Metallic Coatings: Zvese Zvaunoda Kuziva

Yekupedzisira update 08/31, Inofungidzirwa nguva yekuverenga: 5 mins

Metal coated parts

Themetallic coatingndiyo nzira yekuvhara chikamu chechinhu nekuwedzera kwesimbi uye alloys kudzivirira ngura.Pamusoro pekudzivirira kuparara, iyo simbi yesimbi inonatsiridza iyo mechanika, yemuviri, uye inoyevedza zvimiro zvezvikamu zvinoiswa (Substrate).Pane nzira dzakati wandei dzekuwana simbi yesimbi iri pamusoro, kusanganisira electrochemically, makemikari, uye mechanically.

Zingi, cadmium, aruminiyamu, chrome, nickel, uye sirivheri ndiwo masimbi akajairika anoshandiswa kuMetallic coating.Nekudaro, Zinc ndiyo yakajairika mukuita kweindasitiri yekugadzira.

Chinyorwa ichi chinoongorora akawanda esimbi coating matekiniki, kusanganisiraelectroplating, galvanizing, poda coating, thermal spraying, painting, and hard steel coating, pamwe chete nemabhenefiti azvo.

Mhando Dzakajairika dzeMetal coating

1. Electroplating

Electroplating inzira yekugadzira danda rakatetepa resimbi yekuputira pane substrate pamusoro kuburikidza ne electrolysis.Iyo substrate zvinhu inoshanda se cathode, uye iyo yekupfekedza zvinhu seanode mukuita.Aqueous solutions yeasidhi, mabhesi, kana munyu anoshandiswa kuitisa ikozvino.Pano, iyo yakavharwa zvinhu inofanira kunge iri muine aqueous solution.

Ioni dzezvinhu zvekupfekedza dzinofamba dzakananga kucathode sezvo magetsi achiiswa kune maelectrode, kwaanoisa layer.Iyi nzira inonyanya kushandiswa mukatikuisa zincpane ferrous material.

Electroplating setup

Iyo yepamusoro inofanirwa kuve yakavharwa zvakaenzana neyakasunungurwa zvinhu kubva kune anode.Iyo deposition vhoriyamu inokanganiswa neakati wandei akasiyana, kusanganisira ikozvino density, electrolysis duration, uye mamwe ma parameter.Ngationei izvi tichishandisa equation yakaoma.

Huwandu hwesimbi yakapfava (V) = KI t

Kupi,

K = electrochemical yakaenzana nguva dzose, iyo inosiyana pane electrodes uye electrolyte mhando

I = ikozvino yakapfuura kuburikidza ne electrolysis (A)

t = nguva ye electrolysis (sec)

Nekupfekedzwa kwemhando, iyo substrate inoda kuchenesa zvakakodzera kubvisa ngura, mafuta, slags, uye kumwe kusakwana kwepamusoro usati waenderera ne electroplating.

2. Galvanization

Galvanized parts

Ndiyo yakajairika simbi yekuputira maitiro umo Zinc yakavharwa pasimbi kana simbi kudzivirira kubva mukuora.Kana wakamboona kuti zvinhu zvese zvesimbi zvine tindi yesirivha inopenya, inopenya pamusoro pazvo, ruvara irworwo rwunokonzerwa nemarara uye rwunozivikanwa sesimbi.Izvo zvikamu zvinoputirwa nekunyudzwa mune inopisa zinc solution, iyo inoumba danda rekudzivirira rakatetepa.

Mukuita kupisa-kunyudza galvanization, iyo yakacheneswa simbi yakanyudzwa (mushure mekunge yasvika pedyo nekunyunguduka kweZinc) mubhavhu rezinc rakanyungudutswa.Pakupedzisira, isina kusimba uye yunifomu yekuputira layer inoumbwa nekumhanyisa masheets kuburikidza nema rollers pakarepo pakupfeka.Metallic coating ine galvanization inodhura zvakanyanya, yakapusa, uye inokurumidza nzira inopa yakakwira corrosion kuramba.

Midziyo uye zvikamu zvemichina yekurima, mota, fenicha, kuvaka, uye zvimwe zvinhu zvakawanda zvese zviri pasi pekuita galvanization.

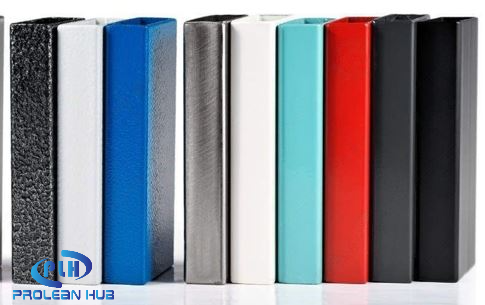

3. Powder coating

Thepoda kupfekanzira inoshandisa electrostatic simba kuisa yakaoma, metallic poda coating pamusoro chikamu chikamu.Hupfu hune tsanga dzakanatswa dze pigment particles dzinopa pamusoro peruvara rwakakodzera.

Pamusoro pezvinhu zvichange zvakaputirwa zvinocheneswa muchikamu chekutanga, apo guruva, ngura, slags, uye chero imwe tsvina inobviswa uchishandisa chero asidi yekuchenesa kana kuti mvura yakasvibiswa, zvichienderana nekushambidzika kwepamusoro uye kupedzisa zvinodiwa zvehutano.Nzira yekuchenesa inowedzerawo kunamatira kwepamusoro kuitira kuti kuvhara kuve kwakanyanya.

Upfu hwakaputirwa chikamu

Zvichienderana nekuguma kwekushandiswa, hupfu hunopfapfaidzwa pamusoro pepamusoro, kana zvikamu zvinonyudzwa mumvura ine poda particles yakamiswa.Mushure maizvozvi, zvikamu zvinopisa kuti zviite kuti hupfu hunyunguduke uye hunamatira kuchivharo zvakachengeteka.

Midziyo yakawanda yesimbi ine poda inoiswa kudzivirira kuita ngura.Iyo inzira inodhura inoita kuti zvigadzirwa uye zvikamu zvigare zvakasimba.

4. Paint coating

Paint-coated metal surface.

"Metallic pendi coating" inoreva kuisa pendi dzakasiyana-siyana dzemvura kune zvinhu.Nzira yekugadzira imwe simbi yakatetepa simbi inodzivisa ngura ndeyechinyakare.Nekudaro, kuumbwa kweruvara chinhu chakakosha mukuti zano iri rinoshanda sei.Naizvozvo, kuumbwa kwependi kwakasiyana kunodiwa zvichienderana nerudzi rwezvinhu, nharaunda yakafumurwa, uye nekuita zvinodiwa.

Iyo pendi yekuputira haina kusimba kupfuura dzimwe nzira dzesimbi dzekupfeka dzatakaongorora nekuti dzinoita kupera mushure mechinguva.Nekudaro, ichiri nzira yakanakisa yekugadzira zvigadzirwa uye zvikamu zvinozoiswa mukati memba-inodzivirira corrosion.

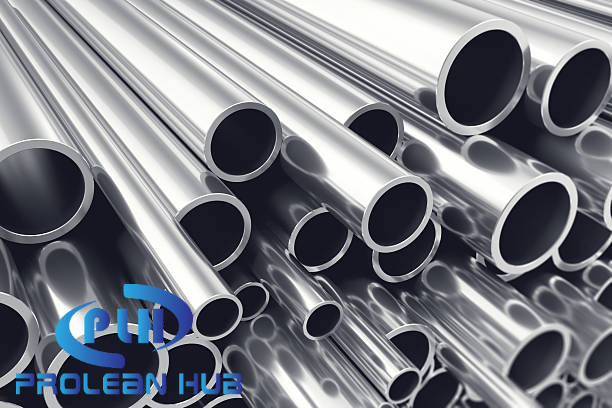

5. Thermal spraying

Iyo inopisa yekupfapfaidza coating inonyanya kuzivikanwa kune simbi yesimbi yezvimiro zvesimbi.Simbi inoshandiswa muzvirongwa zvidiki nezvihombe zvakaita senjanji, njanji, uye zvivakwa zvesimbi zvinoiswa pachena kune zvakatipoteredza uye zvinoda dziviriro yakasimba pakuumbwa kwe ngura.Nekuda kwehukuru hwazvo, zvimiro izvi zvinonetsa galvanize, electroplate, kana jasi nesimbi dzekudzivirira kuburikidza nedzimwe nzira.Asi uchishandisa nzira yekupfapfaidza yekupisa, zvinokwanisika kupfekedza nzvimbo dzesimbi neZinc, aluminium, kana zinc-aluminium alloys.

Thermal spraying operation

Kuchenesa kunoitwa muchikamu chekutanga kuvandudza kunamatira kwepamusoro uye kubvisa kusakwana kwepamusoro.Tevere, pfuti yekupfapfaidza ine inopisa sosi (okisijeni gasi murazvo kana magetsi arc) inodyiswa nehupfu hwesimbi kana mafomu ewaya.Zvadaro mvura Zinc kana aluminium inopfapfaidzwa pamusoro pepamusoro uchishandisa jeti yemhepo yakamanikidzwa.Aluminium inogona kugara ichiiswa sechivhariso layer pamberi peZinc kuti ivandudze kushanda kwayo.Inoshandisa ma oxides etitanium, chromium, uye nickel.

Zvino ngatitaurei zvishoma pamusoro pekuputira simbi pasimbi sezvo zvivakwa zvakawanda nhasi zvakavakwa nesimbi, uye marudzi ese akasiyana emaindasitiri anoshandisa zvigadzirwa nesimbi zvakagadzirwa nesimbi.

Hard Steel Coating

Chinangwa chekutanga chekuputira chakaoma chesimbi ndechekuvandudza kusadzivirira kwayo uye kusimba mune inotsvedza nzira kuitira kuti igone kumira nyore nharaunda dzakaomarara pasina kuparara.

Zvikamu zvine simbi yakaoma

Maitiro mazhinji, anosanganisira hydraulics, kusimudza, uye hydrophilic, zvinoenderana nekutsvedza kunoenderera kwenzvimbo;kana iyo yekuputira yakanyungudutswa, mapeji anorasikirwa nekukwanisa kurwisa corrosion, izvo zvinoita kuti iyo nzira ikundike.Nokudaro, iyo yakasimba yekuputira inogona kutsungirira kukweshwa uye kutsvedza pasina kusvuura iyo yakavharwa layer.

Zvakanakira

· Kuisa simbi inodzivirira pamusoro inodzivirira zvinhu kubva pakuora uye kupera.

· Mushure mekushandisa iyo simbi yekuputira, inoramba kupera uye kubvaruka, ichiita iyo yekupedzisira-chigadzirwa chakanyanya kusimba.

· Iyo yekuwedzera layer inobatsirawo neiyo substrate zvinhu zvemakanika uye hunhu hwemuviri, sekuoma uye kusimba.

· Wakambonzwa izwi iri“utsanana hwesimbi”?Inotaura nezvekuchengetedza nzvimbo yakachena kwenguva yakareba.Pamusoro neMetallic coating inodzivirira kuumbwa kweguruva mukati mayo uye inochengetedza hutsanana.

· Mushure mekuputirwa nesimbi, iyo substrate yepamusoro ichaita seinopenya uye ichikwezva, zvichiita kuti zvive nyore kuisa mavara panguva yekumashure-kugadzirisa.

Applications

Anenge ese maindasitiri, anosanganisira aerospace, mota, zvekurima, zvekudzivirira, zvekurapa, uye zvekuvaka, zvinoda zvikamu uye zvigadzirwa zvinodzivirirwa kubva kusimbi yesimbi.

Mhedziso: Metallic Coating Service paProleanHub

Chinangwa chekutanga chesimbi yesimbi ndeyekudzivirira iyo yepasi kubva pakuora kuti iwedzere kusimba kwechigadzirwa chekupedzisira.Kune nzira dzakasiyana-siyana dzekuwana simbi yesimbi;takakurukura nzira dzakakosha munyaya ino.Kusarudzwa kweiyo chaiyo yekupfekedza maitiro kunoenderana nerudzi rwechinyorwa, chinodiwa kutsanangurwa, hupfumi, ongororo, uye zvimwe zvakawanda zvinhu.Saka, maitiro anogona kunge akaoma kwauri.

Isu tinopa masevhisi ekuputira simbi, anosanganisira electroplating, galvanization, poda coating, dema oxide, uye kunyange simbi yakaoma.Yedu nyanzvi mainjiniya akashanda muchikamu chekupedzisa kweanopfuura makore gumi achakusarudzira nzira yekupfeka, zvichienderana nekuda kwako uye mutengo-kushanda.Saka, kana iwe uchida chero inoenderana sevhisi kana kubvunzana, usazezetaura nesu.

FAQ's

Ndeipi yakanakisa simbi coating yepurojekiti yangu?

Iyo simbi yekuvhara mhando inotsamira pane yako purojekiti substrate zvinhu uye mamwe ma parameter.

Ndeapi marudzi akajairika esimbi coating?

Electroplating, galvanizing, poda coating, thermal spraying, uye pendi ndiwo marudzi akajairika ekuputira simbi.

Chii chinonzi hard steel coating?

Yakaomeswa simbi yesimbi imhando yemhando yesimbi yekuputira maitiro emidziyo yesimbi inotora chikamu mukutsvedza kushanda nguva dzose, iyo inonyanya kuve nemaokisi, nitrides, carbides, borides, kana kabhoni.

Chii chinangwa chekutanga chesimbi yesimbi?

Chinangwa chekutanga chesimbi yesimbi ndeyekudzivirira simbi kubva mukuora uye kuwedzera kusimba kwechigadzirwa chekupedzisira.

Nguva yekutumira: Aug-03-2022