Likhoele tsa machining: Tsohle tseo u hlokang ho li tseba

Nchafatso ea ho qetela:09/06 Nako ea ho bala: 8 mets

Likhoele ke likarolo tse tlatsang lekhalo la ho kenya le ho hokahanya ho kopanngoeng ha likarolo ho matlafatsa matla le ho tšoarella ha lihlahisoa tsa ho qetela indastering ea lefats'e ea tlhahiso, e itšetlehileng haholo ka lehokelo le ho lokisoa ha likarolo ho theha lihlahisoa tsa ho qetela.

Likhoele ke li-helical tse tsoelang pele holim'a cylindrical le conical surfaces tse sebelisetsoang ho kopanya karolo ea mochine le ea sehlahisoa.Ho itšetlehile ka kopo, likhoele li bōptjoa ka hare kapa ka ntle.Likhoele tse entsoeng ka holim’a khetla e ka ntle li tsejoa e le likhoele tse ka ntle, athe likhoele tse karolong e ka hare li bitsoa likhoele tse ka hare.Bakeng sa machining, ho na le mekhoa e meraro haholo, Milling, ho lokisa likhoele ka mochini oa lathe, le ho seha lefu,

Mefuta ea likhoele

Ho na le mefuta e fapaneng ea likhoele, joalo ka likhoele tse arohaneng, likhoele tsa screw screw, Lag Screw, Self-Tapping Screw, ON fasteners, Thread-Forming Screw, le Type U Screw.Har'a li-fasteners tsena tsa ON, likhoele tse arohaneng le likhoele tsa screw ea mochini ke mefuta e sebelisoang hangata indastering ea tlhahiso.Hape, ho ea ka Unified Screw Thread System, likhoele tsa NC (mahoashe) le UNF (Fine) ke mekhahlelo e tloaelehileng ea likhoele.

Mona ha re tšohleng likhoele tsa kahare le kantle ka bokhutšoanyane.

Likhoele Tsa ka Hare

Khoele e potolohang ka har'a sekoti, joalo ka nate, e bitsoa khoele e ka hare.Ho sebetsa ka hare ho khoele (Mosali) ho etsoa ka sesebelisoa se khethehileng sa ho roala molomo o le mong.Ka lehlakoreng le leng, likhoele tse ling tse ka hare li sehoa ka sesebelisoa sa setso se tsejoang e le khoele-tap.Likhoele tse ka hare li amohela screw ebe li e notlela ka har'a workpiece.

Khetha sesebelisoa se nang le boholo bo loketseng ba lebitso bakeng sa machining ea khoele ea ka hare 'me u lokise bophara ba lesoba moo u tla etsa likhoele ho latela ts'ebeliso ea ho qetela.

Ha ho ntse ho etsoa likhoele tsena kaMechine ea CNC, likhoele tsa sebele li tlameha ho tlosoa setšoantšong sa CAD, ho siea feela setšoantšo se seholo sa bophara.Sebelisa kamano e fanoeng ho bala bophara ba ho tlanya;

Diameter of the core hole = Thepa bophara - Thepa pitch

Kapa,

Thepa bophara = Core lesoba bophara + Thread sekontiri se metsi.

Fumana sebaka se bohareng ebe u phunya lesoba joalo ka bophara bo baliloeng pele ba lesoba, 'me u tobetse sekoting sa lesoba ka pompo le chamfer e nang le sinki ea likhato tse 90.Joale potoloha ka har'a lesoba la mantlha ho theha likhoele tse tsoelang pele.

Likhoele Tsa Kantle

Khoele e kobeha karolong e ka ntle ea moqomo oa fastener, joalo ka bolt.Lathe ke mochini o sebetsang hantle haholo ebile o sebelisoa haholo bakeng sa ho hlahisa likhoele tsa kantle ho li-workpieces.Molamu ofe kapa ofe oa cylindrical o ka fetoloang o loketse ho theha li-profiles tsa khoele ea kantle.U ka khetha sesebelisoa ho latela botebo bo hlokahalang ba sekontiri.

Ho seha likhoele tsa kantle ho qala ka ho thaepa (round-die) le ho hokela mochini oa lathe.Lithako li tlameha ho kenngoa pele 'me li chese ka likhato tse 45.Hona joale ama bohale ba workpiece ka sesebelisoa sa ho itšeha pele u se potoloha nako e telele bolelele ba sona ho etsa khoele e tsoelang pele.

Likhoele tsa ka hare le tsa kantle

Terminology in Threads machining

Terminology in thread Machining

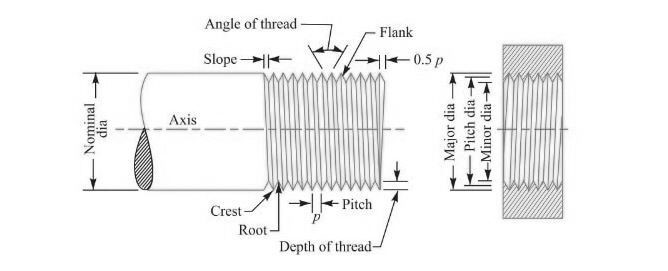

Motso:Likhoele tse peli tse feto-fetohang li etsa sebaka se bataletseng kapa se chitja ka tlase, kapa bokaholimo ba khoele ea khoele bo tsejoa e le motso.

Crest:Bokaholimo ba likhoele tse entsoeng ka mahlakore a mabeli a khoele (karolo e lebelletsoeng ea khoele)

LephakoBokaholimo bo hokahanya motso oa khoele le bokaholimo ebe bo kopana le karolo ea eona.

Khoele ea khoele:Angle e entsoe ka mahlakore a mabeli a bapileng a likhoele tse peli ka har'a sefofane sa axial se bitsoang thread angle.

Botebo ba maoto:Sebaka sa axial pakeng tsa crest le motso se tsejoa e le botebo ba khoele.

Sekhahla:Sebaka pakeng tsa likhoele tse peli tse tšoanang

Helix angle:Angle pakeng tsa helix ea khoele le mola o tloaelehileng ho axis ea ho potoloha

Bophara bo boholo:Bophara ba cylinder e inahaneloang ea co-axial e amang bokaholimo ba khoele e kantle (kapa motso kapa khoele e ka hare)

Bophara bo bonyenyane: Bophara ba mokhopo o inahaneloang oa co-axial o amang motso oa khoele e ka ntle (kapa crest ea khoele e ka hare)

Pitch Diameter:karolelano ea bophara bo boholo le bo fokolang

Mekhoa ea ho seha khoele ea machining

Ho khaola likhoele ho etsa hore ho be bonolo ho theha lihokelo tse sehiloeng holim'a likarolo.Haeba u khaola likhoele tse ka hare, etsa bonnete ba hore e ka kenya le ho notlela molekane oa eona ha e ntse e etsa khokahanyo.

Ho khetha mokhoa o motle ka ho fetisisa oa ho khaola khoele ho bohlokoa;lintlha tse ngata li tlameha ho nkoa, tse kang botekgeniki, moruo, tšebeliso ea nako, ho nepahala, le ho fumaneha ha lisebelisoa.

1. Milling

Millinge ka sebelisoa ho khaola likhoele ka likhoele tse ka hare le tse kantle.E sebelisa motsamao oa selikalikoe oa lisebelisoa tsa khoele ho hlahisa khoele ka selikalikoe se le seng sa motsamao oa lateral.Mokhoa ona o sebelisetsoa ho khaola likhoele tsa boholo bo fapaneng, empa o loketse ka ho fetisisa bakeng sa likoti tse kholoanyane.Likhoele tse entsoeng ka mochini oa ho sila li theha apheletso e phahameng ya bokahodimole ho nepahala ha dimensional consistency.

Ho lokisa likhoele ka ho sila

Ka ho sila likhoele, ho na le mefuta e 'meli ea lisebelisoa tse sebetsang le tse tsebahalang: carbide e tiileng le indexable.Meno a ho itšeha a lisebelisoa tsena a bapile ho fapana le ho hlongoa joalo ka pompo.Mechini ea likhoele tse nang le meno a mangata e seha khoele ho ea likarolong tse tebileng tsa eona ka lesoba le le leng le pota-potileng hohle.Hobane lisebelisoa tsa indexable hangata ha li tšoanelehe bakeng sa masoba a bophara ba lisenthimithara tse 0.625, lisebelisoa tsa carbide li sebelisoa haholo-holo bakeng sa boholo ba masoba a manyenyane;leha ho le joalo, ho roala ka sesebelisoa sena ho batla ho theko e boima haeba ho sa hlokahale ho nepahala ho phahameng.Sesebelisoa sa indexable ha se theko e tlase hobane o hloka feela ho khutlisa cutter kamora ho e reka.

Ho na le melemo e mengata ea ho sebelisa thread-milling.Ho fapana le ho phunya, ho ka sebetsanang le mefuta e fapaneng ea li-diameter ka sesebelisoa se le seng, ho tlanya ho ka sebetsana feela le bophara bo tsitsitseng ka sesebelisoa se le seng, 'me lipompo tse kholoanyane tsa bophara li boetse li theko e boima.

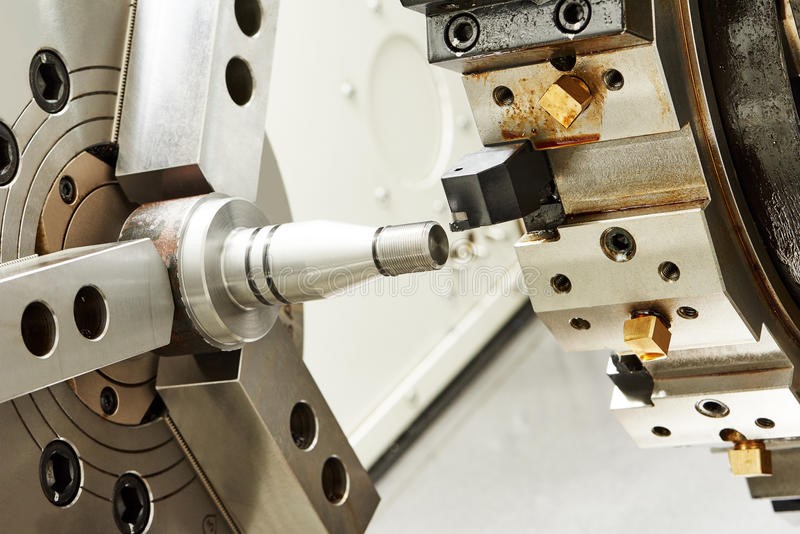

2. Li-Threads Machining le Lathe

Ho sebelisoa sesebelisoa sa ho fetola ntlha e le 'ngoe se kenyang carbide bakeng sa seha sena.Pele o tsoela pele ka ho seha, ho hlokahala lipalo tse ling ho khaola khoele ka mochini oa lathe, joalo ka sekontiri se metsi, loto, botebo, le bophara bo boholo le bo nyane.

Thepa ea pompo ke mokhoa o sebetsang ka ho fetisisa oa ho tlanya ka mochini oa lathe.Leha ho le joalo, mosebetsi o tlameha ho qala ka ho kenngoa ka har'a chuck.

Ho etsa likhoele ka Lathe

· Beha khoele-bit le bophahamo ho ntlha e bohareng ea Lathe.Sesebelisoa sa sesebelisoa se lokela ho ba sekhutlong se nepahetseng sa workpiece.

· Atametsa sesebelisoa sa khoele haufi le sesebelisoa.

· Jwale, suthisa motshwaro.Ka mohlala, haeba u batla ho hlahisa likhoele ka sekontiri sa 1 mm, sesebelisoa sa khoele se tlameha ho tsamaea sebaka sa 1 mm ha workpiece e qeta phetoho e le 'ngoe.Kahoo, tsoela pele ho latela.

3. Ho poma-shoela

Ho poma-shoela likhoele

Ke mokhoa o otlolohileng le o theko e tlaase oa ho khaola khoele e ka sebelisoang bakeng sa tlhahiso ea bongata e sa hlokeng tekanyo e phahameng ea ho nepahala le boleng.Threading dies e theha khoele ea kantle e lumellanang le khoele ea eona ea kahare.

Pele o tsoela pele ka ho khaola khoele ka lefu, karolo ea pele ea ho qetela ea workpiece e tlameha ho chesoa ka likhato tse 45, tse ka etsoang ka mochine kapa ka letsoho.Ka nako eo, ka kopo khetha dia dia loketseng loketseng 'me tighten e ka die-stock ka mor'a ho beha dies ka qetellong-lehlakoreng, e ka habonolo rotated hammoho bolelele ho bopa likhoele.

Li-threading dies li sebelisoa haholo indastering ea tšepe le ea tlhahiso ho lokisa likhoele ka mekoting kapa liboutung.Likhoele tse entsoeng ka li-dies li eketsa matla le nako e telele ha li ntse li fokotsa litšenyehelo tsa thepa hobane masala a fokolang a tšepe a senyeha nakong ea ts'ebetso.

Litlhahiso tsa bohlokoa tsa moralo

· Etsa bonnete ba hore bokaholimo ba workpiece bo tšoana ho pholletsa le bolelele ba eona pele u tsoela pele ka ho itšeha.

· Ho etsa likhoele tsa ka ntle, chamfer lehlakoreng la ho qetela ka angle ea 45-degree pele u seha.Ho hlokahala countersink qetellong ea khoele e ka hare.

· Haeba ho se na litlhoko tse khethehileng bakeng sa likopo tsa nako e tlang, ho molemo ho rala likhoele tse nang le bophahamo bo tlase le boholo bo tloaelehileng.

· Botenya ba khoele bo lokela ho khethoa e le hore bo khone ho mamella khatello ha ho kopanngoa.

Ho qeta bokaholimo bakeng sa likhoele

Likhoele tse nang le top finishing

Ka mor'a ho qeta ho sebetsa, ho qetela ha likhoele ho bohlokoa bakeng sa mabaka a botle, ho ntlafatsa ts'ebetso ea sehlahisoa ka kakaretso, le ho lelefatsa bophelo ba sona.Ho phaella moo, ke tsela e molemo ka ho fetisisa ea ho thibela ho bola le ho senyeha ha holim'a metsi 'me kahoo ho qoba ho hlōleha ha ho kopanya mechine.

Ho penta leoxide e ntšoho qeta ke mekhoa e 'meli e sebetsang ea ho qeta holim'a likhoele.Leha ho le joalo, penta e ke ke ea tšoarella nako e telele ha e bapisoa le qetello ea black oxide.

Black-oxide e qetella

Ha e le hantle ke lera le lenyenyane la magnetite (Fe3O4) le koahelang bokaholimo ba khoele.Hobane botenya ba "black-oxide" e koahetsoeng ke ntho e nyenyane, ha e ame botsitso ba dimensional, litekanyetso tsa moralo kapa thepa.Bakeng sa ho qeta oxide e ntšo, sehlopha sa likhoele tse entsoeng ka mochini se qoelisoa ka har'a motsoako oa letsoai oa alkaline mocheso o loketseng (130 ho isa ho 150 0C).

Tse latelang ke mehato e lokelang ho lateloa bakeng sa ho qeta likhoele tse ntšo.

- 1. U sebelisa tharollo ea metsi a alkaline, hloekisa likhoele (ka lihlopha).

- 2. Hloekisa hang-hang ka metsi a hloekisitsoeng hobane litharollo tsa alkaline li ka sebetsa ka holim'a khoele 'me tsa senya ntlha ea mantlha.

- 3. Hloekisa ka metsi hape ho fokotsa ho hloekisa acid.

- 4. Kenya likhoele ka tharollo ea alkaline e belang metsotso e 5 ho isa ho e 45.

- 5. U sebelisa jete ea metsi, hloekisa ka metsi a hatelitsoeng 'me u behelle ka thōko ho omisa.

- 6. Ho ntlafatsa ts'ebetso ea likhoele tse senyehileng le botle bo botle, sebelisa boka, oli, lacquer kapa lisebelisoa tse ling tsa ho roala.

- 7. Hona joale sehlopha sa likhoele se se se loketse lits'ebetso tse lebisitsoeng.

Qetello

Ho etsa likhoele ke ts'ebetso ea bohlokoa tlhahisong.Ka hona, khetho ea mokhoa o nepahetseng oa mochini o bohlokoa haholo.E lokela ho ba ho latela ts'ebeliso ea ts'ebeliso ea ho qetela, boteng ba tekheniki, le bokhoni ba moruo.E ka 'na ea batla e rarahane, empa e ke ke ea hlokomolohuoa.

U ka buisana le litsebi tsa mekhoa ea ho roka ho tloha ho moralo ho ea ho qetela.Re na le sehlopha sa baenjiniere ba nang le boiphihlelo ba tla u thusa ho etsa likhoele.Re fana ka lits'ebeletso tsa machining a likhoele ho tsoa mekhoeng eohle, Ho sila, ho etsa likhoele ka mochini oa lathe, le ho seha, hoo e batlang e le ntho e ngoe le e ngoe eo u e hlokang mabapi le likhoele.Kahoo, haeba u hloka tšebeletso leha e le efe e amanang le eona, ka kopo u se ke ua tsilatsila iteanye le rona.

FAQ's

Hobaneng ha machining a likhoele e le a bohlokoa tlhahisong?

Ho etsa likhoele ke o mong oa mekhoa e sebetsang ka ho fetesisa ea ho etsa sekhechana se le seng.Likhoele lia hlokahala ho hokahanya mekhoa e fapaneng le likarolo tsa sehlahisoa.E matlafatsa manonyeletso le likhokahano tsa likarolo tse ngata tse nang le meaho e otlolohileng haholo.

Mekhoa e tsebahalang ea ho etsa likhoele ke efe?

Milling, Lathe machine, and dies ke mekhoa e tsebahalang haholo le e sebetsang bakeng sa machining a likhoele indastering ea tlhahiso.

Mokhoa o motle ka ho fetisisa oa ho etsa likhoele ke ofe?

E ipapisitse le lintlha tse fapaneng tse kang boholo ba likhoele, mofuta oa lits'ebetso, ho fumaneha ha tekheniki, bokhoni ba moruo, le tlhoko ea ho nepahala.

Na ho qeta holimo ho bohlokoa bakeng sa likhoele?

Ee, ho bohlokoa ho thibela mafome le ho eketsa botsitso ba likhokahano hammoho le boipiletso ba botle.

Nako ea poso: Jun-16-2022