Maitiro ekuona kugadzikana kweakajeka epurasitiki jekiseni kuumba - FAQ gwara

Inofungidzirwa nguva yekuverenga:4 maminitsi, 55 masekondi

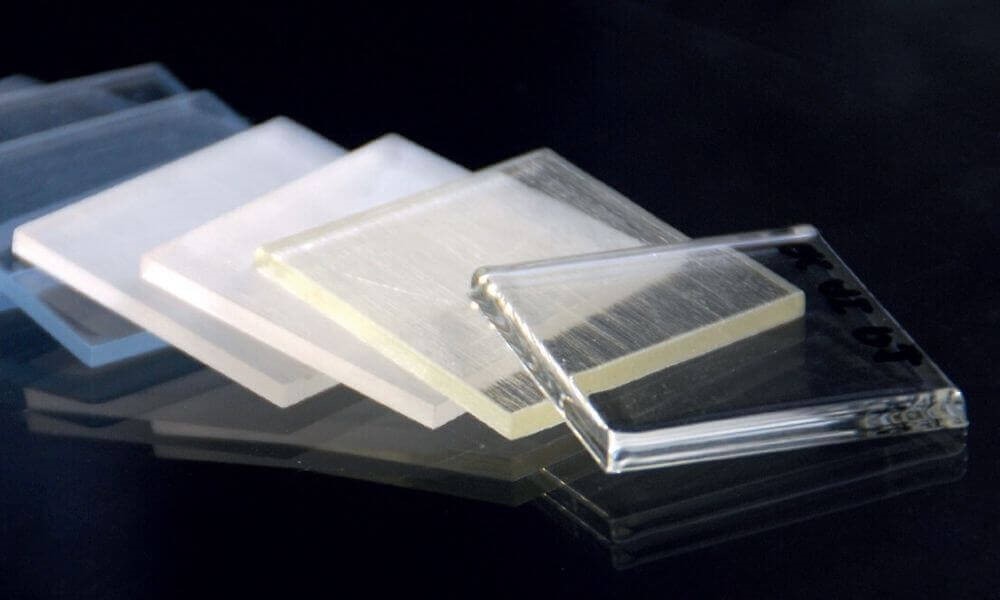

Transparent plastic pellets

Nezvakanakira uremu huremu, kusimba kwakanaka, kusununguka kwekuumbwa uye kudhura kwakaderera, mapurasitiki ari kuwedzera kutsiva girazi mune akawanda maapplication, kunyanya mune optical chiridzwa uye maindasitiri ekurongedza, ari kukura nekukurumidza.Nekudaro, zviridzwa zvemaziso uye indasitiri yekurongedza zvine zvakakwirira zvinodikanwa maererano nekujeka, kusimba, kukanganisa kupikisa uye kuoma.Naizvozvo, kutarisisa kunofanirwa kubhadharwa kune iyombishi zvinhu, maitiro, midziyo uye moldkuve nechokwadi chekuti zvigadzirwa zvepurasitiki zvinosangana nezvinodiwa zvezvikamu.Unogonawokubata mainjiniya eduzvakananga kubvunzurudza mahara.

Transparent plastic card

Mapurasitiki akajeka anofanirwa kutanga aine dhigirii yakakwira yekujeka, chechipiri anofanirwa kunge aine imwe dhigirii yesimba uye abrasion kuramba, kugona kuramba kukanganiswa, kuve neakanaka kupisa kupisa, kuve nemakemikari anopikisa uye kuve neakaderera kunyura kwemvura, ipapo chete anogona. vanosangana nezvinodiwa zvekujeka mukushandiswa uye vanoramba vasina kushanduka kwenguva yakareba.PPT inoshandiswa mukurongedza uye midziyo nekuti inofanirwa kutambanudzwa kuti iwane yakanaka michina zvivakwa.

Raw material tsvina, ramba wakaoma

Munguva yekuzadza, kutarisisa kunofanirwa kubhadharwa pakuisa chisimbiso uye kuve nechokwadi chekuti iyo mbishi yakachena.Kunyanya, hunyoro huri mune yakasvibirira hunogona kukonzera kuderera mushure mekupisa, saka hunofanirwa kuomeswa, uye mukuumbwa kwejekiseni, zvinhu zvinofanirwa kuwedzerwa uchishandisa hopper yakaoma.Imwe pfungwa yekucherechedza ndeyekuti panguva yekuomesa, mweya wekupinda unofanirwa kusefa uye kuderedzwa kuti uve nechokwadi chekuti hausvibise zvinhu zvakasvibirira.

Injection pressure uye kukurumidza

Chechipiri, semapurasitiki akajeka ane nzvimbo yakakwira yekunyungudika uye kusayerera zvakanaka, kuitira kuti ive nechokwadi chemhando yepamusoro yechigadzirwa, tembiricha yedhiramu, jekiseni rinomanikidza, kumhanya kwejekiseni uye mamwe maparamita ekuita anofanirwa kugadziridzwa zvakanaka kuti jekiseni repurasitiki rizadze. kuumba uye kusaberekakushushikana kwemukati uye kukonzera deformation yechigadzirwa uye kuputika.

Kucheneswa kwemadhiramu, screws uye accessories

Kudzivirira kusvibiswa kwezvinhu zvakasvibirira uye mune screw uye depressions kune yekare zvinhu kana kusvibiswa, kunyanya kuderera kwekushisa kwekugadzikana kweiyo resin iripo, saka isati yashandiswa, mushure mekuvhara inoshandiswa kune screw cleaning agent.

Kumira kwenguva pfupi kuderedza kupisa

Kana kumira kwekanguva, kuitira kudzivirira mbishi kutonhora kwakanyanya kugara kwenguva yakareba, zvichikonzera kuderera, iyo yakaoma uye tembiricha yedhiramu inofanira kuderedzwa, sePC, PMMA uye kumwe kupisa kwembiya kunofanirwa kuderedzwa kusvika 160 ℃ kana zvishoma. .(Hopper tembiricha yePC inofanira kudzikiswa kusvika pazasi 100 ℃)

Matambudziko anofanirwa kucherechedzwa mukugadzirwa kwe mold (kusanganisira dhizaini yechigadzirwa)

Kudzivirira kusanaya zvakanaka kwekudzoka, kana kutonhodza zvisina kuenzana zvichikonzera kuumbwa kwakashata kwepurasitiki, kuremara kwepamusoro uye kuparara.

Kazhinji, pfungwa dzinotevera dzinofanira kuonekwa mukugadzira mold.

1. Ukobvu hwemadziro hunofanira kunge hwakafanana sezvinobvira uye kuburitsa kutsetseka kunofanira kunge kwakakura zvakakwana;2. Chikamu chekushandura chinofanira kunge chiri zvishoma nezvishoma Round uye chinyoro pamusoro, kudzivirira makona akapinza.Yakapinza mipendero inogadzirwa, kunyanya kune zvigadzirwa zvePC hazvifanirwe kunge zvine mapeji;3. The sprue.Mumhanyi anofanira kunge akafara uye akareba sezvinobvira, uye nzvimbo ye sprue inofanira kuiswa maererano ne shrinkage condensation process, uye matsime emvura anotonhora anofanira kuwedzerwa kana zvichidiwa;4. Pamusoro pe mold inofanira kuva yakajeka uye yakachena, ine yakaderera roughness (zvichida zvishoma kudarika 0.8);5. Gomba rekupinza mhepo.Iyo slot inofanira kunge yakakwana kuburitsa mhepo uye gasi mukunyungudika nenguva;6. Kunze kwePET, ukuru hwemadziro hahufanire kunge hwakaonda, kazhinji kwete pasi pe1mm.

Matambudziko anofanirwa kucherechedzwa mukuita jekiseni molding process (kusanganisira izvo zvinodiwa nemushini wekuumba jekiseni)

Kuti uderedze kushushikana kwemukati nekuremara kwepamusoro, zvinotevera zvikamu zvejekiseni molding process zvinofanirwa kucherechedzwa.

1, inofanirwa kushandisa siruu yakakosha, ine yakaparadzana tembiricha-inodzorwa jekiseni jekiseni jekiseni muchina;2, tembiricha yejekiseni mupurasitiki resin haina kuora nzvimbo, zvakakodzera kushandisa tembiricha yepamusoro yejekiseni;3, kudzvinyirirwa kwejekiseni: kazhinji kukwirira kukunda hurema hwekunyungudika viscosity, asi kudzvanywa kwakanyanya kunoburitsa kushushikana kwemukati kunokonzerwa nekunetseka kuburitswa uye deformation;4, jekiseni kumhanya: kusangana nenyaya yekuzadza mold, kazhinji inofanira kunge yakaderera, zviri nani kushandisa inononoka-inokurumidza-inononoka yakawanda-nhanho jekiseni 5, kubata nguva uye kuumbwa kutenderera: mune yekusangana nekuzadza chigadzirwa, hapana kubondera, bubble;inofanira kuva pfupi sezvinobvira, kuitira kuderedza kunyunguduka mubhari yekugara nguva;6, screw speed uye back pressure: muchimiro chekusangana nemhando yeplasticization, inofanira kunge yakaderera sezvinobvira, kudzivirira mukana wekuderera;7, tembiricha yekuumbwa: kutonhora kwechigadzirwa kwakanaka kana kwakaipa, kukanganisa kwemhando kwakanaka, saka tembiricha yekuumbwa inofanirwa kukwanisa kunyatso kudzora maitiro.Kana zvichibvira, kupisa kwe mold kunofanira kunge kwakakwirira.

Zvimwe zvinhu

Kudzivirira kushatisa kwemhando yepamusoro, iyo yekuburitsa mumiriri inofanirwa kushandiswa zvishoma panguva yekuumbwa kwejekiseni;kana uchishandisa zvakashandiswa zvakare hazvifanirwe kunge zvakakura kupfuura 20%.

Kune zvigadzirwa kunze kwePET, mushure mekurapa kunofanirwa kuitwa kubvisa kushushikana kwemukati.PMMA inofanira kuomeswa pa 70-80 ° C kwemaawa mana mumhepo inopisa;PC inofanira kuomeswa mumhepo yakachena, glycerine.Liquid parafini nezvimwe zvinopisa pa110-135 ° C uye nguva inobva pane chigadzirwa, kusvika maawa anopfuura gumi anodiwa.PET, kune rumwe rutivi, inofanirwa kuita bi-directional kutambanudza maitiro kuitira kuti iwane yakanaka ma mechanic properties.

Jekiseni molding inoshandiswa zvakanyanya mumaindasitiri akasiyana siyana uye inogona kuwana isina musono, chaiyo misa kugadzirwa kwezvikamu munguva pfupi.Nhoroondo yeProLean Techinopa majekiseni ekuumba masevhisi ezvakawanda zvezvinhu, zvinosanganisira mapurasitiki uye elastomers.Simplyrodha modhi yakouye tora yekukurumidza yemahara quote uye zano pane ane hukama masevhisi.

Nguva yekutumira: Kubvumbi-11-2022