I-Metallic Coatings: Konke Odinga Ukukwazi

Isibuyekezo sokugcina ngo-08/31, Isikhathi esilinganiselwe sokufunda: 5 imiz

Izingxenye eziboshwe ngensimbi

Ienamathela metallicinqubo yokumboza ingxenye yezinto ezibonakalayo ngesendlalelo esengeziwe sensimbi nama-alloys ukugwema ukugqwala.Ngokungeziwe ekuvimbeleni ukuwohloka, i-metallic coating ithuthukisa izakhiwo zemishini, zomzimba, nezobuhle zezingxenye ezisetshenziswayo (i-Substrate).Kunezindlela eziningana zokufeza ungqimba lwensimbi phezulu, okuhlanganisa i-electrochemically, amakhemikhali, kanye nemishini.

I-Zinc, i-cadmium, i-aluminium, i-chrome, i-nickel, nesiliva yizinsimbi ezivamile ezisetshenziselwa ukuhlanganisa i-Metallic.Kodwa-ke, i-Zinc iyona evame kakhulu ekusebenzeni kwemboni yokukhiqiza.

Lesi sihloko sizohlola izindlela eziningi zokuhlanganisa i-metallic, kuhlanganiseelectroplating, galvanizing, powder coating, thermal spraying, painting, hard steel coating, kanye nezinzuzo zako.

Izinhlobo Ezivamile Zokuhlanganisa Metal

1. I-Electroplating

I-Electroplating iyinqubo yokwakha ungqimba oluncane lwensimbi enamathela endaweni engaphansi nge-electrolysis.I-substrate material isebenza njenge-cathode, kanye nezinto zokumboza njenge-anode kule nqubo.Izixazululo ezinamanzi zama-asidi, izisekelo, noma usawoti zisetshenziselwa ukuqhuba umsinga.Lapha, izinto eziboshwe kufanele ziqukethwe kusisombululo esinamanzi.

Ama-ion wezinto zokumboza ahamba abheke ku-cathode njengoba ugesi usetshenziswa kuma-electrode, lapho afaka khona ungqimba.Le ndlela isetshenziswa kaningi phakathii-zincphezu kwensimbi.

Ukusethwa kwe-Electroplating

Ubuso kufanele buhlanganiswe ngokulinganayo ngezinto ezikhululiwe ku-anode.Ivolumu yokubeka ithintwa okuguquguqukayo okuningana, okuhlanganisa ukuminyana kwamanje, ubude besikhathi se-electrolysis, namanye amapharamitha.Ake sikubone ngeso lengqondo lokhu sisebenzisa isibalo esiyinkimbinkimbi.

Umthamo wensimbi plated (V) = KI t

Lapho,

K= i-electrochemical equivalent constant, ehluka ngama-electrode nohlobo lwe-electrolyte

I= okwamanje idlule ku-electrolysis (A)

t= isikhathi se-electrolysis (isekhondi)

Ukuze kuhlanganiswe ikhwalithi, i-substrate idinga ukuhlanza ngokufanele ukuze kukhishwe ukugqwala, amafutha, ama-slags, nokunye ukungapheleli kwendawo ngaphambi kokuqhubeka ne-electroplating.

2. I-galvanization

Izingxenye ezifakwe amagalani

Kuyinqubo ejwayeleke kakhulu yokuhlanganisa i-metallic lapho i-Zinc igcotshwa ngensimbi noma ngensimbi ukuze ivikeleke ekugqwaleni.Uma uke waqaphela ukuthi cishe zonke izimpahla zensimbi zine-tint yesiliva ekhazimulayo, ecwebezelayo ebusweni bazo, lowo mbala ubangelwa ukugqama futhi waziwa ngokuthi yi-galvanized steel.Izingxenye zifakwa uthayela ngokucwiliswa kusisombululo se-zinc esishisayo, esakha ungqimba oluncane oluvikelayo.

Enqubweni yokucwilisa okushisayo okushisayo, isisekelo sensimbi esihlanziwe sacwiliswa (ngemuva kokuthi sifinyelele eduze nendawo yokuncibilika yeZinc) kubhavu we-zinc encibilikisiwe.Okokugcina, ungqimba olubuthakathaka nolufanayo lokugqoka luyakhiwa ngokugijima amashidi ngokusebenzisa ama-roller ngokushesha lapho kuhlanganiswe.I-Metallic coating nge-galvanization iyindlela engabizi kakhulu, elula, futhi esheshayo enikeza ukumelana nokugqwala okuphezulu.

Izimpahla kanye nezingxenye zemishini yezolimo, izimoto, impahla yasendlini, ukwakhiwa, nezinye izinto eziningi konke kungaphansi kwenqubo yokufaka uthayela.

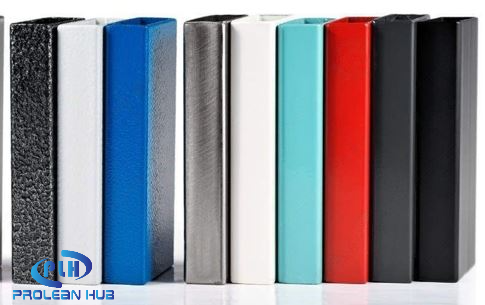

3. I-Powder enamathela

Ii-powder enamathelaindlela isebenzisa amandla e-electrostatic ukuze kufakwe impushana eyomile, eyinsimbi ebusweni bengxenye.Impushana iqukethe izinhlamvu ezicwengekile zezinhlayiya ze-pigment ezinikeza ubuso umbala ofanele.

Ingaphezulu lezinto ezizobe zimbozwe zihlanzwa esigabeni sokuqala, lapho uthuli, ukugqwala, ama-slags, nanoma yikuphi okunye ukungcola kususwa kusetshenziswa noma ukuhlanzwa kwe-asidi noma amanzi a-distilled nje, kuye ngokuhlanzeka kwendawo kanye nezidingo zekhwalithi zokuqeda.Inqubo yokuhlanza iphinde ikhulise ukunamathela kwendawo ukuze ukugqoka kuzosebenza kangcono.

Ingxenye eboshwe nge-powder

Kuye ngesicelo sokugcina, i-powder ifafazwa phezulu, noma izingxenye zicwiliswa oketshezini ngezinhlayiya zempushana zimisiwe.Ngemva kwalokho, izingxenye ziyashiswa ukuze zenze impushana incibilike futhi inamathele kukhava ngokuphepha.

Ifenisha yensimbi eminingi inempushana egcotshwa ukuvimbela ukugqwala.Kuyindlela engabizi kakhulu eyenza imikhiqizo nezingxenye zihlale isikhathi eside.

4. Ukupenda ngopende

Indawo yensimbi ehlanganiswe ngopende.

"I-metallic paint coating" ibhekisela ekufakeni amapende oketshezi ahlukahlukene ezindaweni ezibonakalayo.Inqubo yokwakha ungqimba oluncane lwensimbi olumelana nokugqwala lungokwesiko kakhulu.Nokho, ukwakheka kombala kuyisici esibalulekile endleleni lelisu elisebenza ngayo.Ngakho-ke, ukwakheka okuhlukile kopende kuyadingeka ngokusekelwe ohlotsheni lwezinto ezibonakalayo, indawo eveziwe, kanye nezidingo zokusebenza.

Indwangu kapende ayiqinile kangako kunezinye izindlela zokumboza ngensimbi esizihlolile ngoba ivamise ukuguga ngemva kwesikhashana.Kodwa-ke, kuseyindlela enhle kakhulu yokwenza imikhiqizo nezingxenye ezizofakwa endlini zimelana nokubola.

5. Ukufafaza okushisayo

I-thermal spraying coating idume kakhulu ngongqimba lwensimbi lwezakhiwo zensimbi.Insimbi esetshenziswa ezinhlelweni ezincane nezinkulu ezifana nezitimela, amathrekhi, namabhilidi ensimbi achayeka emvelweni futhi adinga ukuvikeleka okuqinile ekubumbeni ukugqwala.Ngenxa yobukhulu bazo, lezi zakhiwo ziyinselele ukwenza i-galvanize, i-electroplate, noma ukugqoka ngezinsimbi zokuzivikela ngezinye izindlela.Kodwa usebenzisa inqubo yokufafaza okushisayo, kungenzeka ukumboza izindawo zensimbi ngeZinc, i-aluminium, noma i-zinc-aluminium alloys.

Ukusebenza kokufafaza okushisayo

Ukuhlanza kwenziwa esigabeni sokuqala ukuze kuthuthukiswe ukunamathela kwendawo futhi kususe ukungapheleli kwendawo.Okulandelayo, isibhamu se-spray esinomthombo wokushisa (i-oxygen gas flame noma i-arc kagesi) inikezwa ngempushana yensimbi noma amafomu ocingo.Khona-ke i-Zinc ewuketshezi noma i-aluminium ifafazwa phezulu kusetshenziswa indiza yomoya ecindezelwe.I-Aluminiyamu ingase isetshenziswe kaningi njengesendlalelo sokuvimbela ngaphambi kwe-Zinc ukuze kuthuthukiswe ukusebenza kahle kokunameka.Isebenzisa ama-oxide e-titanium, i-chromium, ne-nickel.

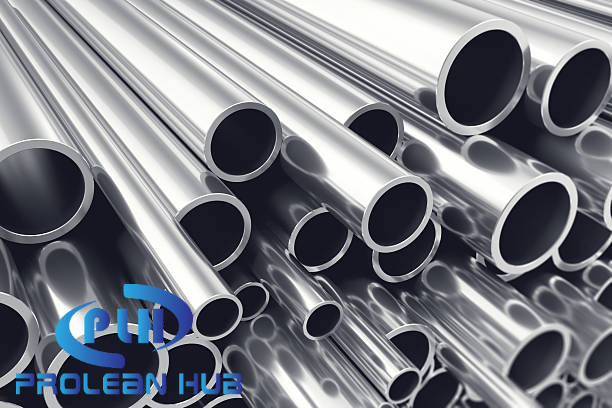

Manje ake sikhulume kancane mayelana nokunameka kwensimbi kunsimbi njengoba izakhiwo eziningi namuhla zakhiwe ngensimbi, futhi zonke izinhlobo zezimboni zisebenzisa imikhiqizo nezingxenye ezenziwe ngensimbi.

I-Hard Steel Coating

Umgomo oyinhloko we-hard coating yensimbi ukuthuthukisa ukumelana nokugqwala kwayo namandla kumshini wokuslayida ukuze ikwazi ukumelana kalula nezindawo ezinokhahlo ngaphandle kokuwohloka.

Izingxenye ezinensimbi eqinile

Izindlela eziningi, ezihlanganisa ama-hydraulic, ukuphakamisa, kanye ne-hydrophilic, zincike ekushelelekeni okuqhubekayo kwezindawo;uma i-coating ihlutshiwe, izindawo ezingaphezulu zilahlekelwa amandla azo okumelana nokugqwala, okubangela ukuthi umshini wehluleke.Ngakho-ke, ukunamathela okuqinile kungakwazi ukubekezelela ukukhuhlwa nokushelela ngaphandle kokuxebuka ungqimba olumboziwe.

Izinzuzo

· Ukusebenzisa ungqimba lwensimbi oluvikelayo endaweni kuvikela impahla ekuwohlokeni nasekuguge.

· Ngemuva kokufaka i-coating yensimbi, izomelana nokuguga, okwenza umkhiqizo wokugcina uhlale isikhathi eside kakhulu.

· Isendlalelo esengeziwe siphinde sisize ngezici zemishini nezomzimba ze-substrate, njengokuqina namandla.

· Wake walizwa leli gama“inhlanzeko yensimbi”?Ibhekisela ekugcineni indawo engaphezulu ihlanzekile isikhathi eside.Indawo ene-Metallic coating ivimbela ukwakheka kothuli futhi igcina inhlanzeko.

· Ngemuva kokumbozwa ngensimbi, indawo engaphansi izobonakala icwebezela futhi ikhanga, okwenza kube lula ukusebenzisa imibala ngesikhathi sokucutshungulwa.

Izinhlelo zokusebenza

Cishe zonke izimboni, okuhlanganisa i-aerospace, ezezimoto, ezolimo, ezokuvikela, ezokwelashwa, nezokwakha, zidinga izingxenye nemikhiqizo evikelwe ekuhlanganisweni kwensimbi.

Isiphetho: Isevisi ye-Metallic Coating atI-ProleanHub

Inhloso eyinhloko ye-metallic coating ukuvikela indawo ebonakalayo ekugqwaleni ukuze kuthuthukiswe ukuqina komkhiqizo wokugcina.Kunezindlela ezehlukene zokuthola ukunameka kwensimbi;sixoxe ngezindlela ezibalulekile kulesi sihloko.Ukukhethwa kwenqubo efanele yokumboza kuncike ohlotsheni lwezinto ezibonakalayo, ukucaciswa okudingekayo, ezomnotho, ukuhlaziya, nezinye izici eziningi.Ngakho, inqubo ingase ibe yinkimbinkimbi kuwe.

Sinikezela ngezinsizakalo zokumboza ngensimbi, okuhlanganisa i-electroplating, i-galvanization, i-powder coating, i-oxide emnyama, ngisho nezingqimba zensimbi eqinile.Onjiniyela bethu abangongoti asebesebenze emkhakheni wokuqedela i-surface iminyaka engaphezu kweshumi bazokukhethela indlela elungile yokumboza, kuye ngesidingo sakho kanye nokusebenza kahle kwezindleko.Ngakho-ke, uma udinga noma iyiphi isevisi ehlobene noma ukubonisana, ungangabaziXhumana nathi.

Imibuzo Evame Ukubuzwa

Iyiphi i-metallic coating engcono kakhulu yephrojekthi yami?

Uhlobo lokumboza ngensimbi luncike ezintweni ezingaphansi kwephrojekthi yakho kanye namanye amapharamitha.

Yiziphi izinhlobo ezijwayelekile ze-metallic coating?

I-Electroplating, i-galvanizing, i-powder coating, isifutho esishisayo, nokudweba yizinhlobo ezivamile zokumboza ngensimbi.

Kuyini ukunamathela kwensimbi eqinile?

Ukufakwa kwensimbi eqinile kuwuhlobo oluthile lwenqubo yokuhlanganisa insimbi yezingxenye zensimbi ezibamba iqhaza ekusebenzeni kokushelela ngokuqhubekayo, okuqukethe ikakhulukazi ama-oxide, ama-nitride, ama-carbides, ama-boride, noma ikhabhoni.

Iyini inhloso eyinhloko yokunameka kwensimbi?

Inhloso eyinhloko yezingubo zensimbi ukuvimbela insimbi ukuthi ingagqwali futhi ikhulise ukuqina komkhiqizo wokugcina.

Isikhathi sokuthumela: Aug-03-2022