Ukungcoliswa kokungunda, Ilitye lezintso leHlabathi lePlastiki

Ixesha lokufunda eliqikelelweyo: imizuzu emi-4, imizuzwana emi-4

Xa umntu enokutya okungaqhelekanga, ukuqokelela kwe-calcium oxalate ngenxa yeprotheyini ephezulu, okanye ukuqokelela kweemveliso zenkunkuma ngenxa yamanqatha aphezulu kunye noshukela, okanye ukubekwa kweetyuwa zomchamo ngenxa yokuphila okungapheliyo, kunokubangela ukubunjwa kwamatye amaninzi.Kwaye ukubola komngundo yimvula encinci evela kwiplastiki etyhidiweyo kwaye emva kokuqokelela kwexesha, kwindawo yokubumba eveliswa ngokunamathela.Nje ukuba umphezulu wokungunda uncanyathiselwe isikali sokungunda, ukuqokelelwa kwesikali sokungunda okulandelayo kuya kukhawuleza kwaye kukhawuleze.

Ukungcola komngundo kumphezulu wokungunda

Amatye kukuqokelelwa kwe-calcium oxalate kunye nezinye iimveliso ezilahlwayo ezivela kukutya okutyayo;iidiphozithi zomngundo zizongezo zealekyuli ezincinci ezifana ne-flame retardants kunye ne-lubricant, kwaye zinokuba zi-oligomers ezibangelwa ukuthotywa kwe-thermal.Ngaphambi kokuba ube "lilitye", isikali sokungunda sinokuba yi-volatilization yegesi engachaphazeli imveliso ukuba ikhutshwe ngexesha.Kanye njengomchamo wetyuwa calcium oxalate phambi kwelitye, akukho bungozi ekuseleni amanzi amaninzi kunye nokuwakhupha ngexesha.Ukungcola komngundo kufana nendlela kunye nenkqubo yokuveliswa kwakhona kwamatye.Ukungcola komngundo kunokuthintela umjelo wokukhupha, kubangela ukuba iimveliso zeplastiki zitshiswe, zinokuthi zibambelele kwimveliso, njengoko ukungcoliswa komzimba wangaphandle kunokuchaphazela iimpawu zombane zemveliso.Umzi-mveliso ocutshungulwayo kwafuneka ucoce umngundo ngelixa uvelisa, kwaye kunokwenzeka ukuba iimveliso ezineziphene zaphuma xa bezingayazi kwasekuqaleni.

Ukubumba kufuneka kusulwe ngedayimane yokusila intlama rhoqo kwiiyure ezimbalwa

Eli nqaku liza kuthetha ngezizathu ze-mold deposits ezivela kwiinkalo ezintathu eziphambili: izinto eziphathekayo, inkqubo kunye nokubumba.Eli nqaku liza kuthetha ngezizathu ze-mold deposits ezivela kwiinkalo ezintathu eziphambili: izinto eziphathekayo, inkqubo kunye nokubumba.

1Izinto eziphathekayo

Izinto eziphathekayo zihlala zisona sizathu siphambili sokubonakala kweziphene zesikali sokungunda.Ihlalutywe ngokubanzi ngokwezi mbono zintathu zilandelayo.

Eyokuqala yiukubola kwe-resin yeplastiki.Iresin kokusingqongileyo ngaphaya kobushushu bayo bokubola ukuvelisa ii-oligomers, kokukhona ukubola kuya kuthotyelwa kulwakhiwo olungaphezulu, lubonwa ikakhulu kumahluko obushushu obunyibilikayo phakathi kweemveliso zealloyi.Umxholo we-monomer oshiyekileyo wee-resin ezahlukeneyo ngokwazo zinempembelelo.

Okwesibini nguimvula yezongezo ze-molecule ezincinci.Iiplastiki ezilungisiweyo ziya kongezwa ekuqulunqweni kweentlobo ezahlukeneyo zokudibanisa ukuze zinike izinto eziphathekayo ukusebenza okanye umsebenzi ofanelekileyo, imvula kwindawo enamafutha idla ngokuba luphawu lwezongezo, ngoko ke kulula ukuba yintsika yokubumba eqhotyoshelwe kuyo ngexesha lokubumba.

Eyesithathu nguimpembelelo yee-pigments.Iiplastiki zobunjineli be-Thermoplastic kwi-pigment enyibilikayo kumaqondo obushushu aphezulu, ziya kunciphisa ukuzinza kwe-thermal yezinto ezibunjwayo, okukhokelela ekuthotyweni kwepolymer kunye nokubola kwendibaniselwano ye-pigment ukwenza i-mold foiling.

2Inkqubo yokubumba

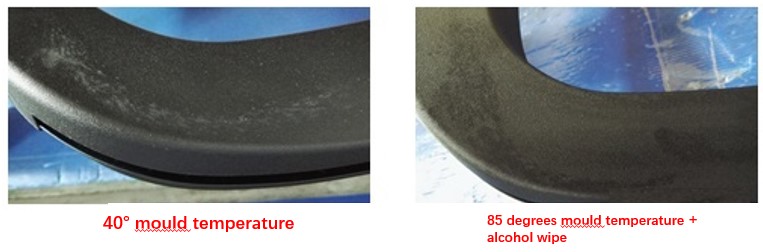

Iimolekyuli ezincinci zezongezo, iimveliso zokubola kwe-resin kunye nezinye ii-oligomers, kubushushu obuphezulu kuqala ngohlobo lwe-gasification okanye i-liquefaction, ukudibana nokungunda kwaphola kwaye kuncanyathiselwe kukungunda, okukhona kusezantsi iqondo lobushushu bomphezulu wokungunda, kokukhona ukungcola kokungunda kuncanyathiselwe. .

Amazinga ahlukeneyo emveliso yesikali sokungunda kumaqondo obushushu aphezulu naphantsi

Ukunciphisa isantya sokutofa kwindawo ethile yemveliso nako kunokwandisa ixesha lokuvela kweediphozithi zokungunda.Ukuba isantya senaliti sikhawuleza kakhulu kwinqanaba lokukhupha umoya, igesi ye-oligomer ayiyi kuba nexesha elaneleyo lokuphuma kwi-mold cavity;ukuba isantya sokucheba sikhawuleza kakhulu kudonga olucekethekileyo okanye kwindawo yekona, kuya kwenza lula ukuba isantya sokucheba sigqithise umlinganiselo wokugqibela wokucheba wesixhobo.

3Uyilo lokungunda kunye noLondolozo

Ngeukubumba imbaleki eshushu kunye nobushushu obubuthathaka imathiriyeli ekrwada, ixesha lokuhlala elinyibilikayo liya kuba lide, ngaloo ndlela kwandisa umngcipheko wokungcola komngundo ngenxa yokubola kwezinto ezikrwada.Ke ngoko, isikrufu somatshini wokubumba inaliti kufuneka sicocwe.

Ukukhupha umngundo, ukuba inkqubo yokukhupha umoya yenzelwe ngokufanelekileyo ngokwaneleyo ukususa i-oligomers e-vaporized okanye i-liquefied kwi-mold ngexesha elifanelekileyo ngaphambi kokuba i-mold idibanise, i-mold fouling phenomenon iya kuba buthathaka.

Ukwenza izixhobo ezibuthathaka zokucheba,izinto ezinjalo zihlala zisebenzisa iimbaleki ezinkulu kunye namasango, i-gating yamanqaku amaninzi inokunciphisa umgama wokuhamba, isantya esisezantsi sokutofa kunye nokunciphisa umngcipheko wokubumba ukubumba.

Iidiphozithi zomngundo zilula ukususa kwizigaba zokuqala zokubunjwa, ngoko imingxuma yokubumba kunye nemijelo yokukhupha kufuneka icocwe kwaye igcinwe rhoqo, umzekelo emva komyalelo ngamnye.Ukuba umngundo awugcinwanga kwaye unikwe inkonzo ixesha elide, kuya kuba nzima kakhulu ukususa iileya ezityebileyo zesikali sokungunda eso fom.

Iingubo ezingenanto, Iingubo ezikhethekileyo ezingeyontonga (umzekelo, i-PVD coatings) kumphezulu we-cavity inokuthintela ukubunjwa kwe-mold foil kwaye kufuneka ivavanywe ukuvavanya ukusebenza kwengubo.Ukunyangwa kwe-Titanium nitride kwindawo yangaphakathi yokubumba kunokuthintela ukubunjwa kwe-mold foiling kwi-mold.

I-injection molding isetyenziswa ngokubanzi kumashishini ahlukeneyo kwaye inokufikelela kwi-seamless, imveliso echanekileyo yobuninzi beengxenye ngexesha elifutshane.I-PorLean Tech ibonelela ngeenkonzo zokubumba inaliti kwizinto ezininzi, kubandakanya iiplastiki kunye ne-elastomers.Faka ngokulula imodeli yakhokwaye ufumane isicatshulwa esisimahla kunye neengcebiso kwiinkonzo ezinxulumeneyo.

Ixesha lokuposa: Apr-13-2022