Ukuma Okuphezulu Kwezokukhiqiza: Isilinganiso, Izinto Ezithinta & Nokunciphisa

Isibuyekezo sokugcina:09/01, isikhathi sokufunda: 5 imiz

Ukuqedwa kweSurface emagebhugebhu

Masiqonde ubulukhuni obungaphezulu ngegama lokuqedela elingaphezulu.Inqubo yokwenza bushelelezi ingaphezulu lezingxenye ezikhiqiziwe kanye nemikhiqizo yaziwa ngokuthi i-surface finishing, ehlolwa kusetshenziswa ubulukhuni obungaphezulu.Ipharamitha edume kakhulu yezibalo ze-Roughness ngu-Ra.Ibonisa ukuchezuka kwencazelo ye-arithmetical ngaphezulu.Ingxenye encane ye-Rakusho ukuthungwa okushelelayo.

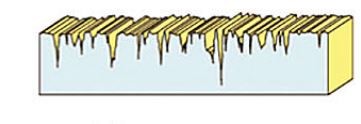

Ubuhhadlahhadla bobuso buwukungajwayelekile kokuthungwa kwendawo okwakhiwa uchungechunge lwezakhiwo ze-crest kanye ne-trough.Lawa ma-crests kanye nama-troughs angaba yi-microscopic futhi abonakale, kuye ngezinga elibukhali.Izinga eliphezulu lezinto ezingavuthiwe noma imikhiqizo eqediwe libalulekile embonini yokukhiqiza.Akukhona nje kuphela mayelana nokukhanga kobuhle kodwa futhi kuthinta ukusebenza kwezingxenye kanye nekhwalithi iyonke.

Ukukalwa Kokuqina Kobuso

Iphrofayili yendawo elukhuni

Ubulukhuni obungaphezulu buchazwa ngokuthi"Ra,“futhi iyunithi layo lingama-microns (µ).U-Ra unikeza isilinganiso somehluko phakathi kwe-crest (ubude) kanye ne-trough (ukujula) endaweni engaphezu kobude bokulinganisa.

Ukulinganisa okungaphezulu kubalulekile ekukhiqizeni izingxenye ezithembekile nezingashintshi kanye nemikhiqizo ekukhiqizeni okunembayo.Ngakho-ke, amapharamitha angaphezulu kufanele akalwe futhi aqashwe ngokucaciswa okudingekayo.Isibonelo, ukukala ubulukhuni obungaphezulu kuyisango lokuzuza ukuqedwa kwendawo edingekayo.

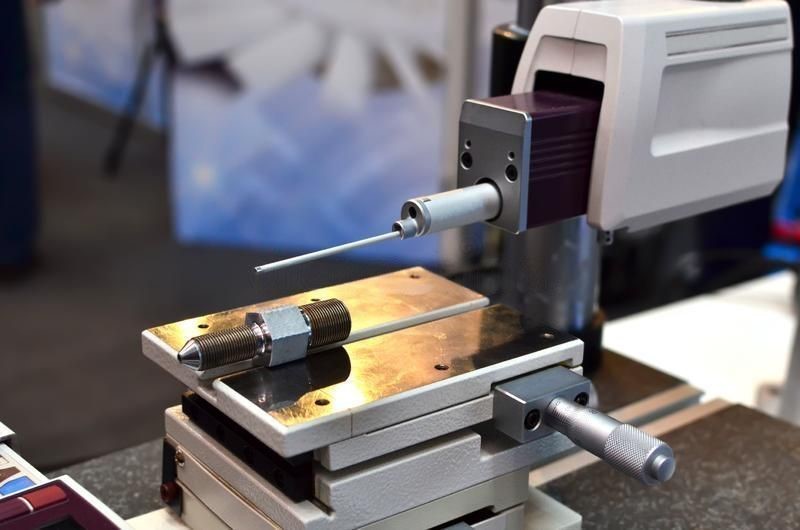

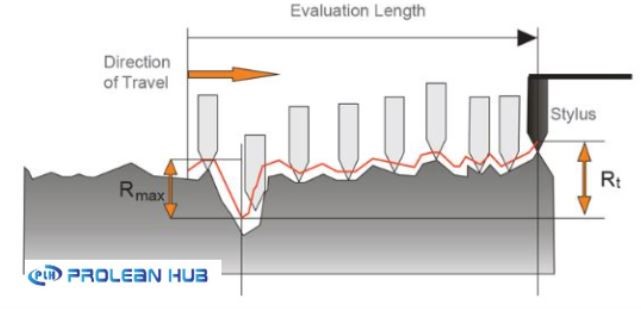

1. Isilinganiso nge-probe.

Lena indlela yokuxhumana yokulinganisa ubulukhuni bendawo.Ukuze uthathe Isilinganiso, i-probe noma usiba kufanele uthinte phezulu.

Ukulinganisa Ukuqina nge-probe

I-skid ihamba kuqala ukuze kutholwe ireferensi, bese i-probe ilandela ngemuva ukuze ihambe phezu komhlaba ngama-crests nama-troughs ngenkathi ithumela amasignali kagesi ukuthuthukisa iphrofayili engaphezulu.Ngemuva kwalokho, ukugoqa okungaphezulu kungatholakala kuphrofayela edaliwe.

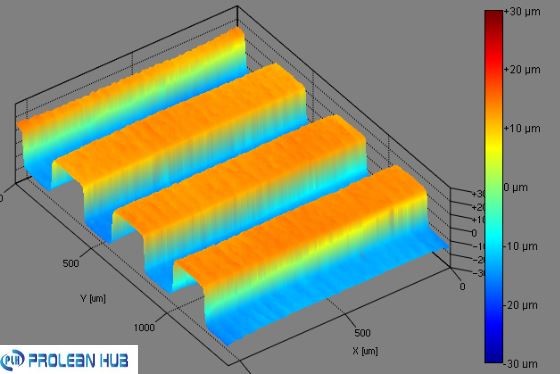

2. Iphrofayili ye-Optical

Le ndlela usamagagasi alula noma amaza omsindo.Idivayisi ithumela amagagasi e-ultrasonic phezulu futhi ithola ukubonakaliswa.Ukuma kwegagasi elibonisiwe kusetshenziselwa ukwakha iphrofayela yendawo ye-3D futhi kubalwe Ukushuba.

Iphrofayili ye-3D ye-roughness evela ku-optical profilometry

3. Ukuqhathanisa

Kule ndlela, umenziiqhathanisa ubuso bomkhiqizo nomkhiqizo nezingxenye ezijwayelekile ezikalwe ngaphambilinibese ekhetha eseduze esebenzisa umuzwa wabo.Nakuba Akuyona indlela eqondile kakhulu, ingasetshenziswa lapho ukunemba okuphezulu kungadingeki, futhi ukudweba okuqhubekayo kuzosetshenziswa phezulu.

Ubunzima Vs.Ukukhiqiza

Enye yezinkomba zokusebenza ezibalulekile zezingxenye ezikhiqiziwe i-Roughness.Amazinga abalulekile obumahwasha obungaphezulu aholela emifantwini ngenkathi kusetshenziswa futhi athuthukise amathuba okugqwala okukhulu lapho evezwe endaweni ezungezile.Ngaphezu kwalokho, i-Roughness inganciphisa ukusebenza kahle futhi ekugcineni ilimaze uhlelo lwemishini lapho kudingeka khona ukungqubuzana okuphansi ngoba indawo engajwayelekile inyusa ukungqubuzana phakathi kwezingxenye.

Kuye ngohlelo lokusebenza, ingxenye ngayinye yomshini inomkhawulo ongaphezulu ohlukile wobunzima bobuso.Isibonelo, izakhi lapho ukungqubuzana kuwukukhathazeka kunokubekezelela okuphansi Kobulukhuni ngoba ukusebenza kuba nzima, futhi ingxenye iyaqhekeka lapho Ukushuba kuphezulu kakhulu.

Imicu kanye nezindawo zokukhwelana zingaba nenani elifanelekile Lokurhabaxa ngoba lokhu akuphazamisi ukukhwelana futhi kusiza ukufaka kahle phakathi kwezingxenye.Futhi, indawo lapho umdwebo udingekile ubheka izinga elithile Lokubi, okuthuthukisa ukunamathela futhi kwenza inqubo ibe lula.

Ubunzima obuphezulu kweminye imisebenzi evamile yokukhiqiza

| Ukusebenza | Ra(Ubuningi) | Ra(okuncane) |

| I-Flame Cutting | 25 | 12.5 |

| Ukugaya | 6.3 | 0.8 |

| Broaching | 3.2 | 0.8 |

| Ukuhlela, Ukubumba | 12.5 | 1.6 |

| Ukubhoboza | 6.3 | 1.6 |

| I-Chemical Milling | 6.3 | 1.6 |

| Khetha.Discharge Machining | 4.75 | 1.6 |

| Investment Casting | 3.2 | 1.6 |

| I-Sand Casting | 25 | 12.5 |

| Ukugaya | 1.6 | 0.1 |

| Ukucija | 0.8 | 0.1 |

| I-Electro-Polish | 0.8 | 0.1 |

| Ukupholisha | 0.4 | 0.1 |

| I-Laser | 6.3 | 0.8 |

| Boring, Turning | 6.3 | 0.4 |

Amanani obunzima bobuso emisebenzini ehlukahlukene

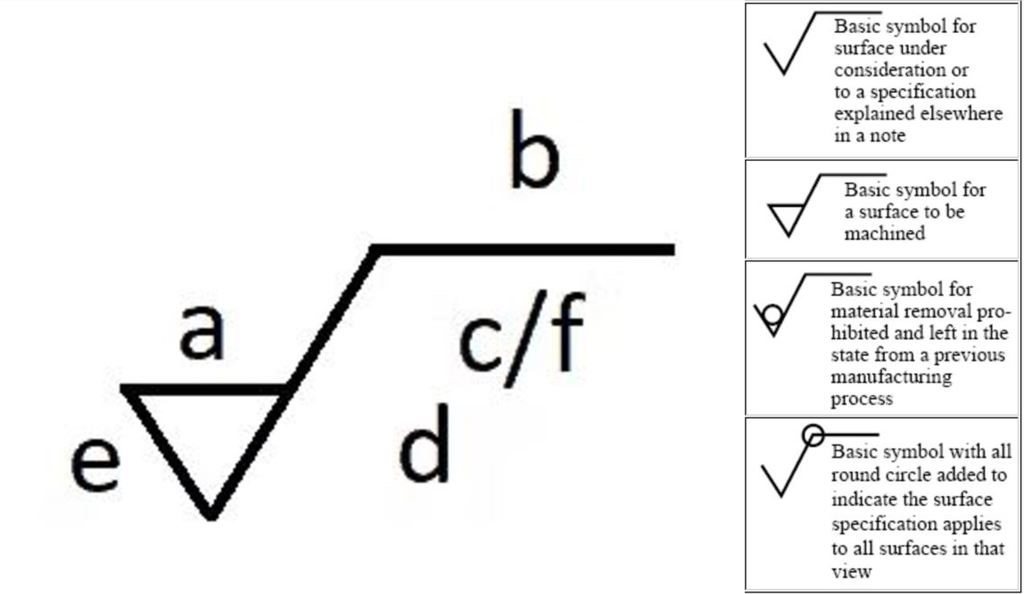

Izimpawu Zokugaqa Kobuso

Ake siqale sixoxe ngezifinyezo ezisetshenziswa ezimpawu ngaphambi kokudlulela ezimpawini ngokwazo.Uma ubheka izimpawu zokuqeda phezulu emidwebeni yokukhiqiza, uzobona izifinyezo ezihlukahlukene.

|

| Incazelo |

| Ra | Ubulukhuni obuphakathi nendawo, incazelo ye-arithmetic yabo bonke ubude beziqongo ukusuka kumugqa wereferensi.

|

| Rubuningi | Ibanga eliphezulu eliqondile phakathi kwe-crest ne-trough |

| Rz | Isilinganiso esiphezulu sokuphakama kwama-crests angu-5 aphezulu, |

| · Rt | Ubude obuphelele bephrofayela yobunzima |

Uhlu Lwezifinyezo

Izimpawu zokugwedla kobuso

| a | Inani lokuqina ku-micrometer ( µm) |

| b | Indlela yokukhiqiza |

| c | Ubude besampula Bokuqina (mm noma intshi) |

| d | isiqondiso sobuso silele |

| e | ubuncane besidingo sokususwa kwezinto (mm) |

| f | isilinganiso esiphezulu sobude beziqongo |

Incazelo yezinto eziguquguqukayo ezisetshenziswa kuzimpawu

Ngokuhlaziya izimpawu zokuma okungaphezulu emdwebeni wokukhiqiza, abaklami nabasebenza bangaxhumana nesimo sokuqedwa kwendawo kunoma iyiphi ingxenye emshinini.

Isibonelo, u-opharetha we-CNC anganquma emdwebeni womklami ukuthi kungakanani okubalulekile okufanele kukhishwe phezulu ngesikhathi sokuqeda.

Yiziphi izici ezithinta izinga lobunzima obungaphezulu?

Lezi zici ezintathu ezilandelayo zithinta ukuhwalala komhlaba;Ukusebenza kokusika, Ukugaya, nokulawula imingcele (Isivinini sokusika kanye nezinga lokuphakelayo).

1. Cutting Operation

Ngemva kokuba umsebenzi wokusika usuphothuliwe nge CNC imishini, ithuluzi lokusika lishiya izinsalela endaweni yokusika ngenxa yokucindezela ngesikhathi sokukhululwa kwethuluzi ku-workpiece.

Lezi zinsalela (ezibizwa ngokuthi i-burr) nazo zithinta ukuqina kohlangothi okudingekayo kwezingxenye.Izici ezilandelayo zizonquma ubukhulu kanye nenani lezinsalela endaweni eshiywe ithuluzi lokusika.

- Ukuchezuka ku-engeli yokusika

- Ukuchezuka kwerediyasi yethulithiphu

- Izinga lokudla

- deformation ngenkathi ukusika

2. Ukugaya

Inqubo yokugaya ekukhiqizeni isebenzisa imidiya eqinile, egayayo, futhi izinga lokushisa lingafinyelela phezulu njengo-1500 ° C phakathi nenqubo.Unqenqema lwezinhlayiya eziqhumayo luzokhiqiza ukugeleza kokushisa kwepulasitiki ngenxa yezinga lokushisa eliphezulu lokusebenza, okushiya ukuhwalala okuncane ebusweni.

3. Ukusika Isivinini & Izinga lokuphakelayo

Isivinini sokusika esiphezulu sikhulisa ukwakheka kwama-chips, futhi nosayizi wama-chips nawo uzokwanda kakhulu.Ngakho-ke ithuluzi lizoshiya ama-burrs amaningi ebusweni ngoba isivinini sokusika sizokwandisa ukungqubuzana phakathi kwethuluzi nendawo yokusika, okwandisa inani lika-Ra.Futhi, izinga eliphezulu lokuphakelayo lizokwandisa ukuphakama kwezinsalela endaweni.

Ngingawanciphisa kanjani ama-roughness?

· Setha izinga lokuphakelayo elifanele ngoba izinga eliphezulu lokuphakela libangela ukuba kube nensalela eningi endaweni yokusika.Ukuze unciphise Ukuqina, sebenzisa uketshezi olusebenzayo lokusika kanye namathuluzi okusika anembile.

· Ama-engeli achezukile aphezulu akhiqiza ama-machining burrs namamaki ngaphezulu, ngakho-ke wanciphise.

· Ngenxa yokuthi ukugqokwa kwamathuluzi kwandisa ubulukhuni, pholisha ukugaya ngaphambi kokugaya.

· Ukungqubuzana kukhuliswa ukudlidliza kumathuluzi omshini, okubangela ukuthi indawo engaphezulu ibe mabi.Ngakho-ke, ngaphambi kokuqhubeka nokusebenza kwemishini, nciphisa ukudlidliza bese wengeza uketshezi lokusika.

· Khetha impahla yethuluzi lomshini ngokusekelwe kuzici zempahla eluhlaza.Isibonelo, uma wenza izinto eziqinile, sebenzisa amathuluzi e-carbide aqukethe umkhondo.Ithuluzi kufanele futhi libe kahle ngokufanayo.

Isiphetho

Ingaphezulu kufanele lihlale liwela ngaphakathi kwemikhawulo ethile yokumahhadla ngesikhathi sokukhiqiza ngokuya ngokucaciswa kwengxenye yomshini.Ra iphakamisa ukuthi kufanele samukele noma senqabe iphrojekthi mayelana nokuqedwa kwendawo.I-profilometer ibala ubulukhuni bendawo ye-arithmetic ngokuthola ubude obumaphakathi bezinto ezingalungile ezakha ingxenye yokumadladla kusukela kumugqa wereferensi.

Ukwelashwa kokuqina kwendawo, ukucutshungulwa okwengeziwe kuyadingeka, njengokususa, ukugaya, nokupholisha.Lezi zindlela zisiza ukuthola inani lobunzima ngaphakathi komkhawulo ofiselekayo.Kodwa-ke, lokhu kucutshungulwa kwangemuva kwengeza ezindlekweni zokukhiqiza, ngakho-ke kungcono ukucabangela isici esibucayi ekuklanyweni komkhiqizo kanye nenqubo yokukhiqiza.I-ProleanHubinabaklami nonjiniyela abasebenza ngokukhethekile ekulawuleni inqubo nokuqedwa kwendawo.Zizwe ukhululekile ukuXhumana nathiuma udinga noma iyiphi iphrojekthi ewela ngaphakathi komkhawulo wobunzima obufunekayo.

Imibuzo Evame Ukubuzwa

Buyini ubulukhuni obungaphezulu?

Ubulukhuni bobuso ipharamitha enikeza umbono wokuqedwa kwendawo ezingxenyeni ezikhiqiziwe nezimpahla.Itshela okungahambi kahle kwendawo futhi kufanele ibe ngaphakathi komkhawulo ofunekayo.

Ingabe indawo emangelengele inomthelela kwikhwalithi yomkhiqizo?

Yebo, izindawo ezimaholoholo zinamandla amakhulu okugqwala nokuqhekeka.Futhi, kuthinta ukugcotshwa kwezingxenye.

Ingabe i-roughness inakho ukusebenza okuhle?

Yebo, ubulukhuni obungaphezulu bungaba usizo lapho umdwebo udinga ukufakwa ngoba kwandisa ukunamathela.Futhi, izingxenye ezizohlanganiswa azikhathazi nge-Roughness.

Yini eshiwo ngo-Ra?

U-Ra waziwa njengobuqhwaga bomhlaba obumaphakathi, indlela ye-arithmetic yazo zonke izindawo eziphakeme zeziqongo ukusuka kumugqa wereferensi.

Yiziphi izindlela ezijwayelekile zokukala ubulukhuni bendawo?

Ukuqhathaniswa neshadi elivamile lokumahhadla, Ukukala ngophenyo, kanye ne-Optical profilometry izindlela ezintathu ezijwayelekile zokulinganisa ubulukhuni bendawo.

Isikhathi sokuthumela: Jul-05-2022