Ixesha loMjikelo weMveliso kwi-CNC Machining

Ixesha eliqikelelweyo lokufunda: imizuzu esi-7 kunye nesekondi eli-10.

Isiqulatho

I Ukubala Ixesha uMjikelo weMveliso

II Umjikelo wexesha lemisebenzi eyahlukeneyo (Ukugaya, ukujika, kunye nokugrumba)

III Indlela eyongezelelweyo yokubala

IV Ukunciphisa Ixesha le-Cycle

V Ukuqukumbela

VI FAQ's

CNC machining

Ixesha lomjikelo kwi-machining ye-CNC libhekisela kwixesha elifunekayo ukugqiba umsebenzi omnye okanye ngaphezulu.Kuyo nayiphi na iprojekthi ye-CNC yomatshini, ixesha lomjikelo libalulekile ukuhlalutya ixesha elikhokelayo kunye nokunciphisa iindleko zamalungu athile okanye iimveliso zokuphela.

Iphembelela ixabiso elipheleleyo leeprojekthi zobuchwephesha be-CNC kunye nezinye izinto ezifana nohlobo lwemathiriyeli, ukuntsonkotha, kunye nokuchaneka.Ukubala ixesha lomjikelo kubandakanya ukusombulula ubudlelwane bemathematika kwimisebenzi efana nokusila, ukujika, ukugrumba, nokunye okuninzi.

Eli nqaku liza kubonelelaa Ushwankathelo olufutshane lwexesha lobalo lwexesha lemisebenzi yomatshini eyahlukeneyo ye-CNC, iimpembelelo zexesha lomjikelo wemveliso kunye neendlela zayo zokunciphisa.

Ukubalwa kwexesha loMjikelo weMveliso

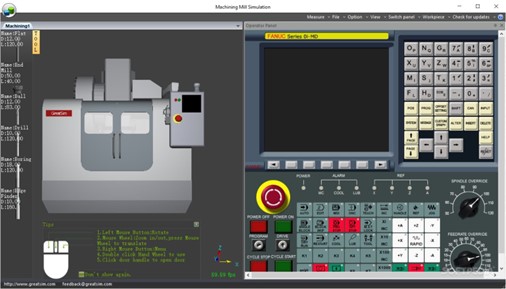

Uqikelelo lwexesha lomjikelo kwiphaneli yolawulo

, ixesha lomatshini lifana namanye amaxesha, kunye nomlinganiselo womgama ohanjwe sisixhobo ukuya kwisantya.Ixesha eliqhelekileyo lomatshini wayo yonke imisebenzi, kubandakanywa ukuguba, ukujika, ukujongana, kunye nezinye ezininzi, zinokubonakaliswa ngokwezibalo ngolu hlobo lulandelayo.(IYunithi yesi-5 yokubala ixesha loMatshini, ngo-2012).

T=L/(f*N)

Okanye,

Ixesha lomjikelo (T) = (L * inani lokudlula)/(f*N)

Apho,

L= ubude besixhobo somsebenzi (mm)

N= ujikelezo lweworkpiece ngomzuzu (rpm)

= 1000* isantya sokusika (V)/π*Ububanzi (D)

f= Umyinge wesondlo (mm/min)

f=ukutya ngokwe revolution=ukutya izinyo ngalinye * inani lamazinyo = 0.1 * 20 = 2mm,

Le ntetho yemathematika inika ingcamango elula malunga nexesha lomatshini kunye nokuba lingakanani ixesha elifunekayo ekwenzeni umsebenzi othile.

Ixesha lokujikela leMisebenzi eyahlukeneyo

1. CNC Milling

Njengoko sele kuchaziwe, ifomula jikeleleT=L/f*Nisetyenziselwa ukubala ixesha lomjikelo kuyo yonke inkqubo yomatshini yeCNC.Nangona kunjalo, indlela yemeko nganye yokubala i-variable inokwahluka.

Kumsebenzi wokusila, izinga lokutya libalwa ngokwezinga lokutya ngezinyo ngalinye.Ifuna inani lamazinyo, iincam zokusika, okanye iifluti kwisixhobo.

Izinga lokutyisa (f) = isondlo ngezinyo ngalinye * inani lamazinyo

Ubude = Ubude bomsebenzi + Isixhobo ngaphezu kweeHambo x Inani lokudlula + ubude bokufikelela kwisixhobo.

Umsebenzi wokugaya we-CNC

Umzekelo, ubude bomatshini bomsebenzi wokusila ngobunzulu be-4mm, ubude be-workpiece ye-200 mm, i-cutter diameter ye-200mm, indlela yesixhobo kunye nomgama wokuhamba we-4 mm, izinga lokutya ngezinyo ngalinye yi-0.2 mm, isantya sokusika i-30 m / min & 30 amazinyo iya kubaL = 200 mm + 4 mm * Inani lokudlula + 4mm.

Ukufumana inani lokudlula, ubungakanani bendawo yokubeka okanye nayiphi na enye into kufuneka yahlulwe ngobunzulu bokusikwa (isixhobo esinokuthi sinqumle kangakanani) kanye).Makhe siqwalasele ubungakanani be-slot 20mm * 20mm kwimeko yethu, isixhobo sidlula amaxesha ama-5 phezu kwendawo yokusebenza ukusika i-20mm.

Ngoko, L = 200 mm + 4 mm * 5 + 4mm = 224 mm

2. Ukujika kwe-CNC

I-CNC yajika iinxalenye

Ukujika kwe-CNC kubhekisa ekudalweni kwamalungu ajikiweyo kusetyenziswa isixhobo esinenqaku elinye.Ubalo lwexesha lomjikelo lomsebenzi wokujika alifani nomsebenzi wokusila.Ubude bukwasekelwe kwifomula yeL= Ubude bomsebenzi + Isixhobo phezu kweeHambo x Inani lokudlula + ubude bokufikelela kwisixhobokunye noMyingeI-RPM (N) = 1000* ukusika isantya / π* umndilili wedayamitha.

Masibale isondlo ngokwe-revolution (f) & RPM (N) yomsebenzi wokujika ngokuthatha umzekelo omnye esiwenzele umsebenzi wokusila ngasentla.

Ekubeni ifidi ngezinyo ngalinye ukwahluka eyaziwayo, sibala ifidi revolution (f) ngeUphinda-phinda isondlo kwizinyo ngalinye ngeNani lamazinyo.

f= 0.1 * 30 = 3mm/revolution

N= ujikelezo lweworkpiece ngomzuzu (rpm)

= 1000* isantya sokusika (V)/π*Ububanzi (D)

= 1000*30/ 3.14* 200

= 47.77 rpm

Ixesha elipheleleyo lomjikelezo wemveliso liya kuba(T) = L* inani lokupasa/f*N = 224*5/ (3*47.77) = 7.81 imizuzu

3. CNC Drilling

Ukugaya i-CNC kubandakanya ukudala imingxuma ejikelezayo kwindawo yokusebenza emileyo kunye nesixhobo esijikelezayo.Ixesha lomjikelo lokomba libhekisa kwixesha lokudala imingxuma enye okanye ngaphezulu, exhomekeke kwisixhobo somatshini, isantya sokutya, kunye nesantya seSpindle.

Ixesha lomjikelo wokugrumba (T) = (Id*i)/f*v

Apho,

i= Inani lemingxuma

Id= Ubunzulu bokomba (mm)

v= Isantya sokujikeleza (/min)

f= Umyinge wesondlo (mm/ rev)

Indlela eyongezelelweyo yokubala

Kukho enye indlela ethe ngqo yokuqikelela ixesha lomjikelo wemveliso kumatshini we-CNC.Inokubalwa ngokwahlula ixesha elityalwe ngenani elipheleleyo leenxalenye okanye iimveliso eziveliswayo(Verma, 2022).

Ixesha lomjikelo (T) = Ixesha elipheleleyo / inani leenxalenye eziveliswayo okanye iimveliso

Umzekelo, ukuba i-CNC machining set-up yenza iziqwenga eziyi-12 ezifanayo ngeyure enye, ixesha lokujikela kwinxalenye enye yimizuzu emi-5.

Ixesha lomjikelo = 1 iyure/ 12 iinxalenye = 60 imizuzu/ 12 iinxalenye = 5 imizuzu/ inxalenye

Ukunciphisa Ixesha le-Cycle

Njengoko ixesha lomjikelo wemveliso linxulunyaniswa nexesha elikhokelayo kunye neendleko ezipheleleyo zeeprojekthi zoomatshini be-CNC, kufuna ukunciphisa ixesha lomjikelo wokwandisa ixabiso elipheleleyo leenxalenye kunye nemveliso yokuphela ukukhuphisana kwimarike.(A. Vetrivel, 2018).Nangona inkqubo yomatshini ye-CNC ifikelele kwisimo sozinzo, kusenokubakho izinto ezichaphazela ixesha lomjikelo.Ke ngoko, ukulawulwa kwe-Varable of a CNC machining operation kubalulekile ukukhawulezisa inkqubo.

s

Nangona kuyinyani ukuba amaxesha omjikelezo wokusika anciphisa iindleko kunye namaxesha okukhokela, kunokubakho ezinye iimeko apho amaxesha okutyhalela umjikelo angekho ngqiqweni ngenxa yezixhobo kunye nezithintelo zokusebenza.Ukongeza, ukuthoba ixesha lomjikelo ngaphantsi komda ongafunekiyo nako kuchaphazela ukusebenza kwamalungu.Makhe sijonge ngakumbi iingcebiso ezimbalwa ezinengqiqo zokunciphisa ixesha lomjikelo wemveliso.

1. Ukuphuculwa koyilo lwevenkile yokusebenzela

Ukulinganisa ubume bomatshini kwikhompyuter

Uyilo oluntsonkothileyo lomatshini we-CNC lunegalelo kwixesha lomatshini ngenxa yamaxesha okulinda okanye okuhamba ngokungeyomfuneko.Ukuba iiseli zemveliso zisondele, ziya kunciphisa ixesha lomjikelo kwaye zenze kube lula ukuguquka ukusuka komnye umsebenzi ukuya kwenye.Kwanemizuzwana embalwa inokunciphisa amaxesha emveliso kwaye ikhulise imveliso yomatshini.

Ke ngoko, kufuneka ulungise uyilo ngokwendawo ekhoyo, imeko yezinto ezikrwada, kunye nemisebenzi yomatshini ebandakanyekayo.Ukongeza, kukho inketho yokulinganisa ikhompyuter ukufumana eyona ndlela ilungileyo yoyilo, enciphisa ixesha lokuvelisa ngokuphucula ukuhamba komsebenzi.

2. Abasebenzisi abanamava

Ukuveliswa komatshini we-CNC kuxhomekeke kubuchule bomqhubi.Abaqhubi beengcali bangakwazi ukujongana lula neengxaki ezivela ngexesha lokusebenza kwaye baya kukhangela iinkqubo eziqhubekayo zokuphucula.Ukusebenzisa izakhono zabasebenzi kwimveliso kuya kuba negalelo ekuthotyweni kwexesha lomjikelo.

Ke ngoko, ukunciphisa ixesha lomjikelo kuyo nayiphi na iprojekthi ye-CNC yomatshini ifuna abaqhubi abanamava abanobuchule bokuhlalutya.

3. Ukuphucula imodeli ye-3D

Umatshini we-CNC unokudala iijiyometri ezintsonkothileyo ezinomgangatho ophezulu wokuchaneka komda.Nangona kunjalo, ubunzima kwandisa ixesha lomjikelo.Ukuba umyili udala uyilo olulula ngokusemandleni ngaphandle kokuphazamisa iimpawu ezifunekayo kunye nokusebenza, ixesha liya kuncitshiswa kakhulu.Uyilo oluntsonkothileyo lufuna isixhobo esintsokothileyo nesisoloko sisetwa ukugqibezela umsebenzi.

Ke, kungcono ukususa ukuntsonkotha okungafunekiyo kuyilo kwaye ulungise olona landelelwano lomatshini kwixesha elifutshane lomjikelo.Ukongeza, sisebenzisana ngokusondeleyo nabaphuhlisi ukulungisa uyilo olufanelekileyo ukufezekisa elona xesha likhawulezayo lomjikelo wemveliso.

4. Imveliso ezenzekelayo

Inkqubo ezenzekelayo ihlala isebenza ngakumbi kwaye ikhawuleza kunomzamo wezandla.Unokuphelisa umsebenzi omninzi wabantu njengoko kunokwenzeka.Ukunciphisa ixesha lomjikelo kunokwenzeka usebenzisa oomatshini be-CNC abanesantya esiphezulu kunye nesoftware yekhamera ephezulu njenge-CAM eqinileyo(A. Vetrivel, 2018)

Iinkqubo ze-automation ziqikeleleka ngakumbi kwaye zinceda ekufumaneni amaxesha omjikelezo ochanekileyo kunye nokuphucula okuqhubekayo.Xa usenza ngokuzenzekelayo inkqubo yokuvelisa, oomatshini bahlala bemile kwaye bakhulisa ixesha lomjikelo womsebenzi womatshini ngamnye we-CNC.Nangona kunjalo, inkqubo yokuzenzekelayo idinga utyalo-mali olubalulekileyo lokuqala, kodwa lunokuba luncedo ekuhambeni kwexesha.

5. Lungiselela ukusebenza koomatshini

Ukufudumeza okugqithisileyo, ukungcangcazela, kunye nezithintelo zangaphakathi zezinye izithintelo koomatshini be-CNC kunye nabanye oomatshini bokwenza.Ezi ziguquko zinciphisa ukusebenza kwemveliso kwaye zifake isandla kwixesha elide lokujikeleza.

Ukunqanda ezi zinto zixhalabisayo, abavelisi kufuneka babeke phambili ukuhlolwa rhoqo, ukugcinwa kwamaxesha athile, ukubuyisela isitokhwe, ukulinganisa, kunye nezinye izenzo.

Ukuqukumbela

Kwimisebenzi yomatshini we-CNC, ixesha lomjikelo wemveliso linokuqikelelwa kusetyenziswa ifomyula elula ebandakanya ubude bomatshini, izinga lokutya, isantya somatshini, kunye nezinye izinto eziguquguqukayo.Isenokutshintshwa kancinane ngokusekwe kumsebenzi othile we-CNC, njengokugaya, ukujika, kunye nokugrumba.Ngenxa yokuba ixesha lomjikelo lidityaniswe ngokungenakuqhathaniswa kwiindleko kunye nexesha lokukhokela kuyo nayiphi na iprojekthi yomatshini we-CNC, ukulungelelanisa ixesha lomjikelo longeza ekunciphiseni iindleko zizonke.Kukho iindlela ezahlukeneyo zokunciphisa ixesha lomjikelo, njengokuzenzekela, ukugcinwa rhoqo, abasebenzi abaqeqeshiweyo, kunye nabanye abaninzi.Nangona ixesha lokujikeleza linokubalwa kusetyenziswa ezinye izinto eziguquguqukayo zomatshini, ezinye izinto zichaphazela umphumo ochanekileyo, njengomzamo womntu, ukungcangcazela, ukushisa okugqithisileyo, kunye nobuchule bomqhubi.

Izinto ezininzi kufuneka ziqwalaselwe ukuphucula ixesha lomjikelo lokunciphisa iindleko, kwaye iProleanHub inokuba liqabane elifanelekileyo lentsebenziswano kwiprojekthi yakho yomatshini ye-CNC.Sinikezela ngeenkonzo zobuchwephesha zeCNC ezineenketho zezinto ezingama-50+ kwimisebenzi eyahlukeneyo.Iingcali zethu zokuvelisa zisebenzisana ngokusondeleyo nabaphuhlisi ukwandisa ixesha lomjikelo ukuze bafumane iziphumo ezigqwesileyo ngexabiso eliphantsi.

Ii-FAQ's

Yintoni ukubaluleka kwexesha lomjikelo wemveliso kwi-CNC machining?

Ixesha elifunekayo ukugqiba umsebenzi omnye okanye ngaphezulu we-CNC womatshini ubizwa ngokuba lixesha lomjikelo wemveliso.Kuba ixesha elininzi lilingana neendleko ezingaphezulu, kubalulekile ukuthoba lonke ixabiso kunye nexesha lokukhokela lamalungu okanye imveliso yokugqibela.

Zeziphi iinguqu eziyimfuneko ukubala ixesha lomjikelo?

Ixesha lomjikelo libalwa kusetyenziswa ubude bomatshini, isantya, izinga lokutya, iirevolutions ngomzuzu, kunye nezinye izinto.Nangona kunjalo, igalelo elifunekayo linokwahluka ukusuka kumatshini omnye ukuya kwelinye.

Linokuncitshiswa njani ixesha lomjikelo wemveliso?

Ukuphuculwa kweemodeli ze-3D, ukunciphisa ixesha lokunciphisa oomatshini, ulungelelwaniso olufanelekileyo lomatshini, i-automation, iingcali zabaqhubi, kunye nokugcinwa rhoqo koomatshini bonke banegalelo ekwehliseni ixesha lomjikelo wemveliso.

Ngaba ndinokunciphisa ixesha lomjikelo kangangoko?

Hayi, kukho imiqobo ethile yokunciphisa ixesha lomjikelo.Ezi ziquka amandla omatshini, iipropati eziphathekayo, umgangatho ofunekayo, kunye nomzamo womntu.

Ngaphaya koko, ukunciphisa ixesha lomjikelo ngaphantsi komda ofunekayo kuchaphazela oomatshini abasebenzayo kunye nomgangatho wamalungu okanye iimveliso zokugqibela.

Uluhlu lweencwadi

1. A. Vetrivel, AA (2018).Ixesha lokuvelisa kunye nokuNcitshiswa kwexesha lokuCwangciswa kwi-CNC Machine Shop.Ijenali yeHlabathi yoPhando kubuNjineli, iSayensi kunye noLawulo (IJRESM), 1-2.

2. Unit 5 Machining Ixesha Ukubala.(2012).KwiUCwangciso lweNkqubo kunye nokuqikelelwa kweendleko(iphe. 2-3).siridyaengg.

3. Verma, E. (2022).Ukuqonda Ixesha le-TAKT kunye nexesha le-Cycle vs. Ixesha lokukhokela.Simplilearn.com.

Ixesha lokuposa: Dec-09-2022