Izinqubo Ezivamile Zokuqeda Ubuso Beshidi Lensimbi

Isikhathi sokufunda esilinganiselwe:8 amaminithi, 3 imizuzwana

Ukukhetha indawo efanele yokuqeda ingaphezulu kubalulekile ekufezeni umsebenzi nokubukeka kwengxenye yomklamo.Ama-surface finishes ahlukene anganikeza ukuqedwa okuhlukene kanye nokuthungwa.Isikhathi, impahla, amathuluzi kanye lula ukucubungulanazo ziyizici okufanele zicatshangelwe.Ngakho-ke, kubalulekile ukuqonda ezinye zezindlela zokwelapha ezivamile ukuze uqinisekise ukuthi okulungile kukhethwa kusukela ekuqaleni.Kulesi sihloko, sizochaza ezinye zezindlela zokwelapha ezivame kakhulu.Ungakwazi futhixhumana nonjiniyela bethu ngqo ngokubonisana mahhala.

I-Electroplating:Kusixazululo se-electroplating, ama-ion ashajwe ngogesi anamathiselwe ebusweni bomkhiqizo ngaphansi kwesenzo senkambu kagesi ukuze kwakhe ungqimba lokucwenga.

Ukufutha ngempushana: Ukufafaza ngempushana kuyinqubo yokumboza esebenzisa ukukhishwa kwe-corona ukwenza izimbotshana zohlobo lwempushana zinamathele kucwecwe lokusebenza.Ngemuva kokufafaza kwe-powder bese kulandela izinyathelo ezishisayo zokuncibilika nokuphulukisa, kuzokwakhiwa ifilimu yokumboza ebusweni bomsebenzi.

I-Electrophoresis:Inqubo ye-electrophoresis ihlukaniswe yabai-anodic electrophoresisfuthii-cathodic electrophoresis.Uma izinhlayiya zepende zikhokhiswa kabi futhi i-workpiece iyi-anode, izinhlayiya zepende zifakwa endaweni yokusebenza ngaphansi kwesenzo senkambu kagesi ukuze zenze ifilimu ebizwa ngokuthi i-anodic electrophoresis;ngokuphambene, uma izinhlayiya zopende zikhokhiswa kahle futhi i-workpiece iyi-cathode, izinhlayiya zepende zifakwa ku-workpiece ukuze zenze ifilimu ebizwa ngokuthi i-cathodic electrophoresis.

Ukucwiliswa kwepulasitiki: I-alias yokucwilisa ipulasitiki eyaziwa nangokuthi i-plastic coating, ipulasitiki yokucwilisa ukushisa, ukushisa kusetshenziswe i-plastic coating.I-Dip molding (i-plastic coating) iyinqubo yokugqoka ipulasitiki.Ngokusho kwezinto zokusetshenziswa ezihlukene ezisetshenziswa ekubumbeni idiphu zingahlukaniswa zibei-liquid dip (i-coating)plastic kanyei-powder dip (ukugqoka)ipulasitiki.Imikhiqizo yepulasitiki ye-Dip isetshenziswe kakhulu ezicini ezihlukahlukene zokukhiqiza nokuphila ekhaya nakwamanye amazwe, njengokuthi: izingubo zethu zansuku zonke zokumisa i-hanger, ama-pliers, isikelo esisembozweni senjoloba, i-valve wrench yamanzi, njll.

I-oxidation: i-oxidation yensimbi ebusweni bomsebenzi, ukwakha ifilimu evikelayo eqinile ebusweni bomsebenzi, okwandisa ukumelana nokugqwala kwe-workpiece.Ngokuvamile kunezinhlobo ezimbili ze-oxidation: i-chemical oxidation kanye ne-anodic oxidation.Kuyindlela evamile yokwelashwa kwendawo.

Ukuxubha:Ukuxubha okungaphezulu ukwelapha okungaphezulu okwakha iphethini yomugqa endaweni yokusebenza ngokusebenzisa imikhiqizo e-abrasive ukunikeza umphumela wokuhlobisa.Ngoba ukwelashwa kokuxubha okungaphezulu kungabonisa ukuthungwa kwezinto zensimbi, ngakho-ke kuye kwathandwa abasebenzisi abaningi kakhulu futhi basetshenziswa kabanzi.

Upende wokubhaka: tUkufafaza, ukushisa okuphezulu okubhaka, njll., ebusweni bento efafazwe ngemibala ehlukahlukene kapende esetshenziselwa ukuhlobisa ukubukeka futhi kungandisa izakhiwo zokulwa nokugqwala, ngokuvamile kukhona upende wokubhaka owuketshezi kanye nopende wokubhaka oyimpushana, okuyimpushana. upende wokubhaka uvame kakhulu, indawo yokubhaka yokubhaka ayihambisani, izidingo ze-EMC zesifunda azivumeli upende wokubhaka.

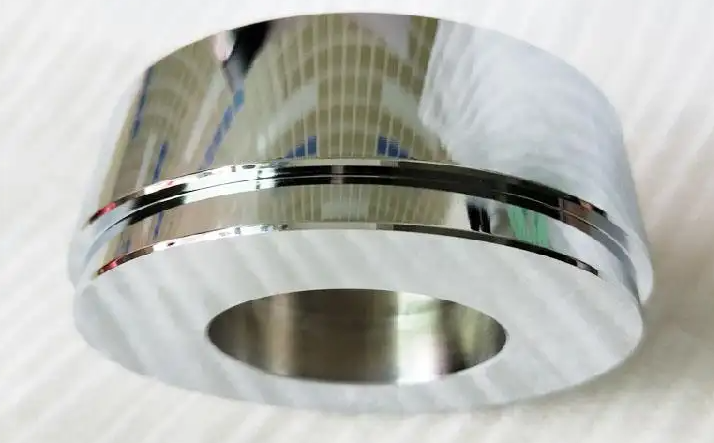

Inqubo yokwelapha ebusweni - i-electroplating

Kufakwe amagalani

Ipayipi lensimbi eliphehliwe

1, I-cyanide galvanizing

2, Zincate galvanizing

3, I-Chloride ifakwe i-galvanized

4, i-sulfate galvanizing

Imboni yokugalela amanzi iyimboni engcolisayo, nakuba isetshenziswa kabanzi futhi inezindleko eziphansi, ayihlangabezani nezindinganiso ze-ROHS, ngakho-ke zama ukungasebenzisi imikhiqizo enamakha.

I-Chrome Plating

I-Chrome Plating

Umgomo wenqubo ufana nokufaka ama-galvanizing.

Uma kuqhathaniswa ne-electro-galvanization yendabuko;I-anti-corrosion enamandla kakhulu, izikhathi ezi-7-10 ezingcono kune-galvanization, kanye nendawo enhle, kodwa izindleko eziphezulu.

I-Dacromet, inqubo ye-chrome plating ethuthuke kakhulu, ubuchwepheshe obusha bokwelashwa kwendawo, uma kuqhathaniswa nenqubo yendabuko ye-electroplating, i-Dacromet "i-plating eluhlaza".

Inqubo yokwelapha ebusweni - ukumbozwa ngempushana

I-Powder Coating

Umgomo wenqubo yokuhlanganisa impuphu:

I-electrostatic powder spraying:ikakhulukazi ngokusebenzisa ama-electrode ukuze upende upende (impuphu), bese ufafazwa entweni ngecala eliphambene, emandleni kagesi ngaphansi kwesenzo sempushana exhunywe ngokulinganayo ebusweni bento.

Izici zenqubo ye-powder coating:

Ukufafaza nge-powder electrostaticngeke kubangele ukungcoliswa komoya, impushana ingaphinda isetshenziswe ukuze kuncishiswe izindleko zokusetshenziswa kwezinto ezibonakalayo, ukumboza ukusebenza kwefilimu okuphakeme ukumelana ne-asidi, ukumelana ne-alkali, ukumelana nokugqwala kukasawoti kungcono, ukunamathela nakho kuphakeme.

Inqubo yokwelapha ebusweni - i-electrophoresis

Ingxenye ye-Electrophoresis

Umgomo wenqubo ye-electrophoresis:

Inqubo ye-electrophoresis ihlukaniswe yabai-anodic electrophoresisfuthii-cathodic electrophoresis.Uma izinhlayiya zepende zikhokhiswa kabi, i-workpiece iyi-anode, futhi izinhlayiya zepende zifakwe ku-workpiece ngaphansi kwesenzo samandla kagesi wenkundla ukuze enze ifilimu ebizwa ngokuthi i-anodic electrophoresis;ngokuphambene, uma izinhlayiya zopende zikhokhiswa kahle, i-workpiece yi-cathode, futhi izinhlayiya zepende zifakwe ku-workpiece ukuze zenze ifilimu ebizwa ngokuthi i-cathodic electrophoresis.

Izici zei-anodic electrophoresisyilezi: izinto zokusetshenziswa ezishibhile (ngokuvamile ezishibhile ngo-50% kune-cathodic electrophoresis);imishini elula (ngokuvamile eshibhile ngo-30% kune-cathodic electrophoresis);izidingo zobuchwepheshe eziphansi;ukumelana nokugqwala okumpofu kwe-coating kune-cathodic electrophoresis (cishe i-1/4 yempilo ye-cathodic electrophoresis).

Isizathu sokumelana nokugqwala okuphezulu kwei-cathodic electrophoresisukugqoka: i-workpiece yi-cathode, akukho ukuchithwa kwe-anodic, indawo yokusebenza kanye nefilimu ye-phosphate ayibhujiswa;ama-electrophoretic coatings (ngokuvamile ama-resin aqukethe i-nitrogen) anomphumela wokuvikela ensimbi.

Izici zenqubo yokwelashwa kwendawo ye-electrophoretic:

Ifilimu yokupenda ye-Electrophoreticinezinzuzo ze-plump, iyunifomu, i-flat and smooth coating, futhi ubulukhuni, ukunamathela, ukumelana nokugqwala, ukusebenza komthelela kanye nokusebenza kokungena kwefilimu kapende we-electrophoretic kungcono kakhulu kunezinye izinqubo zokugqoka.

Umbala ojwayelekile we-electrophoresis umnyama kakhulu, kanti neminye imibala iyatholakala.

Inqubo yokwelapha ebusweni- Ukucwiliswa kwepulasitiki

Ingxenye yokucwilisa yepulasitiki

Inqubo yenqubo yokucwilisa ipulasitiki:

Ukucwilisa ipulasitiki (i-plastic coating) kuyinqubo yokuhlanganisa ipulasitiki.Ngokwezinto zokusetshenziswa ezihlukene ezisetshenziselwa ukucwilisa ipulasitiki zingahlukaniswa zibe ipulasitiki yokucwilisa uketshezi (i-coating) kanye nepulasitiki yokucwilisa eyimpushana (yokunamathela).Imikhiqizo yepulasitiki ye-Dip isetshenziswe kakhulu ezicini ezihlukahlukene zokukhiqiza nokuphila, njengokumisa iziphanyeko zezingubo, ama-pliers, isikelo emkhonweni wenjoloba, i-valve wrench yamanzi, njll.

Izici zenqubo yokucwilisa ipulasitiki:

Ukusetshenziswa okubanzi, umbala ocebile, ukuvikeleka okuhle, ukumelana nokubanda okuhle kakhulu, ukulondolozwa kokushisa, ukumelana ne-asidi kanye ne-alkali.

Inqubo yokwelapha ebusweni-i-oxidation

| I-Chemical oxidation | I-Anodic oxidation | |

| Izici Zenqubo | Izindleko eziphansi, zingakhiqizwa ngokuqhubekayo ngamanani amakhulu | Izindleko eziphakeme |

| Inqubo ezinzile, ukusebenza okulula, imishini elula, ukugcinwa okulula kwesixazululo, akukho mingcele ngosayizi nokuma kwezingxenye | Ngenxa yesidingo sokunikezwa kwamandla kwangaphandle.Usayizi wengxenye kanye nokuma kuthinta izintambo zamandla | |

| I-Chemical oxidation ingenzeka ngensimbi, i-aluminium, ithusi, isiliva, i-zinc, ithini, i-cadmium nama-alloys ayo.Ngaphezu kwalokho, i-chemical oxidation isetshenziswe ngemiphumela egculisayo kwezinye izinhlelo zokusebenza ezisebenzayo.Ngenxa yalokho, ubuchwepheshe be-chemical oxidation buye bathuthukiswa kakhulu eminyakeni yamuva. | Okuvame ukusetshenziselwa i-anodizing materials njenge-aluminium nama-alloys ayo, i-magnesium ne-magnesium alloys, ne-titanium nama-alloys ayo. | |

| Izimpawu Zesendlalelo Sefilimu | Ifilimu ezacile, ngokuvamile iwugqinsi wama-microns angu-0.5-4 | Ifilimu ewugqinsi |

| Ukuthungwa okuthambile, okungabambisi, ukugqwala okuphansi kanye nokumelana nemihuzuko kune-anodic oxidation | Ukumelana nokugqwala okuhle, ubulukhuni obuphezulu | |

| Ingasetshenziselwa ukuthola izendlalelo ezithile ezisebenzayo amafilimu ane-anodized angakwazi ukuba nazo, njengezendlalelo ze-conductive oxide | Izendlalelo ezithile zefilimu ezisebenzayo zingatholakala, njengokufakwa kwama-alloys kazibuthe kumafilimu anezimbotshana zokulondoloza izinto.Ipuleti le-absorber yelanga, ifilimu eqinile kakhulu, njll. |

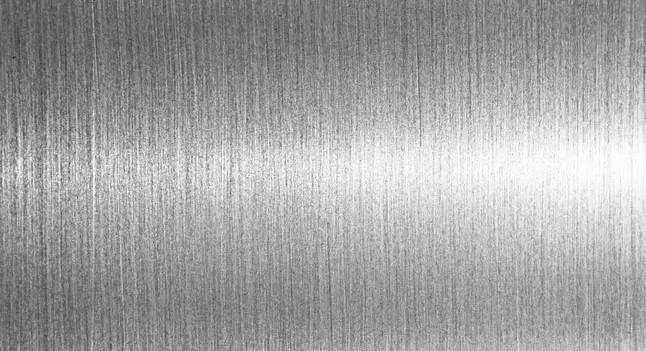

Inqubo yokwelapha ebusweni - ukuxubha

Insimbi exutshiwe

Inokumelana nokugqokwa okuhle kakhulu, ukumelana nezinga lokushisa eliphezulu, ukumelana nokugqwala kanye nokugcinwa okulula kwansuku zonke, ukuthungwa okuhle, ukuhlanzeka okulula kakhulu, impilo ende.

Amaphaneli ezinto zikagesi zasekhaya Imikhiqizo ehlukahlukene yedijithali namaphaneli namaphaneli Amaphaneli elaptop, asetshenziselwa ukwenza amalogo ahlukahlukene, amaswishi e-membrane, ama-nameplates, njll.

Ikesi lekhadi lebhizinisi lensimbi elixutshiwe

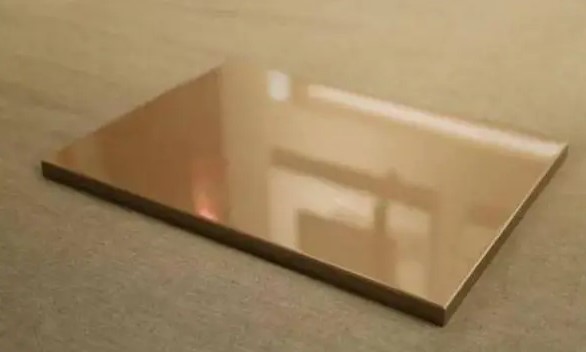

Inqubo yokwelapha ngaphezulu - upende wokubhaka

I-Baking Paint

Baking upende ihlukaniswe yaba izigaba ezimbili, a low-temperature baking ephulukisa izinga lokushisa 140 ° -180 °, esinye isigaba ubizwa ngokuthi izinga lokushisa eliphezulu baking ngopende, lokushisa yayo elapha 280 ° -400 °.

Izinzuzo ze-baking paint:

1, imibala egqamile nezitayela eziningi.

2, kulula ukuhlanza nokunakekela.

3, amaphaneli eminyango kapende wokubhaka omuhle, aqine kakhulu kunamaphaneli eminyango yekristalu ukumelana ne-UV.

4, ukwandisa isikhala ekhishini kunomphumela othile wokukhanya ohambisanayo.

Ukubi ngopende wokubhaka.

Umjikelezo wokukhiqiza mude kakhulu, izinga lobuchwepheshe lidinga izinga eliphezulu le-scrap, ngakho-ke intengo iphezulu, isaba ukungqongqoza nokuklwebheka, lapho umonakalo kunzima ukulungisa, ukufaka esikhundleni sayo yonke;intuthu eyengeziwe ekhishini ethambekele ekuhlukeni kombala.

Ukubumba komjovo kusetshenziswa kabanzi ezimbonini ezahlukahlukene futhi kungafinyelela ukukhiqizwa kwezingxenye ezingenamthungo nokunembe kwezingxenye ngesikhathi esifushane.I-Prolean Tech inikezela ngezinsizakalo zokubumba umjovo zenqwaba yezinto, kufaka phakathi amapulasitiki nama-elastomer.Vele ulayishe eyakhoIfayela le-CADukuthola ikhwotheshini esheshayo, yamahhala kanye nokubonisana ngamasevisi ahlobene.

Isikhathi sokuthumela: Apr-06-2022