Yakajairwa Surface Kupedzisa Maitiro eSheet Metal Materials

Inofungidzirwa nguva yekuverenga:8 maminitsi, 3 masekondi

Kusarudza iyo chaiyo yepamusoro pekupedzisira kwakakosha kuti uwane basa uye kutaridzika kwechikamu dhizaini.Kupedzwa kwakasiyana kwepamusoro kunogona kupa kupera kwakasiyana uye maumbirwo.Iyo nguva, zvinhu, tooling uye nyore kugadzirisazvinhuwo zvinofanira kufungwa nezvazvo.Naizvozvo, zvakakosha kuti unzwisise mamwe eanojairwa epamusoro kurapwa kuti ave nechokwadi chekuti akakodzera anosarudzwa kubva pakutanga.Muchinyorwa chino, tichatsanangura mamwe emamwe marapirwo akajairika epamusoro.Unogonawokubata mainjiniya edu zvakananga kubvunzurudza mahara.

Electroplating:Mumushonga we electroplating, electrostatic charged ions inonamirwa pamusoro pechigadzirwa pasi pechiito chemunda wemagetsi kuti iite plating layer.

Kupfapfaidza hupfu: Kupfapfaidza hupfu inzira yekuputira iyo inoshandisa kubuda kwekorona kuita kuti mapeji emhando yehupfu anonamira kune workpiece.Mushure mehupfu yekupfapfaidza uye ipapo inopisa kunyunguduka uye kurapa matanho, firimu yekuputira ichaumbwa pamusoro peiyo workpiece.

Electrophoresis:Iyo electrophoresis process yakakamurwa kuitaanodic electrophoresisuyecathodic electrophoresis.Kana mapendi epende akapomerwa zvisina kunaka uye workpiece ndiyo anode, mapepa epende anoiswa mubasa rekushanda pasi pechiito chemagetsi ekugadzira firimu inonzi anodic electrophoresis;ukuwo, kana pendi zvimedu zvakanaka mhosva uye workpiece ari cathode, pendi zvimedu vanoiswa ari workpiece kuumba firimu inonzi cathodic electrophoresis.

Plastic dipping: Plastiki dipping alias inozivikanwawo sepurasitiki yekuputira, kupisa kwepurasitiki yekunyudza, kupisa kunoshandiswa kwepurasitiki yekupfeka.Dip molding (plastic coating) iplastic coating process.Zvinoenderana neakasiyana mbichana zvinhu zvinoshandiswa mukuumbwa dip zvinogona kukamurwa kuitamvura dip (kupfeka)plastiki uyepoda dip (kupfeka)plastiki.Dip epurasitiki zvigadzirwa zvakashandiswa zvakanyanya mumhando dzakasiyana dzekugadzira uye hupenyu hwepamba nekune dzimwe nyika, senge: zvipfeko zvedu zvezuva nezuva zvekuomesa hanger, pliers, chigero pachivharo cherabha, wrench yevhavha yemvura, nezvimwe.

Oxidation: oxidation yesimbi pamusoro pebasa rekushanda, kuumba dense inodzivirira firimu pamusoro pebasa rekushanda, kuwedzera kupikisa kwehutu hwebasa rekushanda.Iko kunowanzo kuve nemhando mbiri dzeoxidation: makemikari oxidation uye anodic oxidation.Iyo inowanzoshandiswa pamusoro pekurapa nzira.

Kubhurasha:Surface brushing ndeyekugadziriswa kwepamusoro kunoumba mutsara patani pamusoro peiyo workpiece kuburikidza neabrasive zvigadzirwa kuti ipe yekushongedza maitiro.Nekuti iyo pamusoro pebhurashi kurapwa inogona kuratidza magadzirirwo emidziyo yesimbi, saka yave ichidiwa nevazhinji vashandisi uye zvakanyanya uye zvakanyanya kushandiswa.

Pendi yekubikira: tkupfapfaidza, kupisa kwekushisa kwakanyanya, nezvimwewo, pamusoro pechinhu chakapfapfaidzwa nemavara akasiyana ependi anoshandiswa kushongedza chitarisiko uye anogona kuwedzera anti-corrosion zvivakwa, kazhinji pane mvura yekubikira pendi uye poda yekubheka pendi, iyo hupfu. kubheka pendi ndiyo yakanyanya kuwanda, yekubikira pendi pendi haisi conductive, EMC inodiwa yedunhu haitenderi kubheka pendi.

Surface kurapwa maitiro - electroplating

Galvanized

Galvanized steel pipe

1, Cyanide galvanizing

2, Zincate galvanizing

3,Chloride yakabatiswa

4, Sulfate galvanizing

Indasitiri yeGarivanizing iindasitiri inosvibisa, kunyangwe ichishandiswa zvakanyanya uye yakaderera mutengo, haina kusangana neROHS zviyero, saka edza kusashandisa galvanized zvigadzirwa.

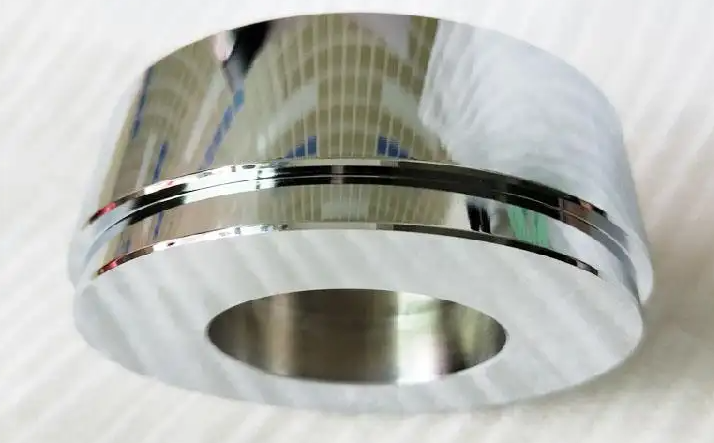

Chrome Plating

Chrome Plating

Iyo misimboti yemaitiro yakafanana nekuita galvanizing.

Kuenzaniswa neyechinyakare electro-galvanization;yakanyanya kusimba anti-corrosion, 7-10 times zviri nani pane galvanization, uye yakanaka nzvimbo, asi yakakwira mutengo.

Dacromet, iyo yakanyanya kukwirira chrome plating process, inyowani yekurapa tekinoroji, ichienzaniswa neyechinyakare electroplating process, Dacromet i "girini plating".

Surface treatment process ye - powder coating

Powder Coating

Powder coating process musimboti:

Electrostatic powder spraying:kunyanya kuburikidza electrodes kuti polarize pendi (upfu), uye ipapo kuti kupfapfaidzwa pamusoro chinhu nechaji yakapesana, mumagetsi munda simba pasi pechiito cheupfu uniformly akabatanidzwa pamusoro pechinhu.

Zvinoumba poda coating process:

Powder electrostatic sprayinghazvizokonzerese kusvibiswa kwemuchadenga, hupfu hunogona kudzokororwa kudzikisa mutengo wekushandisa kwezvinhu, kupfekedza firimu kuita kwepamusoro asidi kuramba, alkali resistance, salt corrosion resistance iri nani, adhesion zvakare yakakwirira.

Pamusoro pekurapa maitiro e - electrophoresis

Electrophoresis chikamu

Process musimboti electrophoresis:

Iyo electrophoresis process yakakamurwa kuitaanodic electrophoresisuyecathodic electrophoresis.Kana mapepa epende akapomerwa zvakashata, iyo workpiece ndiyo anode, uye mapepa epende akaiswa pane workpiece pasi pekuita kwesimba remagetsi rekugadzira firimu rinonzi anodic electrophoresis;ukuwo, kana pendi zvimedu zvakanaka mhosva, workpiece ndiyo cathode, uye pendi zvimedu vanoiswa pamusoro workpiece kuumba firimu inonzi cathodic electrophoresis.

Hunhu hweanodic electrophoresisvari: zvakachipa mbishi zvinhu (kazhinji 50% zvakachipa pane cathodic electrophoresis);midziyo iri nyore (kazhinji 30% yakachipa kupfuura cathodic electrophoresis);yakaderera michina zvinodiwa;kushomeka kwekushomeka kwekupotera pane cathodic electrophoresis (inenge 1/4 yehupenyu hwe cathodic electrophoresis).

Chikonzero chepamusoro corrosion resistance yecathodic electrophoresiskupfeka ndiko: workpiece ndiyo cathode, hapana anodic dissolution, workpiece pamusoro uye phosphate film haina kuparadzwa;electrophoretic coatings (kazhinji nitrogen-containing resins) ine kudzivirira kwesimbi.

Zvimiro zve electrophoretic surface treatment process:

Electrophoretic pendi firimuine mabhenefiti ehurembera, yunifomu, yakapfava uye yakatsetseka yakapfava, uye kuoma, kunamatira, corrosion resistance, kukanganiswa kwekuita uye kupinda mukati kweelectrophoretic pendi firimu zviri nani pane mamwe maitiro ekuputira.

Iyo yakajairika electrophoresis ruvara itema kazhinji, uye mamwe mavara anowanikwawo.

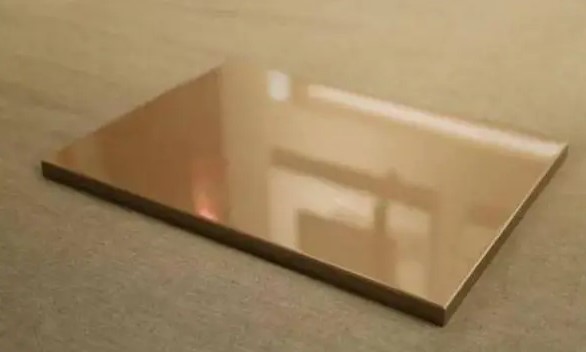

Surface treatment process- Plastic dipping

Plastic dipping part

Maitiro musimboti wekunyudza epurasitiki:

Dipping plastiki (plastic coating) iplastic coating process.Zvinoenderana neakasiyana mbichana anoshandiswa kunyudza epurasitiki anogona kukamurwa kuita mvura dipping (coating) epurasitiki uye poda dipping (coating) epurasitiki.Zvigadzirwa zvepurasitiki zveDip zvakashandiswa zvakanyanya mumhando dzakasiyana dzekugadzira uye hupenyu, sekuomesa zvipfeko zvinorembera, pliers, chigero parubha sleeve, mvura valve wrench, nezvimwe.

Maitiro maitiro ekunyurura epurasitiki:

Wide application, yakapfuma ruvara, kuchengetedzwa kwakanaka, yakanakisa kutonhora kuramba, kuchengetedza kupisa, asidhi uye alkali kuramba.

Surface treatment process-oxidation

| Kemikari oxidation | Anodic oxidation | |

| Process Features | Mutengo wakaderera, unogona kugadzirwa nguva dzose muhuwandu hukuru | Mutengo wepamusoro |

| Yakagadzikana maitiro, nyore kushanda, nyore midziyo, nyore kugadzirisa mhinduro, hapana kurambidzwa pahukuru uye chimiro chezvikamu | Nekuda kwekudiwa kwekunze kwemagetsi.Chikamu saizi uye chimiro chinokanganisa tambo dzemagetsi | |

| Kemikari oxidation inogoneka yesimbi, aruminiyamu, mhangura, sirivha, zingi, tini, cadmium uye alloys avo.Mukuwedzera, makemikari oxidation yakashandiswa nemigumisiro inogutsa mune mamwe maitiro anoshanda.Nekuda kweizvozvo, makemikari oxidation tekinoroji yakagadziridzwa zvakanyanya mumakore achangopfuura. | Inowanzo shandiswa anodizing zvinhu zvakaita sealuminium nema alloys ayo, magnesium uye magnesium alloys, uye titanium nema alloys ayo. | |

| Film Layer Characteristics | Firimu rakatetepa, kazhinji 0.5-4 microns gobvu | Firimu gobvu |

| Yakapfava magadzirirwo, asiri-abrasive, yakaderera corrosion uye abrasion kuramba pane anodic oxidation | Good corrosion resistance, high hardness | |

| Inogona kushandiswa kuwana mamwe matinji anoshanda ayo anodized mafirimu asingakwanise kuve nawo, senge conductive oxide layer | Mamwe akakosha anoshanda firimu akaturikidzana anogona kuwanikwa, senge deposition yemagineti alloys mumaporous mafirimu ekuchengetedza zvinhu.Solar absorber plate, Ultra-hard film, etc. |

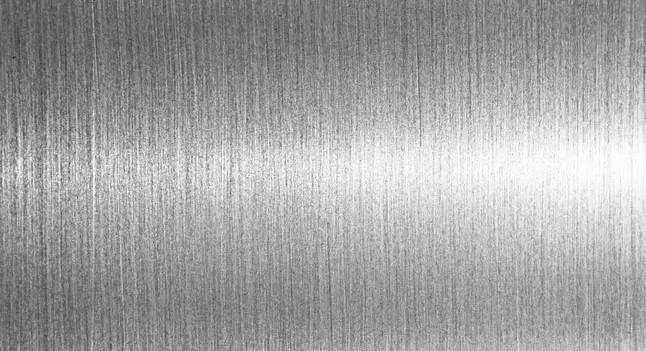

Surface treatment process ye - brushing

Brushed simbi

Iyo ine yakanakisa kupfeka kuramba, yakakwirira tembiricha kuramba, corrosion kuramba uye nyore kugadzirisa zuva nezuva, yakanaka magadzirirwo, yakanyanya nyore kuchenesa, hupenyu hwakareba.

Mapaneru emidziyo yemumba Yakasiyana siyana zvigadzirwa zvemadhijitari uye mapaneru Laptop mapaneru, anoshandiswa kugadzira akasiyana marogo, membrane switch, nameplates, nezvimwe.

Brushed metal business card case

Surface kurapwa maitiro e - kubheka pendi

Kubika Paint

Kubika pendi rakakamurwa muzvikamu zviviri, yakaderera-tembiricha kubheka pendi kuporesa tembiricha 140 ° -180 °, mumwe muchikwata inonzi yakakwirira-tembiricha kubika pendi, ayo kurapa tembiricha 280 ° -400 °.

Zvakanakira kubheka pendi:

1, mavara akajeka uye akawanda masitayera.

2, nyore kuchenesa uye kutarisira.

3, yakanaka yekubikira pendi yemusuwo mapaneru, akasimba kupfuura ekristaro gonhi mapaneru UV kuramba.

4, kuwedzera nzvimbo yekicheni ine imwe inopindirana mwenje mhedzisiro.

Kubikira pendi kukanganisa.

Kutenderera kwekugadzira kwakarebesa, chiyero chehunyanzvi chinoda chiyero chakakura, saka mutengo wakakwira, kutya kugogodza uye kukwenya, kana kukanganisa kwakaoma kugadzirisa, kutsiva iyo yese;utsi hwakawanda mukicheni hunowanzoita kusiyana kwemavara.

Jekiseni molding inoshandiswa zvakanyanya mumaindasitiri akasiyana siyana uye inokwanisa kuwana isina musono uye chaiyo misa kugadzirwa kwezvikamu munguva pfupi.Prolean Tech inopa majekiseni ekuumba masevhisi kune akawanda ezvigadzirwa, zvinosanganisira mapurasitiki uye elastomers.Simply upload yourCAD fairayekukurumidza, yemahara quote uye kubvunzana pane ane hukama masevhisi.

Nguva yekutumira: Kubvumbi-06-2022