvimbo yewelding uye ichida hunyanzvi hwepamusoro, inokodzera simbi dzakaomarara senge kabhoni simbi nemarata esimbi ane ukobvu huri pasi pe3.2 mm.

4. Plasma Arc Welding

Plasma arc welding operation

Mune plasma arc welding, simbi coalescence inogadzirwa neyakaomeswa arc yakagadzirwa nepamusoro-velocity rwizi rweionized gasi inonzi plasma.Mumabasa mazhinji eplasma arc welding, jeti yeplasma inogadzirwa nekudziisa gasi remugodhi mukamuri retorch polenta uye nekumanikidza plasma kuburikidza neinomanikidza muromo.Chidziviriro chechidimbu chinowanikwa kuburikidza neplasma uye chinowedzerwa nerubatsiro rwekudzivirira gasi.Magasi ekudzivirira anoshandisa argon, helium, kana musanganiswa weargon nehydrogen kana helium.

Iyo inopisa simba ye plasma stream yakanyanyisa uye yakanyanya kusimba nekuda kweiyo constricted arc, inobvumira kupinda kwakadzika.Nekuda kweizvozvo, inogadzira yakagadzikana, yakamanikana, uye inokurumidza weld mushezha simbi.Mashizha esimbi anogona kubatanidzwa uchishandisa plasma arc welding ine kana isina filler zvinhu.Masimbi ane ferrous uye asiri-ferrous, kusanganisira mashizha asina kusimba, anogona kubatanidzwa uchishandisa plasma arc welding.

5. Laser-danda welding

Laser beam welding operation

Mulaser beam welding, danda rephoton rakareba rakanongedza panzvimbo yewelding rinopisa mashizha esimbi uye rinoabatanidza nekugadzira dziva rekukweshesa.Chakanyanya mukana weiyi welding process ndechekuti pachave nenzvimbo diki-inokanganiswa nekupisa nekuda kweiyo yakadzika simba-density photons beam.

Lasers weldakakodzera simbi dzemapepa ane tembiricha yekunyungudika uye kupisa conductivity, seCarbon & Stainless simbi, titanium, uye Aluminium.Nekuda kwekuti maweldings akamanikana anowanikwa nyore, anoshandiswa kugadzira magiya magiya, mabhegi emhepo, maoko, uye pacemaker.

Kune maviri akajairwa michina yelaser welding mashandiro papepa simbi, iwo mapfupi uye akareba-wavelength marudzi.Marefu-wavelength masosi ari CO2-mhando lasers, nepo mapfupi-wavelength muchina ari YAG, dhisiki, kana fiber matanda.Musiyano mukuru ndewekuti michina ine pfupi-wavelength inonyungudutsa zvinhu nekukurumidza kupfuura refu.

Zvino ngatienzanisei imwe neimwe yewelding maitiro ekunzwisisa zviri nani;

| SN | Type | Welding speed | Zvishandiso zvepepa |

| 1 | MIG | 20 kusvika ku30" / Mineti otomatiki: kusvika ku1oo ″ / miniti | Carbon & simbi isina tsvina, Aluminium |

| 2 | TIG | 4 kusvika ku10" / Mineti otomatiki: Kusvikira ku80 ″ / miniti | Simbi, Chromium, titanium, mhangura, magnesium |

| 3 | Stick | 3 ku6" / Mineti | simbi dzakaoma se carbon steel uye iron sheets |

| 4 | Laser danda | 40 kusvika ku140″ / miniti (zvichienderana nemanyorero kana otomatiki) | Zvishandiso zvine nzvimbo yakakwira yekunyungudika, Carbon & simbi isina tsvina, titanium |

| 5 | Plasma arc | 10 kusvika ku20" / Mineti, otomatiki: anosvika 125 ″ / miniti | Zvose ferrous uye kwete-ferrous |

Kuenzanisa pakati welding maitiro

Mhando dzenzvimbo dzewelding & Symbols

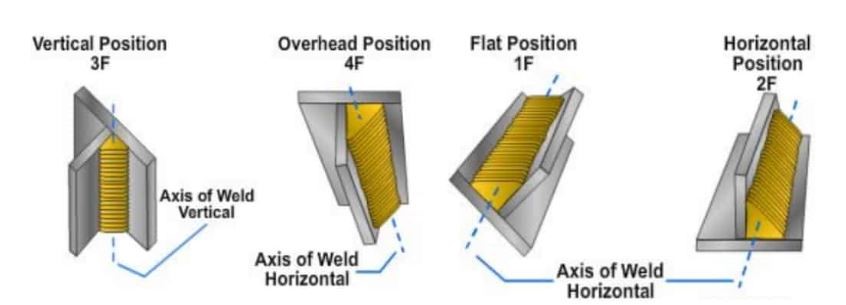

Kune mana emhando dzemhando dzewelding zvinzvimbo Flat (1), Horizontal (2), Vertical (3), uye Overhead (4).Nhamba iri mubhuraketi inomiririra chiratidzo cherudzi.Zvakare, ese mafillet (F) uye groove welding (G) anogona kuiswa mumakirasi mana ese.Ngatinzwisise zviratidzo izvi nemuenzaniso;

i. 3 F: Fillet welding munzvimbo yakatwasuka

ii. 4 G: groove welding munzvimbo yepamusoro

iii. 2 F: Fillet welding mune Horizontal chinzvimbo

Various welding zvinzvimbo

Mune fillet welding, iyo yekupedzisira yekumusoro yenzvimbo yakachinjika inoiswa yakatarisana nenzvimbo yakatwasuka mune L-yakaita perpendicular chinzvimbo.Paunenge uri mugororo welding, paunenge uri mugororo welding, ese simbi pepa kuti isungirwe inorara mundege imwe chete (Yakatwasuka).

Zvinhu zvinofanirwa kutariswa panguva yepepa simbi welding

Nokuda kwemuchato wakagadzikana uye wakasimbiswa, zvinhu zvakasiyana-siyana zvinofanira kufungwa nezvazvo.Ngatitarisei zvimwe zvezvinhu zvakakosha zvakadzama;

1. Filler zvinhu

Sarudza chizadziso chinokwanisa pakupedzisira kudzivirira ngura uye kugadzira ngura.Zvakare, rangarira kuti danda rekuzadza rinofanirwa kuve rakatetepa kupfuura iro jecha resimbi ukobvu.Semuenzaniso, danda rekuzadza rinofanira kunge riri pakati pe0.7 ne1 mm kana ukaronga kubatanidza simbi yepepa iri 1.5 mm gobvu.

2. Electrode size

Saizi ye electrode inofanira kusarudzwa zvichienderana nekupisa (magetsi) akaiswa uye dhigirii rewelding inodiwa.Semuenzaniso, electrode ine dhayamita ye0.125 inches inoshanda zvakanyanya kune yakamanikana welding uye kushoma kupisa mamiriro.

3. Zvisungo papepa rekushanda

Kushandisa chibatiso kugadzirisa iyo welding chinzvimbo kwakakosha kuti uwane yakagadzikana welding uye simba.Mukuwedzera, pepa rinoda kusungirirwa zvakanaka kudzivirira mapepa ekushanda kubva pakuchinja panguva yekuputika.

Mazano ekusangana nematambudziko panguva yewelding

· Zvakanakisisa kushandisa muromo wakanongedza electrode kuti uchengete arc uye puddle zviri diki uye zvichidzorwa sezvinobvira paunenge uchipinza munzvimbo dzakasimba pakati pemarata esimbi nekuti izvi zvinochengeta nzvimbo yekupisa iri munzvimbo dzakamanikidzwa zvakanyanya.

· Edza welding pane prototypes usati watanga sheet simbi welding maitiro kuti uve nechokwadi chemhando uye kupera kwepamusoro.

· Paunenge uchiita MIG welding, fambisa pfuti yewelding munzira yakatwasuka ine kukurumidza kukurumidza kufamba kunokwanisika kana nzvimbo yearc yava kupisa.Ichadzivirira kubva pakuneta.

· Dzivisa kusiya chero maburi munzvimbo yewelding nekuti ivo vanozoita semapini ekunyorova uye kukurudzira kuumbwa kwekuora.

· Kuti ubvise kupisa, hunza nzvimbo yakakanganiswa nekupisa inosangana nechando chinogadzirwa nemhangura kana Aluminium.

Mhedziso

Kusarudza yakafanira welding tekinoroji yakavakirwa pashizha simbi uye inodiwa zvigadzirwa zvakatemwa kwakakosha.Mushure mekusarudza mhando yewelding, zvinhu zvakati wandei, zvinosanganisira saizi ye electrode, filler material, clamp position, nezvimwe, zvinofanirwa kutariswa.PaProlean, tinopa nyanzvisheet metal welding kubvunzana uye masevhisikubva pakugadzira iyo welding paramita kusvika kune laser yekucheka uye welding zvinoenderana nezvaunoda.Bata injiniya weduzvakananga kune rumwe ruzivo.

FAQ's

Ndedzipi dzakanakisa nzira dzekushongedza neaviri AC & DC?

Yakasiyana-siyana welding nzira dzinoshanda pamhando mbiri.Nekudaro, MIG welding ingave yakanyanya kunaka kana ukashandisa ese AC&DC masosi.

Ndeapi marudzi akajairika ewelding yemashizha esimbi?

Pane nzira shanu dzakajairwa dzekugadzira simbi dzesimbi, dzinosanganisira TIG, MIG, Stick, Laser beam & plasma welding.

Ndeipi muganho wekukora wesheet metal welding?

O.8 mm ndiyo yakaderera ukobvu inogumira kune sheet metal welding.Nekudaro, kana iwe uchida kupinza mapepa akadzikira pane izvo, unogona kushandisa MIG welding neMIG welding, asi iva nechokwadi chekuti electrode tip yakapinza-yakapinza.

Ndezvipi zvinhu zvakakosha zvinofanirwa kutariswa paunenge uchiita mashandiro ewelding?

Electrode & Filler tsvimbo saizi, ukobvu hweshizha rekushanda, rakaisirwa kupisa, nzvimbo yekusungirira, uye chengetedzo ndizvo zvinonyanya kutariswa.

Nguva yekutumira: Jul-08-2022