Nto Roughness nyob rau hauv Manufacturing: Ntsuas, cuam tshuam yam & Tsawg

Hloov tshiab kawg: 09/01, lub sij hawm nyeem: 5 mins

Kev ua tiav ntawm qhov ntxhib nto

Cia peb nkag siab qhov roughness ntawm qhov chaw nrog lub sijhawm ua tiav.Cov txheej txheem ntawm smoothening nto ntawm cov khoom tsim thiab cov khoom yog lub npe hu ua nto finishing, uas yog tshuaj xyuas siv deg roughness.Qhov nrov tshaj plaws parameter rau kev ua lej ntawm Roughness yog Ra.Nws qhia tus lej lej txhais tau tias sib txawv ntawm qhov chaw.Ib tug me me Raimplies ib tug smoother kev ntxhib los mos.

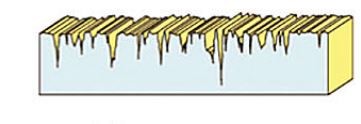

Deg roughness yog irregularity nyob rau hauv qhov kev ntxhib los mos nto tsim los ntawm series ntawm crest thiab trough lug.Cov crests thiab troughs no tuaj yeem ua qhov microscopic thiab pom, nyob ntawm qhov roughness theem.Qhov saum npoo zoo ntawm cov khoom siv raw lossis cov khoom tiav yog qhov tseem ceeb hauv kev tsim khoom.Nws tsis yog tsuas yog hais txog kev zoo nkauj tab sis kuj cuam tshuam rau qhov chaw 'kev ua haujlwm thiab tag nrho qhov zoo.

Kev ntsuas ntawm Nto Roughness

Rough nto profile

Qhov saum npoo roughness yog denoted los ntawm"Ra,“thiab nws chav tsev yog microns (µ).Ra muab qhov nruab nrab qhov sib txawv ntawm crest (qhov siab) thiab trough (qhov tob) ntawm qhov chaw tshaj qhov ntsuas qhov ntev.

Kev ntsuas qhov saum npoo yog qhov tseem ceeb rau kev tsim cov khoom txhim khu kev qha thiab zoo ib yam thiab cov khoom hauv precision manufacturing.Yog li ntawd, qhov ntsuas qhov chaw yuav tsum tau ntsuas thiab saib xyuas raws li qhov yuav tsum tau ua.Piv txwv li, ntsuas qhov roughness ntawm qhov chaw yog lub rooj vag kom ua tiav qhov yuav tsum tau ua tiav.

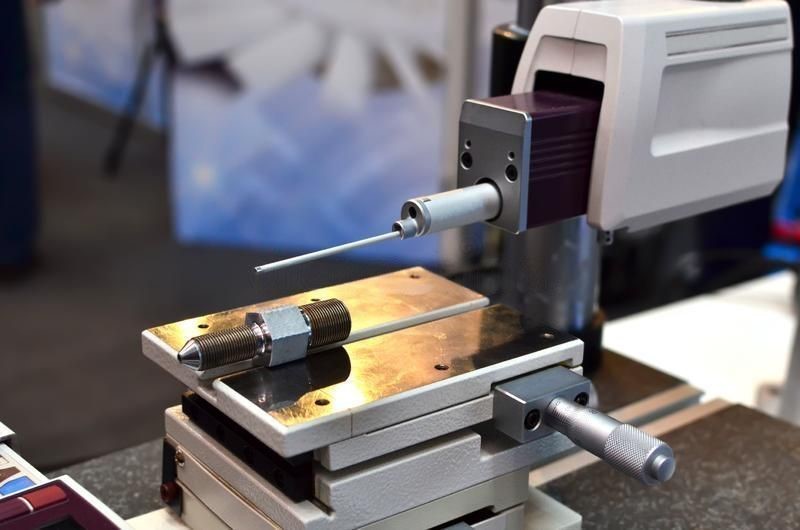

1. Kev ntsuas nrog kev sojntsuam.

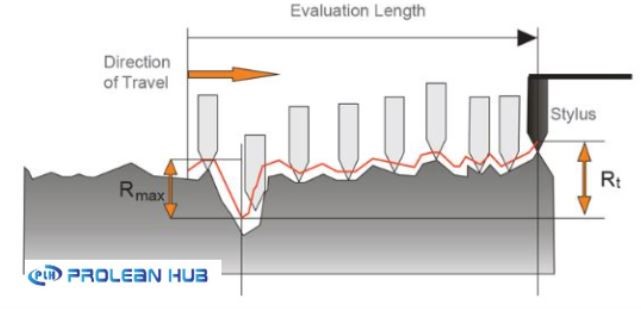

Qhov no yog txoj kev sib cuag ntawm kev ntsuas qhov roughness.Txhawm rau ntsuas qhov ntsuas, ib qho kev sojntsuam lossis lub stylus yuav tsum kov qhov chaw.

Kev ntsuas Roughness nrog kev sojntsuam

Lub skid txav ua ntej los tsim cov kev siv, thiab qhov kev sojntsuam tom qab txav mus rau saum npoo los ntawm crests thiab troughs thaum xa hluav taws xob teeb liab los tsim qhov profile nto.Tom qab ntawd, qhov roughness ntawm qhov chaw tuaj yeem tau txais los ntawm qhov tsim profile.

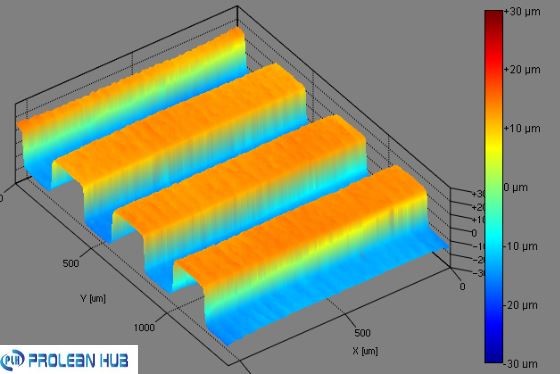

2. Optical profiles

Txoj kev no uses lub teeb nthwv dej los yog suab nthwv dej.Cov cuab yeej xa ultrasonic nthwv dej rau saum npoo thiab tau txais kev xav.Txoj hauj lwm ntawm qhov cuam tshuam yoj yog siv los tsim 3D nto profile thiab xam qhov Roughness.

Roughness 3D profile los ntawm optical profileometry

3. Kev sib piv

Nyob rau hauv txoj kev no, cov chaw tsim khoompiv cov khoom nto nrog cov khoom nrog cov qauv ntsuas yav dhau losthiab xaiv qhov ze tshaj plaws siv lawv qhov kev nkag siab.Txawm hais tias nws tsis yog ib txoj hauv kev meej heev, nws tuaj yeem siv qhov twg tsis xav tau qhov tseeb dua, thiab ntxiv cov duab kos yuav raug siv rau ntawm qhov chaw.

Roughness Vs.Kev tsim khoom

Ib qho ntawm cov kev ntsuas tseem ceeb rau kev tsim khoom yog Roughness.Cov theem tseem ceeb ntawm qhov chaw roughness ua rau tawg thaum siv thiab txhim kho qhov muaj peev xwm ntawm corrosion huab cua thaum raug rau ib puag ncig.Tsis tas li ntawd, Roughness tuaj yeem txo qhov ua tau zoo thiab qhov kawg ua rau lub tshuab ua haujlwm tsis muaj kev sib txhuam vim tias qhov tsis sib xws ua rau muaj kev sib txhuam ntawm cov khoom.

Nyob ntawm daim ntawv thov, txhua yam khoom siv tshuab muaj qhov sib txawv sab sauv rau qhov roughness ntawm qhov chaw.Piv txwv li, cov ntsiab lus uas kev sib txhuam yog qhov kev txhawj xeeb muaj qhov ua siab ntev rau Roughness vim tias kev ua haujlwm nyuaj, thiab cov khoom tawg thaum lub Roughness siab dhau.

Cov xov thiab mating nto tuaj yeem muaj qhov ncaj ncees ntawm Roughness vim tias qhov no tsis cuam tshuam nrog kev sib tw thiab pab kom haum haum ntawm cov khoom.Tsis tas li ntawd, qhov chaw uas cov tha xim yog tsim nyog txiav txim siab txog qee qib ntawm Roughness, uas txhim kho cov nplaum thiab ua rau cov txheej txheem yooj yim.

Nto roughness nyob rau hauv qee yam kev tsim khoom lag luam

| Kev ua haujlwm | Ra(Qhov siab tshaj) | Ra(yam tsawg kawg) |

| Nplaim Txiav | 25 | 12.5 ib |

| Milling | 6.3 | 0.8 ua |

| Broaching | 3.2 | 0.8 ua |

| Planning, Shaping | 12.5 ib | 1.6 |

| Drilling | 6.3 | 1.6 |

| Tshuaj Milling | 6.3 | 1.6 |

| Xaiv.Tshem tawm Machining | 4.75 ib | 1.6 |

| Kev nqis peev Casting | 3.2 | 1.6 |

| Xuab zeb Casting | 25 | 12.5 ib |

| Sib tsoo | 1.6 | 0.1 |

| Honing | 0.8 ua | 0.1 |

| Electro-Polish | 0.8 ua | 0.1 |

| Polishing | 0.4 | 0.1 |

| Laser | 6.3 | 0.8 ua |

| Ntshai, Tig | 6.3 | 0.4 |

Nto roughness qhov tseem ceeb hauv ntau yam haujlwm

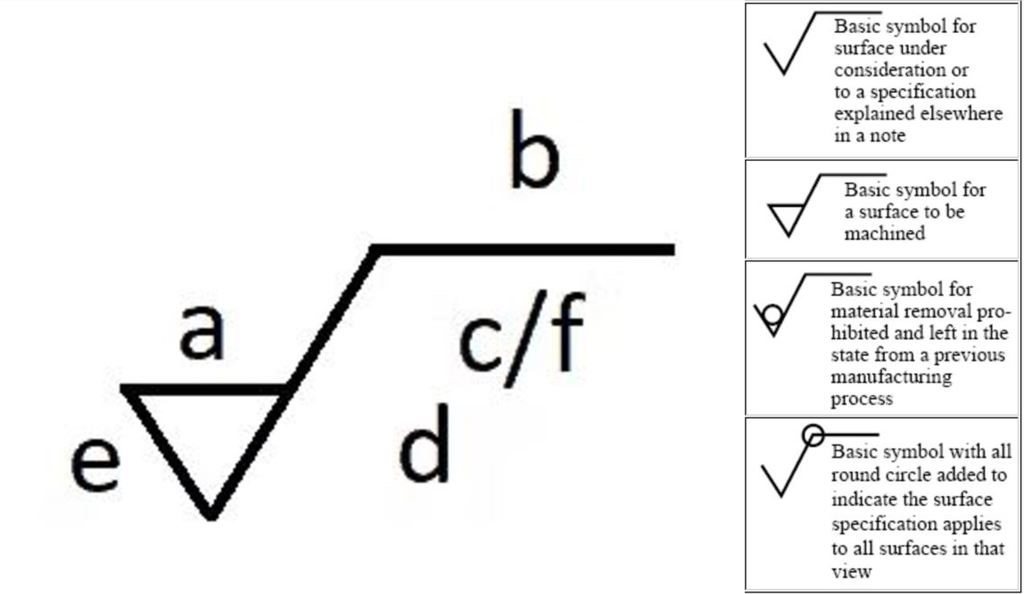

Cov cim rau Nto Roughness

Cia peb xub tham txog cov ntawv luv uas siv hauv cov cim ua ntej mus rau cov cim lawv tus kheej.Yog tias koj saib cov cim nto moo ntawm kev tsim cov duab kos, koj yuav pom ntau cov ntawv luv.

|

| Lub ntsiab lus |

| Ra | Qhov nruab nrab ntawm qhov roughness, tus lej lej ntawm txhua qhov siab ntawm cov peaks los ntawm kab siv.

|

| Rmax | Maximum Vertical nrug ntawm crest thiab trough |

| Rz | Qhov nruab nrab qhov siab tshaj plaws ntawm 5 qhov siab tshaj plaws crests, |

| · Rt | Tag nrho qhov siab ntawm qhov roughness profile |

Daim ntawv teev npe Abbreviations

Nto roughness cim

| a | Roughness tus nqi hauv micrometer (µm) |

| b | Txoj kev tsim khoom |

| c | Qhov ntev ntawm Roughness (mm los yog nti) |

| d | kev taw qhia ntawm qhov chaw nteg |

| e | Yam tsawg kawg nkaus yuav tsum tau tshem tawm cov khoom (mm) |

| f | nruab nrab qhov siab tshaj plaws ntawm peaks |

Lub ntsiab lus ntawm kev hloov pauv siv hauv cov cim

Los ntawm kev txheeb xyuas cov cim roughness ntawm qhov chaw hauv kev tsim cov duab kos, cov neeg tsim qauv thiab cov neeg ua haujlwm tuaj yeem sib txuas lus lub xeev ntawm qhov chaw tiav hauv txhua qhov kev sib xyaw ua ke.

Piv txwv li, tus neeg teb xov tooj CNC tuaj yeem txiav txim siab los ntawm cov neeg tsim qauv kos duab ntau npaum li cas cov khoom yuav tsum tau muab tshem tawm ntawm qhov chaw thaum ua tiav.

Yam dab tsi cuam tshuam qhov degree ntawm qhov roughness?

Cov nram qab no peb yam cuam tshuam rau saum npoo roughness;Txiav kev ua haujlwm, sib tsoo, thiab tswj tsis tau (Txiav ceev & pub tus nqi).

1. Txiav kev ua haujlwm

Tom qab txiav kev ua haujlwm tiav nrog CNC machining, cov cuab yeej txiav tawm cov seem seem ntawm qhov chaw txiav vim yog lub siab thaum lub cuab yeej tso tawm ntawm lub workpiece.

Qhov seem no (hu ua burr) kuj cuam tshuam rau cov khoom tsim nyog qhov kev ruaj ntseg.Cov hauv qab no yuav txiav txim siab qhov loj thiab ntau npaum li cas ntawm qhov seem ntawm qhov chaw sab laug los ntawm cov cuab yeej txiav.

- Qhov sib txawv ntawm lub kaum sab xis txiav

- Tooltip radius deflection

- Pub tus nqi

- deformation thaum txiav

2. Sib tsoo

Cov txheej txheem sib tsoo hauv kev tsim khoom siv nruj, abrasive sib tsoo xov xwm, thiab qhov kub tuaj yeem ncav cuag li 1500 ° C thaum lub sijhawm ua haujlwm.Lub ntug ntawm cov khoom abrasive yuav tsim cov yas thaum tshav kub kub ua haujlwm vim qhov kub ua haujlwm siab, tawm hauv me ntsis roughness ntawm qhov chaw.

3. Txiav ceev & pub tus nqi

Kev txiav nrawm dua yuav ua rau cov chips tsim, thiab qhov loj ntawm cov chips kuj yuav ntau dua.Li no lub cuab yeej yuav tawm ntau burrs rau ntawm qhov chaw vim hais tias lub siab txiav ceev yuav ua rau kom muaj kev sib txhuam ntawm lub cuab tam thiab txiav nto, ua rau tus nqi Ra.Tsis tas li ntawd, tus nqi pub ntau dua yuav ua rau qhov siab ntawm qhov seem ntawm qhov chaw.

Kuv tuaj yeem txo qhov roughness ntawm qhov chaw?

· Teem tus nqi noj kom zoo vim tias tus nqi pub ntau ua rau ntau qhov seem rau ntawm qhov txiav.Txhawm rau txo qhov Roughness, siv cov kua txiav zoo thiab cov cuab yeej txiav.

· High deflection angles tsim machining burrs thiab cov cim ntawm qhov chaw, yog li txo lawv.

· Vim tias cov cuab yeej hnav ua rau qhov chaw roughness, Polish lub grind ua ntej sib tsoo.

· Kev sib txhuam yog nce los ntawm kev vibration hauv cov cuab yeej machining, uas ua rau lub ntsej muag rougher.Yog li ntawd, ua ntej pib nrog kev ua haujlwm machining, txo qis kev vibration thiab ntxiv cov kua txiav.

· Xaiv cov cuab yeej machining cov khoom raws li cov yam ntxwv ntawm cov khoom siv raw.Piv txwv li, yog tias koj machining cov ntaub ntawv nyuaj, siv cov cuab yeej carbide uas muaj cov hlau lead.Cov cuab yeej kuj yuav tsum yog uniformly zoo.

Xaus

Qhov saum npoo yuav tsum ib txwm poob rau hauv qee qhov kev txwv roughness thaum lub sijhawm tsim khoom raws li qhov tshwj xeeb ntawm cov khoom siv kho tshuab.Ra qhia tias peb yuav tsum lees txais lossis tsis lees txais qhov project hais txog qhov chaw tiav.Lub profileometer suav cov lej lej ntawm qhov roughness los ntawm kev txiav txim siab qhov nruab nrab qhov siab ntawm qhov tsis sib xws uas ua rau cov roughness tivthaiv los ntawm kab siv.

Rau kev kho deg roughness, yuav tsum tau ua ntxiv, xws li deburring, sib tsoo, thiab polishing.Cov txheej txheem no pab kom tau txais tus nqi roughness nyob rau hauv qhov xav tau txwv.Txawm li cas los xij, qhov kev ua tiav tom qab no ntxiv rau cov nqi tsim khoom, yog li nws yog qhov zoo dua los xav txog qhov tsis zoo ntawm cov khoom tsim thiab kev tsim khoom.ProleanHubmuaj cov kws tsim qauv thiab engineers uas tshwj xeeb hauv kev tswj cov txheej txheem thiab nto tiav.Xav tias dawb rautiv tauj pebyog tias koj xav tau ib qhov project uas poob hauv qhov xav tau roughness txwv.

FAQ's

Qhov roughness yog dab tsi?

Nto roughness yog qhov parameter uas muab lub tswv yim ntawm kev ua tiav ntawm qhov chaw tsim khoom thiab cov khoom.Nws qhia qhov tsis sib xws ntawm qhov chaw thiab yuav tsum nyob rau hauv qhov xav tau txwv.

Puas yog qhov chaw ntxhib cuam tshuam rau qhov zoo ntawm cov khoom?

Yog, Rough nto muaj peev xwm ua rau corrosion thiab tawg.Tsis tas li ntawd, nws cuam tshuam rau lubrication ntawm qhov chaw.

Puas yog Roughness muaj daim ntawv thov zoo?

Yog, deg roughness yuav pab tau thaum lub painting yuav tsum tau siv vim nws ua rau kom cov adhesiveness.Tsis tas li ntawd, qhov yuav tsum tau sib tov tsis cuam tshuam nrog Roughness.

Dab tsi yog txhais los ntawm Ra?

Ra yog lub npe hu ua qhov nruab nrab ntawm qhov roughness, tus lej lej ntawm txhua qhov siab ntawm lub ncov los ntawm kab siv.

Dab tsi yog cov txheej txheem rau kev ntsuas qhov roughness?

Kev sib piv nrog tus qauv roughness daim duab, Kev ntsuas nrog qhov kev sojntsuam, thiab Optical profilometry yog peb txoj hauv kev los ntsuas qhov roughness.

Lub sij hawm xa tuaj: Plaub Hlis-05-2022