Mold Fouling, itsvo Dombo rePlastiki World

Inofungidzirwa nguva yekuverenga: 4 maminitsi, 4 masekondi

Kana munhu aine chikafu chisina kujairika, kuunganidzwa kwecalcium oxalate nekuda kweprotein yakakwira, kana kuunganidzwa kwemarara nekuda kwemafuta akawandisa uye shuga, kana kuisirwa weti munyu nekuda kwehupenyu hwekugara, kunogona kukonzera kuumbwa kwematombo makuru.Uye kusvibisa mold imvura shoma kubva mupurasitiki yakanyungudutswa uye mushure mekuunganidza nguva, muvhu rinogadzirwa nekunamatira.Kana iyo mold yave ne mold scale yakasungirirwa, iyo inotevera mold scale kuunganidza ichave nekukurumidza uye nekukurumidza.

Mold kusvibisa pamusoro pevhu

Matombo ndiko kuunganidzwa kwecalcium oxalate uye zvimwe zvinoraswa kubva pakudya kwakabikwa;mold deposits madiki mamorekuru ekuwedzera akadai seanodzoreredza murazvo uye mafuta ekuzora, uye anogona kunge ari maoligomers anokonzerwa nekupisa kwekupisa.Isati yava "dombo", mold scale inogona kunge iri gaseous volatilization iyo isingakanganisi kugadzirwa kana yakadhirwa nenguva.Sezvakangoita weti yemunyu calcium oxalate pamberi pedombo, hapana chakaipa pakunwa mvura yakawanda uye kuibvisa nenguva.Mold fouling yakafanana nemaitiro uye maitiro ekugadzirazve dombo.Mold fouling inogona kuvhara chiteshi chekuburitsa, zvichiita kuti zvigadzirwa zvepurasitiki zvipiswe, zvinogona zvakare kunamatira kune chigadzirwa kunokanganisa chitarisiko, sezvo kusvibiswa kwemuviri wekunze kungakanganisawo magetsi echigadzirwa.Fekitori yekugadzira yaifanira kuchenesa mold ichigadzira, uye pane mukana wekuti zvigadzirwa zvakakanganisika zvakabuda ivo vasingazvizive pakutanga.

Zviumbwa zvinofanira kupukuta nedhaimondi rekukuya paste maawa mashomanana

Ichi chinyorwa chichataura pamusoro pezvinokonzeresa mold deposits kubva pazvinhu zvitatu zvikuru: zvinhu, maitiro uye mold.Ichi chinyorwa chichataura pamusoro pezvinokonzeresa mold deposits kubva pazvinhu zvitatu zvikuru: zvinhu, maitiro uye mold.

1Material

Material kazhinji ndicho chikonzero chikuru chekuonekwa kwekuremara kwe mold scale.Kazhinji inoongororwa kubva pamaonero matatu anotevera.

Yokutanga ndiyokuora kwepurasitiki resin.Resin mumhoteredzo kupfuura tembiricha yekuora kwayo kugadzira oligomers, iyo yakanyanya kuora inonamatira kune kuvaka-up kwezvimwe, zvinonyanya kuoneka mukunyunguduka kwekushisa musiyano pakati pezvigadzirwa zvealloy.Izvo zvakasara monomer zvemukati zveakasiyana resin pachazvo zvine zvazvinoita.

Yechipiri ndiyokunaya kwediki molecule additives.Mapurasitiki akagadziridzwa achawedzerwa pakugadzirwa kwezvakasiyana-siyana zvekuwedzera kuti zvipe izvo zvinyorwa kuita kwakakodzera kana basa, kunaya kune iyo ine mafuta pamusoro inowanzova hunhu hwekuwedzera, saka zviri nyore kuve mold foiling yakanamatira pairi panguva yekuumbwa.

Yechitatu ndiyokukanganisa kwe pigment.Thermoplastic engineering mapurasitiki mune pigment kunyunguduka pakupisa kwakanyanya, inoderedza kugadzikana kwekupisa kwechinhu chekuumbwa, zvichikonzera kushatiswa kwepolymer uye kuparara kweiyo pigment musanganiswa kuita mold fouling.

2Molding Process

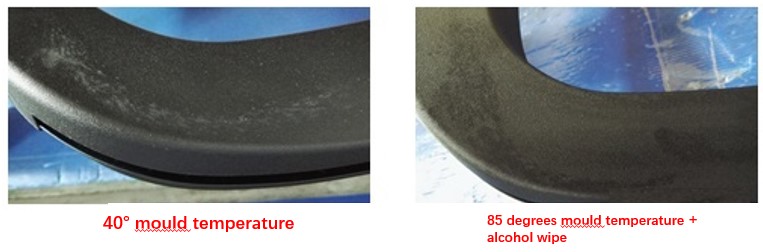

Madiki mamorekuru ezviwedzere, resin decomposition zvigadzirwa uye mamwe oligomers, mukupisa kwakanyanya kutanga nenzira yegasification kana liquefaction, kusangana ne mold kwakatonhodzwa uye kusungirirwa kune mold, iyo yakadzikira tembiricha ye mold pamusoro, iyo yakawanda mold yakanamatira. .

Mitemo yakasiyana yekugadzirwa kwe mold scale pakupisa uye kuderera kwe mold

Kudzikisa kumhanya kwejekiseni pane imwe nzvimbo yechigadzirwa kunogona zvakare kurebesa nguva yekuti mold deposits ioneke.Kana iyo jekiseni yekumhanyisa ichimhanya zvakanyanya munhanho yemhepo, iyo oligomer gasi haizove nenguva yakakwana yekubuda mugomba;kana kumhanya kwejekiseni kuchimhanya zvakanyanya mumadziro akatetepa kana chinzvimbo chekona, zvinokonzeresa kuti chiyero chaicho cheshear chipfuure chekupedzisira shear mwero wechinhu.

3Mold Dhizaini Uye Kuchengeta

Withinopisa mumhanyi kuumba uye kupisa kusinganzwisisike mbishi zvinhu, iyo nguva yekugara yakanyunguduka ichave yakareba, nekudaro ichiwedzera njodzi yekusvibisa mold nekuda kwekuora kwezvinhu.Naizvozvo, iyo jekiseni molding muchina screw inoda kucheneswa.

Mold venting, kana iyo venting system yakagadzirirwa zvakakwana kuti ibvise iyo vaporized kana liquefied oligomers kubva mukuumbwa panguva yakakodzera iyo mold isati yanyunguduka, iyo mold fouling phenomenon ichave zvakare isina simba.

Kugadzira shear sensitive materials,zvinhu zvakadaro zvinowanzo shandisa yakakura saizi yekumhanya uye magedhi, akawanda-poinzi gating anogona kuderedza kuyerera kureba, yakaderera jekiseni velocity uye kuderedza njodzi yekuumba fouling kuumbwa.

Mold deposits zviri nyore kubvisa mumatanho ekutanga ekuumbwa, saka mold cavities uye exhaust nzira dzinofanira kucheneswa uye kuchengetedzwa nguva dzose, semuenzaniso mushure mekunge odha yega yega yaitwa.Kana iyo mold isina kuchengetedzwa uye kushumirwa kwenguva yakareba, zvichave zvakanyanya kuoma kubvisa akakora akaturikidzana e mold scale iyo fomu.

Zvipfeko zvisina kumira, mabhanhire anokosha asina-tsvimbo (eg PVD coatings) panzvimbo yemhango anogona kudzivirira kuumbwa kwekusvibiswa kwe mold uye inofanira kuongororwa kuti iongorore kushanda kwekuputira.Titanium nitride kurapwa mukati meiyo mold inogona kudzivirira kuumbwa kwekusvibisa mold pane mold.

Jekiseni molding inoshandiswa zvakanyanya mumaindasitiri akasiyana siyana uye inogona kuwana isina musono, chaiyo misa kugadzirwa kwezvikamu munguva pfupi.PorLean Tech inopa majekiseni ekuumba masevhisi ezvakawanda zvezvinhu, zvinosanganisira mapurasitiki uye elastomers.Ingoisa modhi yakouye tora yekukurumidza yemahara quote uye zano pane ane hukama masevhisi.

Nguva yekutumira: Kubvumbi-13-2022