Common Surface Finishing Processes for Sheet Metal Materials

Lub sijhawm nyeem ntawv kwv yees:8 nqi,3sn

Xaiv qhov zoo saum npoo tiav yog qhov tseem ceeb rau kev ua tiav cov haujlwm thiab cov tsos ntawm qhov tsim.Kev sib txawv ntawm qhov chaw tiav tuaj yeem muab qhov sib txawv thiab textures.Lub sijhawm, cov khoom siv, cov cuab yeej thiab kev ua haujlwm yooj yimkuj yog yam uas yuav tsum tau xav txog.Yog li ntawd, nws yog ib qho tseem ceeb kom nkag siab txog qee qhov kev kho mob saum npoo kom paub meej tias qhov zoo yog xaiv los ntawm qhov pib.Nyob rau hauv tsab xov xwm no, peb yuav piav qhia txog qee yam ntawm cov kev kho mob feem ntau.Koj tuaj yeem ua tautiv tauj peb cov engineers ncaj qha rau kev sab laj dawb.

Electroplating:Nyob rau hauv ib qho kev daws teeb meem electroplating, electrostatically them ions txuas rau saum npoo ntawm cov khoom nyob rau hauv qhov kev txiav txim ntawm hluav taws xob teb los tsim ib txheej plating.

Hmoov txau: Hmoov txau yog txheej txheej txheej uas siv corona tawm los ua hmoov-hom txheej ua raws li cov khoom ua haujlwm.Tom qab cov hmoov txau thiab tom qab ntawd kub melting thiab kho cov kauj ruam, ib txheej zaj duab xis yuav raug tsim rau ntawm qhov chaw ntawm lub workpiece.

Electrophoresis:Cov txheej txheem electrophoresis tau muab faib uaanodic electrophoresisthiabcathodic electrophoresis.Yog tias cov xim pleev xim tsis zoo thiab cov khoom ua haujlwm yog cov anode, cov xim pleev xim rau hauv qhov chaw ua haujlwm nyob rau hauv qhov kev txiav txim ntawm hluav taws xob teb los ua ib zaj duab xis hu ua anodic electrophoresis;Piv txwv li, yog tias cov xim pleev xim tau zoo thiab cov khoom ua haujlwm yog cathode, cov xim pleev xim tau tso rau hauv qhov chaw ua haujlwm los tsim cov yeeb yaj kiab hu ua cathodic electrophoresis.

Yas dipping: Yas dipping alias tseem hu ua yas txheej, cua sov dipping yas, kub siv yas txheej.Dip molding (yas txheej) yog txheej txheej yas.Raws li cov khoom siv sib txawv siv hauv dip molding tuaj yeem muab faib uakua nplaum (coating)yas thiabhmoov dip (coating)yas.Cov khoom siv yas dip tau siv dav hauv ntau yam ntawm kev tsim khoom thiab lub neej nyob hauv tsev thiab txawv teb chaws, xws li: peb cov khaub ncaws txhua hnub ziab khaub ncaws, pliers, txiab ntawm lub hau roj hmab, dej valve wrench, thiab lwm yam.

Oxidation: oxidation ntawm cov hlau nyob rau saum npoo ntawm lub workpiece, tsim ib tug ntom tiv thaiv zaj duab xis nyob rau saum npoo ntawm lub workpiece, ua rau corrosion kuj ntawm lub workpiece.Feem ntau muaj ob hom oxidation: tshuaj oxidation thiab anodic oxidation.Nws yog ib txoj kev kho saum npoo.

txhuam hniav:Kev txhuam hniav nto yog kev kho deg uas tsim cov kab qauv ntawm qhov chaw ua haujlwm los ntawm cov khoom siv abrasive los muab cov nyhuv zoo nkauj.Vim tias qhov kev kho mob txhuam hniav tuaj yeem cuam tshuam qhov kev ntxhib los mos ntawm cov ntaub ntawv hlau, yog li nws tau hlub los ntawm cov neeg siv ntau thiab ntau thiab ntau thiab siv ntau dua.

Baking xim: tthrough spraying, kub kub ci, thiab lwm yam., nyob rau saum npoo ntawm cov khoom siv txau nrog ntau yam xim ntawm cov xim siv los ua kom zoo nkauj thiab tuaj yeem ua rau kom muaj kev tiv thaiv corrosion, feem ntau muaj cov kua ci ci thiab cov hmoov ci xim, ntawm cov hmoov nplej. ci xim yog qhov feem ntau, ci xim ntawm qhov chaw tsis muaj hluav taws xob, EMC cov cai hauv cheeb tsam tsis tso cai rau cov xim ci.

Cov txheej txheem kho deg - electroplating

Galvanized

Galvanized steel yeeb nkab

1, Cyanide galvanizing

2, Zinc galvanizing

3, chloride galvanized

4, Sulfate galvanizing

Galvanizing kev lag luam yog kev lag luam muaj kuab paug, txawm tias siv dav thiab tus nqi qis, nws tsis ua raws li ROHS cov qauv, yog li sim tsis txhob siv cov khoom siv galvanized.

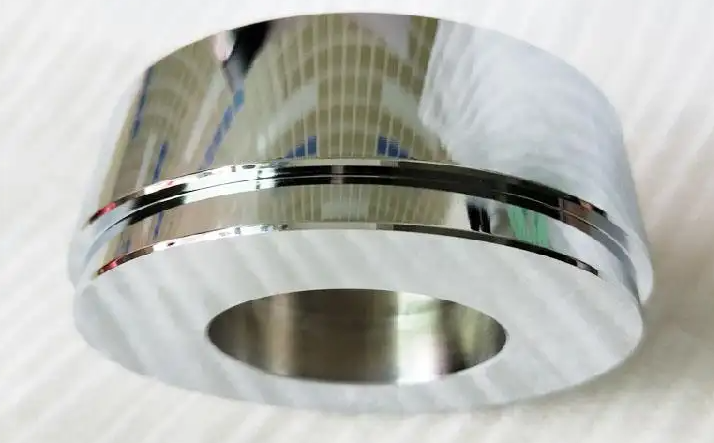

Chrome Plating

Chrome Plating

Cov txheej txheem txheej txheem yog tib yam li galvanizing.

Piv nrog cov tsoos electro-galvanization;tsis tshua muaj zog tiv thaiv corrosion, 7-10 npaug zoo dua galvanization, thiab zoo nkauj nto, tab sis tus nqi siab dua.

Dacromet, cov txheej txheem chrome plating siab tshaj plaws, yog cov cuab yeej kho tshiab saum npoo av, piv nrog cov txheej txheem electroplating, Dacromet yog "ntsuab plating".

Kev kho deg txheej txheem ntawm - hmoov txheej

Hmoov Txheej

Hmoov txheej txheej txheem txheej txheem:

Electrostatic hmoov txau:Feem ntau yog los ntawm electrodes los polarize cov xim (hmoov), thiab tom qab ntawd yuav tsum tau txau rau ntawm cov khoom nrog tus nqi sib txawv, nyob rau hauv lub zog hluav taws xob nyob rau hauv qhov kev txiav txim ntawm cov hmoov uniformly txuas rau saum npoo ntawm cov khoom.

Nta ntawm hmoov txheej txheej txheem:

Hmoov electrostatic txauyuav tsis ua rau huab cua muaj kuab paug, hmoov tuaj yeem rov ua dua los txo cov nqi ntawm cov khoom siv, txheej zaj duab xis kev ua tau zoo dua acid tsis kam, alkali tsis kam, ntsev corrosion kuj zoo dua, adhesion kuj siab dua.

Kev kho deg txheej txheem ntawm - electrophoresis

Electrophoresis ib feem

Txheej txheem txheej txheem ntawm electrophoresis:

Cov txheej txheem electrophoresis tau muab faib uaanodic electrophoresisthiabcathodic electrophoresis.Yog tias cov xim pleev xim tsis zoo, cov khoom ua haujlwm yog anode, thiab cov xim pleev xim rau ntawm qhov chaw ua haujlwm nyob rau hauv qhov kev txiav txim ntawm hluav taws xob teb quab yuam los ua ib zaj duab xis hu ua anodic electrophoresis;Piv txwv li, yog tias cov xim pleev xim tau zoo, lub workpiece yog cathode, thiab cov xim pleev xim tau tso rau ntawm qhov chaw ua haujlwm los tsim cov yeeb yaj kiab hu ua cathodic electrophoresis.

Cov yam ntxwv ntawmanodic electrophoresisyog: pheej yig raw khoom (feem ntau 50% pheej yig dua cathodic electrophoresis);Cov khoom siv yooj yim (feem ntau 30% pheej yig dua li cathodic electrophoresis);qis dua kev cai;tsis zoo corrosion kuj ntawm txheej tshaj cathodic electrophoresis (li 1/4 ntawm lub neej ntawm cathodic electrophoresis).

Yog vim li cas rau siab corrosion kuj ntawmcathodic electrophoresistxheej yog: lub workpiece yog lub cathode, tsis muaj anodic dissolution, lub workpiece nto thiab phosphate zaj duab xis yog tsis puas;electrophoretic coatings (feem ntau nitrogen-muaj resins) muaj kev tiv thaiv zoo ntawm cov hlau.

Cov yam ntxwv ntawm cov txheej txheem electrophoretic nto:

Electrophoretic xim zaj duab xismuaj qhov zoo ntawm plump, uniform, ca thiab du txheej, thiab hardness, adhesion, corrosion kuj, cuam tshuam kev ua tau zoo thiab nkag mus rau electrophoretic xim zaj duab xis yog ho zoo dua li lwm cov txheej txheem txheej.

Cov xim electrophoresis feem ntau yog xim dub, thiab lwm yam xim kuj muaj.

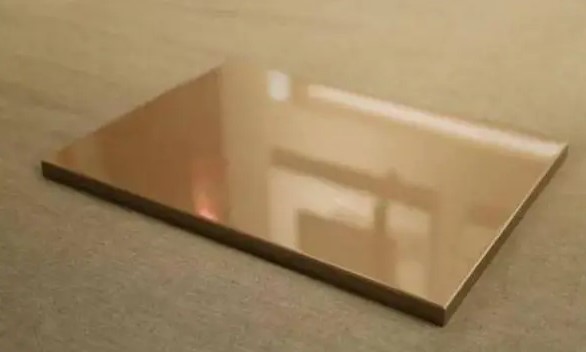

Txheej txheem kev kho deg- Yas dipping

Yas dipping ib feem

Txheej txheem txheej txheem ntawm dipping yas:

Dipping yas (yas txheej) yog txheej txheem txheej yas.Raws li cov khoom siv sib txawv siv rau dipping yas tuaj yeem muab faib ua kua dipping (txheej) yas thiab hmoov dipping (txheej) yas.Cov khoom siv yas dip tau siv dav hauv ntau yam ntawm kev tsim khoom thiab lub neej, xws li ziab khaub ncaws hangers, pliers, txiab ntawm lub tes tsho roj hmab, dej valve wrench, thiab lwm yam.

Txheej txheem cov yam ntxwv ntawm dipping yas:

Daim ntawv thov dav, nplua nuj xim, kev tiv thaiv zoo, zoo heev tiv taus txias, kub preservation, acid thiab alkali tsis kam.

Kev kho deg txheej txheem-oxidation

| Tshuaj oxidation | Anodic oxidation | |

| Txheej txheem nta | Tus nqi qis, tuaj yeem tsim tsis tu ncua hauv ntau qhov ntau | Tus nqi siab dua |

| Cov txheej txheem ruaj khov, kev ua haujlwm yooj yim, cov cuab yeej siv yooj yim, kev saib xyuas yooj yim ntawm kev daws, tsis muaj kev txwv ntawm qhov loj thiab cov duab ntawm qhov chaw | Vim qhov xav tau rau kev siv hluav taws xob sab nraud.Qhov loj me thiab cov duab cuam tshuam cov kab hluav taws xob | |

| Tshuaj oxidation yog ua tau rau hlau, txhuas, tooj liab, nyiaj, zinc, tin, cadmium thiab lawv cov alloys.Tsis tas li ntawd, tshuaj oxidation tau siv nrog cov txiaj ntsig zoo hauv qee qhov kev ua haujlwm.Yog li ntawd, tshuaj oxidation tshuab tau tsim muaj txiaj ntsig zoo nyob rau xyoo tas los no. | Feem ntau siv rau cov khoom siv anodizing xws li txhuas thiab nws cov alloys, magnesium thiab magnesium alloys, thiab titanium thiab nws cov alloys. | |

| Zaj duab xis txheej yam ntxwv | Nyias zaj duab xis, feem ntau 0.5-4 microns tuab | tuab zaj duab xis |

| Kev ntxhib los mos, tsis muaj abrasive, qis dua corrosion thiab abrasion tsis kam tshaj anodic oxidation | Zoo corrosion kuj, siab hardness | |

| Yuav siv tau kom tau txais qee cov txheej txheem ua haujlwm uas cov yeeb yaj kiab anodized tsis tuaj yeem muaj, xws li cov txheej txheem oxide conductive | Qee qhov tshwj xeeb ua haujlwm cov yeeb yaj kiab tuaj yeem tau txais, xws li tso cov hlau nplaum sib nqus hauv cov yeeb yaj kiab ntxeem tau rau cov khoom khaws cia.Hnub ci absorber phaj, ultra-hard zaj duab xis, thiab lwm yam. |

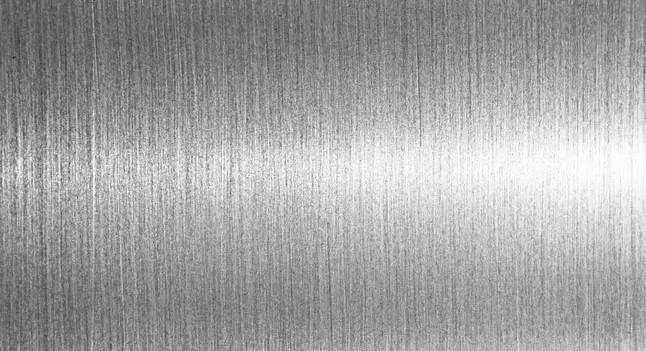

Kev kho deg txheej txheem ntawm - txhuam hniav

Txhuam hlau

Nws muaj kev hnav zoo heev, kub tsis kam, tiv thaiv corrosion thiab yooj yim txij nkawm txhua hnub, kev ntxhib los mos zoo nkauj, yooj yim heev los ntxuav, lub neej ntev.

Cov khoom siv hauv tsev Ntau yam khoom siv digital peripherals thiab panels Laptop panels, siv los ua ntau yam logos, membrane keyboards, nameplates, thiab lwm yam.

Brushed hlau ua lag luam daim npav rooj plaub

Kev kho deg txheej txheem ntawm - ci xim

Baking Xim

Cov xim ci yog muab faib ua ob pawg, qhov kub thiab txias ntawm qhov ci ci ntawm 140 ° -180 °, lwm yam yog hu ua high-temperature ci xim, nws qhov kub thiab txias ntawm 280 ° -400 °.

Qhov zoo ntawm ci xim:

1, ci xim thiab ntau yam.

2, yooj yim los ntxuav thiab tu.

3, zoo ci xim qhov rooj vaj huam sib luag, muaj zog ntau dua li siv lead ua qhov rooj vaj huam sib luag UV tsis kam.

4, txhawm rau kom qhov chaw ntawm chav ua noj muaj qee qhov ua kom pom kev zoo.

Baking xim tsis zoo.

Lub voj voog ntau lawm ntev dhau lawm, qib ntawm cov cuab yeej siv tshuab yuav tsum muaj cov khoom seem siab, yog li tus nqi siab, ntshai ntawm khob thiab khawb, ib zaug qhov kev puas tsuaj yog qhov nyuaj los kho, hloov tag nrho;ntau cov pa taws hauv chav ua noj ua rau muaj xim sib txawv.

Kev txhaj tshuaj molding yog dav siv nyob rau hauv ntau yam kev lag luam thiab tuaj yeem ua tiav seamless thiab meej ntau lawm ntawm cov khoom hauv lub sijhawm luv luv.Prolean Tech muab kev txhaj tshuaj molding rau kaum ob ntawm cov ntaub ntawv, suav nrog cov yas thiab elastomers.Tsuas yog upload kojCAD cov ntaub ntawvkom ceev, pub dawb hais thiab kev sab laj txog cov kev pabcuam cuam tshuam.

Post lub sij hawm: Apr-06-2022