Kupanga ulusi: Zonse zomwe muyenera kudziwa

Kusintha komaliza:09/06 Nthawi yowerenga: 8 min

Ulusi ndi zigawo zomwe zimadzaza kusiyana kwa kuyenerera ndi kugwirizanitsa pamagulu a magawo kuti apititse patsogolo mphamvu ndi kukhazikika kwa zinthu zomaliza mu makampani opanga zinthu padziko lonse lapansi, zomwe zimadalira kwambiri ulalo ndi kuyenerera kwa zigawo kuti apange zinthu zomaliza.

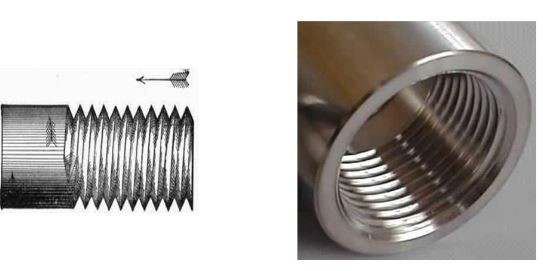

Ulusi ndi m'mphepete mwa ma helical osalekeza pama cylindrical ndi ma conical omwe amagwiritsidwa ntchito polumikizana ndi makina ndi zida.Kutengera kugwiritsa ntchito, ulusi umapangidwa mkati kapena kunja.Ulusi umene umapangidwa pa chigoba chakunja umatchedwa ulusi wakunja, pamene ulusi wamkati umatchedwa ulusi wamkati.Kwa makina, pali njira zitatu, Kugaya, kukonza ulusi ndi makina a lathe, ndi kufa-kudula,

Mitundu ya ulusi

Pali mitundu yosiyanasiyana ya ulusi, monga ulusi wotalikirana, ulusi wa screw screw, Lag Screws, Self-Tapping Screws, ON fasteners, Thread-Forming Screws, ndi Type U Screws.Pakati pa zomangira za ON izi, ulusi wotalikirana ndi ulusi wamakina ndi mitundu yomwe imagwiritsidwa ntchito kwambiri pamakampani opanga.Komanso, malinga ndi Unified Screw Thread System, NC (coarse) ndi UNF (Fine) ulusi ndi magulu okhazikika.

Apa tikambirane ulusi wamkati ndi wakunja mwachidule.

Ulusi Wamkati

Ulusi umene umayenda mozungulira mkati mwa chomangira, monga mtedza, umatchedwa ulusi wamkati.Kupanga ulusi wamkati (Wachikazi) kumapangidwa ndi chida china cholumikizira milomo imodzi.Mosiyana ndi izi, ulusi wina wamkati umadulidwa ndi chida chachikhalidwe chodziwika kuti ulusi-tap.Ulusi wamkati amavomereza wononga ndi kutsekera mu workpiece.

Sankhani chida chomwe chili ndi kukula koyenera kwa ulusi wamkati ndikukonza m'mimba mwake momwe mungapangire ulusi pakugwiritsa ntchito komaliza.

Pamene kupanga ulusi izi ndiCNC makina, ulusi weniweniwo uyenera kuchotsedwa pachojambula cha CAD, ndikusiya mbiri yayikulu yokha.Gwiritsani ntchito mgwirizano womwe wapatsidwa kuti muwerengere kuchuluka kwa kugunda;

Diameter of hole pachimake = Tap m'mimba mwake - Phokoso la ulusi

Kapena,

Tap diameter = Core hole diameter + Thread pitch.

Pezani pakati ndi kubowola dzenjelo monga momwe munawerengera kale dzenjelo, kenako dinani m'mphepete mwa dzenjelo ndi chida chapampopi ndi chopukutira chokhala ndi ma degree 90 countersink.Tsopano zungulirani mu dzenje lapakati kuti mupange ulusi wopitilira.

Ulusi Wakunja

Ulusi umapinda kunja kwa tsinde la chomangira, monga bawuti.The Lathe ndi makina othandiza kwambiri komanso ogwiritsidwa ntchito kwambiri popanga ulusi wakunja pazinthu zogwirira ntchito.Ndodo iliyonse ya cylindrical yomwe ingatembenuzidwe ndiyoyenera kupanga mbiri yakunja ya ulusi.Mutha kusankha chidacho potengera kuya kwa phula komwe kumafunikira.

Kudula kwa ulusi wakunja kumayamba ndi kufa kwa ulusi (kuzungulira-kufa) ndikumangirira pamakina a lathe.Mphepetezo ziyenera kuyikidwa poyamba ndi kuzizira pa madigiri 45.Tsopano gwirani m'mphepete mwa workpiece ndi chida chodulira musanachizungulire kutalika kwake kuti mupange ulusi wopitilira.

Ulusi Wamkati & Wakunja

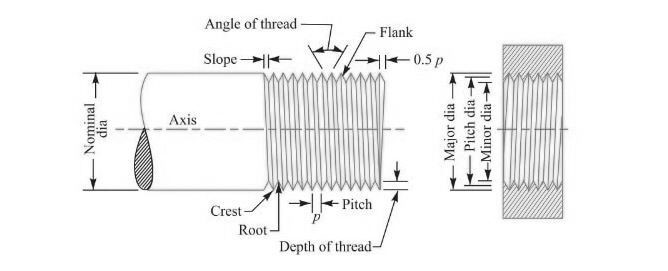

Terminology mu Threads Machining

Terminology mu makina opanga ulusi

Muzu:Zingwe ziwiri zosinthika zimapanga malo athyathyathya kapena ozungulira pansi, kapena pansi pa nsonga ya ulusi imadziwika kuti muzu.

Crest:Kumtunda kwa ulusi wopangidwa ndi mbali ziwiri za ulusi (gawo loyembekezeredwa la ulusi)

Mbali:Ulusiwo umagwirizanitsa muzu ndi pachimake cha ulusi ndipo umalumikizana ndi ulusi wina.

Ngongole ya ulusi:Ngongole imapangidwa ndi mbali ziwiri zoyandikana za ulusi ulusi mu axial plane yotchedwa ulusi angle.

Kuzama kwa mayendedwe:Mtunda wa axial pakati pa crest ndi muzu umadziwika kuti kuya kwa ulusi.

Kuyimba:Mtunda pakati pa ulusi wofananawo

Helix angle:Ngongola pakati pa helix ya ulusi ndi mzere womwe ndi wabwinobwino kumtunda wozungulira

Diameter yayikulu:Diameter ya co-axial cylinder yolingalira yomwe imakhudza nsonga ya ulusi wakunja (kapena muzu kapena ulusi wamkati)

Chigawo chaching'ono: Diameter ya co-axial cylinder yolingalira yomwe imakhudza muzu wa ulusi wakunja (kapena ulusi wamkati)

Pitch Diameter:avereji ya mainchesi akuluakulu ndi ang'onoang'ono

Njira zodulira ulusi wopangira makina

Kudula ulusi kumapangitsa kuti zikhale zosavuta kupanga maulalo opindika pazigawo.Ngati mudula ulusi wamkati, onetsetsani kuti ikhoza kulowetsa ndi kutseka inzake pamene mukugwirizanitsa.

Kusankha njira yabwino yodulira ulusi ndikofunikira;zinthu zambiri ziyenera kuganiziridwa, monga luso, zachuma, kugwiritsa ntchito nthawi, kulondola, ndi kupezeka kwa zida.

1. Kugaya

Kugayaangagwiritsidwe ntchito kudula ulusi pa ulusi wamkati ndi kunja.Imagwiritsa ntchito njira yozungulira yopangira ulusi kuti ipange ulusi mu bwalo limodzi la kayendetsedwe kake.Njirayi imagwiritsidwa ntchito podula ulusi wamitundu yosiyanasiyana, koma ndiyoyenera mabowo akuluakulu.Ulusi wopangidwa ndi makina amphero amapanga akumaliza pamwambandi kusinthasintha kofananako.

Kupanga ulusi ndi mphero

Mu mphero ya ulusi, pali mitundu iwiri ya zida zogwira mtima komanso zodziwika bwino: carbide yolimba ndi indexable.Mano odulira zidazi amakhala ofanana m'malo mokhazikika ngati wapampopi.Makina opangira mano ambiri amadula ulusiwo mpaka kuzigawo zake zakuya mu dzenje limodzi lozungulira.Chifukwa zida zolozera nthawi zambiri sizoyenera mabowo okhala ndi mainchesi osakwana 0.625, zida za carbide zimagwiritsidwa ntchito makamaka pamabowo ang'onoang'ono;komabe, ulusi ndi chida ichi ndi mtengo penapake ngati mkulu mwatsatanetsatane si chofunika.Chida cholozera ndi chotsika mtengo chifukwa mumangofunika kusintha chodulira mukachigula.

Pali zabwino zambiri zogwiritsira ntchito ulusi-mphero.Mosiyana ndi kugogoda, komwe kumatha kuthana ndi ma diameter osiyanasiyana ndi chida chimodzi, kugogoda kumangogwira mdulidwe wokhazikika ndi chida chimodzi, komanso matepi okulirapo ndi okwera mtengo.

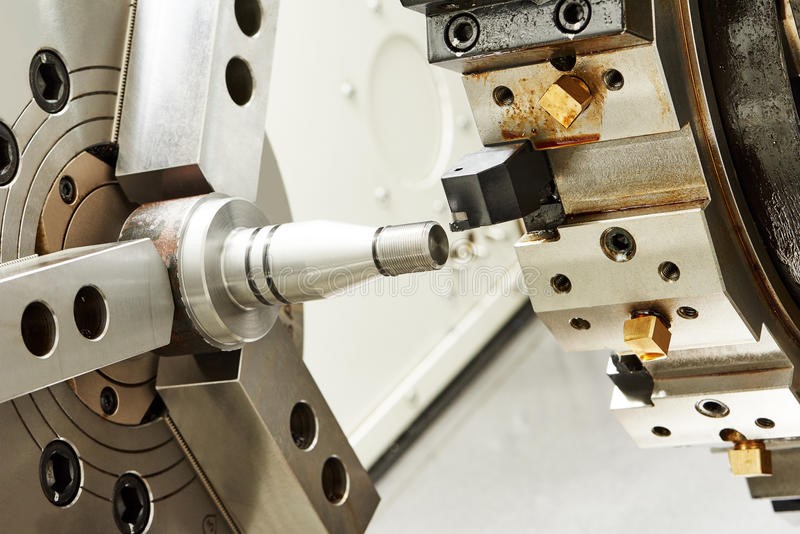

2. Ulusi Machining ndi Lathe

Chida chotembenuza nsonga imodzi chokhala ndi choyikapo cha carbide chimagwiritsidwa ntchito podula uku.Musanayambe kudula, kuwerengera kwina kumafunika kudula ulusi ndi makina a lathe, monga phula, lead, kuya, ndi mainchesi akuluakulu & ang'onoang'ono.

Chogwirira chapampopi ndiye njira yothandiza kwambiri pogogoda ndi makina a lathe.Komabe, chogwirira ntchito chimayenera kumangirizidwa koyamba mu chuck.

Kupanga ulusi ndi Lathe

· Khazikitsani ulusi-bit ndi kutalika mpaka pakati pa Lathe.Chidacho chiyenera kukhala pakona yoyenera ya workpiece.

· Bweretsani chida cholumikizira pafupi ndi chogwirira ntchito.

· Tsopano, sunthani chogwirira.Mwachitsanzo, ngati mukufuna kupanga ulusi ndi phula la 1 mm, chida cholumikizira chiyenera kusuntha mtunda wa 1 mm pamene workpiece imamaliza kusintha kumodzi.Choncho, pitirirani nazo.

3. Kufa-kudula

Kufa-kudula ulusi

Ndi njira yowongoka komanso yotsika mtengo yodulira ulusi yomwe ingagwiritsidwe ntchito popanga zinthu zambiri zomwe sizifuna kulondola komanso kudalirika.Ulusi umafa umapanga ulusi wakunja wogwirizana ndi ulusi wake wamkati.

Musanayambe kudula ulusi ndi kufa, mbali yoyamba ya workpiece iyenera kugwedezeka pa madigiri 45, zomwe zingatheke ndi makina kapena manja.Kenako, chonde sankhani kufa kwake koyenera ndikumangitsa mukufa-katundu mutatha kuyika mafelemu kumapeto, komwe kumatha kuzunguliridwa motalika kuti mupange ulusi.

Threading dies amagwiritsidwanso ntchito kwambiri m'mafakitale opangira zitsulo ndi kupanga kukonza ulusi m'mabowo kapena ma bolts.Ulusi wopangidwa ndi ma dies amawonjezera mphamvu komanso kulimba kwinaku amachepetsa mtengo wazinthu chifukwa zotsalira zochepa zachitsulo zimawonongeka panthawiyi.

Malangizo ofunikira opangira

· Onetsetsani kuti pamwamba pa workpiece ndi yunifolomu mu utali wonse musanayambe ndi kudula.

· Kuti mupange ulusi wakunja, chamfer mbali yomaliza pamakona a digirii 45 musanadule.Chophimba chowerengera chimafunika kumapeto kwa ulusi wamkati.

· Ngati palibe zofunikira zenizeni za ntchito zamtsogolo, ndibwino kupanga ulusi wokhala ndi kutalika kochepa komanso kukula kwake.

· Makulidwe a ulusi amayenera kusankhidwa kuti athe kupirira kukakamiza polumikizana.

Kumaliza pamwamba kwa ulusi

Ulusi wokhala ndi kumaliza pamwamba

Mukamaliza ndi makinawo, kumaliza kwa ulusi kumakhala kofunikira pazifukwa zokometsera, kumawongolera magwiridwe antchito onse, ndikuwonjezera moyo wake.Kuonjezera apo, ndiyo njira yabwino kwambiri yopewera dzimbiri ndi kuwonongeka kwa pamwamba ndipo motero kupewa kulephera kwa makina ogwirizanitsa.

Kupenta ndiwakuda oxidekumaliza ndi njira ziwiri zogwirira ntchito zomaliza pamwamba pa ulusi.Komabe, kujambula sikukhalitsa kwa nthawi yayitali poyerekeza ndi kumaliza kwa black oxide.

Black-oxide amatha

Ndilo gawo laling'ono la magnetite (Fe3O4) lomwe limakutira pamwamba pa ulusi.Chifukwa makulidwe a zokutira zakuda-osayidi ndizochepa, sizikhudza kukhazikika kwa mawonekedwe, magawo apangidwe, kapena katundu.Kuti okusayidi wakuda athe, ulusi wopangidwa ndi makina umamizidwa mumchere wamchere pa kutentha koyenera (130 mpaka 150 0C).

M'munsimu ndi masitepe oti muzitsatira pomaliza ulusi wa black-oxide.

- 1. Pogwiritsa ntchito njira yamadzi yamchere, yeretsani ulusi (mumagulu).

- 2. Sambani nthawi yomweyo ndi madzi osungunuka chifukwa madzi amchere amatha kuchitapo kanthu ndi ulusi ndikuwononga ulusi woyamba.

- 3. Yambani ndi madzi kachiwiri kuti muchepetse asidi kuyeretsa.

- 4. Miwiritsani ulusi mumchere wotentha wa alkaline kwa mphindi 5 mpaka 45.

- 5. Pogwiritsa ntchito jeti lamadzi, yeretsani ndi madzi oponderezedwa ndikuyika pambali kuti ziume.

- 6. Kuti ulusi usachite dzimbiri komanso kukongola kwake, ikani sera, mafuta, lacquer, kapena zida zina zachiwiri zokutira.

- 7. Tsopano gulu la ulusi ndilokonzeka kugwiritsa ntchito zomwe mukufuna.

Mapeto

Kupanga ulusi ndi njira yofunika kwambiri popanga.Chifukwa chake, kusankha njira yoyenera yopangira makina ndikofunikira kwambiri.Ziyenera kukhala molingana ndi kugwiritsa ntchito komaliza, kupezeka kwaukadaulo, komanso kuthekera kwachuma.Zitha kukhala zovuta, koma sizinganyalanyazidwe.

Mukhoza kukaonana ndi akatswiri mu ulusi njira kuchokera ku mapangidwe mpaka pamwamba kumaliza.Tili ndi gulu lodziwa zambiri la mainjiniya omwe angakuthandizeni kupanga ulusi.Timapereka ntchito zopangira ulusi kuchokera ku njira zonse, Kugaya, kukonza ulusi ndi makina a lathe, ndi kudula kufa, pafupifupi chilichonse chomwe mungafune pa ulusi.Chifukwa chake, ngati mukufuna ntchito yofananira, chonde musazengereze kutero Lumikizanani nafe.

FAQs

Chifukwa chiyani kupanga ulusi ndikofunikira pakupanga?

Kupanga ulusi ndi imodzi mwa njira zothandiza kwambiri zopangira chidutswa chimodzi.Ulusi umafunika kuti ugwirizane ndi njira zosiyanasiyana ndi magawo azinthu.Zimalimbitsa zolumikizana ndi kulumikizana kwa zigawo zingapo zokhala ndi zowongolera zowongoka kwambiri.

Kodi njira zodziwika bwino zopangira ulusi ndi ziti?

Kugaya, makina a Lathe, ndi kufa ndi njira zodziwika kwambiri komanso zothandiza pakupangira ulusi pamakampani opanga.

Kodi njira yabwino kwambiri yopangira ulusi ndi iti?

Zimatengera zinthu zosiyanasiyana monga kukula kwa ulusi, mtundu wa ntchito, kupezeka kwaukadaulo, kuthekera kwachuma, ndi kufunikira kolondola.

Kodi kutsirizitsa pamwamba ndikofunikira pa ulusi?

Inde, ndikofunikira kuti tipewe dzimbiri ndikuwonjezera kukhazikika kwa zolumikizira pamodzi ndi kukopa kokongola.

Nthawi yotumiza: Jun-16-2022