Mkpuchi ọla: Ihe niile I Kwesịrị Ịma

Mmelite ikpeazụ 08/31, Oge ọgụgụ echere: 5 nkeji

Akụkụ ndị kpuchiri ígwè

Nkeọla mkpuchibụ usoro nke na-ekpuchi akụkụ ihe onwunwe na ihe mkpuchi ọzọ nke metal na alloys iji zere corrosion.Na mgbakwunye na igbochi mmebi ahụ, mkpuchi ọla na-eme ka ihe eji arụ ọrụ, anụ ahụ, na ihe ịchọ mma nke akụkụ ndị a na-etinye (Substrate).Enwere ọtụtụ ụzọ isi nweta oyi akwa dara n'elu, gụnyere electrochemically, chemically, na mechanically.

Zinc, cadmium, aluminum, chrome, nickel, na ọlaọcha bụ ọla a na-ejikarị eme ihe maka mkpuchi ọla.Otú ọ dị, Zinc bụ ihe a na-ahụkarị na omume nke ụlọ ọrụ mmepụta ihe.

Isiokwu a ga-enyocha ọtụtụ usoro mkpuchi ọla, gụnyereelectroplating, galvanizing, mkpuchi ntụ ntụ, spraying thermal, eserese, na mkpuchi ígwè siri ike, yana uru ha bara.

Ụdị ihe mkpuchi ígwè ndị a na-ahụkarị

1. Electrorating

Electroplating bụ usoro nke na-emepụta ihe mkpuchi metal dị mkpa n'elu ala site na electrolysis.Ihe eji eme ihe na-arụ ọrụ dị ka cathode, na ihe mkpuchi dị ka anode na usoro.A na-eji ihe ngwọta nke acid, bases, ma ọ bụ nnu mee ihe iji duzie ihe dị ugbu a.N'ebe a, ihe mkpuchi ahụ kwesịrị ịdị na ngwọta mmiri.

Ion ihe mkpuchi ahụ na-aga na cathode ka a na-etinye ọkụ eletrik na electrodes, ebe ha na-edobe oyi akwa.A na-ejikarị usoro a eme ihe nana-etinye Zincna ihe ferrous.

Ntọlite electrolating

A ghaghị kpuchie elu ahụ nke ọma na ihe ndị a tọhapụrụ na anode.Ọtụtụ mgbanwe na-emetụta olu nkwụnye ego, gụnyere njupụta dị ugbu a, oge electrolysis na paramita ndị ọzọ.Ka anyị were nha anya dị mgbagwoju anya were anya nke a.

Olu nke metal plated (V) = KI t

Ebee,

K = electrochemical dakọtara mgbe niile, nke dị iche na electrodes na ụdị electrolyte

I = ugbu a gafere site na electrolysis (A)

t = oge electrolysis (sekọnd)

Maka mkpuchi dị mma, mkpụrụ ahụ kwesịrị ịdị ọcha nke ọma iji wepụ nchara, mmanụ, slags na ezughị okè ndị ọzọ tupu ya aga n'ihu na electroplating.

2. Galvanization

Akụkụ galvanized

Ọ bụ usoro mkpuchi ọla a na-ahụkarị nke a na-ekpuchi Zinc na ígwè ma ọ bụ ígwè iji chebe ya pụọ na mmebi.Ọ bụrụ na ị hụtụla na ihe fọrọ nke nta ka ọ bụrụ ngwongwo nchara niile nwere ọmarịcha ọla ọcha na-egbuke egbuke n'elu ha, agba ahụ sitere na galvanization ma mara ya dị ka ígwè galvanized.Akụkụ ahụ na-galvanized site n'itinye n'ime ihe ngwọta zinc na-ekpo ọkụ, nke na-emepụta oyi akwa nchebe dị mkpa.

N'ime usoro ịgbanye galvanization nke na-ekpo ọkụ, a na-etinye ígwè ntọala ahụ a kpochara (mgbe ọ rutere nso ebe Zinc na-agbaze) n'ime bat zinc gbazere.N'ikpeazụ, a na-emepụta akwa mkpuchi na-adịghị ike na nke edo site na-agba ọsọ na mpempe akwụkwọ na rollers ozugbo na mkpuchi.Ihe mkpuchi ọla na galvanization bụ usoro dị ọnụ ala, dị mfe na ngwa ngwa nke na-enye nnukwu nguzogide corrosion.

A na-edobe akụrụngwa na akụrụngwa nke igwe ọrụ ugbo, ụgbọ ala, arịa ụlọ, ihe owuwu, na ọtụtụ ihe ndị ọzọ niile n'okpuru usoro galvanization.

3. Mkpuchi ntụ ntụ

Nkemkpuchi ntụ ntụusoro na-eji ike electrostatic tinye ihe mkpuchi ntụ ntụ dara kpọrọ nkụ n'elu akụkụ ahụ.Ntụ ntụ nwere ọka a nụchara anụcha nke ụmụ irighiri pigmenti nke na-enye elu ahụ agba kwesịrị ekwesị.

A na-ehichapụ elu nke ihe a ga-ekpuchi na nke mbụ, ebe a na-ewepụ uzuzu, nchara, slags, na mmetọ ọ bụla ọzọ site na iji ma ọ bụ acid dị ọcha ma ọ bụ naanị mmiri mmiri na-ekpo ọkụ, dabere na ịdị ọcha nke elu na imecha ihe ndị a chọrọ.Usoro nhicha ahụ na-emekwa ka nrapado nke elu dị elu ka mkpuchi ahụ wee dịkwuo irè.

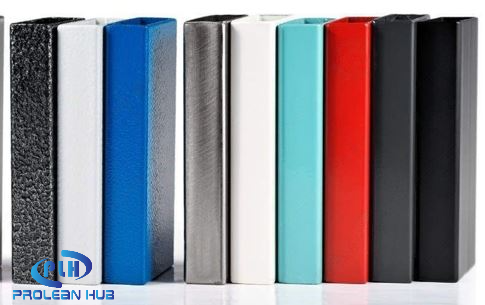

Akụkụ kpuchiri ntụ ntụ

Dabere na ngwa njedebe, a na-efesa ntụ ntụ n'elu elu, ma ọ bụ akụkụ ndị ahụ na-agbanye n'ime mmiri mmiri na-eme ka ihe ndị na-ekpo ọkụ kwụsịtụrụ.Mgbe nke ahụ gasịrị, a na-ekpo ọkụ ihe ndị ahụ iji mee ka ntụ ntụ na-agbaze ma rapara na mkpuchi ahụ nke ọma.

Ọtụtụ ngwá ụlọ ígwè nwere ihe mkpuchi ntụ ntụ iji gbochie nchara ịpụta.Ọ bụ ụzọ dị ọnụ ahịa nke na-eme ka ngwaahịa na akụkụ ya dịkwuo ogologo.

4. Ihe mkpuchi agba

N'elu igwe ejiri agba agba.

"Mkpuchi agba ọla" na-ezo aka n'itinye agba mmiri dị iche iche n'elu ihe.Usoro nke imepụta akwa akwa igwe agbakwunyere nke na-eguzogide corrosion bụ omenala.Otú ọ dị, nhazi nke agba bụ akụkụ dị mkpa na otú atụmatụ a si dị irè.Ya mere, a na-achọ ụdị agba dị iche iche dabere na ụdị ihe onwunwe, ebe a na-ekpughere ya, na ihe ndị chọrọ ịrụ ọrụ.

Mkpuchi agba adịghị adịgide adịgide karịa ụzọ mkpuchi ọla ndị ọzọ anyị nyochara n'ihi na ọ na-aka ike mgbe obere oge gasịrị.Otú ọ dị, ọ ka bụ ụzọ magburu onwe ya isi mee ngwaahịa na akụkụ ndị a ga-etinye n'ime ụlọ na-eguzogide corrosion.

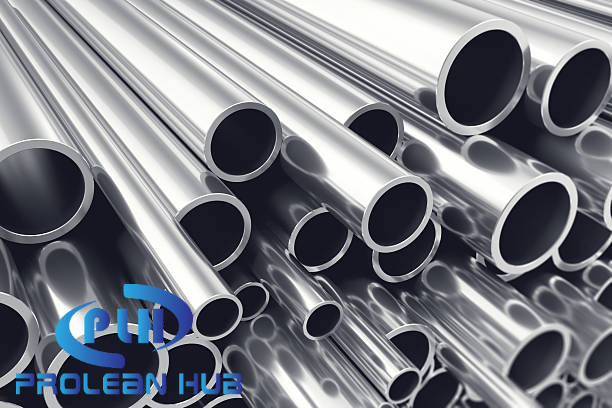

5. Ịfesa thermal

The thermal spraying mkpuchi bụ kasị ama maka dara oyi akwa nke ígwè Ọdịdị.Igwe a na-eji obere na nnukwu sistemu dị ka ụzọ ụgbọ oloko, egwu, na ụlọ ígwè na-ekpughere gburugburu ebe obibi ma chọọ nchebe siri ike megide nchara.N'ihi nha ha, ihe owuwu ndị a na-esiri ike iji galvanize, electroplate, ma ọ bụ mkpuchi ọla na-echebe site na ụzọ ndị ọzọ.Mana iji usoro ịgbasa ọkụ, ọ ga-ekwe omume iji Zinc, aluminum, ma ọ bụ zinc-aluminom alloys kpuchie elu igwe.

Thermal spraying ọrụ

A na-eme ihicha na nke mbụ iji meziwanye nrapado nke elu ma wepụ ezughị okè n'elu.Na-esote, a na-eji ntụ ntụ ígwè ma ọ bụ waya na-enye égbè na-esi ísì ọkụ (ọkụ ikuku oxygen ma ọ bụ arc eletrik).Mgbe ahụ, a na-efesa Zinc mmiri mmiri ma ọ bụ aluminom n'elu site na iji ụgbọ elu ikuku abịakọrọ.Enwere ike itinye aluminom ugboro ugboro dị ka oyi akwa mgbochi n'ihu Zinc iji kwalite ịdị mma mkpuchi ahụ.Ọ na-eji oxides nke titanium, chromium, na nickel.

Ugbu a, ka anyị kwuo ntakịrị banyere mkpuchi metal na ígwè ebe ọ bụ na a na-eji ígwè arụ ọtụtụ ụlọ taa, na ụdị ọrụ dị iche iche na-eji ngwaahịa na akụkụ ígwè eme ihe.

Mkpuchi Steel siri ike

Ebumnuche bụ isi nke mkpuchi siri ike maka ígwè bụ imeziwanye nguzogide corrosion na ike ya na usoro mmịfe ka o wee nwee ike iguzogide gburugburu ebe kachasị njọ na-enweghị mmebi.

Akụkụ nwere mkpuchi ígwè siri ike

Ọtụtụ usoro, gụnyere hydraulics, ibuli elu, na hydrophilic, na-adabere na mmịfe elu na-aga n'ihu;ọ bụrụ na a na-ehichapụ ihe mkpuchi ahụ, ihe ndị dị n'elu na-efunahụ ike ha iguzogide corrosion, nke na-eme ka usoro ahụ daa.N'ihi ya, mkpuchi siri ike nwere ike ịtachi obi na-ehichapụ ya na slide na-enweghị bee oyi akwa mkpuchi.

Uru

· Itinye oyi akwa metal nchebe n'elu na-echebe ihe ahụ pụọ na mmebi na iyi.

· Mgbe etinyere mkpuchi metal ahụ, ọ ga-eguzogide iyi na ịkwa akwa, na-eme ka ngwaahịa njedebe dịkwuo ogologo.

· Ihe mgbakwunye ahụ na-enyekwa aka na njirimara akụrụngwa na nke anụ ahụ, dị ka isi ike na ike.

· Ị nụtụla okwu ahụ"Metal ịdị ọcha"?Ọ na-ezo aka na idobe elu ọcha ruo ogologo oge.Igwe mkpuchi ọla na-egbochi ime uzuzu na ya ma na-edobe ịdị ọcha.

· Mgbe mkpuchi ọla, elu nke mkpụrụ ga-apụta na-egbuke egbuke ma na-adọrọ adọrọ, na-eme ka ọ dị mfe itinye agba n'oge nhazi.

Ngwa

Ihe fọrọ nke nta ka ọ bụrụ ụlọ ọrụ niile, gụnyere ikuku ikuku, ụgbọ ala, ọrụ ugbo, nchekwa, ahụike, na ihe owuwu, chọrọ akụrụngwa na ngwaahịa echekwara na mkpuchi ọla.

Mmechi: Ọrụ mkpuchi igwe naProleanHub

Ebumnuche bụ isi nke mkpuchi ọla bụ iji chebe ihe dị n'elu site na corrosion iji kwalite ịdịte aka nke ngwaahịa ikpeazụ.Enwere ụzọ dị iche iche nke ịnweta mkpuchi metal;anyị atụlewo ụzọ ndị pụtara ìhè n'isiokwu a.Nhọrọ nke usoro mkpuchi kwesịrị ekwesị na-adabere n'ụdị ihe ahụ, nkọwa achọrọ, akụnụba, nyocha, na ọtụtụ ihe ndị ọzọ.Yabụ, usoro a nwere ike ịdị gị mgbagwoju anya.

Anyị na-enye ọrụ mkpuchi ọla ndị ọkachamara, gụnyere electroplating, galvanization, mkpuchi ntụ ntụ, oxide ojii, na ọbụna akwa nchara siri ike.Ndị injinia ọkachamara anyị bụ ndị rụworo ọrụ na mpaghara imecha elu ihe karịrị afọ iri ga-ahọrọ ụzọ mkpuchi mkpuchi ziri ezi maka gị, dabere na mkpa gị na ọnụ ahịa bara uru.Yabụ, ọ bụrụ na ịchọrọ ọrụ ma ọ bụ ndụmọdụ metụtara ya, egbula oge ime yakpọtụrụ anyị.

FAQ

Kedu mkpuchi ọla kacha mma maka ọrụ m?

Ụdị mkpuchi ọla na-adabere n'ụdị ihe eji eme ihe na ihe ndị ọzọ.

Kedu ụdị mkpuchi ọla a na-ahụkarị?

Electroplating, galvanizing, mkpuchi ntụ ntụ, ịgbasa ọkụ, na eserese bụ ụdị mkpuchi ọla a na-ahụkarị.

Kedu ihe mkpuchi nchara siri ike?

Ihe mkpuchi nchara siri ike bụ ụdị usoro mkpuchi ọla maka ihe nchara nke na-ekere òkè na ọrụ mmịfe na-aga n'ihu, nke nwere oxides, nitrides, carbides, borides, ma ọ bụ carbon.

Gịnị bụ isi nzube nke ọla mkpuchi?

Ebumnuche bụ isi nke mkpuchi ọla bụ iji gbochie ígwè ahụ ka ọ ghara imebi ma mee ka ọ dịkwuo ogologo oge nke ngwaahịa ikpeazụ.

Oge nzipu: Ọgọst-03-2022