Pwm Fouling, Lub raum Pob Zeb Ntawm Lub Ntiaj Teb Yas

Lub sijhawm nyeem ntawv kwv yees: 4 feeb, 4 vib nas this

Thaum ib tug neeg muaj kev noj zaub mov tsis tu ncua, kev sib sau ntawm calcium oxalate vim muaj protein ntau, lossis cov khoom pov tseg vim muaj roj ntau thiab qab zib, lossis tso zis ntsev vim kev ua neej nyob tsis tu ncua, tuaj yeem tsim cov pob zeb loj.Thiab pwm fouling yog me ntsis nag los ntawm cov yas molten thiab tom qab lub sij hawm tsub zuj zuj, nyob rau hauv cov pwm nto tsim los ntawm adhesion.Thaum cov pwm saum npoo muaj pwm scale txuas, cov pwm pwm tom ntej yuav ua kom nrawm dua thiab nrawm dua.

Pwm fouling ntawm pwm nto

Pob zeb yog qhov sib xyaw ntawm calcium oxalate thiab lwm yam khoom pov tseg los ntawm kev noj zaub mov noj;pwm deposits yog me me molecule additives xws li nplaim retardants thiab lubricants, thiab tej zaum kuj yog oligomers los ntawm thermal degradation.Ua ntej dhau los ua "pob zeb", pwm nplai tuaj yeem yog cov pa roj carbon monoxide uas tsis cuam tshuam rau kev tsim khoom yog tias ntws tawm hauv lub sijhawm.Ib yam li cov zis ntsev calcium oxalate ua ntej pob zeb, tsis muaj teeb meem hauv kev haus dej ntau dua thiab ntws tawm hauv lub sijhawm.Pwm fouling zoo ib yam li cov txheej txheem thiab txheej txheem ntawm pob zeb rov tsim dua tshiab.Pwm fouling tuaj yeem thaiv cov pa tawm channel, ua rau cov khoom yas scorched, kuj tuaj yeem ua raws li cov khoom cuam tshuam rau cov tsos, vim tias txawv teb chaws lub cev tuaj yeem cuam tshuam cov khoom hluav taws xob ntawm cov khoom.Lub Hoobkas ua haujlwm yuav tsum tau ntxuav cov pwm thaum tsim khoom, thiab muaj peev xwm ua kom cov khoom tsis zoo ntws tawm thaum lawv tsis paub txog nws thaum ntxov.

Cov pwm yuav tsum tau wiped nrog pob zeb diamond sib tsoo muab tshuaj txhuam txhua ob peb teev

Kab lus no yuav tham txog qhov ua rau pwm deposits los ntawm peb yam tseem ceeb: khoom, txheej txheem thiab pwm.Kab lus no yuav tham txog qhov ua rau pwm deposits los ntawm peb yam tseem ceeb: khoom, txheej txheem thiab pwm.

1Khoom siv

Cov khoom siv feem ntau yog qhov laj thawj tseem ceeb rau qhov pom ntawm pwm qhov tsis xws luag.Feem ntau txheeb xyuas los ntawm peb qhov kev xav hauv qab no.

Thawj yog tusdecomposition ntawm yas resin.Resin nyob rau hauv ib puag ncig tshaj nws qhov decomposition kub los tsim oligomers, ntau decomposition yuav adhered rau lub build-up ntawm ntau, feem ntau pom nyob rau hauv lub melt kub txawv ntawm cov khoom alloy.Cov ntsiab lus monomer residual ntawm cov resins sib txawv lawv tus kheej kuj muaj kev cuam tshuam.

Qhov thib ob yog qhovnag lossis daus ntawm me me molecule additives.Hloov kho cov yas yuav muab ntxiv rau kev tsim ntau yam khoom ntxiv kom muab cov khoom tsim nyog los yog kev ua haujlwm, nag lossis daus rau oily nto feem ntau yog cov yam ntxwv ntawm cov additives, yog li nws yooj yim los ua pwm fouling txuas rau nws thaum molding.

Qhov thib peb yogqhov cuam tshuam ntawm pigments.Thermoplastic engineering plastics nyob rau hauv cov xim melting ntawm qhov kub thiab txias, yuav txo qhov thermal stability ntawm cov khoom molding, uas ua rau degradation ntawm cov polymer thiab decomposition ntawm cov xim ua ke los ua pwm fouling.

2Txheej txheem molding

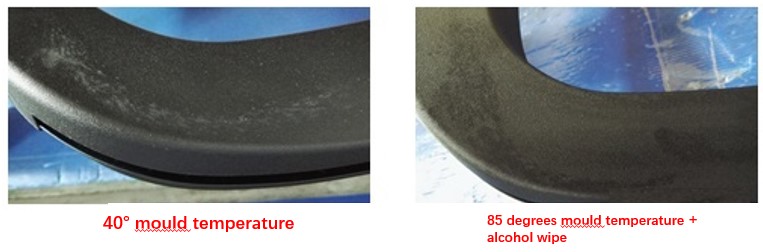

Me me molecules ntawm additives, resin decomposition khoom thiab lwm yam oligomers, nyob rau hauv high kub ua ntej nyob rau hauv daim ntawv ntawm gasification los yog liquefaction, kev sib cuag nrog cov pwm yog txias thiab txuas mus rau lub pwm, qhov kub ntawm cov pwm nto, ntau pwm fouling txuas. .

Cov nqi sib txawv ntawm pwm scale ntau lawm ntawm siab thiab qis pwm kub

Txo qhov kev txhaj tshuaj nrawm ntawm qhov chaw tshwj xeeb ntawm cov khoom tuaj yeem ncua sijhawm rau cov pwm tso tawm kom pom.Yog tias qhov kev txhaj tshuaj nrawm nrawm dhau rau theem venting, cov roj oligomer yuav tsis muaj sijhawm txaus los tawm ntawm pwm kab noj hniav;yog tias qhov kev txhaj tshuaj nrawm dhau ntawm cov phab ntsa nyias los yog kaum txoj haujlwm, nws yuav yooj yim ua rau qhov tseeb shear npaum li cas tshaj qhov kawg shear tus nqi ntawm cov khoom.

3Pwm Tsim Thiab Kho

Nrogkub khiav molding thiab kub rhiab raw cov ntaub ntawv, lub sij hawm nyob hauv yaj yuav ntev dua, yog li ua rau muaj kev pheej hmoo ntawm pwm fouling vim raw khoom decomposition.Yog li ntawd, lub tshuab txhaj tshuaj molding tshuab yuav tsum tau ntxuav.

Pwm venting, yog hais tias lub venting system yog tsim tau zoo txaus kom tshem tawm cov vaporized los yog liquefied oligomers los ntawm cov pwm nyob rau hauv lub sij hawm ua ntej pwm condenses, cov pwm fouling tshwm sim kuj yuav tsis muaj zog.

Tsim shear rhiab cov ntaub ntawv,xws li cov ntaub ntawv feem ntau yog siv cov loj loj khiav thiab rooj vag, multi-point gating yuav txo tau qhov khiav deb, tsis tshua muaj txhaj tshaj tawm thiab txo qhov kev pheej hmoo ntawm pwm fouling tsim.

Pwm deposits yog yooj yim rau tshem tawm nyob rau hauv thaum ntxov theem ntawm tsim, yog li pwm kab noj hniav thiab cov pa tawm yuav tsum tau ntxuav thiab tswj tsis tu ncua, piv txwv li tom qab txhua qhov kev txiav txim tiav.Yog tias cov pwm tsis tau khaws cia thiab ua haujlwm ntev, nws yuav nyuaj heev kom tshem tawm cov txheej tuab ntawm cov pwm pwm uas daim ntawv.

Non-stick coatings, tshwj xeeb uas tsis yog-stick txheej (xws li PVD txheej) ntawm cov kab noj hniav tuaj yeem tiv thaiv kev tsim cov pwm fouling thiab yuav tsum tau sim los ntsuas qhov ua tau zoo ntawm cov txheej txheem.Kev kho titanium nitride nyob rau sab hauv ntawm cov pwm tuaj yeem tiv thaiv kev tsim pwm fouling ntawm pwm.

Txhaj tshuaj molding yog dav siv nyob rau hauv ntau yam lag luam thiab tuaj yeem ua tiav seamless, precision loj ntau lawm ntawm qhov chaw nyob rau lub sijhawm luv luv.PorLean Tech muaj kev txhaj tshuaj molding rau kaum ob ntawm cov ntaub ntawv, suav nrog cov yas thiab elastomers.Tsuas yog upload koj tus qauvthiab tau txais cov lus qhia dawb ceev thiab cov lus qhia txog cov kev pabcuam cuam tshuam.

Post lub sij hawm: Apr-13-2022