IiNkqubo zokuQeda uMphezulu oQhelekileyo kwiiMathiriyeli zeSinyithi

Ixesha lokufunda eliqikelelweyo:8 imizuzu, 3 imizuzwana

Ukukhetha ukugqiba umgangatho ochanekileyo kubalulekile ekufezekiseni umsebenzi kunye nokubonakala koyilo lwenxalenye.Ukugqitywa komphezulu ohlukeneyo kunokubonelela ngeendlela ezahlukeneyo zokugqitywa kunye nokuthungwa.Ixesha, izinto, izixhobo kunye nokulula kokulungiswazikwangoothunywashe abafanele baqwalaselwe.Ke ngoko, kubalulekile ukuqonda ezinye iindlela zonyango eziqhelekileyo zomphezulu ukuqinisekisa ukuba ochanekileyo uyakhethwa kwasekuqaleni.Kweli nqaku, siza kuchaza ezinye zezona zonyango zixhaphakileyo kumphezulu.Unako kwakhonaqhagamshelana neenjineli zethu ngqo uthethwano simahla.

Electroplating:Kwisisombululo se-electroplating, i-ioni ene-electrostatically charged ifakwe kumphezulu wemveliso phantsi kwesenzo sommandla wombane ukwenza umaleko wokutya.

Ukutshiza ngomgubo: Ukutshiza umgubo yinkqubo yokugquma esebenzisa ukukhutshwa kwe-corona ukwenza iingubo zohlobo lomgubo zibambelele kwi-workpiece.Emva kokutshiza kwepowder kwaye emva koko ukunyibilika okushushu kunye namanyathelo okuphilisa, ifilimu yokugqoka iya kwenziwa phezu kwendawo yokusebenza.

Electrophoresis:Inkqubo ye-electrophoresis ihlulwe ibei-anodic electrophoresiskwayei-cathodic electrophoresis.Ukuba iipeyinti zepeyinti zihlawuliswa kakubi kwaye i-workpiece yi-anode, iinqununu zepeyinti zifakwe kwi-workpiece phantsi kwesenzo sentsimi yombane ukwenza ifilimu ebizwa ngokuba yi-anodic electrophoresis;ngokuchaseneyo, ukuba iipeyinti zepeyinti zihlawulwe kakuhle kwaye i-workpiece yi-cathode, i-particle yepeyinti ifakwe kwi-workpiece ukwenza ifilimu ebizwa ngokuba yi-cathodic electrophoresis.

Ukudipha ngeplastiki: Iplastiki yokudipha i-alias ekwabizwa ngokuba yiplastiki yokutyabeka, iplastiki yokudipha ubushushu, ubushushu busebenzise ukutyabeka kweplastiki.Dip ukubumba (iplastiki yokugquma) yinkqubo yokugquma iplastiki.Ngokwemathiriyeli ekrwada eyohlukeneyo esetyenziswa ekubumbeni idiphu inokwahlulwa ibeidiphu engamanzi (ukwaleka)iplastiki kunyeidiphu yomgubo (ukugquma)iplastiki.Iimveliso zeplastiki zediphu zisetyenziswe ngokubanzi kwiinkalo ezahlukeneyo zemveliso kunye nobomi basekhaya nakwamanye amazwe, njengale: iimpahla zethu zemihla ngemihla zomisa i-hanger, iipliers, isikere kwi-cover rubber, i-valve wrench yamanzi, njl.

I-oxidation: i-oxidation yesinyithi phezu kwendawo yokusebenza, ukwenza ifilimu ekhuselekileyo yokukhusela ebusweni bomsebenzi, ukwandisa ukunyanzeliswa kwe-corrosion ye-workpiece.Kukho iintlobo ezimbini ze-oxidation ngokubanzi: i-chemical oxidation kunye ne-anodic oxidation.Yindlela eqhelekileyo yonyango lomphezulu.

Ukubrasha:Ukuxubha umphezulu lunyango olungaphezulu olwenza ipateni yomgca kumphezulu womsebenzi ngokusebenzisa iimveliso ezirhabaxa ukubonelela ngesiphumo sokuhombisa.Ngenxa yokuba unyango lokuxubha umphezulu lunokubonakalisa ukuthungwa kwezinto zetsimbi, ngoko kuye kwathandwa ngabasebenzisi abaninzi nangaphezulu kwaye kusetyenziswa ngokubanzi.

Ipeyinti yokubhaka: tUkutshiza ngokucokisekileyo, ukubhaka ubushushu obuphezulu, njl.njl., kumphezulu wezinto ezitshizwe ngemibala eyahlukeneyo yepeyinti esetyenziselwa ukuhombisa inkangeleko kwaye inokonyusa iipropathi zokulwa nokubola, ngokuqhelekileyo kukho ipeyinti yokubhaka engamanzi kunye nepeyinti yokubhaka engumgubo, apho umgubo. ipeyinti yokubhaka yeyona ixhaphakileyo, indawo yokubhaka ipeyinti ayiqhubeki, iimfuno ze-EMC zommandla azivumeli ipeyinti yokubhaka.

Inkqubo yonyango yomhlaba - i-electroplating

Iigalvanized

Umbhobho wentsimbi owenziwe ngamachiza

1, iCyanide galvanizing

2, Zincate galvanizing

3, iChloride yenziwe yagalvanized

4, iSulfate galvanizing

Ishishini lokugalela i-galvanizing lishishini elingcolisayo, nangona lisetyenziswa ngokubanzi kwaye liphantsi kwexabiso eliphantsi, alihambisani nemigangatho ye-ROHS, ngoko ke zama ukuba ungasebenzisi iimveliso zegalvanized.

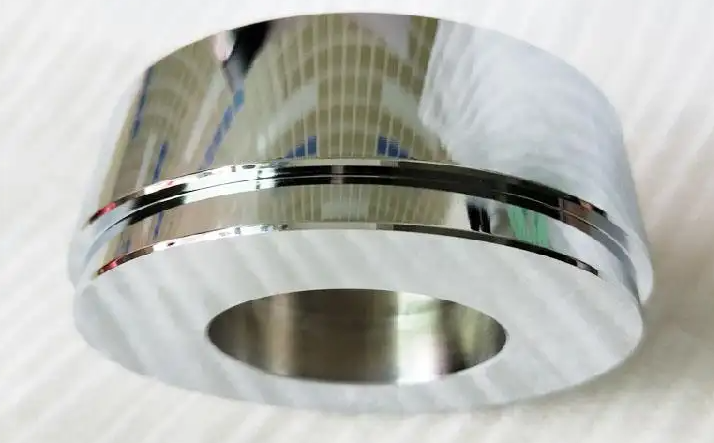

I-Chrome Plating

I-Chrome Plating

Umgaqo wenkqubo ufana nokufaka igalvanizing.

Xa kuthelekiswa ne-electro-galvanization yemveli;I-anti-corrosion enamandla kakhulu, amaxesha angama-7-10 angcono kune-galvanization, kunye nomphezulu omhle, kodwa ixabiso eliphezulu.

I-Dacromet, eyona nkqubo iphezulu ye-chrome yokubeka, iteknoloji entsha yonyango, xa kuthelekiswa nenkqubo ye-electroplating yendabuko, i-Dacromet "yi-plating eluhlaza".

Inkqubo yonyango yobuso - ukugquma komgubo

Powder Coating

Umgaqo wenkqubo yokugquma umgubo:

Ukutshiza ngomgubo we-Electrostatic:ubukhulu becala ngokusebenzisa electrode ukuba polarize ipeyinti (umgubo), kwaye emva koko ukuba utshizwe kwi into ngentlawulo ngokuchaseneyo, kumandla ombane endle phantsi kwesenzo somgubo ngokulinganayo encanyathiselwe kumphezulu wento.

Iimpawu zenkqubo yokugquma umgubo:

Ukutshiza ngomgubo we-electrostaticayiyi kubangela ukungcoliseka kwe-atmospheric, i-powder ingahlaziywa ukuze inciphise iindleko zokusetyenziswa kwezinto eziphathekayo, i-coating film performance i-higher acid resistance, i-alkali resistance, i-salt corrosion resistance, i-adhesion nayo iphezulu.

Inkqubo yonyango yomhlaba - i-electrophoresis

Electrophoresis inxalenye

Inkqubo yomgaqo we-electrophoresis:

Inkqubo ye-electrophoresis ihlulwe ibei-anodic electrophoresiskwayei-cathodic electrophoresis.Ukuba iipeyinti zepeyinti zihlawuliswa kakubi, i-workpiece yi-anode, kwaye iinqununu zepeyinti zifakwe kwi-workpiece phantsi kwesenzo samandla ombane ombane ukwenza ifilimu ebizwa ngokuba yi-anodic electrophoresis;ngokuchaseneyo, ukuba iipeyinti zepeyinti zihlawuliswa ngokuqinisekileyo, i-workpiece yi-cathode, kunye neepeyinti zepeyinti zifakwe kwi-workpiece ukwenza ifilimu ebizwa ngokuba yi-cathodic electrophoresis.

Iimpawu zei-anodic electrophoresiszezi: izinto ezikhaphukhaphu ekrwada (ngokuqhelekileyo 50% zitshiphu ngaphezu electrophoresis cathodic);izixhobo ezilula (ngokuqhelekileyo 30% zitshiphu ngaphezu electrophoresis cathodic);iimfuno ezisezantsi zobugcisa;ukuxhathisa ukonakala kwe-corrosion ye-coating kune-cathodic electrophoresis (malunga ne-1/4 yobomi be-cathodic electrophoresis).

Isizathu sokumelana nomhlwa okuphezulu kwei-cathodic electrophoresisi-coating yi: i-workpiece yi-cathode, akukho ukutshatyalaliswa kwe-anodic, i-workpiece surface kunye nefilimu ye-phosphate ayitshatyalaliswa;i-electrophoretic coatings (ngokuqhelekileyo i-nitrogen-containing resins) inefuthe lokukhusela kwisinyithi.

Iimpawu zenkqubo yonyango ye-electrophoretic surface:

Ifilimu yepeyinti ye-Electrophoreticineenzuzo ze-plup, iyunifomu, i-flat and smooth coating, kunye nobunzima, ukunamathela, ukuxhathisa ukubola, ukusebenza kwempembelelo kunye nokusebenza kokungena kwefilimu yepeyinti ye-electrophoretic ingcono kakhulu kunezinye iinkqubo zokugqoka.

Umbala oqhelekileyo we-electrophoresis umnyama kakhulu, kwaye neminye imibala iyafumaneka.

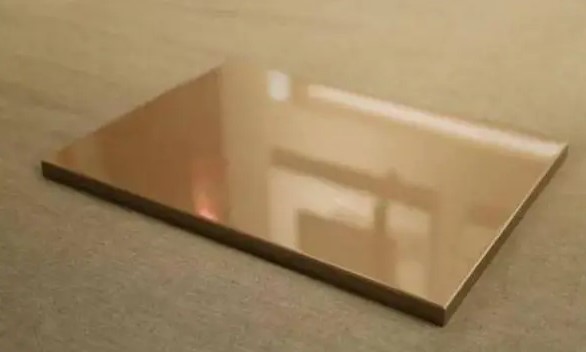

Inkqubo yonyango lomphezulu- Ukudipha ngeplastiki

Inxalenye yeplastiki yokudipha

Inkqubo yokudipha iplastiki:

Ukudipha iplastiki (iplastiki yokugquma) yinkqubo yokugquma iplastiki.Ngokwemathiriyeli ekrwada eyohlukeneyo esetyenziselwa ukudipha iplastiki inokohlulwa ibe yiplastiki yokudipha (yokugquma) kunye nomgubo wokudipha (ukwambathisa) iplastiki.Iimveliso zeplastiki zediphu zisetyenziswe ngokubanzi kwimiba eyahlukeneyo yemveliso kunye nobomi, njengokumisa iimpahla zokuxhoma iimpahla, iipliers, isikere kumkhono werabha, isitshixo sevalve yamanzi, njl.

Iimpawu zenkqubo yokudipha iplastiki:

Ukusetyenziswa okubanzi, umbala otyebileyo, ukhuseleko olulungileyo, ukumelana nokubanda okugqwesileyo, ukugcinwa kobushushu, iasidi kunye nokuxhathisa kwealkali.

Inkqubo yonyango lomphezulu-oxidation

| Ukukhutshwa kweekhemikhali | I-Anodic oxidation | |

| Iimpawu zeNkqubo | Iindleko eziphantsi, zinokuveliswa ngokuqhubekayo ngobuninzi obukhulu | Iindleko eziphezulu |

| Inkqubo ezinzileyo, ukusebenza okulula, izixhobo ezilula, ukugcinwa lula kwesisombululo, akukho zithintelo kubukhulu kunye nokuma kwamacandelo | Ngenxa yesidingo sobonelelo lwangaphandle lwamandla.Ubungakanani benxalenye kunye nokumila kuchaphazela iintambo zamandla | |

| I-oxidation yekhemikhali inokwenzeka ngentsimbi, i-aluminiyam, ubhedu, isilivere, i-zinc, i-tin, i-cadmium kunye ne-alloys yazo.Ukongezelela, i-chemical oxidation isetyenziswe ngeziphumo ezanelisayo kwezinye izicelo zokusebenza.Ngenxa yoko, itekhnoloji ye-chemical oxidation iphuhliswe kakhulu kwiminyaka yakutshanje. | Ngokuqhelekileyo isetyenziselwa i-anodizing materials ezifana ne-aluminium kunye ne-alloys yayo, i-magnesium kunye ne-magnesium alloys, kunye ne-titanium kunye ne-alloys yayo. | |

| Iimpawu zoMaleko wefilimu | Ifilimu encinci, ngokubanzi i-0.5-4 microns ubukhulu | Ifilimu eshinyeneyo |

| Ubume obuthambileyo, obungaqholiyo, ukuthotywa okusezantsi kunye nokuxhathisa kwe-abrasion kune-oxidation ye-anodic | Ukuxhathisa okulungileyo kokubola, ubunzima obuphezulu | |

| Ingasetyenziselwa ukufumana ezinye iileya ezisebenzayo ezingenakuba nazo iifilim ezine-anodized, ezinje nge-conductive oxide layers | Ezinye iileya zefilimu ezisebenzayo ezikhethekileyo zinokufunyanwa, njengokubekwa kwe-alloys magnetic kwiifilimu ezinamaqabunga ezigcina izinto.I-solar absorber plate, ifilimu ye-ultra-hard, njl. |

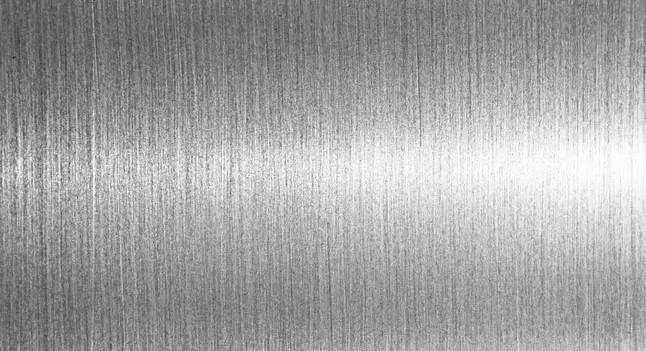

Inkqubo yonyango ngaphezulu - ukuxubha

Intsimbi ebrashiweyo

Inokumelana nokunxiba okugqwesileyo, ukumelana nobushushu obuphezulu, ukuxhathisa ukubola kunye nokugcinwa okulula kwemihla ngemihla, ukuthungwa okuhle, kulula kakhulu ukuyicoca, ubomi obude.

Iiphaneli zezixhobo zasekhaya Iimveliso zedijithali ezahlukeneyo iiperipherals kunye neepaneli Iiphaneli zeLaptop, ezisetyenziselwa ukwenza iilogo ezahlukeneyo, iiswitshi zemembrane, iiplate zamagama, njl.

Ityala lekhadi leshishini lesinyithi elixutyiweyo

Inkqubo yonyango yomhlaba - ipeyinti yokubhaka

Ipeyinti yokubhaka

Ipeyinti yokubhaka yahlulwe yangamacandelo amabini, iqondo eliphantsi lobushushu lokubhaka ipeyinti yokunyanga iqondo lobushushu le-140 ° -180 °, olunye udidi lubizwa ngokuba yipeyinti yokubhaka yobushushu obuphezulu, ubushushu bayo bokunyanga i-280 ° -400 °.

Izinto eziluncedo ngepeyinti yokubhaka:

I-1, imibala eqaqambileyo kunye nezitayela ezininzi.

2, kulula ukuyicoca kwaye uyikhathalele.

I-3, iipaneli zomnyango wepeyinti yokubhaka elungileyo, yomelele ngakumbi kuneepaneli zecango zekristale ukuxhathisa kwe-UV.

I-4, ukwandisa indawo yekhitshi inomphumela othile wokukhanya ohambelanayo.

Ukungalungi kwepeyinti yokubhaka.

Umjikelo wokuvelisa ude kakhulu, inqanaba lobuchwepheshe lifuna izinga eliphezulu le-scrap, ngoko ixabiso liphezulu, ukwesaba ukunkqonkqoza kunye nemikrwelo, xa umonakalo kunzima ukulungisa, ukubuyisela yonke into;umsi ongaphezulu ekhitshini othanda ukungafani kombala.

Isitofu sokubumba sisetyenziswa ngokubanzi kumashishini ahlukeneyo kwaye sinokufikelela kwimveliso engenamthungo kunye nechanekileyo yobuninzi beengxenye ngexesha elifutshane.I-Prolean Tech ibonelela ngeenkonzo zokubumba inaliti kwizinto ezininzi, kubandakanya iiplastiki kunye nee-elastomers.Faka nje eyakhoIfayile yeCADukukhawuleza, ukucaphula simahla kunye nokubonisana kwiinkonzo ezinxulumeneyo.

Ixesha lokuposa: Apr-06-2022