Injection Molding Kugadzikana KwePlastiki Yakajeka - PMMA, PC, PET

Inofungidzirwa nguva yekuverenga:3 maminitsi, 37 masekondi

Anonyanya kushandiswa mapurasitiki akajeka pamusika nhasi polymethyl methacrylate (inowanzozivikanwa se acrylic kana plexiglass, PMMA), polycarbonate (PC), polyethylene terephthalate (PET), transparent nylon, AS (acrylic-styrene copolymer), polysulfone (PSF) zvichingoenda zvakadaro.Iwo matatu anonyanya kushandiswa epurasitiki ndiPMMA, PC uye PET.Nekuda kwekunetsa kwenzvimbo, zvinotevera nhaurirano yezvivakwa uye jekiseni molding maitiro emapurasitiki matatu aya.Unogonawokubata mainjiniya eduzvakanangana nemahara ekubvunza masevhisi.

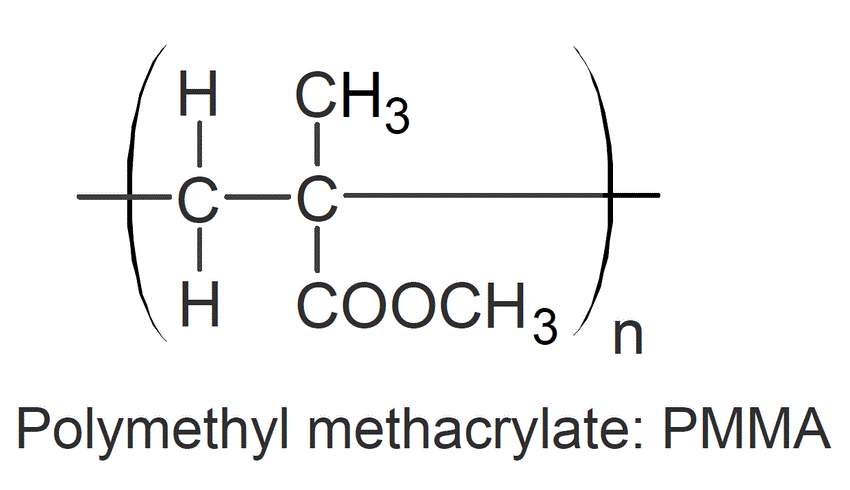

1, PMMA

PMMA Plastic Raw Material

PMMA ine yakakwira viscosity uye zvishoma kuderera kuyerera, saka inofanirwa kubaiwa pane yakakwira tembiricha uye pakudzvanywa kwejekiseni, uko tembiricha yejekiseni ine simba rakakura kupfuura kudzvanywa kwejekiseni, uye kukwirisa kudzvanywa kwejekiseni, zviri nani shrinkage yechigadzirwa.

Jekiseni tembiricha renji yakafara, tembiricha kunyunguduka iri 160 ℃, nepo decomposition tembiricha anosvika 270 ℃, saka zvinhu tembiricha gadziriso renji yakafara uye processability zviri nani.Naizvozvo, kuti uvandudze fluidity, kupisa kwejekiseni kwakakosha.Kukanganisa kwakashata, kusimba, nyore kukwenya, nyore brittle kupaza uye mamwe matambudziko, anofanirwa kuwedzerwa nekuwedzera tembiricha yekuumbwa, kuvandudza maitiro ekugadzirisa, kukunda kukanganisa uku.

2, pc

PC sheet

PC ine yakakwira viscosity, yakanyanya kunyunguduka tembiricha, kushomeka kwemvura, saka inofanira kunge yakakwira tembiricha jekiseni (pakati pe270-320 ℃), yakatetepa huwandu hwekugadziriswa kwekushisa kwezvinhu, maitiro haana kunaka sePMMA, kugadzirisa kwakaoma zvishoma kupfuura. PMMA.jekiseni kudzvinyirirwa pamvura yekukanganisa idiki, asi nekuda kweiyo viscosity, ichiri kudikanwa kuve yakakura jekiseni kudzvanywa, iyo inoenderana kuitira kudzivirira kushushikana kwemukati kunogadzirwa. pfupi sezvinobvira.

3, PET

PET bhodhoro

PET yekugadzira tembiricha yakakwira, uye tembiricha yekugadziridza huwandu hwakatetepa (260-300 ℃), saka iyo manufacturability haina kunaka, asi mushure mekunyunguduka, kuyerera kwakanaka.Mechanical simba uye kuita hakuna kukwirira mushure mejekiseni, uye inofanirwa kuvandudzwa kuburikidza nekutambanudza maitiro uye gadziriso yekuvandudza mashandiro.

Mold tembiricha inoda kudzorwa nemazvo kuitira kudzivirira warpage.Chinhu chakakosha mu deformation, saka kurudziro kune inopisa mumhanyi molds.Iyo tembiricha ye mold inoda kuve yakakwira zvikasadaro zvinokonzeresa kupenya kwepasi uye kunetsa mukudhirowa.

Kukanganisa uye mhinduro dzezvikamu zvepurasitiki zvinoonekera

Izvo zvinokanganisa zvinenge zvinotevera:

Sirivha zviyo nekuzadza mold uye condensation process, iyo yemukati stress anisotropic pesvedzero, yakatwasuka kutungamira kwekushushikana, zvekuti resin inoyerera pane yakatarisa, uye isiri-kuyerera yekutarisa kuburitsa rakasiyana refractive index uye kuzvarwa kweflash filament. , kana ichiwedzera, inogona kuita kuti chigadzirwa chionekwe chakatsemuka.Kuwedzera kune jekiseni molding maitiro uye mold kutarisisa, izvo zvakanakisa zvigadzirwa zve annealing kurapwa.Semuyenzaniso, PC zvinhu zvinogona kudziyisa kusvika 160 ℃ kana kupfuura kwemaminetsi 3-5, uye wozotonhodzwa zvoga.

Mhepo inoputikanekuda kweresin mukati memvura uye imwe gasi haigone kuburitswa, (mune mold condensation process) kana nekuda kwekusakwana kuzadza, kudonhedza pamusoro uye nekukurumidza kukwirisa uye kuumbwa kwevacuum bubbles.

Kupenya kwepasi kwakashatanekuda kwekushata kwe mold, kune rumwe rutivi kukonzeresa nekukurumidza kuitira kuti resin isakwanise kukopa mamiriro emuvhu, zvese izvi zvinoita kuti uso hwayo hubudise kusaenzana kudiki, uye chigadzirwa chinorasikirwa nekupenya kwayo.

Shock rippleinoreva kuumbwa kwe dense ripple kubva kugedhi rakatwasuka sepakati, chikonzero ndechekuti viscosity yekunyunguduka yakakurisa, zvinhu zvemberi zvakanyungudutswa mugomba, uyezve zvinhu zvakapaza nepakati peiyi condensation, uye pamusoro pekuvhunduka.

Huru chenazvinonyanya kukonzerwa nekudonha kweguruva mumhepo kana mbishi hunyoro hunenge hwakakurisa uye hunokonzerwa.

Utsi huchena uye mavara matemazvinonyanya kukonzerwa nekuparara kana kuparara kwebhari resin nekuda kwekupisa kwepamusoro kwepurasitiki mubhodhoro.

Jekiseni molding inoshandiswa zvakanyanya mumaindasitiri akasiyana siyana uye inogona kuwana isina musono, chaiyo misa kugadzirwa kwezvikamu munguva pfupi.PorLean Tech inopa majekiseni ekuumba masevhisi ezvakawanda zvezvinhu, zvinosanganisira mapurasitiki uye elastomers.Simplyrodha modhi yakouye tora yekukurumidza yemahara quote uye zano pane ane hukama masevhisi.

Nguva yekutumira: Kubvumbi-12-2022