Lokacin Zagayowar Haɓaka a cikin Injin CNC

Kiyasta lokacin Karatu: Minti 7 da sakan 10.

Teburin Abubuwan Ciki

I Lissafin Lokacin Zagayowar Ƙirƙira

II Lokacin zagayowar ayyuka daban-daban (Milling, juyawa, & hakowa)

III Ƙarin Hanyar Lissafi

IV Rage Lokacin Zagayowar

V Kammalawa

VI FAQ's

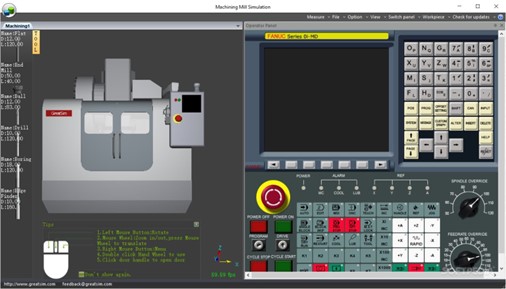

Injin CNC

Lokacin sake zagayowar a cikin mashin ɗin CNC yana nufin lokacin da ake buƙata don kammala ayyukan mashin ɗin ɗaya ko fiye.Ga kowane aikin injin ɗin CNC, lokacin sake zagayowar yana da mahimmanci don nazarin lokacin jagorar da rage farashin takamaiman sassa ko samfuran ƙarewa.

Yana rinjayar gaba ɗaya farashin ayyukan injinan CNC tare da sauran abubuwa kamar nau'in kayan abu, rikitarwa, da daidaito.Ƙididdigar lokacin zagayowar ya ƙunshi warware alaƙar lissafi don ayyuka kamar niƙa, juyawa, hakowa, da ƙari mai yawa.

Wannan labarin zai bayara taƙaitaccen bayyani na lissafin lokacin sake zagayowar don ayyukan injinan CNC daban-daban, tasirin lokacin sake zagayowar samarwa & hanyoyin rage ta.

Ƙididdigar Lokacin Zagayowar Ƙirƙira

Ƙimar lokacin sake zagayowar a cikin kwamiti mai kulawa

, lokacin mashin ɗin yana kama da sauran lokuta, da kuma rabon nisan tafiya ta kayan aiki zuwa sauri.Babban lokacin injina na duk ayyuka, gami da niƙa, juyawa, fuskantar, da dai sauransu, ana iya bayyana su ta hanyar lissafi kamar haka.(Kididdigar Lokacin Ma'aikata Na 5, 2012).

T=L/(f*N)

Ko kuma,

Lokacin zagaye (T) = (L * adadin wucewa)/ (f* N)

Ina,

L= Tsawon aikin injin (mm)

N = juyi na aikin aikin a minti daya (rpm)

= 1000* saurin yanke (V)/π* Diamita (D)

f= Yawan ciyarwa (mm/min)

f = ciyar da juyin juya hali = ciyar da hakori * adadin hakora = 0.1 * 20 = 2mm,

Wannan furci na lissafi yana ba da ra'ayi mai sauƙi game da lokacin mashin ɗin da kuma lokacin da ake buƙata don yin aiki na musamman.

Lokacin Zagayowar Ayyuka daban-daban

1. CNC Milling

Kamar yadda aka riga aka bayyana, tsarin gaba ɗayaT=L/f*Nana amfani da shi don ƙididdige lokacin sake zagayowar don kowane tsarin mashin ɗin CNC.Koyaya, hanyar kowane shari'a don ƙididdige ma'auni na iya bambanta.

A cikin aikin niƙa, ana ƙididdige ƙimar ciyarwa dangane da ƙimar ciyar da haƙori.Yana buƙatar adadin hakora, yankan gefuna, ko sarewa akan kayan aiki.

Yawan ciyarwa (f) = ciyar da kowane haƙori * adadin haƙora

Tsawon Lokaci = Tsawon Aiki + Kayan aiki akan Balaguro x Yawan wucewa + Tsawon kayan aiki.

CNC milling aiki

Misali, da machining tsawon ga wani milling aiki tare da zurfin yanke na 4mm, workpiece tsawon 200 mm, abun yanka diamita na 200mm, kayan aiki m & kan tafiya nesa na 4 mm, ciyar kudi da hakori 0.2 mm, yankan gudun 30 m / min & 30 hakora za su kasanceL= 200 mm + 4 mm * Yawan wucewa + 4mm.

Don samun adadin wucewa, girman ramin ko kowane nau'i ya kamata a raba shi ta zurfin yanke (yadda zurfin kayan aiki zai iya yanke) sau ɗaya).Bari mu yi la'akari da girman da Ramin 20mm * 20mm a cikin yanayin, da kayan aiki wuce sau 5 a kan workpiece yanke 20mm.

Don haka, L= 200 mm + 4 mm * 5 + 4mm = 224 mm

2. Canjin CNC

CNC juya sassa

Juyawar CNC tana nufin ƙirƙirar sassan da aka juya ta amfani da kayan aiki guda ɗaya.Lissafin lokacin sake zagayowar don aikin juyawa baya bambanta da aikin milling.A tsawon kuma dogara ne a kan dabara naL= Tsawon Ayuba + Kayan aiki Akan Balaguro x Yawan wucewa + Tsawon kayan aikida MatsakaiciRPM (N) = 1000 * saurin yankewa / π* matsakaicin diamita.

Bari mu ƙididdige ciyarwar kowane juyi (f) & RPM (N) na aikin juyawa ta hanyar ɗaukar misalin da muka yi don aikin niƙa a sama.

Tunda ciyarwar kowane haƙori shine sanannen canji, muna ƙididdige ciyarwar kowane juyin juya hali (f) taninka ciyar da kowane hakori da Yawan hakora.

f= 0.1 * 30 = 3mm/juyin juya hali

N = juyi na aikin aikin a minti daya (rpm)

= 1000* saurin yanke (V)/π* Diamita (D)

= 1000*30/ 3.14* 200

= 47.77 rpm

Jimlar lokacin sake zagayowar samarwa zai kasance(T) = L* lambar wucewa/f*N = 224*5/ (3*47.77) = mintuna 7.81

3. Farashin CNC

CNC hakowa ya ƙunshi halittar zagaye ramukan a tsaye workpiece tare da juyawa kayan aiki.Lokacin zagayowar hakowa yana nufin lokacin ƙirƙirar ramuka ɗaya ko fiye, wanda ya dogara da kayan aikin injin, ƙimar ciyarwa, da saurin Spindle.

Lokacin zagayowar hakowa (T) = (Id *i)/f*v

Ina,

i= Yawan ramuka

Id= Zurfin hakowa (mm)

v= Gudun juzu'i (/min)

f= Yawan ciyarwa (mm/ rev)

Ƙarin Hanyar Lissafi

Akwai wata hanya madaidaiciya ta kimanta lokacin sake zagayowar samarwa a cikin injinan CNC.Ana iya ƙididdige shi ta hanyar rarraba lokacin da aka saka hannun jari ta jimlar adadin sassa ko samfuran da aka samar(Verma, 2022).

Lokacin Zagayowar (T) = Jimlar lokaci/yawan sassa ko samfuran da aka samar

Misali, Idan CNC machining saitin ya yi guda 12 iri ɗaya a cikin sa'a ɗaya, lokacin sake zagayowar sashi ɗaya shine mintuna 5.

Lokacin zagaye = sa'a 1 / sassa 12 = mintuna 60 / sassa 12 = mintuna 5 / sashi

Rage Lokacin Zagayowar

Kamar yadda lokacin sake zagayowar samarwa yana da alaƙa da lokacin jagora da kuma ƙimar ayyukan mashin ɗin CNC gabaɗaya, yana buƙatar rage lokacin sake zagayowar don haɓaka yawan farashin sassa da samfuran ƙarewa don yin gasa a kasuwa.(A. Vetrivel, 2018).Ko da lokacin da tsarin injin CNC ya kai matsayin kwanciyar hankali, har yanzu ana iya samun wasu abubuwan da ke tasiri lokacin sake zagayowar.Sabili da haka, sarrafa Canjin aikin injin CNC yana da mahimmanci don hanzarta aiwatar da aiki.

s

Duk da yake gaskiya ne cewa yanke lokutan sake zagayowar yana rage farashi da lokutan jagora, za a iya samun wasu yanayi inda lokutan sake zagayowar ba su da ma'ana saboda kayan aiki da matsalolin aiki.Bugu da ƙari, rage lokacin sake zagayowar a ƙasa da iyakar da ba a so kuma yana rinjayar ayyukan sassa.Bari mu dubi wasu shawarwari masu ma'ana don rage lokacin zagayowar samarwa.

1. Haɓaka shimfidar wuraren aiki

Simulation na injina a kan kwamfuta

Ƙididdiga mai sarƙaƙƙiya na injina na CNC yana ba da gudummawa ga lokacin injin saboda rashin buƙata ko lokutan wucewa.Idan sel masu samarwa suna kusa, za su rage lokacin sake zagayowar kuma su sauƙaƙa canzawa daga wannan aiki zuwa wani.Ko da ƴan daƙiƙai kaɗan na iya rage lokutan samarwa da haɓaka aikin injin.

Don haka, kuna buƙatar gyara shimfidar wuri bisa ga sararin samaniya, yanayin albarkatun ƙasa, da ayyukan injin da ke ciki.Bugu da ƙari, akwai zaɓi don kwaikwaiyon kwamfuta don nemo mafi kyawun shimfidar wuri, wanda ke rage lokacin samarwa ta hanyar haɓaka aikin aiki.

2. Kwararrun ma'aikata

Yawan aikin injinan CNC kuma ya dogara da ƙwarewar mai aiki.Kwararrun ma'aikata na iya magance matsalolin da ke tasowa yayin aiki cikin sauƙi kuma za su nemi ci gaba da tafiyar matakai.Yin amfani da ƙwararrun albarkatun ɗan adam wajen samarwa zai ba da gudummawa ga raguwar lokacin sake zagayowar.

Don haka, rage lokacin sake zagayowar a cikin kowane aikin mashin ɗin CNC yana buƙatar gogaggun masu aiki tare da iyawar nazari.

3. Inganta samfurin 3D

CNC machining na iya haifar da hadaddun geometries tare da babban matakin daidaiton girma.Koyaya, rikitarwa yana ƙara lokacin sake zagayowar.Idan mai zane ya haifar da zane mai sauƙi kamar yadda zai yiwu ba tare da damun abubuwan da ake buƙata da ayyukan da ake buƙata ba, za a rage lokacin da muhimmanci.Ƙirar ƙira tana buƙatar ƙayyadaddun kayan aiki da yawa da aka saita don kammala aikin.

Don haka, yana da kyau a cire abubuwan da ba dole ba daga ƙira da kuma gyara mafi kyawun tsarin mashin ɗin don ɗan gajeren lokaci.Bugu da ƙari, muna haɗin gwiwa tare da masu haɓakawa don gyara ƙira mai kyau don cimma lokacin sake zagayowar samarwa da sauri.

4. Production aiki da kai

Tsarin sarrafa kansa koyaushe yana da inganci da sauri fiye da ƙoƙarin hannu.Kuna iya kawar da aikin ɗan adam kamar yadda zai yiwu.Rage lokacin zagayowar yana yiwuwa ta amfani da injunan CNC masu sauri da software na ci gaba kamar CAM mai ƙarfi(A. Vetrivel, 2018)

Hanyoyin sarrafawa ta atomatik sun fi tsinkaya kuma suna taimakawa wajen samun daidaitattun lokutan zagayowar tare da ci gaba da haɓakawa.Lokacin da kuka sarrafa tsarin masana'anta, injin ɗin ya kasance a tsaye kuma yana haɓaka lokacin sake zagayowar kowane aikin injin CNC.Koyaya, tsarin sarrafa kansa yana buƙatar babban saka hannun jari na farko, amma yana iya zama da fa'ida a cikin dogon lokaci.

5. Inganta aikin injina

Dumama mai yawa, girgizawa, da ƙuntatawa na ciki wasu ƙuntatawa ne na injinan CNC da sauran injinan masana'anta.Waɗannan masu canji suna rage aikin samarwa kuma suna ba da gudummawa ga tsawon lokacin sake zagayowar.

Don guje wa waɗannan abubuwan damuwa, masana'antun yakamata su ba da fifikon dubawa akai-akai, kulawa na lokaci-lokaci, sabuntawa, daidaitawa, da sauran ayyuka.

Kammalawa

A cikin ayyukan injin CNC, ana iya ƙididdige lokacin sake zagayowar samarwa ta amfani da tsari mai sauƙi wanda ya haɗa da tsayin injin, ƙimar ciyarwa, saurin injin, da sauran masu canji.Zai yiwu a ɗan canza shi dangane da takamaiman aikin CNC, kamar niƙa, juyawa, da hakowa.Saboda lokacin sake zagayowar yana da alaƙa da tsada da lokacin jagora na kowane aikin mashin ɗin CNC, haɓaka lokacin sake zagayowar yana ƙara yawan rage farashin.Akwai hanyoyi daban-daban don rage lokacin zagayowar, kamar sarrafa kansa, kulawa akai-akai, ƙwararrun ma'aikata, da sauran su.Kodayake ana iya ƙididdige lokacin sake zagayowar ta amfani da wasu sauye-sauyen injina, wasu abubuwan suna shafar ingantaccen sakamako, kamar ƙoƙarin ɗan adam, girgiza, zafi mai yawa, da ƙwarewar mai aiki.

Dole ne a yi la'akari da abubuwa da yawa don inganta lokacin zagayowar don rage farashi, kuma ProleanHub na iya zama cikakkiyar abokin haɗin gwiwa don aikin injin ku na CNC.Muna ba da sabis na injin CNC masu sana'a tare da zaɓuɓɓukan kayan 50+ don ayyuka daban-daban.Kwararrun masana'antun mu suna haɗin gwiwa tare da masu haɓakawa don haɓaka lokacin sake zagayowar don kyakkyawan sakamako a farashi mai rahusa.

FAQ's

Menene mahimmancin lokacin sake zagayowar samarwa a cikin mashin ɗin CNC?

Lokacin da ake buƙata don kammala ɗaya ko fiye da ayyukan mashin ɗin CNC ana kiransa lokacin sake zagayowar samarwa.Tunda ƙarin lokaci yayi daidai da ƙarin farashi, yana da mahimmanci don rage duka farashi & lokacin jagorar sassa ko samfurin ƙarshen.

Menene ma'auni masu mahimmanci don ƙididdige lokacin zagayowar?

Ana ƙididdige lokacin zagayowar ta amfani da tsayin injina, saurin gudu, ƙimar ciyarwa, juyi a minti ɗaya, da sauran dalilai.Koyaya, shigarwar da ake buƙata na iya bambanta daga aiki ɗaya zuwa na gaba.

Ta yaya za a iya rage lokacin sake zagayowar samarwa?

Haɓaka samfuran 3D, raguwar machining downtime, mafi kyawun shimfidar injina, sarrafa kansa, ƙwararrun ma'aikata, da kula da injuna na yau da kullun duk suna ba da gudummawa ga rage lokacin zagayowar samarwa.

Zan iya rage lokacin zagayowar da yawa?

A'a, akwai wasu ƙuntatawa don rage lokacin zagayowar.Waɗannan sun haɗa da iyawar injin, kaddarorin kayan aiki, ingancin da ake buƙata, da ƙoƙarin ɗan adam.

Bugu da ƙari, rage lokacin sake zagayowar ƙasa da ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun kayan aikin ke haifar da ingantattun sassa ko samfuran ƙarshe.

Littafi Mai Tsarki

1. A. Vetrivel, AA (2018).Lokacin Ƙirƙira da Rage Lokacin Zagayawa a Shagon Injin CNC.Jarida ta Duniya na Bincike a Injiniya, Kimiyya da Gudanarwa (IJRESM), 1-2.

2. Raka'a 5 Lissafin Lokacin Injiniya.(2012).A cikiTsare Tsare & Ƙimar Kuɗi(shafi na 2-3).srividyaengg.

3. Verma, E. (2022).Fahimtar Lokacin TAKT da Lokacin Zagayowar vs. Lokacin Jagora.Simplilearn.com.

Lokacin aikawa: Dec-09-2022