Usoro mmecha ihu igwe a na-ahụkarị maka ihe igwe mpempe akwụkwọ

Oge agụpụtara echere:Nkeji 8, 3 sekọnd

Ịhọrọ njedebe elu nke ọma dị oke mkpa iji nweta ọrụ na ọdịdị nke nhazi akụkụ.Ngwunye elu dị iche iche nwere ike inye ihe dị iche iche na textures.Oge, ihe onwunwe, ngwá ọrụ na mfe nhazibụkwa ihe ndị a ga-atụle.Ya mere, ọ dị mkpa ịghọta ụfọdụ ọgwụgwọ elu ndị a na-ahụkarị iji hụ na ahọpụtara nke ziri ezi site na mmalite.N'isiokwu a, anyị ga-akọwa ụfọdụ n'ime ọgwụgwọ elu ndị a na-ahụkarị.Ị nwekwara ikekpọtụrụ ndị injinia anyị ozugbo maka ndụmọdụ n'efu.

Electrorating:N'ime ihe ngwọta electroplating, a na-ejikọta ion ndị a na-akwụ ụgwọ electrostatically n'elu ngwaahịa ahụ n'okpuru ọrụ nke ọkụ eletrik iji mepụta oyi akwa.

Ịfesa ntụ ntụ: Ịfesa ntụ ntụ bụ usoro mkpuchi nke na-eji nkwụsị corona na-eme ka mkpuchi ụdị uzuzu na-adabere na workpiece.Mgbe ntụ ntụ na-agbaze ma na-ekpo ọkụ na-agbaze na usoro ọgwụgwọ, a ga-emepụta ihe nkiri mkpuchi n'elu ọrụ ahụ.

Electrophoresis:A na-ekewa usoro electrophoresis n'imeanodic electrophoresisnaelectrophoresis nke cathodic.Ọ bụrụ na agba agba agba na-adịghị mma na workpiece bụ anode, na agba ahụ na-edebe na workpiece n'okpuru edinam nke electric ubi na-etolite a film akpọ anodic electrophoresis;N'aka nke ọzọ, ọ bụrụ na ihe ndị na-agba agba na-akwụ ụgwọ nke ọma na workpiece bụ cathode, a na-edobe ihe ndị ahụ na-agba na workpiece na-etolite ihe nkiri a na-akpọ cathodic electrophoresis.

Ntinye plastik: Plastic dipping utu aha nke a makwaara dị ka mkpuchi plastik, ikpo ọkụ na-ekpo ọkụ, mkpuchi mkpuchi plastik etinyere okpomọkụ.Ntunye ịkpụzi (mkpuchi plastik) bụ usoro mkpuchi plastik.Dị ka dị iche iche akụrụngwa eji na itinye ịkpụzi nwere ike kewaa n'imeMkpuchi mmiri (ihe mkpuchi)plastic nantụnye ntụ ntụ (ihe mkpuchi)rọba.A na-eji ngwaahịa dip plastic eme ihe n'akụkụ dị iche iche nke mmepụta na ndụ n'ụlọ na ná mba ọzọ, dị ka: uwe anyị na-ehicha akwa kwa ụbọchị, ngwa ngwa, mkpa na mkpuchi rọba, valvụ mmiri, wdg.

Oxidation: oxidation nke metal n'elu nke workpiece, na-akpụ a ok-echebe film n'elu nke workpiece, na-amụba corrosion iguzogide nke workpiece.Enwere ụdị oxidation abụọ n'ozuzu: chemical oxidation na anodic oxidation.Ọ bụ usoro ọgwụgwọ elu a na-ahụkarị.

ihicha:Ịhịa aka n'elu bụ ọgwụgwọ elu nke na-etolite ụkpụrụ ahịrị n'elu nke workpiece site na ngwaahịa abrasive iji nye mmetụta ịchọ mma.N'ihi na ọgwụgwọ ịhịa aka n'elu nwere ike igosipụta ọdịdị nke ihe ígwè, ya mere ọtụtụ ndị ọrụ na-ahụ ya n'anya ma na-ejikarị ya eme ihe.

Agba agba: tngwa ngwa spraying, akwa okpomọkụ baking, wdg, n'elu ihe fesa na agba dị iche iche nke agba na-achọ mma na ọdịdị na ike dịkwuo mgbochi corrosion Njirimara, a na-enwekarị mmiri mmiri na-eme achịcha na agba ntụ ntụ ntụ, nke ntụ ntụ. agba agba bụ ihe a na-ahụkarị, agba agba agba anaghị eduzi, ihe EMC chọrọ nke mpaghara anaghị ekwe ka agba agba.

Usoro ọgwụgwọ elu - electroplating

Galvanized

Galvanized ígwè ọkpọkọ

1, cyanide galvanizing

2, Zincate galvanizing

3, chloride galvanized

4, Sulfate galvanizing

Ụlọ ọrụ Galvanizing bụ ụlọ ọrụ na-emetọ ihe, ọ bụ ezie na a na-ejikarị ya eme ihe na ọnụ ala, ọ naghị erute ụkpụrụ ROHS, ya mere gbalịa ka ị ghara iji ngwaahịa galvanized.

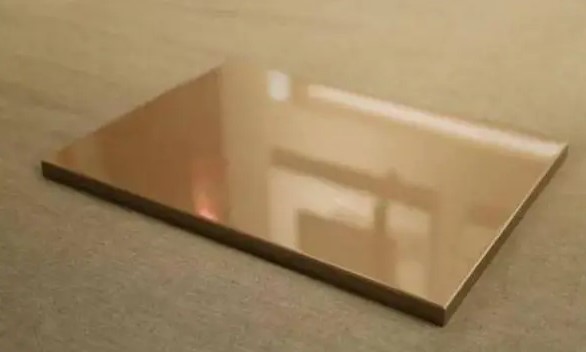

Chrome Plating

Chrome Plating

Usoro usoro bụ otu ihe ahụ dị ka galvanizing.

Tụnyere na omenala electro-galvanization;oke mgbochi corrosion siri ike, 7-10 ugboro dị mma karịa galvanization, na elu mara mma, mana ọnụ ahịa dị elu.

Dacromet, usoro plating chrome kachasị elu, bụ teknụzụ ọgwụgwọ elu ọhụrụ, ma e jiri ya tụnyere usoro electroplating ọdịnala, Dacromet bụ "ihe na-acha akwụkwọ ndụ akwụkwọ ndụ".

Usoro ọgwụgwọ elu nke - mkpuchi ntụ ntụ

Mkpuchi ntụ ntụ

Ụkpụrụ usoro mkpuchi ntụ ntụ:

Electrostatic ntụ ntụ ịgba:tumadi site na electrodes ka polarize agba (ntụ ntụ), wee fesa na ihe na-abụghị ụgwọ, na eletriki ubi ike n'okpuru edinam nke ntụ ntụ uniformly mmasị n'elu ihe.

Akụkụ nke usoro mkpuchi ntụ ntụ:

Ntụ ntụ electrostatic sprayingagaghị eme ka mmetọ ikuku, ntụ ntụ nwere ike ịmegharị iji belata ọnụ ahịa ihe oriri, mkpuchi ihe nkiri na-arụ ọrụ elu acid resistance, alkali resistance, nnu corrosion resistance ka mma, adhesion bụkwa elu.

Usoro ọgwụgwọ elu nke - electrophoresis

Electrophoresis akụkụ

Usoro usoro nke electrophoresis:

A na-ekewa usoro electrophoresis n'imeanodic electrophoresisnaelectrophoresis nke cathodic.Ọ bụrụ na agba agba agba na-adịghị mma, workpiece bụ anode, na agba ahụ na-edebe na workpiece n'okpuru edinam nke electric ubi ike na-etolite a film akpọ anodic electrophoresis;N'aka nke ọzọ, ọ bụrụ na a na-akwụ ụgwọ ihe nkedo ahụ nke ọma, onye na-arụ ọrụ bụ cathode, a na-edobekwa ihe ndị ahụ na-arụ ọrụ na-emepụta ihe nkiri a na-akpọ cathodic electrophoresis.

Njirimara nkeanodic electrophoresisbụ: akụrụngwa dị ọnụ ala (n'ozuzu 50% dị ọnụ ala karịa cathodic electrophoresis);ngwa dị mfe (n'ozuzu 30% dị ọnụ ala karịa cathodic electrophoresis);obere teknụzụ chọrọ;Nguzogide corrosion dara ogbenye nke mkpuchi karịa cathodic electrophoresis (ihe dịka 1/4 nke ndụ cathodic electrophoresis).

Ihe mere na elu corrosion eguzogide nkeelectrophoresis nke cathodicmkpuchi bụ: workpiece bụ cathode, ọ dịghị anodic mgbasa, na workpiece elu na phosphate film adịghị ebibi;mkpuchi electrophoretic (n'ozuzu nitrogen nwere resins) nwere mmetụta nchebe na metal.

Atụmatụ nke usoro ọgwụgwọ elu electrophoretic:

Electrophoretic agba ihe nkirinwere uru nke plump, edo, ewepụghị na-eji ire ụtọ mkpuchi, na ike, adhesion, corrosion eguzogide, mmetụta arụmọrụ na penetration arụmọrụ nke electrophoretic agba film bụ budata mma karịa ndị ọzọ mkpuchi Filiks.

Agba electrophoresis a na-ahụkarị bụ oji, yana agba ndị ọzọ dịkwa.

Usoro ọgwụgwọ elu- Ntinye plastik

Akụkụ ntinye plastik

Usoro usoro nke itinye plastik:

Ngwunye plastik (mkpuchi plastik) bụ usoro mkpuchi plastik.Dị ka ihe dị iche iche dị iche iche eji eme ihe maka ịkụnye plastik nwere ike kewaa n'ime mmiri mmiri mmiri (mkpuchi) plastik na ntụ ntụ ntụ (mkpuchi) plastik.A na-eji ngwaahịa plastik eme ihe n'ọtụtụ ebe n'akụkụ dị iche iche nke mmepụta na ndụ, dị ka ihicha uwe akwa, ngwa ngwa, mkpa na aka uwe roba, mgbanaka valvụ mmiri, wdg.

Njirimara usoro nke itinye plastik:

Ngwa sara mbara, agba ọgaranya, nchebe dị mma, nguzogide oyi dị mma, nchekwa ọkụ, acid na alkali resistance.

Usoro ọgwụgwọ elu-oxidation

| Chemical oxidation | Anodic oxidation | |

| Atụmatụ usoro | Ọnụ ala dị ala, enwere ike imepụta ya n'ihu n'ọtụtụ buru ibu | Ọnụ ego dị elu |

| Usoro kwụsiri ike, ọrụ dị mfe, ngwa ngwa dị mfe, mmezi dị mfe nke ngwọta, enweghị mgbochi na nha na ọdịdị nke akụkụ ahụ | N'ihi mkpa maka ọkụ eletrik dị n'èzí.Akụkụ akụkụ na ọdịdị na-emetụta ahịrị ọkụ | |

| Chemical oxidation ga-ekwe omume maka ígwè, aluminum, ọla kọpa, ọlaọcha, zinc, tin, cadmium na alloys ha.Na mgbakwunye, ejirila kemịkalụ oxidation mee ihe na nsonaazụ na-eju afọ na ụfọdụ ngwa ọrụ.N'ihi ya, teknụzụ oxidation kemịkalụ emebela nke ọma n'afọ ndị na-adịbeghị anya. | A na-ejikarị eme ihe maka anodizing dị ka aluminum na alloys ya, magnesium na magnesium alloys, na titanium na alloys ya. | |

| Njirimara Layer Film | Ihe nkiri dị gịrịgịrị, n'ozuzu oke 0.5-4 microns | Ihe nkiri dị oke egwu |

| Ụdị dị nro, nke na-adịghị emebi emebi, corrosion dị ala na nguzogide abrasion karịa oxidation anodic | Ezigbo nguzogide corrosion, isi ike dị elu | |

| Enwere ike iji nweta ụfọdụ n'ígwé na-arụ ọrụ nke ihe nkiri anodized enweghị ike inwe, dị ka ihe mkpuchi oxide conductive. | Enwere ike nweta ụfọdụ ihe nkiri ihe nkiri na-arụ ọrụ pụrụ iche, dị ka ntinye nke alloys magnetik n'ime ihe nkiri porous maka ihe nchekwa.Efere nke anwụ anwụ, ihe nkiri ultra-hard, wdg. |

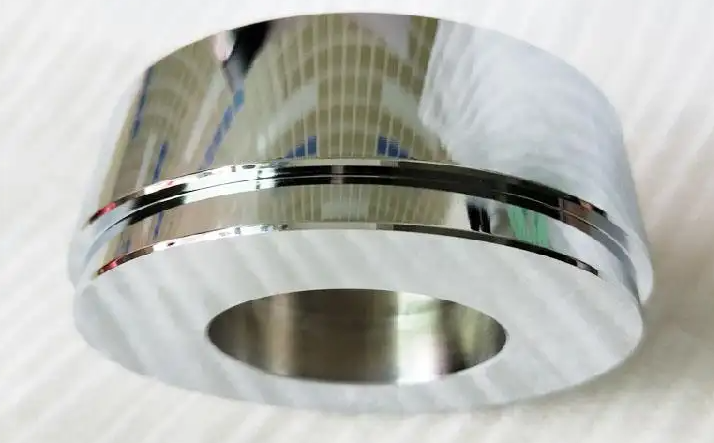

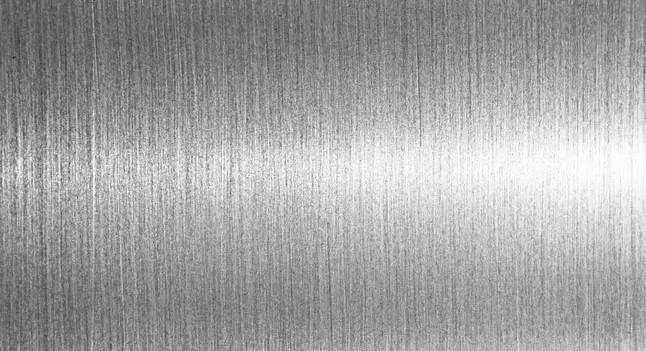

Usoro ọgwụgwọ elu nke - brushing

Igwe a na-akpụ akpụ

Ọ nwere nguzogide iyi nke ọma, oke okpomọkụ na-eguzogide, nguzogide corrosion na mmezi dị mfe kwa ụbọchị, ezigbo udidi, dị mfe dị ọcha, ogologo ndụ.

Ogwe ngwa ụlọ dị iche iche dị iche iche ngwaahịa dijitalụ mpụta na paịlụ Laptọọpụ, ejiri mee akara dị iche iche, mgba ọkụ akpụkpọ ahụ, akara aha, wdg.

Mpempe kaadị azụmahịa ọla a kpụrụ akpụ

Usoro ọgwụgwọ elu nke - agba agba

Agba agba

A na-ekewa agba achịcha n'ime ụzọ abụọ, obere okpomọkụ na-eme achịcha na-agwọta okpomọkụ nke 140 ° -180 Celsius, a na-akpọ ụdị nke ọzọ dị elu na-eme achịcha, okpomọkụ ya na-agwọ 280 ° -400 Celsius.

Uru nke agba achịcha:

1, agba na-egbuke egbuke na ọtụtụ ụdị.

2, dị mfe ihicha na ilekọta.

3, ọnụ ụzọ agba agba dị mma, siri ike karịa ọnụ ụzọ kristal UV mgbochi.

4, na-abawanye ohere nke kichin nwere ụfọdụ mmeju ìhè mmetụta.

Ime agba adịghị mma.

Usoro mmepụta ihe dị ogologo, ọkwa nke nkà na ụzụ na-achọ ọnụ ọgụgụ dị elu, ya mere ọnụahịa ahụ dị elu, na-atụ egwu ịkụ aka na scratches, ozugbo mmebi ahụ siri ike ịrụzi, iji dochie dum;uzuoku ọzọ na kichin na-enwekarị ọdịiche agba.

A na-eji injection injections eme ihe n'ọtụtụ ebe na ụlọ ọrụ dị iche iche ma nwee ike nweta mmepụta nke akụkụ na-enweghị ntụpọ na kpọmkwem n'ime obere oge.Prolean Tech na-enye ọrụ ịkpụzi injection maka ọtụtụ ihe, gụnyere plastik na elastomers.Naanị bulite gịCAD faịlụmaka ngwa ngwa, n'efu na ndụmọdụ gbasara ọrụ ndị metụtara ya.

Oge nzipu: Eprel-06-2022