Yuav ua li cas kom muaj kev ruaj ntseg ntawm pob tshab yas txhaj tshuaj molding - FAQ qhia

Lub sijhawm nyeem ntawv kwv yees:4 feeb,55s

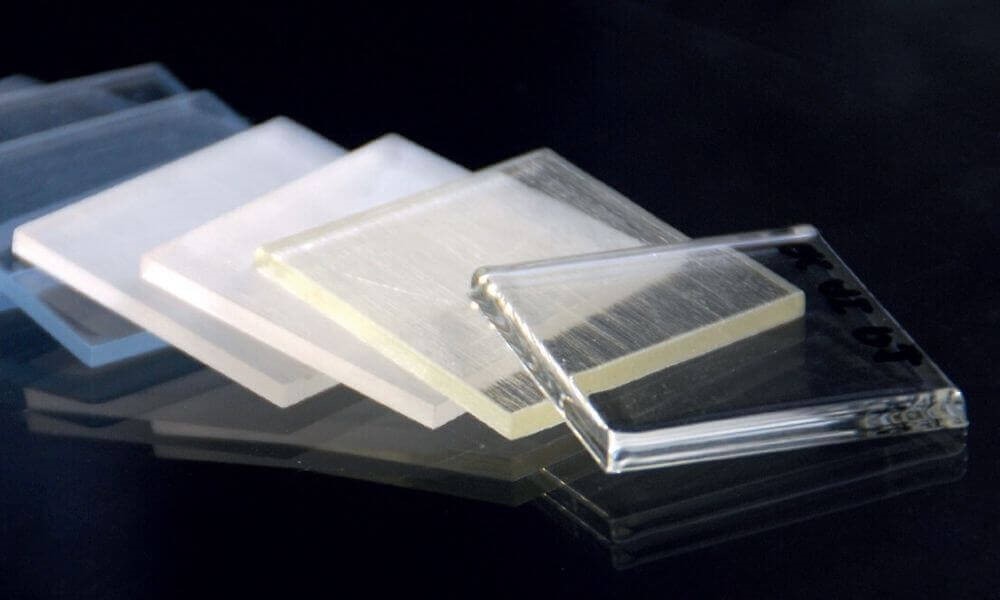

Pob tshab yas pellets

Nrog rau qhov zoo ntawm lub teeb yuag, zoo toughness, yooj yim ntawm molding thiab tsis tshua muaj nqi, yas yog nce hloov iav nyob rau hauv ntau daim ntawv thov, tshwj xeeb tshaj yog nyob rau hauv lub optical instrument thiab ntim industries, uas yog tsim sai heev.Txawm li cas los xij, cov cuab yeej kho qhov muag thiab kev lag luam ntim khoom muaj cov kev xav tau siab hauv cov ntsiab lus ntawm pob tshab, durability, cuam tshuam tsis kam thiab toughness.Yog li ntawd, yuav tsum tau them nyiaj mloog mus rau lubraw khoom, txheej txheem, khoom siv thiab pwmlos xyuas kom meej tias cov khoom yas ua tau raws li qhov yuav tsum tau ua ntawm cov khoom.Koj tuaj yeem ua tautiv tauj peb cov engineersncaj qha rau kev sab laj dawb.

Pob tshab daim npav yas

Cov pob tshab yas yuav tsum ua ntej muaj qhov siab ntawm cov pob tshab, qhov thib ob lawv yuav tsum muaj qee yam ntawm lub zog thiab kev puas tsuaj, muaj peev xwm tiv taus qhov cuam tshuam, muaj cua sov zoo, muaj tshuaj lom neeg zoo thiab muaj qhov nqus dej tsawg, tsuas yog tom qab ntawd tuaj yeem ua tau. lawv ua tau raws li qhov yuav tsum tau ua kom pom tseeb hauv kev siv thiab nyob twj ywm tsis hloov mus ntev.PPT yog siv rau hauv ntim thiab ntim khoom vim nws yuav tsum tau ncab kom tau txais cov khoom zoo.

Raw khoom impurities, kom qhuav

Thaum lub sij hawm sau cov txheej txheem, yuav tsum tau them nyiaj mloog mus rau sealing thiab xyuas kom meej tias cov khoom raw yog huv si.Tshwj xeeb, cov dej noo uas muaj nyob rau hauv cov khoom siv raw tuaj yeem ua rau tsis zoo tom qab cua sov, yog li nws yuav tsum tau qhuav, thiab nyob rau hauv kev txhaj tshuaj molding, cov khoom yuav tsum tau muab ntxiv siv lub hopper qhuav.Lwm lub ntsiab lus yuav tsum nco ntsoov yog tias thaum lub sij hawm ziab, cov cua nkag yuav tsum zoo dua yog lim thiab dehumidified kom ntseeg tau tias nws tsis paug cov khoom siv raw.

Txhaj siab thiab ceev

Thib ob, raws li cov yas pob tshab muaj qhov siab melting point thiab cov dej ntws tsis zoo, txhawm rau ua kom lub ntsej muag zoo ntawm cov khoom, lub chim kub, kev txhaj tshuaj siab, kev txhaj tshuaj nrawm thiab lwm yam txheej txheem yuav tsum tau kho kom zoo kom cov yas txhaj tshuaj tuaj yeem sau cov ntaub ntawv. pwm thiab tsis tsimsab hauv kev ntxhov siab thiab ua rau cov khoom deformation thiab tawg.

Ntxuav cov thoob, screws thiab accessories

Txhawm rau tiv thaiv kev kis kab mob ntawm cov khoom siv raw thiab hauv cov ntsia hlau thiab kev nyuaj siab muaj cov ntaub ntawv qub lossis cov khoom tsis huv, tshwj xeeb tshaj yog tsis zoo thermal stability ntawm cov resin tam sim no, yog li ua ntej siv, tom qab kaw yog siv rau cov ntsia hlau tu tus neeg saib xyuas tu.

Kev nres ib ntus kom txo tau qhov kub thiab txias

Thaum nres ib ntus, txhawm rau tiv thaiv cov ntaub ntawv raw hauv qhov kub siab nyob rau lub sijhawm ntev, ua rau degradation, lub tshuab ziab khaub ncaws thiab lub thoob kub yuav tsum tau txo, xws li PC, PMMA thiab lwm yam kub kub yuav tsum tau txo kom 160 ℃ los yog tsawg dua. .(Hopper kub rau PC yuav tsum raug txo kom qis dua 100 ℃)

Cov teeb meem yuav tsum tau muab sau tseg hauv kev tsim pwm (nrog rau kev tsim cov khoom)

Txhawm rau tiv thaiv tsis zoo rov qab los, lossis qhov txias tsis sib xws uas ua rau cov yas pwm tsis zoo, qhov chaw tsis zoo thiab lwj.

Feem ntau, cov ntsiab lus hauv qab no yuav tsum raug sau tseg hauv kev tsim pwm.

1. Lub phab ntsa thickness yuav tsum yog li niaj zaus raws li qhov ua tau thiab qhov tso tawm txoj kab nqes yuav tsum loj txaus;2. Qhov kev hloov pauv yuav tsum tau maj mam Round thiab du, kom tsis txhob muaj cov ces kaum ntse.Cov npoo ntse yog tsim, tshwj xeeb tshaj yog rau cov khoom PC yuav tsum tsis txhob muaj qhov khoob;3. Lub sprue.Tus khiav yuav tsum dav thiab tuab li qhov ua tau, thiab qhov chaw ntawm lub sprue yuav tsum tau teem raws li cov txheej txheem shrinkage condensation, thiab cov khoom txias txias yuav tsum tau ntxiv yog tias tsim nyog;4. Qhov saum npoo ntawm cov pwm yuav tsum ci thiab huv si, tsis tshua muaj roughness (zoo dua tsawg dua 0.8);5. Lub qhov cua qhov cua.Lub qhov yuav tsum txaus kom tso pa tawm ntawm huab cua thiab cov roj hauv lub sijhawm yaj;6. Tsuas yog PET, phab ntsa tuab yuav tsum tsis txhob nyias dhau, feem ntau tsis pub tsawg tshaj 1 hli.

Cov teeb meem yuav tsum tau muab sau tseg hauv cov txheej txheem txhaj tshuaj molding (nrog rau cov kev cai ntawm lub tshuab txhaj tshuaj molding)

Txhawm rau txo qis kev ntxhov siab sab hauv thiab qhov tsis zoo ntawm qhov chaw, cov hauv qab no ntawm cov txheej txheem txhaj tshuaj molding yuav tsum raug sau tseg.

1, yuav tsum tau siv ib tug tshwj xeeb ntsia hlau, nrog ib tug cais kub-tswj txhaj nozzle txhaj molding tshuab;2, txhaj tshuaj kub nyob rau hauv cov yas resin tsis decompose qhov chaw, nws yog tsim nyog los siv ib tug ntau dua txhaj tshuaj kub;3, kev txhaj tshuaj siab: feem ntau siab dua los kov yeej qhov tsis xws ntawm cov viscosity yaj, tab sis lub siab siab dhau lawm yuav ua rau muaj kev ntxhov siab sab hauv los ntawm kev tso tawm nyuaj thiab deformation;4, kev txhaj tshuaj ceev: kom ua tau raws li cov ntaub ntawv sau pwm, feem ntau yuav tsum qis, nws yog qhov zoo tshaj plaws los siv qeeb-ceev-slow multi-theem txhaj tshuaj 5, tuav lub sij hawm thiab molding voj voog: nyob rau hauv rooj plaub ntawm kev sib ntsib cov khoom filling, tsis muaj dents, npuas;yuav tsum tau luv luv li sai tau, thiaj li yuav txo tau cov yaj nyob rau hauv lub thoob lub sij hawm;6, ntsia hlau ceev thiab rov qab siab: nyob rau hauv qhov chaw ntawm kev ua tau zoo ntawm plasticization, yuav tsum tau tsawg li tsawg tau, tiv thaiv tau decompression;7, pwm kub: qhov txias ntawm cov khoom yog qhov zoo lossis tsis zoo, qhov cuam tshuam rau qhov zoo yog qhov zoo, yog li pwm kub yuav tsum muaj peev xwm tswj tau cov txheej txheem kom raug.Yog tias ua tau, pwm kub yuav tsum siab dua.

Lwm yam

Txhawm rau tiv thaiv qhov tsis zoo ntawm qhov chaw zoo, tus neeg sawv cev tso tawm yuav tsum tau siv me ntsis thaum lub sijhawm txhaj tshuaj molding;Thaum siv cov khoom siv rov siv dua nws yuav tsum tsis txhob siab dua 20%.

Rau cov khoom uas tsis yog PET, kev kho mob tom qab yuav tsum tau ua kom tshem tawm cov kev ntxhov siab sab hauv.PMMA yuav tsum tau qhuav ntawm 70-80 ° C rau 4 teev nyob rau hauv lub voj voog cua kub;PC yuav tsum tau qhuav hauv huab cua huv, glycerine.Kua paraffin thiab lwm yam yog rhuab ntawm 110-135 ° C thiab lub sij hawm nyob ntawm cov khoom, mus txog rau ntau tshaj 10 teev yuav tsum tau.PET, ntawm qhov tod tes, yuav tsum tau ua cov txheej txheem ob-txoj kev ncab kom thiaj li tau txais cov khoom zoo.

Txhaj tshuaj molding yog dav siv nyob rau hauv ntau yam lag luam thiab muaj peev xwm ua tau seamless, precision loj ntau lawm ntawm qhov chaw nyob rau hauv ib lub sij hawm luv luv.ProLean Techmuaj kev txhaj tshuaj molding rau kaum ob ntawm cov ntaub ntawv, nrog rau cov yas thiab elastomers.Tsuas yogupload koj tus qauvthiab tau txais cov lus qhia dawb ceev thiab cov lus qhia txog cov kev pabcuam cuam tshuam.

Lub sij hawm xa tuaj: Plaub Hlis-11-2022