Imisonto yoMatshini: Yonke into ekufuneka uyazi

Uhlaziyo lokugqibela: 09/06 Ixesha lokufunda: 8 imiz

Imisonto ngamacandelwana avala isithuba sokudibanisa kunye nokudibanisa kwindibano yamalungu ukwandisa amandla kunye nokuqina kweemveliso zokugqibela kushishino lwemveliso yehlabathi, oluxhomekeke kakhulu kwikhonkco kunye nokufakwa kwamacandelo ukwenza iimveliso zokugqibela.

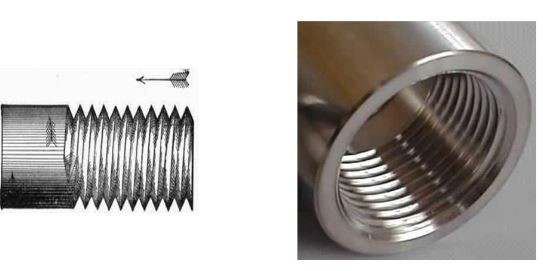

Imisonto yimiphetho ye-helical eqhubekayo kwi-cylindrical kunye ne-conical surfaces esetyenziselwa ukudibanisa oomatshini kunye nemveliso.Ngokuxhomekeke kwisicelo, iintambo zenziwe kwindawo yangaphakathi okanye yangaphandle.Imisonto eyenziwe kwiqokobhe elingaphandle yaziwa ngokuba yimisonto yangaphandle, ngoxa imisonto engaphakathi ibizwa ngokuba yimisonto yangaphakathi.Ngomatshini, kukho iindlela ezintathu eziphambili, Ukugaya, ukwenza intambo ngomatshini welathe, kunye nokufa-kusikwa,

Iintlobo zemisonto

Kukho iindidi ngeendidi zemisonto, njengemisonto evulekileyo, imisonto ye-screw yomatshini, i-Lag Screws, i-Self-Tapping Screws, i-Fasteners, i-Screws-Forming Screws, kunye ne-Type U Screw.Phakathi kwezi zibophelelo ze-ON, imisonto enezithuba kunye nemisonto ye-screw yomatshini zintlobo ezisetyenziswa ngokuqhelekileyo kwishishini lokuvelisa.Kwakhona, ngokweNkqubo ye-Screw Thread System edibeneyo, i-NC (coarse) kunye ne-UNF (eFine) imisonto yimisonto eqhelekileyo.

Apha makhe sixoxe ngemisonto yangaphakathi neyangaphandle ngokufutshane.

Imisonto yangaphakathi

Umsonto ojikeleza ngaphakathi kwesiqhoboshi, njengendongomane, ubizwa ngokuba ngumsonto wangaphakathi.Intambo yangaphakathi (Ibhinqa) i-machining yenziwa ngesixhobo esithile sokuthungatha umlebe omnye.Ngokwahlukileyo, ezinye iintambo zangaphakathi zisikwa ngesixhobo semveli esaziwa ngokuba yi-thread-tap.Imisonto yangaphakathi yamkela isikrufu kwaye usitshixe kwindawo yokusebenza.

Khetha isixhobo esinobungakanani obufanelekileyo begama lomatshini wokwenza umsonto wangaphakathi kwaye ulungise i-diameter yomngxuma apho uya kudala imisonto nganye kwisicelo sokusetyenziswa kokuphela.

Ngelixa kusenziwa le misonto ngeCNC machining, iintambo zangempela kufuneka zisuswe kumzobo weCAD, zishiya kuphela iprofayili enkulu yobubanzi.Sebenzisa unxulumano olunikiweyo ukubala i-diameter yokucofa;

Idayamitha yomngxuma ongundoqo = I-tap diameter - I-Tread pitch

Okanye,

Idayamitha yempompo = Idayamitha yomngxuma ongundoqo + Umsonto wesandi.

Khangela iziko kwaye ugrumbe umngxuma njengedayamitha ephakathi komngxuma ebibalwe ngaphambili, emva koko ucofe udini lomngxuma ngesixhobo sempompo kunye ne-chamfer ene-90-degree countersink.Ngoku jikelezisa kumngxuma ongundoqo ukwenza imisonto eqhubekayo.

Imisonto yangaphandle

Umsonto ugoba umphandle weshafti yesiqhoboshi, njengebholithi.ILathe ngumatshini osebenza kakhulu kwaye osetyenziswa ngokubanzi ekuveliseni imisonto yangaphandle kwizinto zokusebenza.Nayiphi na intonga ye-cylindrical enokuthi iguqulwe ifanelekile ukwenza iiprofayili zentambo zangaphandle.Unokukhetha isixhobo esisekwe kubunzulu bepitch obufunekayo.

Ukusika intambo yangaphandle iqala ngedayi yokuthunga (i-round-die) kunye nokubambelela kumatshini we-lathe.Imiphetho kufuneka ifakwe kuqala kwaye i-chamfer kwi-45 degrees.Ngoku uthinte umphetho we-workpiece kunye nesixhobo sokusika ngaphambi kokuba ujikeleze ubude bayo ukuze wenze intambo eqhubekayo.

Imisonto yangaphakathi nangaphandle

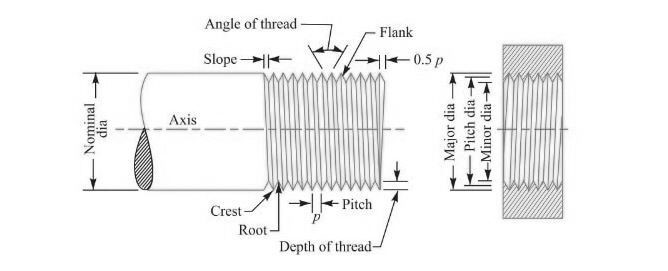

Isigama kumatshini wemisonto

Isigama kumatshini wokwenza imisonto

Ingcambu:Imisonto emibini elungelelanisiweyo yenza indawo ethe tyaba okanye engqukuva ezantsi, okanye umphezulu ongezantsi womsinga waziwa ngokuba yingcambu.

Crest:Umphezulu ongaphandle wemisonto eyenza amacala amabini omsonto (inxalenye eqikelelweyo yomsonto)

Icala:Umphezulu udibanisa ingcambu yomsonto kunye necrest kwaye uqhagamshelane neqabane lawo.

Iengile yomsonto:I-engile yenziwa ngamacala amabini ameleneyo emisonto emibini kwi-axial plane ebizwa ngokuba yi-thread angle.

Ubunzulu bokunyathela:Umgama we-axial phakathi kwe-crest kunye nengcambu waziwa njengobunzulu bentambo.

Isandi:Umgama phakathi kwemisonto emibini efanayo

I-engile ye-Helix:I-angle phakathi kwe-helix yentambo kunye nomgca oqhelekileyo kwi-axis yokujikeleza

Idayamitha enkulu:Idayamitha yengqikelelo ye-axial cylinder echukumisa i-crest yomsonto wangaphandle (okanye ingcambu okanye intambo yangaphakathi)

Idayamitha encinci: Idayamitha yentelekelelo ye-axial cylinder echukumisa ingcambu yomsonto wangaphandle (okanye ikresti yomsonto wangaphakathi)

I-Pitch Diameter:umyinge we-diameter enkulu kunye encinci

Iindlela zokusika umsonto womatshini

Ukusika imisonto kwenza kube lula ukwenza amakhonkco akruqukileyo kumalungu.Ukuba usika imisonto yangaphakathi, qiniseka ukuba inokufaka kwaye itshixe iqabane layo ngelixa udibanisa.

Ukukhetha eyona ndlela ilungileyo yokusika intambo kubalulekile;izinto ezininzi kufuneka ziqwalaselwe, ezifana nobugcisa, uqoqosho, ukusetyenziswa kwexesha, ukuchaneka, kunye nokufumaneka isixhobo.

1. Ukugaya

Ukugayaingasetyenziselwa ukusika imisonto kwimisonto yangaphakathi neyangaphandle.Isebenzisa intshukumo yesetyhula yezixhobo zokudibanisa ukuvelisa intambo kwisangqa esinye sokuhamba kwecala.Le ndlela isetyenziselwa ukusika imisonto yobukhulu obahlukeneyo, kodwa ifaneleke kakhulu kwimingxuma emikhulu.Imisonto eyenziwe ngomatshini wokugaya yenza iumgangatho ophezulu wokugqibakunye nokuhambelana okuchanekileyo.

Ukwenza imisonto ngokusila

Kwi-thread milling, kukho iindidi ezimbini zezixhobo ezisebenzayo nezithandwayo: i-carbide eqinile kunye ne-indexable.Ezi zixhobo zokusika amazinyo ahambelanayo kunokuba amiswe njengetephu.Oomatshini bentambo enamazinyo amaninzi basika intambo ukuya kumaleko anzulu ngomngxuma omnye ojikelezileyo.Ngenxa yokuba izixhobo ze-indexable ngokuqhelekileyo azifanelekanga kwimingxuma enobubanzi obungaphantsi kwe-0.625 intshi, izixhobo ze-carbide zisetyenziselwa ubukhulu becala elincinci;nangona kunjalo, ukuthunga ngesi sixhobo kuyabiza ukuba ukuchaneka okuphezulu akufuneki.Isixhobo esinesalathiso asibizi kakhulu kuba ufuna kuphela ukutshintsha umsiki emva kokuthenga enye.

Kukho iinzuzo ezininzi zokusebenzisa intambo yokusila.Ngokungafaniyo nokucofa, okunokujongana neentlobo ezahlukeneyo zeedamitha ngesixhobo esinye, ukucofa kunokuphatha kuphela i-diameter esisigxina ngesixhobo esinye, kunye neetephu ezinkulu ze-diameter nazo zibiza.

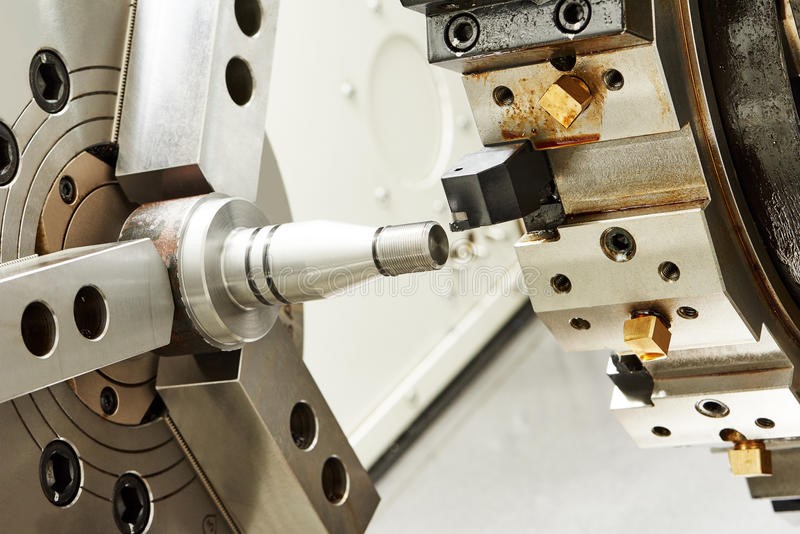

2. Imisonto Machining nge Lathe

Isixhobo sokuguqula i-Single-point nge-carbide insert sisetyenziselwa oku kusika.Ngaphambi kokuba kuqhutyekwe nokusika, ezinye izibalo ziyafuneka ukusika intambo ngomatshini welathe, onje ngepitch, ilothe, ubunzulu, kunye nobukhulu kunye nobukhulu obuncinci.

Umqheba wempompo yeyona ndlela isebenzayo yokucofa ngomatshini welathe.Nangona kunjalo, i-workpiece kufuneka iqale ifakwe kwi-chuck.

Ukwenza imisonto ngeLathe

· Cwangcisa i-thread-bit kunye nobude kwindawo esembindini yeLathe.I-bit yesixhobo kufuneka ibe kwi-engile echanekileyo ye-workpiece.

· Sondeza isuntswana lesixhobo sokuthunga kufutshane nendawo yokusebenza.

· Ngoku, susa isiphatho.Umzekelo, ukuba ufuna ukuvelisa iintambo ngepitch ye-1 mm, isixhobo sokuthunga kufuneka sihambe umgama we-1 mm njengoko i-workpiece igqibezela inguqu enye.Ngoko, qhubeka ngokufanelekileyo.

3. Ukufa-ukusika

Ukunqunyulwa kweentambo

Yindlela echanekileyo kwaye engabizi kakhulu yokusika intambo engasetyenziselwa ukuveliswa kobuninzi obungadingi iqondo eliphezulu lokuchaneka kunye nomgangatho.Umsonto uyafa udala intambo yangaphandle ehambelanayo neqabane layo langaphakathi.

Ngaphambi kokuqhubeka nokusika intambo ngokufa, icala lokuqala lesiphelo somsebenzi kufuneka lihlanjululwe kwii-degrees ezingama-45, ezinokuthi zenziwe ngomatshini okanye ngesandla.Emva koko, nceda ukhethe i-diameter efanelekileyo yokufa kwaye uyiqinise kwi-die-stock emva kokubeka i-dies kwi-end-side, enokuthi ijikelezwe ngokulula ngobude ukwenza imisonto.

Ukufa kwentambo kukwasetyenziswa ngokubanzi kumashishini okwenza isinyithi kunye nemveliso ukulungisa imisonto kwimingxuma ekhuhlayo okanye iibholiti.Imisonto eyenziwe nge-dies yonyusa amandla kunye nokuqina ngelixa inciphisa iindleko zempahla kuba intsalela yentsimbi encinci ichithwa ngexesha lenkqubo.

Iingcebiso eziphambili zoyilo

· Qinisekisa ukuba umphezulu we-workpiece ufana nobude bayo ngaphambi kokuba uqhubeke nokusika.

· Ukwenza imicu yangaphandle, chamfer kwicala lokugqibela kwi-angle ye-45-degree ngaphambi kokusika.I-countersink iyadingeka ekupheleni kwentambo yangaphakathi.

· Ukuba akukho mfuneko ezithile kwizicelo ezizayo, kulungele ukuyila imicu enobude obuphantsi kunye nobukhulu obuqhelekileyo.

· Ubukhulu bomsonto kufuneka bukhethwe ukwenzela ukuba bukwazi ukumelana noxinzelelo ngelixa udibanisa.

Umphezulu-ukugqiba imisonto

Imisonto enomphezulu wokugqiba

Emva kokwenziwa ngomatshini, ukugqitywa komphezulu kwemisonto kubalulekile ngenxa yezizathu zobuhle, kuphucula ukusebenza kwemveliso iyonke, kwaye yandisa ubomi bayo.Ukongezelela, yindlela efanelekileyo yokukhusela i-corrosion kunye nokuchithwa kwendawo kwaye ngaloo ndlela ugweme ukungaphumeleli kokudibanisa komatshini.

Ukupeyinta kunyei-black-oxideukugqiba zimbini iindlela ezisebenzayo zokugqitywa komphezulu wemisonto.Nangona kunjalo, umzobo awuyi kuhlala ixesha elide xa kuthelekiswa nokugqitywa kwe-oxide emnyama.

I-Black-oxide igqiba

Ngokusisiseko ngumaleko we-microscopic wemagnetite (Fe3O4) egquma umphezulu womsonto.Ngenxa yokuba ubukhulu be-black-oxide coating ayibalulekanga, ayichaphazeli ukuzinza kwe-dimensional, iiparamitha zoyilo, okanye iipropati.Ukugqiba i-oxide emnyama, ibhetshi yemicu yomatshini intywiliselwa kwisisombululo setyuwa yealkali kwiqondo lokushisa elifanelekileyo (130 ukuya kwi-150 0C).

Alandelayo ngamanyathelo ekufuneka elandelwe ukugqitywa kwemisonto emnyama.

- 1. Ukusebenzisa isisombululo se-alkaline samanzi, coca imicu (kwiibhetshi).

- 2. Coca ngokukhawuleza ngamanzi adibeneyo kuba izisombululo ze-alkaline zinokusabela kunye nomphezulu wentambo kwaye zithobe umgangatho ophambili.

- 3. Coca ngamanzi kwakhona ukuze unciphise ukucocwa kwe-asidi.

- 4. Gxila imicu kwisisombululo se-alkaline ebilayo imizuzu emi-5 ukuya kwe-45.

- 5. Ukusebenzisa ijethi yamanzi, hlambulula ngamanzi acinezelekileyo kwaye ubeke eceleni ukuze wome.

- 6. Ukuphucula ukuxhathisa kwimisonto kunye nokubukeka kobuhle, sebenzisa i-wax, i-oyile, i-lacquer, okanye ezinye izinto zokugquma zesibini.

- 7. Ngoku ibhetshi yeentambo ilungele izicelo ezijoliswe kuzo.

Ukuqukumbela

Ukwenza imisonto yinkqubo ebalulekileyo kwimveliso.Ke ngoko, ukukhetha indlela efanelekileyo yomatshini kubaluleke kakhulu.Kufuneka kube ngokwesicelo sokusetyenziswa kokuphela, ukufumaneka kobugcisa, kunye nokuba nokwenzeka kwezoqoqosho.Inokuba yinto entsonkothileyo, kodwa ayinakungahoywa.

Unokubonisana neengcali kwiindlela zokuthunga ukusuka kuyilo ukuya ekugqityweni komhlaba.Sineqela elinamava leenjineli eziya kukunceda ekwenzeni imisonto.Sinikezela ngeenkonzo zokucutha intambo kuzo zonke iindlela, Ukugaya, ukwenza intambo ngomatshini welathe, kunye nokusika ukufa, phantse yonke into oyifunayo malunga nemisonto.Ke, ukuba ufuna nayiphi na inkonzo ehambelanayo, nceda ungalibazisi Qhagamshelana nathi.

Ii-FAQ's

Kutheni ukwenziwa kwentambo kubalulekile kwimveliso?

Ukwenza imisonto yenye yezona ndlela zisebenzayo zokwenziwa kweqhekeza elinye.Imisonto iyafuneka ukudibanisa iindlela ezahlukeneyo kunye neenxalenye zemveliso.Iqinisa amajoyina kunye nokudibanisa kwamacandelo amaninzi anezakhiwo ezicacileyo kakhulu.

Zeziphi iindlela ezidumileyo zokwenziwa kwemisonto?

Ukugaya, umatshini weLathe, kwaye uyafa zezona ndlela zidumileyo nezisebenzayo zokwenziwa komsonto kwishishini lemveliso.

Lobuphi olona buchule bokwenza imisonto?

Kuxhomekeke kwizinto ezahlukeneyo ezifana nobukhulu bemisonto, uhlobo lwezicelo, ukufumaneka koBuchule, ukubanakho kwezoqoqosho, kunye nemfuno yokuchaneka.

Ngaba ukugqitywa komphezulu kubalulekile kwimisonto?

Ewe, kubalulekile ukunqanda ukwakheka komhlwa kunye nokwandisa ukuqina koqhagamshelo kunye nesibheno sobuhle.

Ixesha lokuposa: Jun-16-2022