Txhaj Moulding ruaj khov ntawm cov yas pob tshab - PMMA, PC, PET

Lub sijhawm nyeem ntawv kwv yees:3 feeb,37s

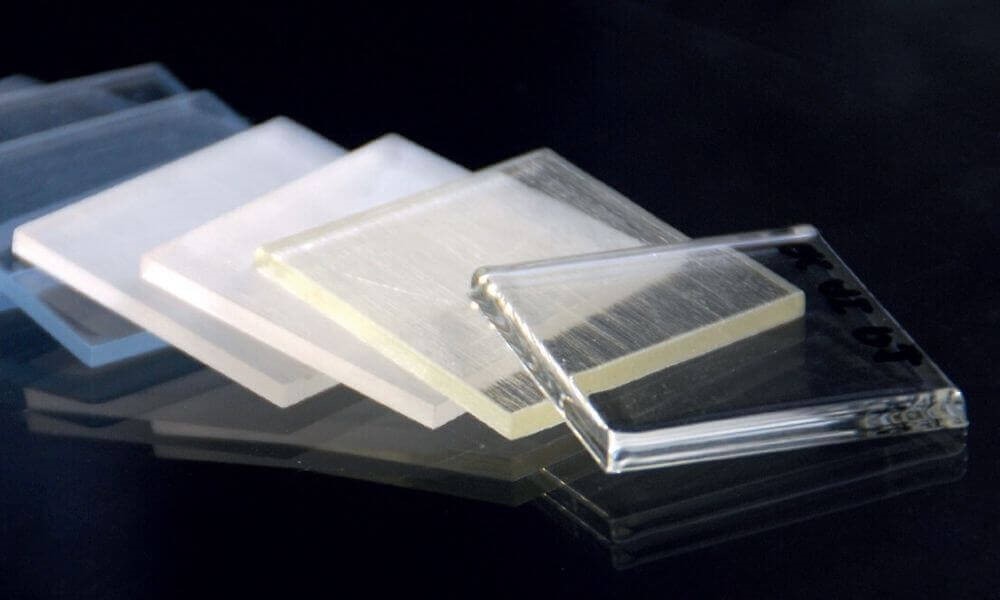

Cov yas pob tshab feem ntau siv hauv khw niaj hnub no yog polymethyl methacrylate (feem ntau hu ua acrylic lossis plexiglass, PMMA), polycarbonate (PC), polyethylene terephthalate (PET), pob tshab nylon, AS (acrylic-styrene copolymer), polysulfone (PSF) thiab lwm yam.Peb feem ntau siv cov yas yog PMMA, PC thiab PET.Vim muaj kev txwv qhov chaw, cov hauv qab no yog kev sib tham txog cov khoom thiab kev txhaj tshuaj molding txheej txheem ntawm peb cov yas no.Koj tuaj yeem ua tautiv tauj peb cov engineersncaj qha rau kev pab tswv yim dawb.

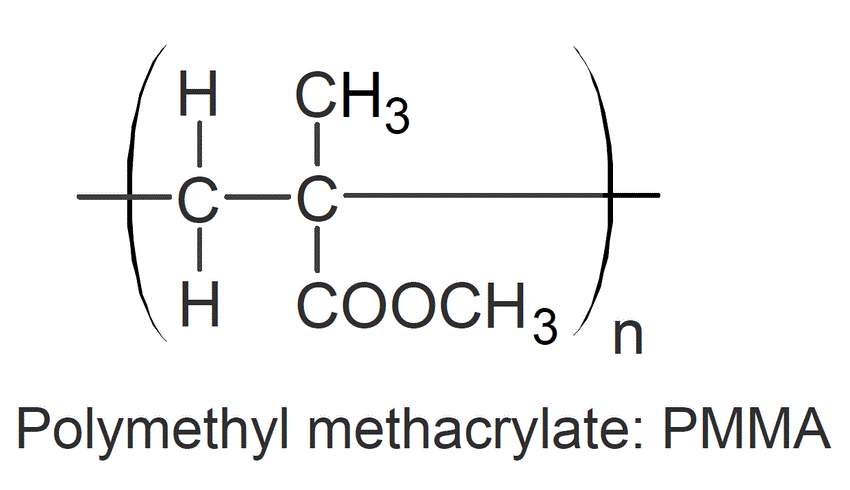

1, PMMA

PMMA Yas Raw Khoom

PMMA muaj viscosity siab thiab me ntsis tsis zoo flowability, yog li nws yuav tsum tau txhaj tshuaj ntawm cov khoom siv kub thiab kev txhaj tshuaj siab, qhov chaw txhaj tshuaj kub muaj qhov cuam tshuam ntau dua li qhov kev txhaj tshuaj siab, thiab qhov siab dua qhov kev txhaj tshuaj, qhov zoo dua. shrinkage ntawm cov khoom.

Kev txhaj tshuaj kub ntau yog qhov dav, qhov kub ntawm qhov melting yog 160 ℃, thaum lub decomposition kub nce mus txog 270 ℃, yog li cov khoom siv kub hloov pauv yog qhov dav thiab cov txheej txheem ua tau zoo dua.Yog li ntawd, txhawm rau txhim kho fluidity, kev txhaj tshuaj kub yog qhov tseem ceeb.Kev cuam tshuam tsis zoo, kev ua haujlwm ntev, yooj yim rau khawb, yooj yim rau kev tawg yooj yim thiab lwm yam teeb meem, yuav tsum tau nce los ntawm kev nce pwm kub, txhim kho cov txheej txheem condensation, kom kov yeej cov teeb meem no.

2, ib pc

PC ntawv

PC muaj viscosity siab, kub yaj, dej tsis zoo, yog li ntawd yuav tsum tau txhaj tshuaj kub (nruab nrab ntawm 270-320 ℃), kuj nqaim ntau yam ntawm cov khoom kub hloov, cov txheej txheem tsis zoo li PMMA, kev ua yog me ntsis nyuaj dua. PMMA.Kev txhaj tshuaj siab ntawm cov kua dej ntawm qhov cuam tshuam yog me me, tab sis vim yog cov viscosity, tseem yuav tsum muaj kev txhaj tshuaj loj dua, qhov sib thooj txhawm rau txhawm rau tiv thaiv kev ntxhov siab sab hauv tsim kom tsis txhob muaj kev ntxhov siab sab hauv, lub sijhawm los tswj lub siab yuav tsum yog. luv li sai tau.

3. PEB

PET lub raj mis

PET forming kub yog siab, thiab cov khoom siv kub hloov pauv yog nqaim (260-300 ℃), yog li cov khoom lag luam tsis zoo, tab sis tom qab melting, fluidity yog qhov zoo.Mechanical zog thiab kev ua tau zoo tsis yog siab tom qab txhaj tshuaj, thiab yuav tsum tau txhim kho los ntawm cov txheej txheem ncab thiab kev hloov kho los txhim kho kev ua haujlwm.

Pwm kub yuav tsum tau tswj kom raug thiaj li tiv thaiv warpage.Ib qho tseem ceeb hauv kev deformation, yog li kev pom zoo rau cov pwm kub khiav.Cov pwm kub yuav tsum siab dua yog tias nws yuav ua rau lub ntsej muag tsis zoo thiab teeb meem hauv demoulding.

Qhov tsis xws luag thiab kev daws teeb meem rau pob tshab yas qhov chaw

Cov defects yog kwv yees li hauv qab no:

Nyiaj nplej los ntawm cov pwm filling thiab condensation txheej txheem, lub internal stress anisotropic cawv, ntsug kev taw qhia ntawm kev nyuaj siab, thiaj li hais tias cov resin ntws ntawm orientation, thiab non-flow orientation los tsim ib tug txawv refractive index thiab yug ntawm lub flash filament. , thaum nws nthuav dav, tej zaum yuav ua rau cov khoom tshwm tawg.Ntxiv nrog rau cov txheej txheem txhaj tshuaj molding thiab pwm xim, cov khoom zoo tshaj plaws rau kev kho mob annealing.Piv txwv li, cov khoom siv PC tuaj yeem ua kom sov rau 160 ℃ lossis ntau dua rau 3-5 feeb, thiab tom qab ntawd txias lawm.

Cua npuasvim cov resin nyob rau hauv dej thiab lwm yam roj tsis tuaj yeem tawm, (nyob rau hauv cov pwm condensation txheej txheem) los yog vim tsis txaus filling, condensing nto thiab ceev heev condensation thiab tsim ntawm lub tshuab nqus tsev npuas.

Tsis zoo nto glossvim yog qhov roughness ntawm pwm, ntawm qhov tod tes, condensing ntxov dhau, yog li cov resin tsis tuaj yeem luam lub xeev ntawm cov pwm saum npoo, tag nrho cov no ua rau nws nto tsim me me unevenness, thiab cov khoom poob nws gloss.

Shock rippleyog hais txog kev tsim cov ntom ntom los ntawm lub rooj vag ncaj raws li qhov chaw, thiab tom qab ntawd cov khoom tawg los ntawm qhov chaw tsim hws, thiab cov nto ntawm lub shock ripple.

Lub ntsej muag dawbfeem ntau yog vim muaj plua plav poob rau hauv cov khoom siv raw hauv huab cua lossis cov khoom siv raw cov ntaub ntawv noo noo loj heev thiab tshwm sim los ntawm.

Cov pa luam yeeb dawb thiab xim dubFeem ntau yog tshwm sim los ntawm decomposition los yog deterioration ntawm lub chim resin vim lub zos overheating ntawm cov yas nyob rau hauv lub thoob.

Txhaj tshuaj molding yog dav siv nyob rau hauv ntau yam lag luam thiab tuaj yeem ua tiav seamless, precision loj ntau lawm ntawm qhov chaw nyob rau lub sijhawm luv luv.PorLean Tech muaj kev txhaj tshuaj molding rau kaum ob ntawm cov ntaub ntawv, suav nrog cov yas thiab elastomers.Tsuas yogupload koj tus qauvthiab tau txais cov lus qhia dawb ceev thiab cov lus qhia txog cov kev pabcuam cuam tshuam.

Post lub sij hawm: Apr-12-2022