Kugadzira Kutenderera Nguva muCNC Machining

Inofungidzirwa Kuverenga Nguva: Maminitsi manomwe nemasekonzi gumi.

Zviri Mukati

Ini Kuverengera Yekugadzira Kutenderera Nguva

II Kutenderera nguva yekushanda kwakasiyana (Kugaya, kutendeuka, & kuchera)

III Yekuwedzera Maitiro ekuverenga

IV Kuderedza Nguva Yekutenderera

V Mhedziso

VI FAQ's

CNC machining

Iyo nguva yekutenderera muCNC machining inoreva nguva inodiwa kupedzisa rimwe kana anopfuura machining mashandiro.Kune chero CNC machining purojekiti, nguva yekutenderera yakakosha kuongorora nguva yekutungamira uye kuderedza mutengo wezvimwe zvikamu kana zvigadzirwa zvekupedzisira.

Iyo inopesvedzera mutengo wakazara weCNC machining mapurojekiti pamwe nezvimwe zvinhu zvakaita semhando yemhando, kuoma, uye nemazvo.Kuverenga kutenderera nguva kunosanganisira kugadzirisa hukama hwemasvomhu hwekuita sekugaya, kutenderedza, kuchera, uye zvimwe zvakawanda.

Ichi chinyorwa chichapaa pfupiso yepfupi yekutenderera nguva komputa yeakasiyana CNC machining mashandiro, zvinokanganisa zvekugadzira kutenderera nguva & nzira dzekudzikisa kwayo.

Kuverengera Yekugadzira Kutenderera Nguva

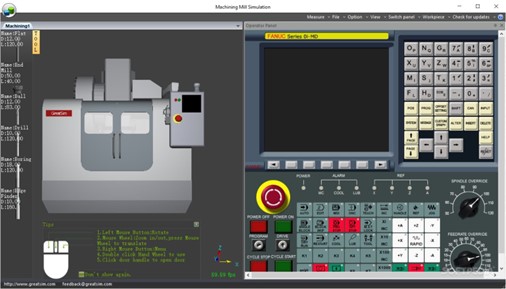

Estimation yenguva yekutenderera mu control panel

, nguva yekugadzira yakafanana nedzimwe nguva, uye reshiyo yedaro rinofambwa nechishandiso kusvika pakumhanya.Iyo yakajairwa machining nguva yemabasa ese, kusanganisira kugaya, kutendeuka, kutarisana, uye zvimwe zvakawanda, inogona kuratidzwa nemasvomhu sezvinotevera.(Chikamu 5 Machining Nguva Yekuverenga, 2012).

T=L/(f*N)

Kana kuti,

Nguva yekutenderera (T) = (L * nhamba yekupfuura)/ (f*N)

Kupi,

L= machining kureba kwechishandiso (mm)

N = shanduko yeworkpiece paminiti (rpm)

= 1000* kucheka kumhanya (V)/π*Diameter (D)

f= Chiyero chekudya (mm/min)

f=feed per revolution= feed per zino * nhamba yemazino = 0.1 * 20 = 2mm,

Uku kutaura kwemasvomhu kunopa zano rakareruka nezve machining nguva uye inguva yakawanda sei inodiwa pakugadzira imwe workpiece.

Nguva Yekutenderera Kwekuita Kwakasiyana

1. CNC Milling

Sezvakatsanangurwa kare, general formulaT=L/f*Ninoshandiswa kuverengera nguva yekutenderera kune yega yega CNC machining process.Nekudaro, imwe neimwe nzira yekuverengera iyo shanduko inogona kusiyana.

Mukushanda kwekugaya, chiyero chekudya chinoverengwa maererano nehuwandu hwekudya pazino.Inoda mazino akati wandei, kuchekwa, kana nyere pachishandiswa.

Chiyero chekudya (f) = chikafu pazino * nhamba yemazino

Kureba = Kureba kweJobho + Chishandiso pamusoro peNzendo x Nhamba Yemapfuura + Chishandiso chekusvika kureba.

CNC milling operation

Semuyenzaniso, kureba kwekugadzira kwekugayo nekudzika kwe4mm, workpiece kureba kwe200 mm, cutter dhayamita ye200mm, nzira yekushandisa & pamusoro pekufamba chinhambwe che 4 mm, chiyero chekudya pazino 0.2 mm, kucheka kukurumidza kwe30 m / min & 30 mazino achavaL = 200 mm + 4 mm * Nhamba yekupfuura + 4mm.

Kuti uwane huwandu hwemapasi, saizi ye slot kana chero chimwe chinhu chinofanirwa kukamurwa nekudzika kwekucheka (kudzika sei mudziyo unogona kucheka) kamwe).Ngatitarisei saizi yeiyo slot 20mm * 20mm mune yedu, chishandiso chinopfuura kashanu pamusoro pechishandiso chekucheka 20mm.

Saka, L = 200 mm + 4 mm * 5 + 4mm = 224 mm

2. CNC Turning

CNC yakashandura zvikamu

CNC kutendeuka kunoreva kugadzirwa kwezvikamu zvakashandurwa uchishandisa iyo single-point chishandiso.Iyo yekutenderera nguva yekuverenga yekushandura basa haina kusiyana neyekugayo.Hurefu hwacho zvakare hwakavakirwa pafomula yekutiL= Kureba kweJobho + Chishandiso pamusoro peNzendo x Nhamba Yemapfuura + Chishandiso chekusvika kurebauye AvharejiRPM (N) = 1000*kucheka kumhanya/π*avhareji dhayamita.

Ngativerengei chikafu chekuchinja (f) & RPM (N) chekushandura nekutora muenzaniso wakafanana watakaita pakugayo pamusoro.

Sezvo kudyisa pazino riri iro rinozivikanwa shanduko, isu tinoverenga chikafu chekuchinja (f) nekuwedzera chikafu pazino neNhamba yemazino.

f= 0.1 * 30 = 3mm/chimurenga

N = shanduko yeworkpiece paminiti (rpm)

= 1000* kucheka kumhanya (V)/π*Diameter (D)

= 1000*30/ 3.14* 200

= 47.77 rpm

Iyo yakazara yekugadzira kutenderera nguva ichave(T) = L* nhamba yekupfuura/f*N = 224*5/ (3*47.77) = 7.81 maminitsi

3. CNC Drilling

Kuchera kweCNC kunosanganisira kugadzirwa kwemakomba akatenderera mune yakamira workpiece ine chishandiso chinotenderera.Iyo yekutenderera nguva yekuchera inoreva nguva yekugadzira imwe kana mamwe maburi, zvinoenderana nemuchina chishandiso, chiyero chekudya, uye Spindle kumhanya.

Drilling kutenderera nguva (T) = (Id*i)/f*v

Kupi,

i= Nhamba yemakomba

Id= Kudzika kwekuchera (mm)

v= Spindle kumhanya (/ min)

f= Chiyero chekudyisa (mm/ rev)

Yekuwedzera Maitirwo Ekuverenga

Pane imwe nzira yakatwasuka yekufungidzira nguva yekugadzira muCNC machining.Inogona kuverengerwa nekugovanisa nguva yakadyarwa nehuwandu hwezvikamu kana zvigadzirwa zvinogadzirwa(Verma, 2022).

Cycle Time (T) = Yese nguva / nhamba yezvikamu zvakagadzirwa kana zvigadzirwa

Semuyenzaniso, kana CNC machining set-up yakaita zvidimbu gumi nembiri zvakafanana muawa imwe, nguva yekutenderera kwechikamu chimwe maminitsi mashanu.

Cycle time = 1 awa/ 12 zvikamu = 60 maminitsi/ 12 zvikamu = 5 maminitsi/ chikamu

Kuderedza Nguva Yekutenderera

Sezvo nguva yekutenderera yekugadzira yakabatana nenguva yekutungamira uye mutengo wakazara weCNC machining mapurojekiti, zvinoda kudzikisira nguva yekutenderera kukwirisa mutengo wakazara wezvikamu uye zvigadzirwa zvekupedzisira kukwikwidza mumusika.(A. Vetrivel, 2018).Kunyangwe iyo CNC machining process yasvika pakugadzikana, panogona kunge paine zvimwe zvinhu zvinopesvedzera nguva yekutenderera.Naizvozvo, kudzora Kusiyanisa kweCNC machining oparesheni kwakakosha kuti ikurumidze kuita.

s

Kunyange chiri chokwadi kuti nguva dzekucheka dzinodzikisira mitengo uye nguva dzekutungamira, panogona kunge paine mamwe mamiriro apo kusunda kutenderera nguva hakuna musoro nekuda kwemidziyo uye zvimhingamipinyi zvekushanda.Mukuwedzera, kudzikisa nguva yekutenderera pasi pemuganho usingadiwi kunokanganisawo kushanda kwezvikamu.Ngatitarisei zvakanyanya kune mashoma ane musoro mazano ekudzikisa kutenderera nguva yekugadzira.

1. Optimization yebasa-shopu marongero

Kufananidza kwemuchina pakombuta

Iyo yakaoma dhizaini yeCNC machining inobatsira kunguva yekugadzira nekuda kwekusina kufanira kwekumirira kana nguva dzekufambisa.Kana masero ekugadzira ari pedyo, anoderedza nguva yekutenderera uye kuita kuti zvive nyore kuchinja kubva kune imwe kushanda kuenda kune imwe.Kunyangwe masekonzi mashoma anogona kupfupisa nguva dzekugadzira uye kuwedzera machining kugadzirwa.

Naizvozvo, iwe unofanirwa kugadzirisa marongero zvinoenderana nenzvimbo iripo, mbishi zvinhu mamiriro, uye machining mashandiro anobatanidzwa.Pamusoro pezvo, pane sarudzo yekuenzanisa komputa kuti uwane yakanakisa dhizaini, iyo inoderedza nguva yekugadzira nekuvandudza mafambiro ebasa.

2. Vashandi vane ruzivo

Kugadzirwa kweCNC machining zvakare kunoenderana nehunyanzvi hweanoshanda.Nyanzvi vanoshanda vanogona kugadzirisa zviri nyore matambudziko anomuka panguva yekushanda uye vanozotsvaga maitiro ekuvandudza anoenderera.Kushandisa zviwanikwa zvevanhu zvine hunyanzvi mukugadzira kunozobatsira mukudzikira kwenguva yekutenderera.

Naizvozvo, kudzikisira kutenderera nguva mune chero CNC machining purojekiti inoda vashandi vane ruzivo vane hunyanzvi hwekuongorora.

3. Optimization ye 3D modhi

CNC machining inogona kugadzira yakaoma geometries ine yakakwira dhigirii yedimensional kurongeka.Zvisinei, kuoma kunowedzera nguva yekutenderera.Kana mugadziri akagadzira dhizaini iri nyore sezvinobvira pasina kukanganisa zvinodiwa uye kushanda, nguva ichaderedzwa zvakanyanya.Yakaomarara dhizaini inoda yakaoma uye yakajairika chishandiso-kumisa kuti upedze basa.

Saka, zviri nani kubvisa kuoma kusingakoshi kubva pakugadzira uye kugadzirisa yakanakisa machining kutevedzana kwenguva pfupi yekutenderera.Pamusoro pezvo, isu tinodyidzana zvakanyanya nevagadziri kugadzirisa iyo yakakodzera dhizaini kuti tiwane inokurumidza kugadzirwa kutenderera nguva.

4. Kugadzira otomatiki

Iyo otomatiki maitiro anogara achinyanya kushanda uye nekukurumidza pane kushanda nemawoko.Iwe unogona kubvisa basa rakawanda revanhu sezvinobvira.Kuderedza nguva yekutenderera kunogoneka uchishandisa yakakwira-kumhanya CNC michina uye yepamusoro cam software yakadai seyakasimba CAM(A. Vetrivel, 2018)

Otomatiki maitiro anonyanya kufanotaura uye anobatsira mukuwana chaiyo kutenderera nguva nekuenderera mberi nekuvandudza.Paunenge uchigadzirisa maitiro ekugadzira, muchina unoramba wakamira uye unokwidziridza nguva yekutenderera yega yega CNC machining operation.Nekudaro, iyo otomatiki maitiro inoda yakakosha mari yekutanga, asi inogona kubatsira mukufamba kwenguva.

5. Gadzirisa kushanda kwemichina

Kupisa kwakanyanya, vibration, uye zvirambidzo zvemukati ndezvimwe zvipingaidzo zvemichina yeCNC nemimwe michina yekugadzira.Izvi zvakasiyana-siyana zvinoderedza kugadzirwa kwekuita uye zvinobatsira kune yakareba kutenderera nguva.

Kuti udzivise izvi zvinonetsa, vagadziri vanofanirwa kuisa pamberi pekutarisa nguva nenguva, kugadzirisa nguva nenguva, kudzoreredza, kuenzanisa, uye zvimwe zviito.

Mhedziso

MuCNC machining mashandiro, iyo nguva yekugadzira kutenderera inogona kufungidzirwa uchishandisa yakapusa formula inosanganisira machining kureba, chiyero chekudya, kumhanya kwemuchina, uye zvimwe zvinosiyana.Inogona kushandurwa zvishoma zvichibva pane chaiyo CNC mashandiro, sekugaya, kutendeuka, uye kuchera.Nekuti nguva yekutenderera yakabatana zvisingaite nemutengo uye nguva yekutungamira yechero CNC machining projekiti, optimize kutenderera nguva kunowedzera kune yakazara mutengo kudzikiswa.Pane nzira dzakasiyana dzekudzikisa kutenderera nguva, senge otomatiki, kugara uchigadzirisa, vakadzidziswa vanoshanda, uye zvimwe zvakawanda.Kunyangwe nguva yekutenderera ichigona kuverengerwa uchishandisa mamwe machining akasiyana, zvimwe zvinhu zvinokanganisa mhedzisiro chaiyo, senge simba revanhu, vibration, kupisa kwakanyanya, uye hunyanzvi hwemushandisi.

Zvinhu zvakati wandei zvinofanirwa kutariswa kuti uvandudze kutenderera nguva yekudzikisa mutengo, uye ProleanHub inogona kunge iri yakanyatsoshanda mubatsiri kune yako CNC machining chirongwa.Isu tinopa inyanzvi CNC machining masevhisi ane makumi mashanu+ zvinhu sarudzo dzemabasa akasiyana.Nyanzvi dzedu dzekugadzira dzinodyidzana pamwe nevagadziri kuti vagone kukwirisa nguva yekutenderera kune yakanakisa mhedzisiro nemutengo wakaderera.

FAQ's

Chii chakakosha chekugadzira kutenderera nguva muCNC machining?

Iyo nguva inodiwa kuti upedze rimwe kana anopfuura CNC machining mabasa inonzi inguva yekugadzira kutenderera.Sezvo nguva yakawanda yakaenzana nemutengo wakawanda, zvakakosha kudzikisa mutengo wese & nguva yekutungamira yezvikamu kana yekupedzisira-chigadzirwa.

Ndeapi machinjiro anodiwa kuverenga nguva yekutenderera?

Nguva yekutenderera inoverengerwa uchishandisa machining kureba, kumhanya, chiyero chekudya, shanduko paminiti, uye zvimwe zvinhu.Nekudaro, iyo inodiwa yekupinza inogona kusiyana kubva kune imwe machining mashandiro kune inotevera.

Nguva yekugadzira inogona kuderedzwa sei?

Kukwidziridzwa kwemhando dze3D, kudzikisira kwemachining kudzika nguva, yakakwana machining dhizaini, otomatiki, nyanzvi vanoshanda, uye nguva dzose magadzirirwo emuchina zvese zvinobatsira mukudzikisa kutenderera kutenderera nguva.

Ndinogona here kuderedza nguva yekutenderera zvakanyanya?

Aiwa, pane zvimwe zvinotadzisa kuderedza kutenderera nguva.Izvi zvinosanganisira kugona kwemichina, zvinhu zvenyama, mhando inodiwa, uye kushanda kwevanhu.

Uyezve, kuderedza nguva yekutenderera pasi pemuganho unodiwa kunokanganisa muchina unomhanya uye mhando yezvikamu kana magumo-zvigadzirwa.

Bibliography

1. A. Vetrivel, AA (2018).Kugadzira Nguva uye Kutenderera Nguva Kuderedzwa muCNC Machine Shop.International Journal of Research in Engineering, Science and Management (IJRESM), 1-2.

2. Unit 5 Machining Nguva Kuverenga.(2012).InMaitiro Kuronga & Mutengo Estimation(p. 2-3).svidyaengg.

3. Verma, E. (2022).Kunzwisisa TAKT Nguva uye Cycle Time vs. Lead Time.Simlilearn.com.

Nguva yekutumira: Zvita-09-2022