Kuvuta Kwambiri Pakupanga: Kuyeza, Zomwe Zimakhudza & Kuchepetsa

Kusintha komaliza: 09/01, nthawi yowerenga: 5 min

Kumaliza kwa Pamwamba Pamwamba

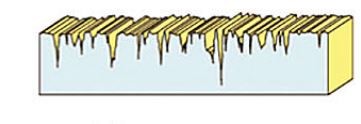

Tiyeni timvetsetse kukhwima kwapamwamba ndi mawu omaliza.Njira yosalala pamwamba pazigawo zopangidwa ndi zinthu zimadziwika kuti kumaliza, komwe kumawunikidwa pogwiritsa ntchito roughness pamwamba.Gawo lodziwika bwino la masamu a Roughness ndi Ra.Imawonetsa kutembenuka kwa masamu pamtunda.Kagulu kakang'ono ka Rakutanthauza kusalala bwino.

Kuuma kwapamtunda ndiko kusakhazikika kwa kapangidwe kake komwe kamapangidwa ndi mitundu ingapo ya ma crest ndi mbiya.Ma crests ndi mbiyawa amatha kukhala ang'onoang'ono komanso owoneka, kutengera kuchuluka kwake.Mawonekedwe a pamwamba a zopangira kapena zomalizidwa ndizofunikira kwambiri pamakampani opanga.Sizokhudza kukongola kokha koma zimakhudzanso magwiridwe antchito ndi mawonekedwe ake onse.

Muyeso wa Kukalipa Pamwamba

Mbiri yoyipa pamwamba

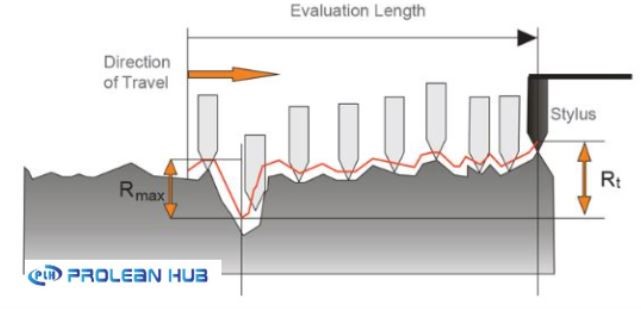

Kuuma kwapamwamba kumatanthauzidwa ndi"Ra,“ndipo gawo lake ndi ma microns (µ).Ra amapereka kusiyana kwapakati pakati pa crest (kutalika) ndi mbiya (kuya) pamwamba pa kutalika kwake.

Kuyeza kwapamtunda ndikofunikira popanga magawo odalirika komanso osasinthika komanso zinthu zomwe zimapangidwa popanga molondola.Choncho, magawo a pamwamba ayenera kuyesedwa ndikuyang'aniridwa ndi zofunikira.Mwachitsanzo, kuyeza kukhwinyata kwapamtunda ndiko njira yopezera kumalizidwa kofunikira.

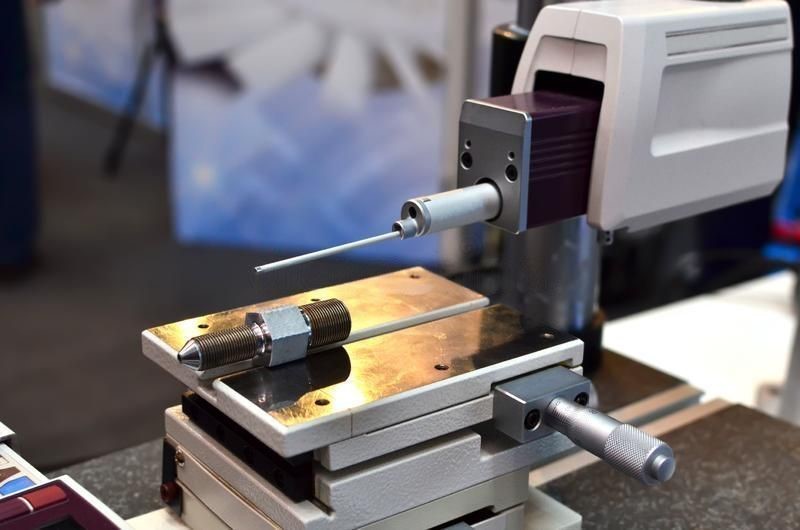

1. Kuyeza ndi kafukufuku.

Iyi ndi njira yolumikizirana yoyezera roughness.Kuti mutenge Muyeso, probe kapena cholembera chiyenera kukhudza pamwamba.

Kuyeza kwa Ukali ndi kafukufuku

The skid imasuntha kaye kuti ikhazikitse kalozera, ndipo kafukufukuyo amatsatira kumbuyo kuti asunthe pamwamba pa ma crests ndi ma troughs pomwe amatumiza ma sign amagetsi kuti apange mawonekedwe apamwamba.Pambuyo pake, roughness ya pamwamba imatha kupezeka kuchokera ku mbiri yopangidwa.

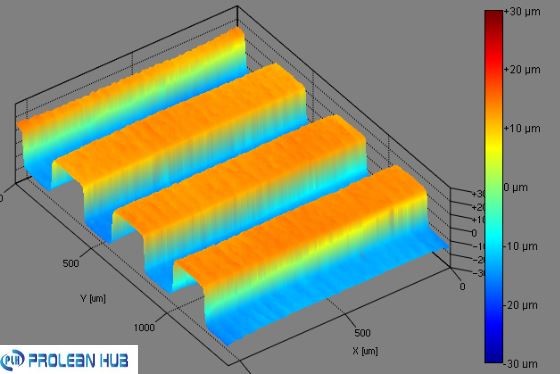

2. Optical profilometry

Njira iyi uses mafunde opepuka kapena mafunde amawu.Chipangizocho chimatumiza mafunde akupanga kumtunda ndikulandila zowunikira.Malo omwe amawonekera amagwiritsidwa ntchito popanga mawonekedwe a 3D ndikuwerengera Kuvuta.

Mbiri ya Roughness 3D kuchokera ku optical profilometry

3. Kuyerekezera

Mwa njira iyi, wopangakuyerekeza pamwamba pa chinthucho ndi zinthu zomwe zidayesedwa kalendikusankha yapafupi kwambiri pogwiritsa ntchito mphamvu zawo.Ngakhale kuti si njira yolondola kwambiri, ikhoza kugwiritsidwa ntchito pamene kulondola kwapamwamba sikufunika, ndipo kujambula kwina kudzagwiritsidwa ntchito pamwamba.

Zovuta Vs.Kupanga

Chimodzi mwazizindikiro zazikulu za magwiridwe antchito opangidwa ndi Roughness.Kuchuluka kwa makulidwe a pamwamba kumapangitsa ming'alu pamene ikugwiritsidwa ntchito ndikupangitsa kuti pakhale dzimbiri lambiri likakhala ndi chilengedwe.Kuphatikiza apo, Kukula kumatha kuchepetsa magwiridwe antchito ndipo pamapeto pake kuvulaza makina amakina pomwe kukangana kochepa kumafunikira chifukwa malo osakhazikika amawonjezera kukangana pakati pazigawozo.

Kutengera kugwiritsa ntchito, gawo lililonse lamakina limakhala ndi malire apamwamba pazovuta zapamtunda.Mwachitsanzo, zinthu zomwe kukangana kumakhala kodetsa nkhawa zimalekerera Zovuta chifukwa maopareshoni amakhala ovuta, ndipo chigawocho chimang'ambika ngati Kukali kwakwera kwambiri.

Ulusi ndi malo okwerera amatha kukhala ndi Vuto lokwanira chifukwa izi sizisokoneza kukweretsa ndipo zimathandizira kukwanirana koyenera pakati pa zigawozo.Komanso, pamwamba pomwe kujambula kuli kofunikira kumaganizira za Ukali wina, womwe umapanga zomatira ndikupangitsa kuti ntchitoyi ikhale yosavuta.

Kuwonongeka kwapang'onopang'ono m'ntchito zina zodziwika zopanga

| Ntchito | Ra(Zambiri) | Ra(zochepera) |

| Kudula Moto | 25 | 12.5 |

| Kugaya | 6.3 | 0.8 |

| Broaching | 3.2 | 0.8 |

| Kupanga, Kupanga | 12.5 | 1.6 |

| Kubowola | 6.3 | 1.6 |

| Chemical Milling | 6.3 | 1.6 |

| Sankhani.Discharge Machining | 4.75 | 1.6 |

| Investment Casting | 3.2 | 1.6 |

| Kuponya Mchenga | 25 | 12.5 |

| Kupera | 1.6 | 0.1 |

| Honing | 0.8 | 0.1 |

| Electro-Polish | 0.8 | 0.1 |

| Kupukutira | 0.4 | 0.1 |

| Laser | 6.3 | 0.8 |

| Wotopetsa, Kutembenuka | 6.3 | 0.4 |

Makhalidwe akukhadzula pamachitidwe osiyanasiyana

Zizindikiro za Kukalipa Pamwamba

Tiyeni tikambirane kaye mawu achidule omwe amagwiritsidwa ntchito mu zizindikiro tisanapite ku zizindikiro zomwezo.Ngati muyang'ana pamwamba pomaliza zizindikiro pa zojambula zopanga, mudzawona zidule zosiyanasiyana.

|

| Tanthauzo |

| Ra | Avereji yazovuta zapamtunda, masamu amatanthauza utali wonse wa nsonga kuchokera pamzere wolozera.

|

| Rmax | Mtunda wokwera kwambiri pakati pa mbiya ndi mbiya |

| Rz | Kutalika kwapakati pa 5 crests apamwamba kwambiri, |

| · Rt | Kutalika konse kwa mbiri yakukhara |

Mndandanda wa Mafupikitsidwe

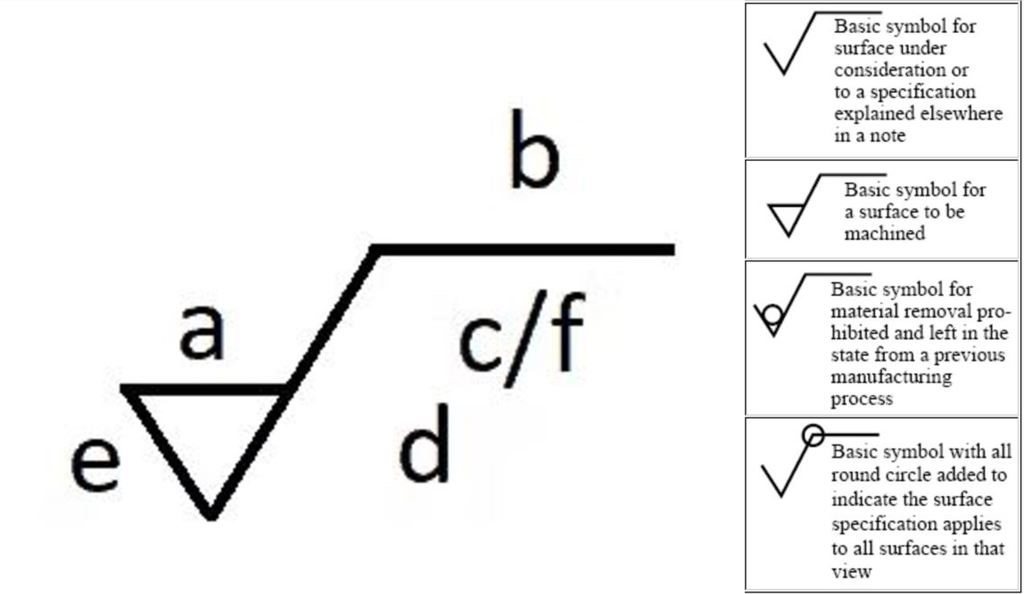

Zizindikiro zakuthwa pamwamba

| a | Mtengo wovuta mu micrometer ( µm) |

| b | Njira yopangira |

| c | Kutalika kwa zitsanzo za Kukakala (mm kapena inchi) |

| d | mayendedwe a pamwamba anagona |

| e | Zofunikira zochepa zochotsa (mm) |

| f | kutalika kwapakati pa nsonga |

Tanthauzo la zosinthika zomwe zimagwiritsidwa ntchito muzizindikiro

Posanthula zizindikiro za kukala kwa pamwamba pa chojambula chopanga, opanga ndi ogwiritsira ntchito amatha kufotokozera momwe kumalizidwira pamwamba kumapangidwira pagawo lililonse lopangidwa ndi makina.

Mwachitsanzo, wogwiritsa ntchito CNC amatha kudziwa kuchokera pazojambula za opanga zinthu zomwe ziyenera kuchotsedwa pamwamba pomaliza.

Ndi zinthu ziti zomwe zimakhudza kuchuluka kwa makulidwe a pamwamba?

Zinthu zitatu zotsatirazi zimakhudza roughness pamwamba;Kudula ntchito, Kupera, ndi kuwongolera magawo (Kudula liwiro & kuchuluka kwa chakudya).

1. Kudula Ntchito

Pambuyo kudula ntchito anamaliza ndi CNC makina, chida chodulira chimasiya zotsalira pamalo odulira chifukwa cha kupanikizika panthawi yomwe chidacho chimatulutsidwa kuchokera ku workpiece.

Chotsalira ichi (chotchedwa burr) chimakhudzanso kukhazikika kofunikira kwa zigawozo.Zotsatirazi zidzatsimikizira kukula ndi kuchuluka kwa zotsalira pamtunda wotsalira ndi chida chodulira.

- Kupatuka kwa ngodya yodula

- Kupatuka kwa radius ya Tooltip

- Kudyetsa mlingo

- deformation pamene kudula

2. Kupera

Njira yogaya popanga imagwiritsa ntchito makina olimba, opukutira, ndipo kutentha kumatha kufika 1500 ° C panthawiyi.Mphepete mwa tinthu ta abrasive timatulutsa kutentha kwa pulasitiki chifukwa cha kutentha kwakukulu kwa ntchito, ndikusiya roughness pang'ono pamwamba.

3. Kudula Kuthamanga & Mtengo Wodyetsa

Kuthamanga kwakukulu kumawonjezera mapangidwe a tchipisi, ndipo kukula kwa tchipisi nakonso kudzakhala kokulirapo.Chifukwa chake chidacho chidzasiya ma burrs ambiri pamtunda chifukwa kuthamanga kwachangu kumawonjezera kukangana pakati pa chida ndi malo odulira, ndikuwonjezera mtengo wa Ra.Komanso, kuchuluka kwa chakudya kumawonjezera kutalika kwa zotsalira pamtunda.

Kodi ndingachepetse bwanji kuuma kwapamtunda?

· Khazikitsani mlingo woyenera wa chakudya chifukwa kuchuluka kwa chakudya kumapangitsa kuti zotsalira zambiri zipangike pamalo odulidwa.Kuti muchepetse Kuyipa, gwiritsani ntchito madzi odulira bwino komanso zida zodulira bwino.

· Ma angles opotoka kwambiri amatulutsa ma machining burrs ndi zizindikiro pamwamba, choncho achepetseni.

· Chifukwa kuvala kwa zida kumawonjezera kukhwimitsa pamwamba, pukutani pogaya musanagaye.

· Kukangana kumawonjezeka ndi kugwedezeka kwa zida zopangira makina, zomwe zimapangitsa kuti pamwamba pakhale khwimbi.Choncho, musanayambe ntchito Machining, kuchepetsa kugwedera ndi kuwonjezera kudula madzimadzi.

· Sankhani chida Machining zinthu zochokera makhalidwe a zopangira.Mwachitsanzo, ngati mukupanga zida zolimba, gwiritsani ntchito zida za carbide zomwe zili ndi ma lead.Chidacho chiyeneranso kukhala chofanana bwino.

Mapeto

Pamwamba nthawi zonse kuyenera kugwera mkati mwa malire azovuta panthawi yopanga molingana ndi momwe makina amagwirira ntchito.Ra zikusonyeza kuti tiyenera kuvomereza kapena kukana polojekiti yokhudzana ndi kutsirizitsa pamwamba.Profilometer imawerengera kuchuluka kwa masamu pozindikira kutalika kwa zolakwika zomwe zimapanga gawo la roughness kuchokera pamzere wolozera.

Kuchiza pamwamba pa roughness, kukonzanso kwina kumafunika, monga kuchotsa, kugaya, ndi kupukuta.Njirazi zimathandizira kuti mtengowo ukhale wovuta mkati mwa malire ofunikira.Komabe, kukonzanso kumeneku kumawonjezera mtengo wopangira, choncho ndi bwino kuganizira za roughness pakupanga ndi kupanga zinthu.Pulogalamu ya ProleanHubali ndi opanga ndi mainjiniya omwe amakhazikika pakuwongolera njira ndikumaliza pamwamba.Khalani omasukaLumikizanani nafengati mukufuna polojekiti iliyonse yomwe ili mkati mwa malire omwe mukufuna.

FAQs

Kodi roughness pamwamba ndi chiyani?

Kuuma kwapamwamba ndi chizindikiro chomwe chimapereka lingaliro la kumaliza pamwamba pazigawo zopangidwa ndi katundu.Imanena zolakwika zapamtunda ndipo iyenera kukhala mkati mwa malire omwe mukufuna.

Kodi pamwamba pake pamakhala zovuta kuti chinthucho chikhale chabwino?

Inde, malo okhwima amakhala ndi kuthekera kwakukulu kochita dzimbiri ndi ming'alu.Komanso, zimakhudza mafuta a ziwalozo.

Kodi Roughness ili ndi ntchito iliyonse yabwino?

Inde, kukhwinyata pamwamba kungakhale kothandiza pamene penti iyenera kuikidwa chifukwa imawonjezera kumamatira.Komanso, ziwalo zomangika sizikukhudzana ndi Kuvuta.

Kodi Ra?

Ra amadziwika kuti pafupifupi roughness pamwamba, njira masamu a nsonga zonse za nsonga kuchokera pa zolozera.

Kodi njira zoyezera kukalipa kwapamwamba ndi ziti?

Poyerekeza ndi tchati chaukali, Kuyeza ndi probe, ndi Optical profilometry ndi njira zitatu zoyezera kuuma kwa pamwamba.

Nthawi yotumiza: Jul-05-2022