Ukuqinisekisa njani ukuzinza kokubumba inaliti yeplastiki ecacileyo-Isikhokelo se-FAQ

Ixesha lokufunda eliqikelelweyo:Imizuzu emi-4, imizuzwana engama-55

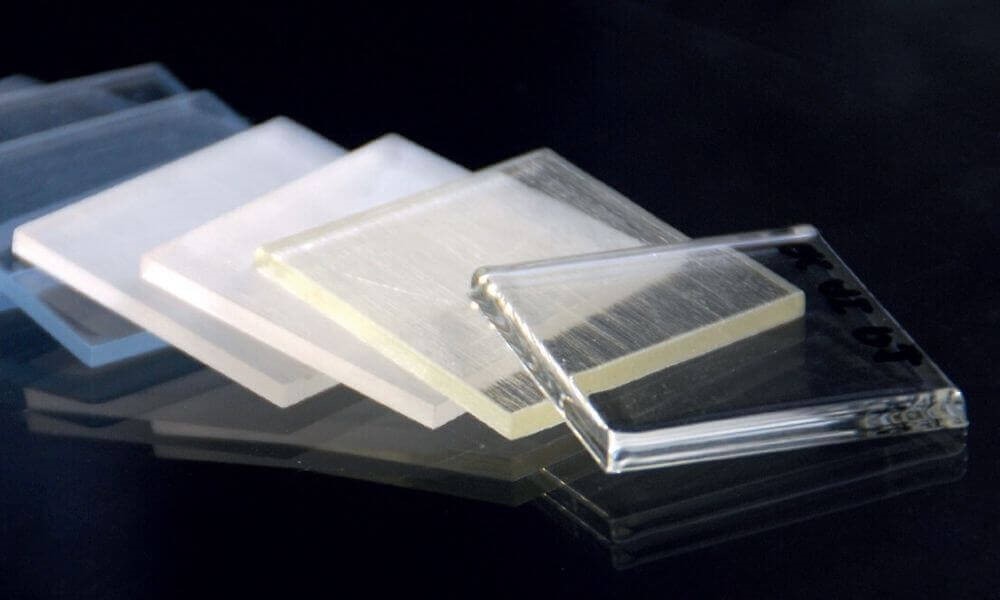

Iipilisi zeplastiki ezicacileyo

Ngeenzuzo zobunzima bokukhanya, ukuqina okuhle, ukukhululeka kokubumba kunye neendleko eziphantsi, iiplastiki zithatha indawo yeglasi kwizicelo ezininzi, ngakumbi kwisixhobo sokukhanya kunye namashishini okupakisha, akhula ngokukhawuleza.Nangona kunjalo, izixhobo ze-optical kunye neshishini lokupakisha zineemfuno eziphezulu malunga nokungafihli, ukuqina, ukuchasana kwempembelelo kunye nokuqina.Ngoko ke, kufuneka kuqwalaselwe ingqaleloimathiriyeli ekrwada, iinkqubo, izixhobo kunye nokungundaukuqinisekisa ukuba iimveliso zeplastiki ziyahlangabezana neemfuno zamalungu.Unako kwakhonaqhagamshelana neenjineli zethungqo uthethwano simahla.

Ikhadi leplastiki ecacileyo

Iiplastiki ezicacileyo kufuneka kuqala zibe neqondo eliphezulu lokungafihli, okwesibini kufuneka zibe neqondo elithile lamandla kunye nokumelana nokukrazula, zikwazi ukuxhathisa impembelelo, zikwazi ukumelana nobushushu, zikwazi ukumelana neekhemikhali kwaye zibe neqondo eliphantsi lokufunxa amanzi, kuphela emva koko. ziyahlangabezana neemfuno zokungafihli ekusetyenzisweni kwaye zihlala zingatshintshi ixesha elide.I-PPT isetyenziselwa ukupakishwa kunye nezikhongozeli kuba kufuneka yolulwe ukufumana iimpawu ezifanelekileyo zoomatshini.

Ukungcola kwempahla ekrwada, gcina yomile

Ngethuba lenkqubo yokuzaliswa, ingqalelo kufuneka ihlawulwe ekutywineni nasekuqinisekiseni ukuba izinto eziluhlaza zicocekile.Ngokukodwa, umswakama oqulethwe kwizinto eziluhlaza unokubangela ukuwohloka emva kokufudumeza, ngoko kufuneka zomiswe, kwaye kwi-injection yokubumba, izinto kufuneka zongezwe usebenzisa i-hopper eyomileyo.Enye ingongoma ekufuneka uyiqaphele kukuba ngexesha lokumisa, umoya wokungena kufuneka ucocwe kwaye uhlanjululwe ukuze uqiniseke ukuba awungcolisi izinto eziluhlaza.

Uxinzelelo lwe-injection kunye nesantya

Okwesibini, njengoko iiplastiki ezicacileyo zinendawo yokunyibilika ephezulu kunye nokuhamba kakubi, ukuze kuqinisekiswe umgangatho wemveliso, ubushushu bomgqomo, uxinzelelo lwenaliti, isantya sokutofa kunye nezinye iiparamitha zenkqubo kufuneka zilungiswe kakuhle ukuze iplastiki yokutofa igcwalise ngundo kwaye ungavelisiuxinzelelo lwangaphakathi kunye nokubangela ukuguqulwa kwemveliso kunye nokuqhekeka.

Ukucocwa kwemibhobho, izikrufu kunye nezixhobo

Ukuthintela ukungcoliseka kwezinto eziluhlaza kunye ne-screw kunye ne-depressions kukho izinto ezindala okanye ukungcola, ngokukodwa ukuzinza okungahambi kakuhle kwe-thermal ye-resin ekhoyo, ngoko ngaphambi kokusetyenziswa, emva kokuba ukuvalwa kusetyenziswe kwi-agent yokucoca i-screw.

Ukumisa okwethutyana ukunciphisa ubushushu

Xa ukumisa okwexeshana, ukuze kuthintelwe izinto ekrwada kwiqondo lobushushu eliphezulu ukuhlala ixesha elide, okubangela ukuthotywa, isomisi kunye iqondo lobushushu umphanda kufuneka kuncitshiswe, ezifana PC, PMMA kunye nezinye iqondo lobushushu umphanda kufuneka kuncitshiswe 160 ℃ okanye ngaphantsi. .(Ubushushu beHopper kwiPC kufuneka buncitshiswe bube ngaphantsi kwe-100℃)

Iingxaki eziza kuphawulwa kuyilo lokubumba (kubandakanywa noyilo lwemveliso)

Ukuthintela ukuphuma kwembuyekezo engekho mgangathweni, okanye ukupholisa okungalinganiyo okukhokelela ekubunjweni kweplastiki okulambathayo, iziphene kunye nokonakala.

Ngokubanzi, la manqaku alandelayo kufuneka aqatshelwe kuyilo lokubumba.

1. Ubunzima bodonga kufuneka bufanane ngokusemandleni kwaye i-slope yokukhulula kufuneka ibe nkulu ngokwaneleyo;2. Icandelo lenguqu kufuneka libe ngokuthe ngcembe Round and smooth over, ukukhusela iikona ezibukhali.Imiphetho ebukhali iveliswa, ngakumbi kwiimveliso zePC akufuneki zibe nezithuba;3. Umhluzi.Umgijimi kufuneka abe ububanzi kunye nobukhulu ngokusemandleni, kwaye indawo ye-sprue kufuneka ibekwe ngokwenkqubo ye-shrinkage condensation, kunye nemithombo yezinto ezibandayo kufuneka zongezwe ukuba kuyimfuneko;4. Umphezulu wesikhunta kufuneka ube oqaqambileyo kwaye ucoceke, kunye nobunzima obuphantsi (ngokukhethekileyo ngaphantsi kwe-0.8);5. Umngxuma wokukhupha umoya.I-slot kufuneka yanele ukukhupha umoya kunye negesi kwi-melted ngexesha;6. Ngaphandle kwe-PET, ubukhulu bodonga akufanele bube buncinci kakhulu, ngokuqhelekileyo bungabi ngaphantsi kwe-1mm.

Iingxaki eziza kuphawulwa kwinkqubo yokubumba isitofu (kubandakanywa neemfuno zomatshini wokubumba inaliti)

Ukuze kuncitshiswe uxinzelelo lwangaphakathi kunye neziphene zomgangatho ophezulu, le miba ilandelayo yenkqubo yokubumba inaliti kufuneka iqatshelwe.

I-1, kufuneka isebenzise isikrufu esikhethekileyo, kunye nomatshini wokubumba wokubumba wenaliti yenaliti yobushushu obulawulwa ngubushushu;2, ubushushu benaliti kwi-resin yeplastiki ayiboli indawo, kufanelekile ukusebenzisa ubushushu obuphezulu benaliti;I-3, uxinzelelo lwenaliti: ngokubanzi luphezulu ukoyisa iziphene ze-viscosity enyibilikayo, kodwa uxinzelelo luphezulu kakhulu luya kuvelisa uxinzelelo lwangaphakathi olubangelwa kukukhululwa okunzima kunye nokuguqulwa;I-4, isantya se-injection: ukuhlangabezana nemeko yokuzalisa ukubumba, ngokubanzi kufuneka ibe phantsi, kungcono ukusebenzisa i-slow-fast-slow-slow multi-stage injection 5, ukubamba ixesha kunye nomjikelo wokubumba: kwimeko yokudibana nokuzaliswa kwemveliso, akukho sibonda, iqamza;kufuneka ibe mfutshane kangangoko, ukuze kuncitshiswe ukunyibilika kwixesha lokuhlala umgqomo;I-6, isantya se-screw kunye noxinzelelo lwangasemva: kwindawo yokuhlangana nomgangatho weplastiki, kufuneka ibe phantsi kangangoko, ukuthintela ukunyanzeliswa;I-7, iqondo lokushisa lokungunda: ukupholisa kwemveliso kulungile okanye kubi, impembelelo kumgangatho mkhulu, ngoko ubushushu bomngundo kufuneka bukwazi ukulawula ngokuchanekileyo inkqubo.Ukuba kunokwenzeka, iqondo lobushushu lokungunda kufuneka libe phezulu.

Eminye imiba

Ukuthintela ukuwohloka komgangatho womphezulu, i-arhente yokukhulula kufuneka isetyenziswe ngokucokisekileyo ngexesha lokubunjwa kwesitofu ngokubanzi;xa usebenzisa imathiriyeli ephinde yaphinda yasetyenziswa akufuneki ibe ngaphezulu kwama-20%.

Kwiimveliso ngaphandle kwe-PET, unyango emva konyango kufuneka luqhutywe ukuphelisa uxinzelelo lwangaphakathi.I-PMMA kufuneka yomiswe kwi-70-80 ° C kwiiyure ze-4 kumjikelezo womoya oshushu;I-PC kufuneka yomiswe emoyeni ococekileyo, i-glycerine.Iparafini engamanzi njlI-PET, kwelinye icala, kufuneka yenze inkqubo yokwelula i-bi-directional ukuze ifumane iimpawu ezifanelekileyo zoomatshini.

Isitofu sokubumba sisetyenziswa ngokubanzi kumashishini ahlukeneyo kwaye sinokufikelela ngaphandle komthungo, ukuveliswa kobunzima obuchanekileyo bamalungu ngexesha elifutshane.I-ProLean Techibonelela ngeenkonzo zokubumba ngesitofu kwizinto ezininzi, kubandakanya iiplastiki kunye neelastomers.Ngokululalayisha imodeli yakhokwaye ufumane isicatshulwa esisimahla kunye neengcebiso kwiinkonzo ezinxulumeneyo.

Ixesha lokuposa: Apr-11-2022