Isikhathi Somjikelezo Wokukhiqiza ku-CNC Machining

Isikhathi Sokufunda Esilinganisiwe: imizuzu eyi-7 nemizuzwana eyi-10.

Okuqukethwe

I Ukubala Isikhathi Somjikelezo Wokukhiqiza

II Isikhathi somjikelezo semisebenzi ehlukene (Ukugaya, ukujika, nokubhola)

III Indlela Eyengeziwe yokubala

IV Ukunciphisa Isikhathi Somjikelezo

V Isiphetho

I-VI FAQ

CNC imishini

Isikhathi somjikelezo kumashini we-CNC sisho isikhathi esidingekayo ukuze kuqedelwe umsebenzi womshini owodwa noma eminingi.Kunoma iyiphi iphrojekthi yemishini ye-CNC, isikhathi somjikelezo sibalulekile ukuhlaziya isikhathi sokuhola futhi unciphise izindleko zezingxenye ezithile noma imikhiqizo yokugcina.

Ithonya izindleko eziphelele zamaphrojekthi womshini we-CNC kanye nezinye izakhi ezifana nohlobo lwezinto ezibonakalayo, ubunkimbinkimbi, nokunemba.Ukubala isikhathi somjikelezo kuhilela ukuxazulula ubudlelwano bezibalo ngemisebenzi efana nokugaya, ukujika, ukubhola, nokunye okuningi.

Lesi sihloko sizohlinzekaa Ukubuka kafushane kokubala isikhathi somjikelezo wemisebenzi ehlukahlukene yemishini ye-CNC, imithelela yesikhathi somjikelezo wokukhiqiza nezindlela zayo zokunciphisa.

Ukubalwa Kwesikhathi Somjikelezo Wokukhiqiza

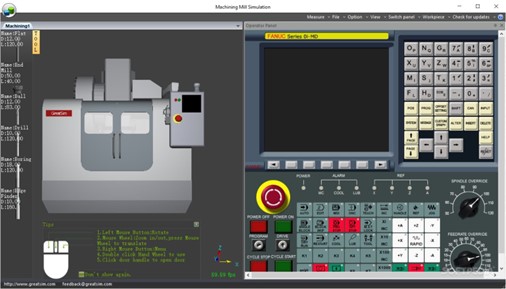

Isilinganiso sesikhathi somjikelezo kuphaneli yokulawula

, isikhathi somshini siyefana nezinye izikhathi, kanye nesilinganiso sebanga elihanjwa ithuluzi ukuya esivinini.Isikhathi somshini esijwayelekile sayo yonke imisebenzi, okuhlanganisa ukugaya, ukujika, ukubheka, nokunye okuningi, kungavezwa ngokwezibalo kanje(Iyunithi 5 yokubala Isikhathi Somshini, 2012).

T=L/(f*N)

Noma,

Isikhathi somjikelezo (T) = (L * inombolo yokudlula)/ (f*N)

Lapho,

L= ubude bomshini wocwecwe lokusebenza (mm)

N= ukuphenduka kwe-workpiece ngomzuzu (rpm)

= 1000* isivinini sokusika (V)/π*Ububanzi (D)

f= Izinga lokuphakelayo (mm/min)

f=isiphakeli ngokwenguquko=isiphakeli ngezinyo ngalinye * inombolo yamazinyo = 0.1 * 20 = 2mm,

Lesi sisho sezibalo sinikeza umbono olula mayelana nesikhathi somshini kanye nokuthi singakanani isikhathi esidingekayo ukuze kwenziwe umsebenzi othile.

Isikhathi Somjikelezo Wemisebenzi Ehlukahlukene

1. I-CNC Milling

Njengoba sekushiwo kakade, ifomula jikeleleT=L/f*Nisetshenziselwa ukubala isikhathi somjikelezo kuyo yonke inqubo yemishini ye-CNC.Nokho, indlela yecala ngalinye yokubala okuguquguqukayo ingase yehluke.

Emsebenzini wokugaya, izinga lokudla libalwa ngokwezinga lokudla ngezinyo ngalinye.Kudinga amazinyo amaningi, imiphetho, noma imitshingo ethuluzini.

Izinga lokuphakelayo (f) = okuphakelayo ngezinyo ngalinye * inombolo yamazinyo

Ubude = Ubude bomsebenzi + Ithuluzi ngaphezu Kokuhamba x Inombolo Yamaphasi + Ubude bendlela Yethuluzi.

Umsebenzi wokugaya we-CNC

Ngokwesibonelo, ubude bomshini womshini wokugaya ngokujula kokusikwa okungu-4mm, ubude bendawo yokusebenza bungama-200 mm, ububanzi bokusika obungama-200mm, indlela yamathuluzi & nebanga lokuhamba elingu-4 mm, izinga lokuphakela ngezinyo ngalinye lingu-0.2 mm, isivinini sokusika esingu-30 m/ min & 30 amazinyo kuyobaL= 200 mm + 4 mm * Inombolo yokudlula + 4mm.

Ukuze uthole inombolo yokudlula, usayizi wesikhala noma esinye isici kufanele sihlukaniswe ngokujula kokusikwa (ithuluzi lingasika lijule kangakanani) kanye).Ake sicabangele usayizi we-slot 20mm * 20mm kithi, ithuluzi lidlula izikhathi ezi-5 phezu kwendawo yokusebenza ukusika 20mm.

Ngakho, L= 200 mm + 4 mm * 5 + 4mm = 224 mm

2. Ukuphenduka kwe-CNC

I-CNC iphendule izingxenye

Ukuphenduka kwe-CNC kubhekise ekwakhiweni kwezingxenye eziphendukile kusetshenziswa ithuluzi lephoyinti elilodwa.Isibalo sesikhathi somjikelezo somsebenzi wokujika asihlukile kunomsebenzi wokugaya.Ubude bubuye busekelwe kufomula yokuthiL= Ubude bomsebenzi + Ithuluzi ngaphezu Kokuhamba x Inombolo Yamaphasi + Ubude bendlela Yethuluzikanye ne-AverageI-RPM (N) = 1000*isivinini sokusika/π*isilinganiso esimaphakathi.

Ake sibale okuphakelayo ngokuphenduka ngakunye (f) kanye ne-RPM (N) yomsebenzi wokujika ngokuthatha isibonelo esifanayo nesenze umsebenzi wokugaya ngenhla.

Njengoba okuphakelayo kwezinyo ngalinye kuwukuguquguquka okwaziwayo, sibala ukuphakelayo ngokuphenduka ngakunye (f) ngokuthiukuphindaphinda okuphakelayo ngezinyo ngalinye ngeNombolo yamazinyo.

f= 0.1 * 30 = 3mm/revolution

N= ukuphenduka kwe-workpiece ngomzuzu (rpm)

= 1000* isivinini sokusika (V)/π*Ububanzi (D)

= 1000*30/ 3.14* 200

= 47.77 rpm

Isikhathi esiphelele somjikelezo wokukhiqiza sizoba(T) = L* inombolo yokudlula/f*N = 224*5/ (3*47.77) = 7.81 imizuzu

3. CNC Drilling

I-CNC drilling ihilela ukwakhiwa kwezimbobo eziyindilinga endaweni yokusebenza enganyakazi ngethuluzi elijikelezayo.Isikhathi somjikelezo wokumba sisho isikhathi sokudala imbobo eyodwa noma ngaphezulu, okuncike kuthuluzi lomshini, izinga lokuphakelayo, kanye nesivinini se-Spindle.

Isikhathi somjikelezo wokubhoboza (T) = (Id*i)/f*v

Lapho,

i= Inani lemigodi

Id= Ukujula kokubhoboza (mm)

v= Isivinini se-spindle (/min)

f= Izinga lokuphakelayo (mm/rev)

Indlela Eyengeziwe yokubala

Kukhona enye indlela eqondile yokulinganisa isikhathi somjikelezo wokukhiqiza kumashini we-CNC.Ingabalwa ngokuhlukanisa isikhathi esitshaliwe ngenani eliphelele lezingxenye noma imikhiqizo ekhiqizwayo(Verma, 2022).

Isikhathi Somjikelezo (T) = Isikhathi esiphelele/inani lezingxenye ezikhiqiziwe noma imikhiqizo

Ngokwesibonelo, uma ukusetha kwemishini ye-CNC kwenza izingcezu ezifanayo eziyi-12 ngehora elilodwa, isikhathi somjikelezo sengxenye eyodwa imizuzu emi-5.

Isikhathi somjikelezo = 1 ihora/ izingxenye eziyi-12 = imizuzu engama-60/ izingxenye eziyi-12 = imizuzu emi-5/ ingxenye

Ukunciphisa Isikhathi Somjikelezo

Njengoba isikhathi somjikelezo wokukhiqiza sihlotshaniswa nesikhathi sokuhola kanye nezindleko eziphelele zamaphrojekthi womshini we-CNC, kudinga ukunciphisa isikhathi somjikelezo ukuze kuthuthukiswe zonke izindleko zezingxenye kanye nemikhiqizo yokugcina ukuze iqhudelane emakethe.(A. Vetrivel, 2018).Ngisho nalapho inqubo yokwenza imishini ye-CNC isifinyelele esimweni sokuzinza, kungase kube nezinto ezithile ezithonya isikhathi somjikelezo.Ngakho-ke, ukulawula Ukuhlukahluka komsebenzi womshini we-CNC kubalulekile ukuze kusheshiswe inqubo.

s

Nakuba kuyiqiniso ukuthi izikhathi zomjikelezo wokusika zehlisa izindleko nezikhathi zokuhola, kungase kube nezimo ezithile lapho izikhathi zomjikelezo wokuphusha zingafaneleki ngenxa yemishini kanye nezingqinamba zokusebenza.Ngaphezu kwalokho, ukwehlisa isikhathi somjikelezo ngaphansi komkhawulo ongathandeki nakho kuthinta ukusebenza kwezingxenye.Ake sibhekisise iziphakamiso ezimbalwa ezinengqondo zokunciphisa isikhathi somjikelezo wokukhiqiza.

1. Ukuthuthukiswa kwesakhiwo sesitolo sokusebenzela

Ukulingiswa kwesakhiwo somshini kukhompuyutha

Isakhiwo esiyinkimbinkimbi somshini we-CNC sinomthelela esikhathini sokusebenza ngenxa yokulinda okungadingekile noma izikhathi zokuhamba.Uma amaseli okukhiqiza eseduze, azonciphisa isikhathi somjikelezo futhi akwenze kube lula ukuguquka ukusuka kokunye ukusebenza kuya kokunye.Ngisho namasekhondi ambalwa anganciphisa izikhathi zokukhiqiza futhi athuthukise ukukhiqiza komshini.

Ngakho-ke, udinga ukulungisa ukwakheka ngokwendawo etholakalayo, isimo sempahla eluhlaza, kanye nemisebenzi yomshini ehilelekile.Ngaphezu kwalokho, kunenketho yokulingisa ikhompuyutha ukuthola ukwakheka okungcono kakhulu, okunciphisa isikhathi sokukhiqiza ngokuthuthukisa ukuhamba komsebenzi.

2. Opharetha abanolwazi

Ukukhiqiza komshini we-CNC nakho kuncike ekhonweni lomsebenzisi.Opharetha abangochwepheshe bangakwazi ukubhekana kalula nezinkinga ezivela ngesikhathi sokusebenza futhi bazobheka izinqubo zokuthuthukisa okuqhubekayo.Ukusebenzisa izinsiza zabantu abanekhono ekukhiqizeni kuzofaka isandla ekwehliseni isikhathi somjikelezo.

Ngakho-ke, ukunciphisa isikhathi somjikelezo kunoma iyiphi iphrojekthi yemishini ye-CNC kudinga opharetha abanolwazi abanamakhono okuhlaziya.

3. Ukuthuthukisa imodeli ye-3D

Imishini ye-CNC ingakha amajiyometri ayinkimbinkimbi ngezinga eliphezulu lokunemba kobukhulu.Nokho, ubunkimbinkimbi buyandisa isikhathi somjikelezo.Uma umklami enza umklamo olula ngangokunokwenzeka ngaphandle kokuphazamisa izici ezidingekayo nokusebenza, isikhathi sizoncishiswa kakhulu.Idizayini eyinkimbinkimbi idinga ithuluzi eliyinkimbinkimbi nelivamile ukusethwa ukuze kuqedelwe umsebenzi.

Ngakho-ke, kungcono ukususa ubunkimbinkimbi obungadingekile ekwakhiweni futhi ulungise ukulandelana kwemishini okuhle kakhulu ngesikhathi esifushane somjikelezo.Ukwengeza, sisebenzisana eduze nonjiniyela ukulungisa idizayini efanelekile ukuze sifinyelele isikhathi somjikelezo wokukhiqiza osheshayo.

4. Ukukhiqiza okuzenzakalelayo

Inqubo ezenzakalelayo ihlala isebenza kahle futhi ishesha kunomzamo owenziwe ngesandla.Ungakwazi ukuqeda umsebenzi womuntu omningi ngangokunokwenzeka.Ukunciphisa isikhathi somjikelezo kungenzeka kusetshenziswa imishini ye-CNC enesivinini esiphezulu kanye nesofthiwe yekhamera ethuthukisiwe njenge-CAM eqinile(A. Vetrivel, 2018)

Izinqubo zokuzenzakalela zibikezelwa kakhudlwana futhi zisiza ekutholeni izikhathi zomjikelezo ezifanele ngokuthuthuka okuqhubekayo.Uma wenza ngokuzenzakalelayo inqubo yokukhiqiza, umshini uhlala umile futhi ukhulisa isikhathi somjikelezo wokusebenza ngakunye kwemishini ye-CNC.Kodwa-ke, inqubo ye-automation idinga ukutshalwa kwezimali okubalulekile kokuqala, kodwa ingaba yinzuzo ngokuhamba kwesikhathi.

5. Lungiselela ukusebenza kwemishini

Ukushisisa ngokweqile, ukudlidliza, kanye nemikhawulo yangaphakathi ezinye izithiyo zemishini ye-CNC neminye imishini yokukhiqiza.Lokhu okuguquguqukayo kunciphisa ukusebenza kokukhiqiza futhi kunomthelela esikhathini somjikelezo omude.

Ukuze ugweme lokhu kukhathazeka, abakhiqizi kufanele babeke phambili ukuhlola okuvamile, ukunakekelwa ngezikhathi ezithile, ukubuyisela isitoko, ukulinganisa, nezinye izenzo.

Isiphetho

Emisebenzini yemishini ye-CNC, isikhathi somjikelezo wokukhiqiza singalinganiswa kusetshenziswa ifomula elula efaka ubude bomshini, izinga lokuphakelayo, isivinini somshini, nokunye okuguquguqukayo.Ingase ishintshwe kancane ngokusekelwe ekusebenzeni okuthile kwe-CNC, njengokugaya, ukujika, nokubhoboza.Ngenxa yokuthi isikhathi somjikelezo sixhunyaniswe ngokungenakuhlukaniswa nezindleko kanye nesikhathi sokuhola sanoma iyiphi iphrojekthi yokwenza imishini ye-CNC, ukukhulisa isikhathi somjikelezo kunezela ekuncishisweni kwezindleko eziphelele.Kunezindlela ezahlukahlukene zokunciphisa isikhathi somjikelezo, njengokuzenzakalela, ukugcinwa njalo, ama-opharetha aqeqeshiwe, nabanye abaningi.Nakuba isikhathi somjikelezo singabalwa kusetshenziswa okuhlukile komshini, ezinye izici zithinta umphumela onembile, njengomzamo womuntu, ukudlidliza, ukushisa okudlulele, kanye nobungcweti bomsebenzisi.

Kunezici ezimbalwa okufanele zicatshangelwe ukuze kuthuthukiswe isikhathi somjikelezo ukuze kwehliswe izindleko, futhi i-ProleanHub ingase ibe uzakwethu osebenza kahle kakhulu obambisene nephrojekthi yakho yokwenza imishini ye-CNC.Sinikezela ngezinsizakalo zobuchwepheshe ze-CNC ezinezinketho zempahla engu-50+ zemisebenzi ehlukahlukene.Ochwepheshe bethu bokukhiqiza babambisana eduze nonjiniyela ukuze balungiselele isikhathi somjikelezo ukuze bathole imiphumela emihle kakhulu ngezindleko eziphansi.

Imibuzo Evame Ukubuzwa

Yini ukubaluleka kwesikhathi somjikelezo wokukhiqiza kumashini we-CNC?

Isikhathi esidingekayo ukuze uqedele umsebenzi womshini owodwa noma ngaphezulu we-CNC ubizwa ngokuthi isikhathi somjikelezo wokukhiqiza.Njengoba isikhathi esiningi silingana nezindleko ezengeziwe, kubalulekile ukwehlisa zonke izindleko nesikhathi sokuhola sezingxenye noma umkhiqizo wokugcina.

Yiziphi izinguquko ezidingekayo ukuze ubale isikhathi somjikelezo?

Isikhathi somjikelezo sibalwa kusetshenziswa ubude bomshini, isivinini, izinga lokuphakelayo, ukuphenduka ngomzuzu, nezinye izici.Kodwa-ke, okokufaka okudingekayo kungase kuhluke kusukela ekusebenzeni komshini kuya kokulandelayo.

Singancishiswa kanjani isikhathi somjikelezo wokukhiqiza?

Ukwenziwa ngcono kwamamodeli e-3D, ukuncishiswa kwesikhathi sokungasebenzi kwemishini, ukwakheka kwemishini efanele, okuzenzakalelayo, ama-opharetha angochwepheshe, nokugcinwa okuvamile kwemishini konke kunomthelela ekwehliseni isikhathi somjikelezo wokukhiqiza.

Ngingakwazi ukunciphisa isikhathi somjikelezo kakhulu?

Cha, kunezingqinamba ezithile zokunciphisa isikhathi somjikelezo.Lokhu kuhlanganisa amandla omshini, izakhiwo zezinto ezibonakalayo, ikhwalithi edingekayo, nomzamo womuntu.

Ngaphezu kwalokho, ukunciphisa isikhathi somjikelezo ngaphansi komkhawulo ofiselekayo kunomthelela emishinini esebenzayo kanye nekhwalithi yezingxenye noma imikhiqizo yokugcina.

I-Bibliography

1. A. Vetrivel, AA (2018).Isikhathi Sokukhiqiza kanye Nokwehliswa Kwesikhathi Somjikelezo ku-CNC Machine Shop.Ijenali Yamazwe Ngamazwe Yocwaningo Kwezobunjiniyela, Isayensi Nokuphathwa (IJRESM), 1-2.

2. Unit 5 Machining Isikhathi Ukubala.(2012).KuUkuhlelwa Kwenqubo Nokulinganisa Kwezindleko(amakhasi 2-3).srividyaengg.

3. U-Verma, E. (2022).Ukuqonda Isikhathi se-TAKT nesikhathi Somjikelezo vs. Isikhathi Sokuhola.I-Simplilearn.com.

Isikhathi sokuthumela: Dec-09-2022