Ƙunƙarar Sama a Ƙirƙira: Aunawa, Abubuwan Tasiri & Ragewa

Sabuntawa ta ƙarshe:09/01, lokacin karantawa: 5 mins

Ƙarshen Ƙaƙƙarfan Sama

Bari mu fahimci rashin ƙarfi na saman tare da lokacin ƙarewar saman.Tsarin sassauƙa na sassan da aka ƙera da samfuran da aka sani da ƙarewar ƙasa, wanda aka yi la'akari da shi ta amfani da ƙarancin ƙasa.Mafi shaharar siga don ƙididdige lissafin lissafi na Roughness shine Ra.Yana nuna ma'anar lissafin lissafi a saman.Karamin Rayana nuna laushi mai laushi.

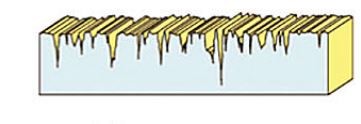

Ƙunƙarar saman ita ce rashin daidaituwa a cikin rubutun saman da aka kafa ta jerin gwano da sifofi.Waɗannan ƙwanƙwasa da tarkace na iya zama ƙwanƙwasa da bayyane, ya danganta da matakin rashin ƙarfi.Ingantattun kayan da aka gama ko samfuran da aka gama suna da mahimmanci a cikin masana'antar masana'anta.Ba wai kawai game da jan hankali ba ne amma kuma yana shafar aikin sassan da ingancin gabaɗaya.

Ma'auni na Roughness Surface

M surface profile

Ana nuna rashin ƙarfi ta ƙasa"Ra,"kuma naúrar sa microns ne (µ).Ra yana ba da matsakaicin bambance-bambance tsakanin ƙwanƙwasa (tsawo) da tudun ruwa (zurfin) akan saman tsayin ma'auni.

Ma'aunin saman yana da mahimmanci don samar da abin dogaro da daidaiton sassa da samfura cikin ƙira.Sabili da haka, ya kamata a auna ma'auni kuma a kula da shi zuwa ƙayyadaddun da ake bukata.Misali, auna tarkacen saman shine ƙofa don cimma kammalawar da ake buƙata.

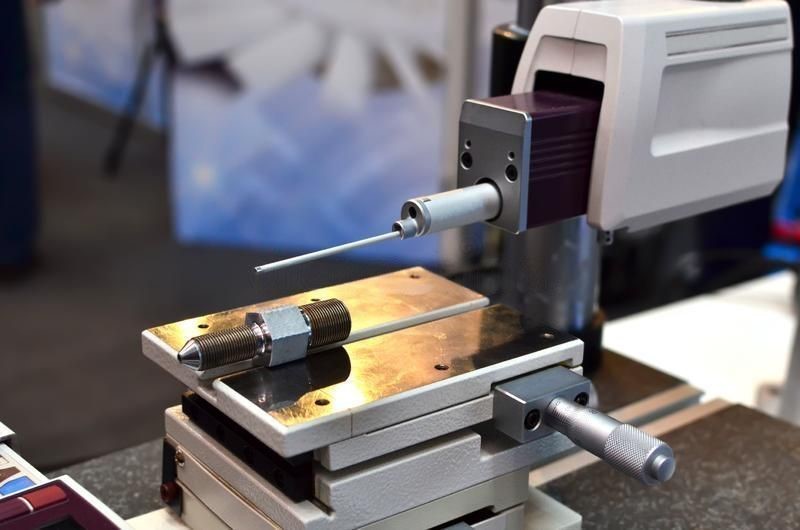

1. Aunawa tare da bincike.

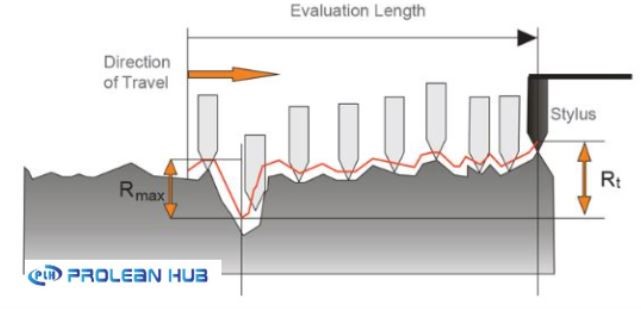

Wannan ita ce hanyar tuntuɓar ma'aunin ma'aunin ƙasa.Don ɗaukar Ma'auni, bincike ko stylus dole ne ya taɓa saman.

Ma'auni na Roughness tare da bincike

Skid yana motsawa da farko don tabbatar da bayanin, kuma binciken yana biye a baya don matsawa saman saman ta cikin ƙugiya da tarkace yayin aika siginar lantarki don haɓaka bayanin martaba.Bayan haka, ana iya samun ɓacin rai daga bayanan da aka ƙirƙira.

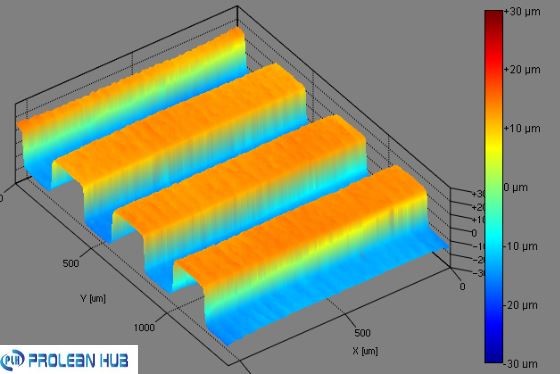

2. Bayanan gani na gani

Wannan hanya usraƙuman haske ko raƙuman sauti.Na'urar tana aika raƙuman ruwa na ultrasonic zuwa saman kuma suna karɓar tunani.Ana amfani da matsayi na kalaman da aka nuna don ƙirƙirar bayanin martaba na 3D da lissafin Roughness.

Bayanan martaba na 3D mai kaushi daga bayanan gani

3. Kwatanta

A wannan hanya, da manufactureryana kwatanta saman samfurin da samfurin tare da daidaitattun sassa da aka auna a bayakuma suna zabar na kusa ta hanyar amfani da hankalinsu.Ko da yake Ba daidai ba hanya ce, ana iya amfani da ita inda ba a buƙatar daidaito mafi girma, kuma za a yi amfani da ƙarin zane a saman.

Roughness Vs.Manufacturing

Ɗayan maɓalli na mahimmin aiki don sassa da aka kera shine Roughness.Mahimman matakan da ke haifar da tsagewa yayin da ake amfani da su kuma suna haɓaka yiwuwar mummunan lalata lokacin da aka fallasa su zuwa yanayin.Bugu da kari, Roughness na iya rage inganci kuma a ƙarshe yana cutar da tsarin injina inda ake buƙatar ƙaramin juzu'i saboda yanayin da bai dace ba yana ƙaruwa tsakanin sassan.

Dangane da aikace-aikacen, kowane nau'in injin yana da iyaka na sama daban-daban don ƙarancin ƙasa.Misali, abubuwan da ke da damuwa suna da ƙarancin juriya ga Roughness saboda ayyuka suna da wahala, kuma ɓangaren yana fashe lokacin da Roughness ya yi yawa.

Zare da mating saman na iya samun daidaitaccen adadin Roughness saboda wannan baya tsoma baki tare da mating kuma yana sauƙaƙe dacewa da dacewa tsakanin abubuwan.Har ila yau, farfajiyar inda zanen ya zama dole ya yi la'akari da wani nau'i na Roughness, wanda ke bunkasa adhesiveness kuma ya sa tsari ya zama mai sauƙi.

Ƙunƙarar ƙasa a wasu ayyukan masana'antu gama gari

| Aiki | Ra(Mafi girma) | Ra(mafi ƙarancin) |

| Yankan harshen wuta | 25 | 12.5 |

| Milling | 6.3 | 0.8 |

| Broaching | 3.2 | 0.8 |

| Tsara, Tsara | 12.5 | 1.6 |

| Yin hakowa | 6.3 | 1.6 |

| Chemical Milling | 6.3 | 1.6 |

| ZaɓeInjin cirewa | 4.75 | 1.6 |

| Zuba Jari | 3.2 | 1.6 |

| Yashi Casting | 25 | 12.5 |

| Nika | 1.6 | 0.1 |

| Girmamawa | 0.8 | 0.1 |

| Electro-Poland | 0.8 | 0.1 |

| goge baki | 0.4 | 0.1 |

| Laser | 6.3 | 0.8 |

| Mai ban gajiya, Juyawa | 6.3 | 0.4 |

Ƙimar ƙaƙƙarfan sararin sama a cikin ayyuka daban-daban

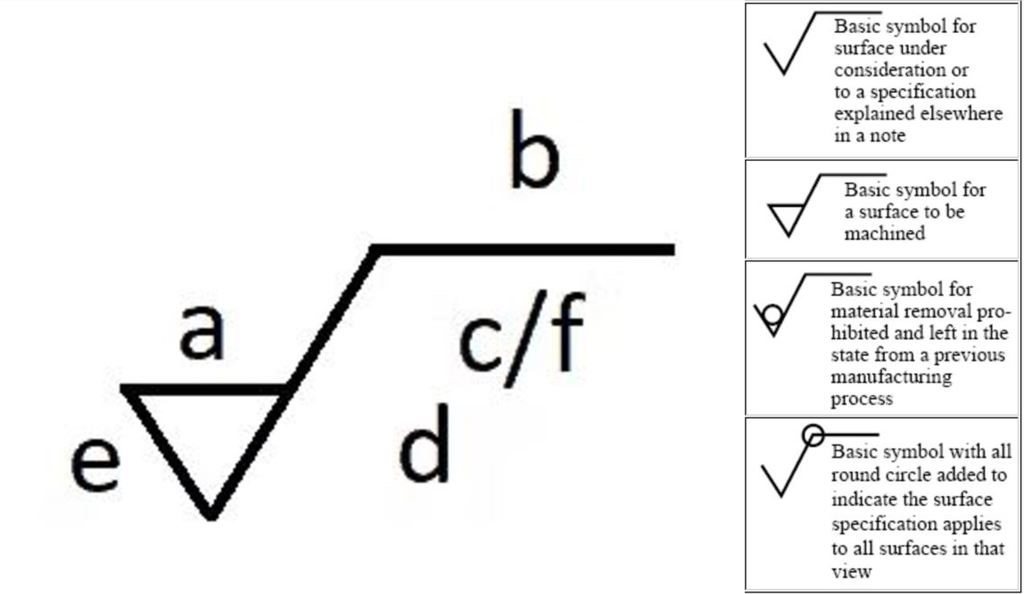

Alamomi don Tashin Sama

Bari mu fara tattauna gajerun abubuwan da aka yi amfani da su a cikin alamomi kafin mu ci gaba zuwa alamomin kansu.Idan ka kalli alamun ƙarewar saman akan zane-zanen masana'anta, zaku ga raguwa iri-iri.

|

| Ma'ana |

| Ra | Matsakaicin rashin ƙarfi na saman, ma'anar lissafi na duk tsayin kololuwa daga layin tunani.

|

| Rmax | Matsakaicin tazara a tsaye tsakanin kurji da kwandon shara |

| Rz | Matsakaicin matsakaicin tsayi na 5 mafi girma, |

| · Rt | Jimlar tsayin bayanin martaba |

Jerin Gajartawa

Alamun rashin ƙarfi na saman

| a | Ƙimar ƙima a cikin micrometer (µm) |

| b | Hanyar samarwa |

| c | Tsawon Samfuran Tsawon (mm ko inch) |

| d | Hanyar saman ta kwanta |

| e | mafi ƙarancin buƙatun cire kayan (mm) |

| f | matsakaicin matsakaicin tsayin kololuwa |

Ma'anar masu canji da aka yi amfani da su a cikin alamomi

Ta hanyar nazarin alamun rashin ƙarfi a cikin zanen masana'anta, masu ƙira da masu aiki za su iya sadar da yanayin ƙarewar saman a kowane ɓangaren injina.

Misali, ma'aikacin CNC na iya tantancewa daga zanen masu zanen kaya nawa ne za a cire daga saman yayin kammalawa.

Waɗanne abubuwa ne ke shafar matakin rashin ƙarfi?

Abubuwa guda uku masu zuwa suna shafar rashin ƙarfi na saman;Yanke aiki, Niƙa, da sigogi masu sarrafawa (Yanke saurin & ƙimar ciyarwa).

1. Aikin Yanke

Bayan an gama aikin yankan tare da Injin CNC, Kayan aikin yankan ya bar ragowar a kan yanki saboda matsa lamba yayin sakin kayan aiki daga kayan aiki.

Wannan saura (wanda ake kira burr) shima yana shafar kwanciyar hankali na abubuwan da suka dace.Abubuwan da ke biyowa za su ƙayyade girman da adadin raguwa a saman da aka bari ta hanyar yankan kayan aiki.

- Bambanci a cikin kusurwar yanke

- Juyawar radius tukwici

- Yawan ciyarwa

- nakasawa yayin yankan

2. Nika

Tsarin niƙa a cikin masana'antu yana amfani da m, abrasive nika kafofin watsa labarai, da kuma yawan zafin jiki na iya kai har zuwa 1500 ° C yayin aiwatar.Gefen ɓangarorin abrasive za su haifar da kwararar zafi na filastik saboda tsananin zafin aiki, yana barin ɗan ƙaramin ƙarfi a saman.

3. Yanke Gudun & Yawan Ciyarwa

Mafi girman saurin yankan yana ƙara haɓakar kwakwalwan kwamfuta, kuma girman kwakwalwan zai kuma fi girma.Saboda haka kayan aiki zai bar ƙarin burrs a saman saboda babban saurin yankewa zai ƙara haɓaka tsakanin kayan aiki da yanki na yanke, ƙara darajar Ra.Hakanan, ƙimar ciyarwa mafi girma zai ƙara tsayin ragowar da ke kan saman.

Ta yaya zan iya rage rashin ƙarfi?

· Saita ƙimar ciyarwar da ta dace saboda yawan ciyarwar yana haifar da ƙarin raguwa don samar da saman yankan.Don rage Roughness, yi amfani da ingantaccen ruwan yankan da ainihin kayan aikin yanke.

· Maɗaukakin kusurwoyi masu jujjuyawa suna samar da burbushin injina da alamomi akan saman, don haka rage su.

· Saboda kayan aiki da lalacewa yana ƙaruwa da rashin ƙarfi, Yaren mutanen Poland niƙa kafin niƙa.

· An ƙara juzu'i ta hanyar girgizawa a cikin kayan aikin injin, wanda ke haifar da ƙasa ya zama mai ƙarfi.Don haka, kafin a ci gaba da ayyukan injin, rage girgiza kuma ƙara yankan ruwa.

· Zabi kayan aikin mashin ɗin bisa ga halaye na albarkatun ƙasa.Misali, idan kuna sarrafa kayan aiki masu ƙarfi, yi amfani da kayan aikin carbide mai ɗauke da gubar.Hakanan dole ne kayan aikin ya kasance mai kyau iri ɗaya.

Kammalawa

Ya kamata a ko da yaushe saman ya faɗi cikin wasu ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙirar ƙira bisa ga ƙayyadaddun kayan aikin injiniya.Ra yana ba da shawarar cewa ya kamata mu karɓa ko ƙin aikin game da ƙarewar ƙasa.Mai ƙididdigewa yana ƙididdige ƙayyadaddun ƙididdiga ta fuskar ƙididdiga ta ƙayyade matsakaicin tsayi na rashin daidaituwa wanda ya ƙunshi ɓangaren rashin ƙarfi daga layin tunani.

Don maganin rashin ƙarfi na sama, ana buƙatar ƙarin aiki, kamar ɓata lokaci, niƙa, da goge goge.Waɗannan hanyoyin suna taimakawa don samun ƙimar ƙaƙƙarfan ƙayyadaddun iyaka.Koyaya, wannan aikin bayan sarrafa yana ƙara farashin masana'anta, don haka yana da kyau a yi la'akari da ƙaƙƙarfan yanayin ƙira da ƙirar samfura.ProleanHubyana da masu zane-zane da injiniyoyi waɗanda suka ƙware a cikin sarrafa tsari da ƙarewa.Jin kyauta dontuntube muidan kuna buƙatar kowane aikin da ya faɗi cikin iyakar ƙaƙƙarfan da ake so.

FAQ's

Menene rashin ƙarfi na saman?

Tashin ƙasa shine ma'aunin da ke ba da ra'ayi na gamawa a cikin sassa da kayayyaki da aka kera.Yana bayyana rashin daidaituwa na saman kuma yakamata ya kasance cikin iyakar da ake so.

Shin m saman yana tasiri ingancin samfurin?

Ee, M saman yana da babban yuwuwar lalata da fasa.Har ila yau, yana rinjayar lubrication na sassan.

Shin Roughness yana da wani ingantaccen aikace-aikace?

Haka ne, rashin ƙarfi na sama zai iya taimakawa lokacin da ake buƙatar yin amfani da zanen saboda yana ƙara mannewa.Hakanan, sassan da za a haɗa ba su damu da Roughness ba.

Me ake nufi da Ra?

An san Ra da matsakaita roughness, ma'anar lissafi na duk tsayin kololuwa daga layin tunani.

Menene daidaitattun hanyoyin auna ma'auni?

Kwatanta tare da daidaitaccen ginshiƙi mai ƙima, Auna tare da bincike, da kuma bayanan gani su ne daidaitattun hanyoyi guda uku don auna taurin saman.

Lokacin aikawa: Jul-05-2022