Izintambo zemishini: Konke odinga ukukwazi

Isibuyekezo sokugcina:09/06 Isikhathi sokufunda: 8 imiz

Imicu yizingxenye ezivala igebe lokufaka nokuxhuma ekuhlanganisweni kwezingxenye ukuze kuthuthukiswe amandla nokuqina kwemikhiqizo yokugcina embonini yokukhiqiza yomhlaba wonke, encike kakhulu ekuxhumaneni nasekufakweni kwezingxenye ukuze kwakhiwe imikhiqizo yokugcina.

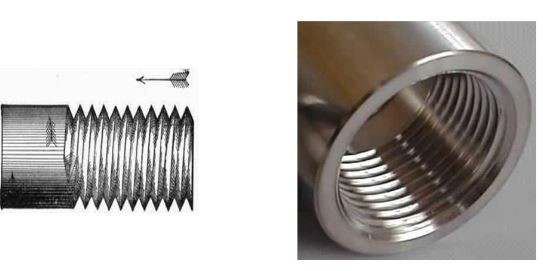

Imicu iyimiphetho ye-helical eqhubekayo endaweni eyisilinda kanye ne-conical esetshenziselwa ukuhlanganisa ingxenye yomshini nengxenye yomkhiqizo.Kuye ngohlelo lokusebenza, izintambo zenziwa endaweni yangaphakathi noma yangaphandle.Imicu eyakhiwe egobolondweni elingaphandle yaziwa ngokuthi imicu yangaphandle, kanti imicu engaphakathi ibizwa ngokuthi imicu yangaphakathi.Ngomshini, kunezindlela ezintathu eziyinhloko, Ukugaya, umshini wokuthunga ngomshini we-lathe, nokusika ukufa,

Izinhlobo zezintambo

Kunezinhlobo ezehlukene zemicu, njengemicu enezikhala, izintambo zesikulufu somshini, Izikulufu eziLag, Izikulufi zokuzithepha, iziqinisi EZOKUQINISA, Izikulufu Ezakha Imicu, kanye Nezikulufu Zohlobo U.Phakathi kwalezi zinto zokubopha KU-ON, izintambo ezinezikhala nemicu yesikulufu somshini yizinhlobo ezivame ukusetshenziswa embonini yokukhiqiza.Futhi, ngokuya Ngohlelo Oluhlanganisiwe Lwe-Screw Thread, i-NC (amaholo) kanye ne-UNF (Fine) izigaba zochungechunge olujwayelekile.

Lapha ake sixoxe ngemicu yangaphakathi neyangaphandle kafushane.

Imicu Yangaphakathi

Intambo egeleza ngaphakathi kwesibophelelo, njengenadi, ibizwa ngokuthi intambo yangaphakathi.Ukwenziwa kwentambo yangaphakathi (Owesifazane) kwenziwa ngethuluzi elithile lokuthunga elinodebe olulodwa.Ngokuphambene, eminye imicu yangaphakathi isikwa ngethuluzi lendabuko elaziwa ngokuthi i-thread-tap.Imicu yangaphakathi yamukela isikulufu bese isikhiyela kucezu lokusebenza.

Khetha ithuluzi elinosayizi ofanelekile wegama lomshini wangaphakathi wochungechunge bese ulungisa ububanzi bembobo lapho uzodala khona imicu ngokohlelo lokusebenza lokusetshenziswa ekugcineni.

Ngenkathi kukhiqizwa lezi zintambo ngeCNC imishini, izintambo zangempela kufanele zisuswe emdwebeni we-CAD, kusale kuphela iphrofayela enkulu yobubanzi.Sebenzisa ukuhlobana okunikeziwe ukubala ububanzi bokuthepha;

Ububanzi bembobo ewumgogodla = Ububanzi bompompi - Iphimbo lochungechunge

Noma,

I-tap diameter = I-Core hole diameter + I-Thread pitch.

Thola indawo ephakathi bese ubhoboza imbobo njengobubanzi bembobo ewumgogodla obalwe ngaphambilini, bese uthepha unqenqema lwembobo ngethuluzi lokuthinta kanye ne-chamfer enosinki oyi-90-degree countersink.Manje zungezisa embobeni ewumgogodla ukuze udale imicu eqhubekayo.

Imicu Yangaphandle

Intambo igoba ngaphandle kweshafti ye-fastener, njengebhawudi.I-Lathe ingumshini osebenza kahle kakhulu futhi osetshenziswa kabanzi ekukhiqizeni imicu yangaphandle ezintweni zokusebenza.Noma iyiphi i-cylindrical rod engashintshwa ifaneleke ukudala amaphrofayili ochungechunge lwangaphandle.Ungakhetha ithuluzi ngokusekelwe ekujuleni kwephimbo okudingekayo.

Ukusika intambo yangaphandle kuqala ngedayi yokulutha (i-round-die) kanye nokubopha emshinini we-lathe.Imiphetho kufanele ifakwe kuqala futhi i-chamfer ku-45 degrees.Manje thinta unqenqema lwe-workpiece ngethuluzi lokusika ngaphambi kokuluzungeza ubude balo ukuze udale intambo eqhubekayo.

Imicu yangaphakathi neyangaphandle

I-Terminology in Threads machining

Amagama emishini yokwenza imicu

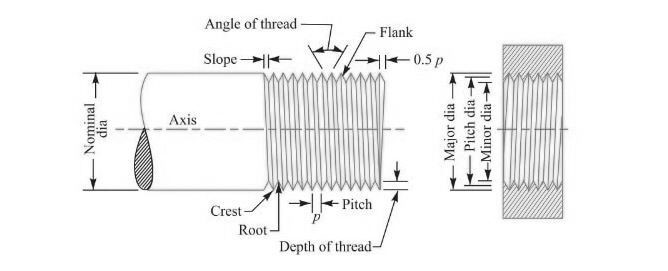

Umsuka:Imicu emibili elungisekayo yakha indawo eyisicaba noma eyindilinga phansi, noma indawo engezansi yemisele ebizwa ngokuthi impande.

Crest:Indawo engaphandle kakhulu yemicu eyakha izinhlangothi ezimbili zomucu (ingxenye ehlongozwayo yochungechunge)

I-Flank:Indawo engaphezulu ixhuma impande nocwephe lwentambo bese ithintana nozakwabo.

I-engeli yochungechunge:I-engeli yakhiwa amahlangothi amabili ancikene emicu emibili endizeni eyi-axial ebizwa ngokuthi i-thread angle.

Ukujula kokunyathela:Ibanga le-axial phakathi kwe-crest nempande laziwa njengokujula kwentambo.

Iphimbo:Ibanga phakathi kwemicu emibili efanayo

I-Helix angle:I-engeli phakathi kwe-helix yentambo kanye nomugqa ovamile ku-eksisi yokuzungezisa

Ububanzi obukhulu:Ububanzi besilinda esicatshangelwayo se-co-axial esithinta i-crest yochungechunge lwangaphandle (noma impande noma intambo yangaphakathi)

Ububanzi obuncane: Ububanzi besilinda esicatshangelwayo se-co-axial esithinta impande yochungechunge lwangaphandle (noma i-crest yomucu wangaphakathi)

I-Pitch Diameter:isilinganiso sobubanzi obukhulu nobuncane

Izindlela zokusika intambo yomshini

Ukusika intambo kwenza kube lula ukwakha izixhumanisi ezisikiwe ezingxenyeni.Uma usika imicu yangaphakathi, qiniseka ukuthi ingafaka futhi ikhiye izakwabo ngenkathi yenza uxhumano.

Ukukhetha indlela engcono kakhulu yokusika intambo kubalulekile;izici eziningi okufanele zicatshangelwe, njengobuchwepheshe, ezomnotho, ukusetshenziswa kwesikhathi, ukunemba, nokutholakala kwamathuluzi.

1. Ukugaya

Ukugayaingasetshenziswa ukusika imicu kuzo zombili izintambo zangaphakathi nezangaphandle.Isebenzisa ukunyakaza okuyisiyingi kwamathuluzi okuthunga ukuze kukhiqizwe intambo kumbuthano owodwa wokunyakaza kwezinhlangothi.Le ndlela isetshenziselwa ukusika izintambo ezinobukhulu obuhlukahlukene, kodwa ifaneleka kakhulu emigodini emikhulu.Imicu eyenziwe ngomshini wokugaya idala ahigh surface finishkanye nokuvumelana kwe-dimensional okunembile.

Ukwenza intambo ngokugaya

Ekugayeni intambo, kunezinhlobo ezimbili zamathuluzi asebenzayo nadumile: i-carbide eqinile ne-indexable.Amazinyo okusika lawa mathuluzi ayahambisana kunokuba amiswe ngendlela engafanele njengompompi.Imishini yentambo enamazinyo amaningi isika intambo izendlalelo zayo ezijulile ngembobo yokujika okukodwa.Ngenxa yokuthi amathuluzi anenkomba ngokuvamile awafaneleki emigodini enobubanzi obungaphansi kwamayintshi angu-0.625, amathuluzi e-carbide asetshenziselwa ngokuyinhloko osayizi bemigodi emincane;Nokho, ukuthunga ngaleli thuluzi kuyabiza kancane uma ukunemba okuphezulu kungadingeki.Ithuluzi elinenkomba libiza kancane ngoba udinga kuphela ukushintsha isisiki ngemva kokusithenga.

Kunezinzuzo eziningi zokusebenzisa i-thread-milling.Ngokungafani nokuthepha, okungabhekana nezinhlobonhlobo zamadayamitha ngethuluzi elilodwa, ukuthepha kungakwazi kuphela ukuphatha ububanzi obugxilile ngethuluzi elilodwa, futhi ompompi abakhulu bobubanzi nabo bayabiza.

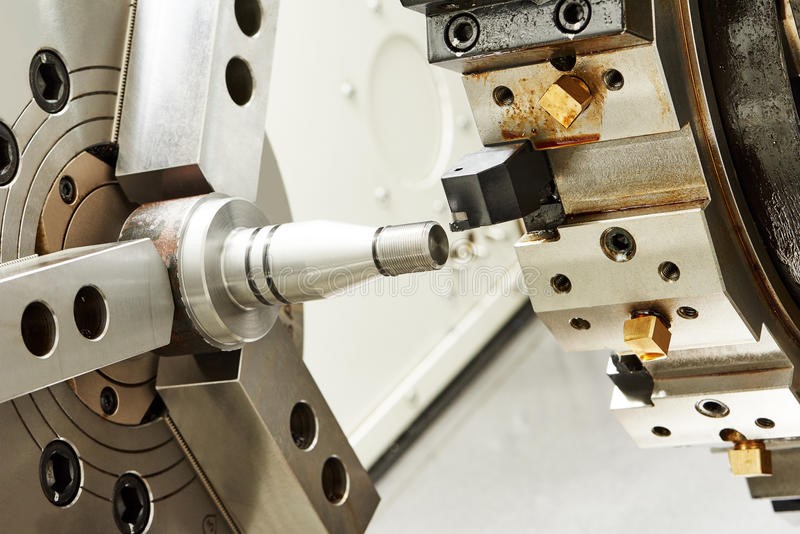

2. Imicu Ukwenza nge Lathe

Ithuluzi lokujika lephoyinti elilodwa elinokufakwa kwe-carbide lisetshenziselwa lokhu kusikwa.Ngaphambi kokuqhubeka nokusika, ezinye izibalo ziyadingeka ukuze usike intambo ngomshini we-lathe, njenge-pitch, umthofu, ukujula, kanye nobubanzi obukhulu & obuncane.

Isibambo sikampompi siyindlela ephumelela kakhulu yokuthinta ngomshini we-lathe.Kodwa-ke, i-workpiece kufanele iboshwe kuqala ku-chuck.

Ukwenza intambo ngeLathe

· Setha i-thread-bit kanye nobude endaweni emaphakathi ye-Lathe.Ibhithi yethuluzi kufanele ibe engeli efanele ye-workpiece.

· Sondeza ithuluzi lokuthunga eduze nendawo yokusebenza.

· Manje, hambisa isibambo.Isibonelo, uma ufuna ukukhiqiza imicu enephimbo elingu-1 mm, ithuluzi lokuthunga kufanele lihambe ibanga elingu-1 mm njengoba ucezu lokusebenza luqeda ukuzungeza okukodwa.Ngakho, qhubeka ngokufanele.

3. Ukufa

Ukunqunywa kwentambo

Kuyindlela eqondile futhi engabizi yokusika intambo engasetshenziselwa ukukhiqizwa ngobuningi okungadingi izinga eliphezulu lokunemba kanye nekhwalithi.Uchungechunge luyafa kudala intambo yangaphandle ehambisana nozakwabo wentambo yangaphakathi.

Ngaphambi kokuqhubeka nokusika intambo ngokufa, uhlangothi lokuqala lokugcina lwe-workpiece kufanele lufakwe ngama-degree angama-45, angenziwa ngomshini noma ngesandla.Bese, sicela ukhethe i-diameter efanelekile bese uyiqinisa kusitokisini sokufa ngemva kokubeka ama-dies ekupheleni, okungaphendukiswa kalula ngobude ukuze udale imicu.

Ama-threading dies nawo asetshenziswa kabanzi ezimbonini zensimbi nezokukhiqiza ukulungisa izintambo emigodini ekhuhliwe noma amabhawodi.Imicu eyenziwe nge-dies yandisa amandla nokuqina kuyilapho kuncipha izindleko zempahla ngoba izinsalela zensimbi ezincane ziyamoshwa ngesikhathi senqubo.

Amathiphu okuklama abalulekile

· Qinisekisa ukuthi ubuso be-workpiece bufana nobude bayo ngaphambi kokuqhubeka nokusika.

· Ukuze wenze imicu yangaphandle, chamfer uhlangothi lokugcina nge-engeli engu-45-degree ngaphambi kokusika.I-countersink iyadingeka ekugcineni kochungechunge lwangaphakathi.

· Uma zingekho izidingo eziqondile zezinhlelo zokusebenza zesikhathi esizayo, kungcono ukuklama izintambo ezinobude obuphansi nosayizi ojwayelekile.

· Ubukhulu bentambo kufanele bukhethwe ukuze bukwazi ukumelana nokucindezela ngenkathi kuhlanganisa.

Ukuqedwa kwendawo yochungechunge

Imicu ene-surface finishing

Ngemuva kokwenziwa ngomshini, ukuqedwa kwezintambo kubalulekile ngenxa yezizathu zobuhle, kuthuthukisa ukusebenza komkhiqizo kukonke, futhi kunwebe impilo yawo.Ngaphezu kwalokho, kuyindlela engcono kakhulu yokuvimbela ukugqwala nokuwohloka kwendawo futhi ngaleyo ndlela ugweme ukwehluleka kokuhlanganisa imishini.

Ukudweba kanyei-black oxideukuqeda yizindlela ezimbili ezisebenzayo zokuqeda phezulu kwemicu.Kodwa-ke, umdwebo ngeke uhlale isikhathi eside uma kuqhathaniswa nokuqedwa kwe-oxide emnyama.

I-Black-oxide iyaphela

Empeleni ungqimba oluncane lwe-magnetite (Fe3O4) olumboza ingaphezulu lomucu.Ngenxa yokuthi ubukhulu be-black-oxide coating abuthinti, akuthinti ukuzinza kwe-dimensional, imingcele yedizayini, noma izakhiwo.Ukuze kuqedwe i-black oxide, iqoqo lemicu eyenziwe ngomshini licwiliswa esixukwini sikasawoti esine-alkali ezingeni lokushisa elifanele (130 kuya ku-150 0C).

Okulandelayo yizinyathelo okufanele zilandelwe ukuze kuqedwe i-black-oxide yemicu.

- 1. Usebenzisa isixazululo se-alkaline, hlanza imicu (ngamaqoqo).

- 2. Hlanza ngokushesha ngamanzi a-distilled ngoba izixazululo ze-alkaline zingasabela phezulu kwentambo futhi zilulaze isiphetho esingaphezulu.

- 3. Hlanza ngamanzi futhi ukuze unciphise ukuhlanzwa kwe-asidi.

- 4. Gxilisa imicu kwisisombululo se-alkaline esibilayo imizuzu emi-5 ukuya kwengama-45.

- 5. Usebenzisa ijethi lamanzi, hlanza ngamanzi anomfutho futhi ubeke eceleni ukuze wome.

- 6. Ukuze uthuthukise ukumelana nokugqwala kwezintambo kanye nokukhanga kobuhle, sebenzisa i-wax, uwoyela, i-lacquer, noma ezinye izinto zokumboza zesibili.

- 7. Manje inqwaba yemicu isilungele izinhlelo zokusebenza eziqondisiwe.

Isiphetho

Ukwenza imicu kuyinqubo ebalulekile ekukhiqizeni.Ngakho-ke, ukukhetha indlela efanele yomshini kubaluleke kakhulu.Kufanele ihambisane nesicelo sokusetshenziswa kokugcina, ukutholakala kobuchwepheshe, nokuba nokwenzeka kwezomnotho.Kungase kube inkimbinkimbi, kodwa ayikwazi ukunganakwa.

Ungathintana nochwepheshe kumasu okuthunga kusuka kumklamo kuya ekuqedeni okungaphezulu.Sineqembu elinolwazi lonjiniyela elizokusiza ekukhiqizeni intambo.Sihlinzeka ngezinsizakalo zokukhanda izintambo ezivela kuwo wonke amasu, Ukugaya, ukwenza intambo ngomshini we-lathe, nokusika izintambo, cishe yonke into oyidingayo mayelana nezintambo.Ngakho-ke, uma udinga noma iyiphi isevisi ehlobene, sicela ungangabazi Xhumana nathi.

Imibuzo Evame Ukubuzwa

Kungani ukwenziwa kwentambo kubalulekile ekukhiqizeni?

Ukwenza intambo kungenye yezindlela eziphumelela kakhulu zokukhiqiza isiqeshana esisodwa.Imicu iyadingeka ukuxhuma izindlela ezahlukahlukene nezingxenye zomkhiqizo.Iqinisa amalunga kanye nokuxhumana kwezingxenye eziningi ezinezakhiwo eziqondile kakhulu.

Imaphi amasu adumile omshini wokwenza imicu?

Ukugaya, umshini we-Lathe, kanye nokufa yizindlela ezithandwa kakhulu nezisebenzayo zomshini womshini embonini yokukhiqiza.

Iyiphi indlela engcono kakhulu yokwenza intambo?

Kuncike ezicini ezihlukahlukene ezifana nosayizi wezintambo, uhlobo lwezinhlelo zokusebenza, ukutholakala kobuchwepheshe, ukuba nokwenzeka kwezomnotho, kanye nemfuneko yokunemba.

Ingabe ukuqedwa kwengaphezulu kubalulekile emicu?

Yebo, Kubalulekile ukuvimbela ukwakheka kokugqwala nokwandisa ukuqina kokuxhumana kanye nokukhanga kobuhle.

Isikhathi sokuthumela: Jun-16-2022