Production Cycle Time mu CNC Machining

Nthawi Yoyerekeza Kuwerenga: Mphindi 7 ndi masekondi 10.

M'ndandanda wazopezekamo

I Kuwerengera Nthawi Yopanga Nthawi

II Nthawi yozungulira yogwirira ntchito zosiyanasiyana (Kupera, kutembenuza, & kubowola)

III Njira yowonjezera yowerengera

IV Kuchepetsa Nthawi Yozungulira

V Mapeto

VI FAQs

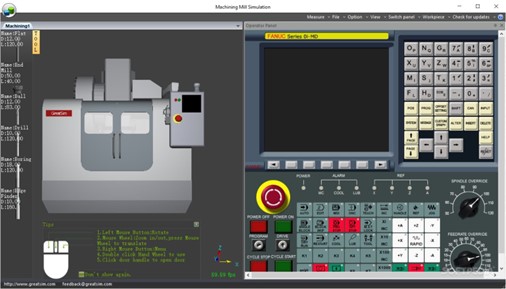

CNC makina

Nthawi yozungulira mu makina a CNC imatanthawuza nthawi yofunikira kuti mumalize ntchito imodzi kapena zingapo.Pantchito iliyonse yopangira makina a CNC, nthawi yozungulira ndiyofunikira kusanthula nthawi yotsogolera ndikuchepetsa mtengo wazinthu zina kapena zomaliza.

Zimakhudza mtengo wonse wa ma projekiti opanga makina a CNC pamodzi ndi zinthu zina monga mtundu wazinthu, zovuta, komanso kulondola.Kuwerengera nthawi yozungulira kumaphatikizapo kuthetsa ubale wamasamu pamachitidwe monga mphero, kutembenuza, kubowola, ndi zina zambiri.

Nkhaniyi iperekaa Chidule chachidule cha kuwerengera kwa nthawi yozungulira pamachitidwe osiyanasiyana a makina a CNC, zovuta za nthawi yozungulira komanso njira zake zochepetsera.

Kuwerengera Nthawi Yopanga Nthawi

Kuyerekeza kwa nthawi yozungulira mu gulu lowongolera

, nthawi yopangira makina ndi yofanana ndi nthawi zina, ndi chiŵerengero cha mtunda woyenda ndi chida ndi liwiro.Nthawi yonse yopangira makina azinthu zonse, kuphatikiza mphero, kutembenuka, kuyang'ana, ndi zina zambiri, zitha kuwonetsedwa mwamasamu motere.(Kuwerengera Nthawi ya Unit 5, 2012).

T=L/(f*N)

Kapena,

Nthawi yozungulira (T) = (L * kuchuluka kwa zodutsa)/ (f*N)

Kumeneko,

L = kutalika kwa makina ogwiritsira ntchito (mm)

N = kusintha kwa workpiece pamphindi (rpm)

= 1000* kudula liwiro (V)/π*Diameter (D)

f= Mlingo wa chakudya (mm/min)

f=chakudya pa revolution=chakudya pa dzino * chiwerengero cha mano = 0.1 * 20 = 2mm,

Mawu a masamuwa amapereka lingaliro losavuta la nthawi yokonza makina komanso nthawi yochuluka yomwe imafunika popanga chinthu china.

Nthawi Yozungulira Yogwirira Ntchito Zosiyanasiyana

1. CNC Milling

Monga tafotokozera kale, chilinganizo chonseT=L/f*Namagwiritsidwa ntchito kuwerengera nthawi yozungulira panjira iliyonse ya CNC Machining.Komabe, njira iliyonse yowerengera zosinthika imatha kukhala yosiyana.

Pa mphero, mlingo wa chakudya umawerengedwa malinga ndi mlingo wa chakudya pa dzino.Pamafunika mano angapo, m'mphepete, kapena zitoliro pa chida.

Mtengo wa chakudya (f) = chakudya pa dzino * chiwerengero cha mano

Utali = Utali wa ntchito + Chida pa Maulendo x Nambala ya Zodutsa + kutalika kwa Chida.

CNC mphero ntchito

Mwachitsanzo, kutalika Machining kwa ntchito mphero ndi akuya odulidwa 4mm, workpiece kutalika 200 mm, wodula awiri 200mm, chida njira & paulendo mtunda wa 4 mm, mlingo chakudya pa dzino 0,2 mm, kudula liwiro 30 m / min & 30 mano adzakhalaL = 200 mm + 4 mm * Chiwerengero cha odutsa + 4mm.

Kuti mupeze kuchuluka kwa ma pass, kukula kwa slot kapena chinthu china chilichonse chiyenera kugawidwa ndi kuya kwa kudula (momwe chida chingadulire) kamodzi).Tiyeni tione kukula kwa kagawo 20mm * 20mm kwa ife, chida kudutsa kasanu pa workpiece kudula 20mm.

Choncho, L = 200 mm + 4 mm * 5 + 4mm = 224 mm

2. Kutembenuka kwa CNC

CNC adatembenuza magawo

Kutembenuka kwa CNC kumatanthauza kupanga magawo otembenuzidwa pogwiritsa ntchito chida cha mfundo imodzi.Kuwerengera nthawi yozungulira kwa ntchito yotembenuza sikusiyana ndi mphero.Kutalika kumatengeranso chilinganizo chaL= Utali wa Ntchito + Chida Chopitilira Maulendo x Nambala Yakudutsa + Kutalika kwa Chidandi AverageRPM (N) = 1000*kudula liwiro/π* avareji ya m'mimba mwake.

Tiyeni tiwerengere chakudya pakusintha (f) & RPM (N) potembenuza potengera chitsanzo chomwe tidachitira pa mphero pamwambapa.

Popeza chakudya pa dzino ndi chosinthika chodziwika, timawerengera chakudya pakusintha (f) ndikuchulukitsa chakudya pa dzino ndi Chiwerengero cha mano.

f= 0.1 * 30 = 3mm/kusintha

N = kusintha kwa workpiece pamphindi (rpm)

= 1000* kudula liwiro (V)/π*Diameter (D)

= 1000*30/ 3.14* 200

= 47.77 rpm

Nthawi yonse yopanga idzakhala(T) = L* nambala yodutsa/f*N = 224*5/ (3*47.77) = 7.81 mphindi

3. CNC Drilling

Kubowola kwa CNC kumaphatikizapo kupanga mabowo ozungulira pamalo ogwirira ntchito ndi chida chozungulira.Nthawi yobowola imatanthawuza nthawi yopangira mabowo amodzi kapena angapo, zomwe zimatengera chida chopangira makina, kuchuluka kwa chakudya, komanso liwiro la Spindle.

Nthawi yobowola (T) = (Id*i)/f*v

Kumeneko,

i= Chiwerengero cha mabowo

Id= Kubowola kuya (mm)

v= Liwiro la spindle (/ min)

f= Mlingo wa chakudya (mm/rev)

Njira Yowonjezera Yowerengera

Palinso njira ina yowongoka yakuyerekeza nthawi yozungulira yopanga mu makina a CNC.Itha kuwerengedwa pogawa nthawi yomwe idayikidwa ndi kuchuluka kwa magawo kapena zinthu zopangidwa(Verma, 2022).

Nthawi Yozungulira (T) = Nthawi yonse / kuchuluka kwa magawo opangidwa kapena zinthu

Mwachitsanzo, ngati CNC Machining set-up anapanga zidutswa 12 zofanana mu ola limodzi, nthawi yozungulira gawo limodzi ndi mphindi zisanu.

Nthawi yozungulira = 1 ola / magawo 12 = mphindi 60 / magawo 12 = mphindi 5 / gawo

Kuchepetsa Nthawi Yozungulira

Popeza nthawi yopanga zinthu imalumikizidwa ndi nthawi yotsogolera komanso mtengo wonse wamapulojekiti opanga makina a CNC, pamafunika kuchepetsa nthawi yozungulira kuti mukwaniritse mtengo wonse wa magawo ndi zinthu zomaliza kuti zipikisane pamsika.(A. Vetrivel, 2018).Ngakhale ndondomeko ya makina a CNC ikafika pokhazikika, pangakhale zinthu zina zomwe zimakhudza nthawi yozungulira.Choncho, kulamulira Kusinthasintha kwa CNC Machining ntchito n'kofunika kuti kufulumizitsa ndondomekoyi.

s

Ngakhale ndizowona kuti nthawi yodulira imatsitsa mtengo komanso nthawi yotsogolera, pakhoza kukhala nthawi zina pomwe nthawi yokankhira siyenera chifukwa cha zida ndi zovuta zogwirira ntchito.Komanso, kutsitsa mkombero nthawi pansi osafunika malire kumakhudzanso magwiridwe antchito.Tiyeni tiwone mwatsatanetsatane malingaliro angapo anzeru ochepetsera nthawi yopangira.

1. Kukhathamiritsa kwa kamangidwe ka malo antchito

Makina opangira makina pakompyuta

Mapangidwe ovuta a makina a CNC amathandizira pakupanga nthawi chifukwa cha kudikirira kosafunikira kapena nthawi yodutsa.Ngati ma cell opanga ali pafupi, amachepetsa nthawi yozungulira ndikupangitsa kukhala kosavuta kusintha kuchokera ku ntchito ina kupita ku ina.Ngakhale masekondi pang'ono amatha kufupikitsa nthawi yopanga ndikukulitsa zokolola zamakina.

Chifukwa chake, muyenera kukonza masanjidwewo molingana ndi malo omwe alipo, momwe zida zopangira zidapangidwira, komanso ntchito zamakina zomwe zikukhudzidwa.Kuphatikiza apo, pali njira yoyeserera yamakompyuta kuti mupeze masanjidwe abwino kwambiri, omwe amachepetsa nthawi yopanga popititsa patsogolo kayendedwe ka ntchito.

2. Othandizira odziwa ntchito

Kupanga kwa makina a CNC kumatengeranso luso la wogwiritsa ntchito.Ogwiritsa ntchito akatswiri amatha kuthana ndi zovuta zomwe zimachitika panthawi yogwira ntchito ndipo adzayang'ana njira zopititsira patsogolo.Kugwiritsa ntchito luso la anthu popanga kumathandizira kuchepetsa nthawi yozungulira.

Chifukwa chake, kuchepetsa nthawi yozungulira mu projekiti iliyonse ya CNC imafunikira odziwa ntchito omwe ali ndi luso lowunikira.

3. Kukhathamiritsa kwa 3D model

CNC Machining amatha kupanga ma geometries ovuta ndi digiri yapamwamba yolondola kwambiri.Komabe, zovuta zimawonjezera nthawi yozungulira.Ngati wopanga amapanga mapangidwe osavuta momwe angathere popanda kusokoneza zofunikira ndi ntchito, nthawi idzachepetsedwa kwambiri.Mapangidwe ovuta amafunikira chida chovuta komanso chokhazikika pafupipafupi kuti amalize ntchitoyi.

Choncho, ndi bwino kuchotsa zovuta zosafunikira pakupanga ndikukonza ndondomeko yabwino kwambiri ya makina kwa nthawi yaifupi yozungulira.Kuphatikiza apo, timagwira ntchito limodzi ndi opanga kukonza mapangidwe abwino kuti tikwaniritse nthawi yofulumira kwambiri yopanga.

4. Zopanga zokha

Njira yopangira makina nthawi zonse imakhala yothandiza komanso yachangu kuposa ntchito yamanja.Mutha kuthetsa ntchito zambiri zaumunthu momwe mungathere.Kuchepetsa nthawi yozungulira kumatheka pogwiritsa ntchito makina othamanga kwambiri a CNC ndi mapulogalamu apamwamba a kamera monga CAM yolimba(A. Vetrivel, 2018)

Njira zodziwikiratu ndizodziwikiratu komanso zimathandizira kupeza nthawi yoyenera yozungulira ndikuwongolera mosalekeza.Mukamagwiritsa ntchito makinawo, makinawo amakhala osasunthika ndikuwongolera nthawi yozungulira ya makina aliwonse a CNC.Komabe, njira yodzipangira yokha imafunikira ndalama zambiri zoyambira, koma zitha kukhala zopindulitsa pakapita nthawi.

5. Sinthani magwiridwe antchito a makina

Kutentha kwambiri, kugwedezeka, ndi zoletsa zamkati ndizovuta zamakina a CNC ndi makina ena opangira.Zosinthazi zimachepetsa magwiridwe antchito ndikuwonjezera nthawi yayitali yozungulira.

Pofuna kupewa izi, opanga ayenera kuika patsogolo kuyendera pafupipafupi, kukonza nthawi ndi nthawi, kubwezeretsanso katundu, kusanja, ndi zina.

Mapeto

Mu CNC Machining ntchito, nthawi kupanga mkombero angayerekezedwe ntchito chilinganizo yosavuta yokhudza Machining kutalika, mlingo chakudya, Machining liwiro, ndi zosintha zina.Ikhoza kusinthidwa pang'ono kutengera ntchito ya CNC, monga mphero, kutembenuza, ndi kubowola.Chifukwa nthawi yozungulira imagwirizana kwambiri ndi mtengo ndi nthawi yotsogolera ya projekiti iliyonse ya CNC, kukhathamiritsa nthawi yozungulira kumawonjezera kutsika kwamitengo yonse.Pali njira zingapo zochepetsera nthawi yozungulira, monga makina opangira okha, kukonza pafupipafupi, ogwira ntchito ophunzitsidwa bwino, ndi ena ambiri.Ngakhale kuti nthawi yozungulira imatha kuwerengedwa pogwiritsa ntchito mitundu ina ya makina, zinthu zina zimakhudza zotsatira zolondola, monga kuyesetsa kwa anthu, kugwedezeka, kutentha kwambiri, komanso ukadaulo wa opareshoni.

Zinthu zingapo ziyenera kuganiziridwa kuti zithandizire kuwongolera nthawi yochepetsera mtengo, ndipo ProleanHub ikhoza kukhala bwenzi labwino kwambiri lothandizira pulojekiti yanu ya CNC.Timapereka akatswiri opanga makina a CNC okhala ndi zosankha 50+ pazantchito zosiyanasiyana.Akatswiri athu opanga zinthu amagwira ntchito limodzi ndi opanga mapulogalamu kuti akwaniritse nthawi yozungulira kuti apeze zotsatira zabwino pamtengo wotsika.

FAQs

Kodi kufunikira kwa nthawi yozungulira kupanga mu CNC Machining ndi kotani?

Nthawi yofunikira kuti mumalize ntchito imodzi kapena zingapo za CNC Machining imatchedwa nthawi yozungulira.Popeza nthawi yochulukirapo ikufanana ndi mtengo wochulukirapo, ndikofunikira kutsitsa mtengo wonse & nthawi yotsogolera ya magawo kapena zomaliza.

Ndi zosintha ziti zofunika kuti muwerengere nthawi yozungulira?

Nthawi yozungulira imawerengeredwa pogwiritsa ntchito kutalika kwa makina, liwiro, kuchuluka kwa chakudya, kusintha pamphindi, ndi zina.Komabe, zomwe zimafunikira zimatha kusiyana ndi makina opangira makina.

Kodi nthawi yopangira zinthu ingachepe bwanji?

Kukhathamiritsa kwa mitundu ya 3D, kuchepetsa kutsika kwa makina, masanjidwe oyenera a makina, makina odzichitira okha, akatswiri ogwiritsa ntchito, komanso kukonza makina pafupipafupi, zonse zimathandizira kuchepetsa nthawi yopanga makina.

Kodi ndingachepetse nthawi yozungulira kwambiri?

Ayi, pali zolepheretsa kuti muchepetse nthawi yozungulira.Izi zikuphatikizapo luso la makina, katundu wakuthupi, khalidwe lofunika, ndi khama laumunthu.

Kuphatikiza apo, kuchepetsa nthawi yozungulira yomwe ili pansi pa malire oyenera kumakhudza makina oyendetsa komanso mtundu wa magawo kapena zinthu zomaliza.

Zolemba

1. A. Vetrivel, AA (2018).Nthawi Yopanga ndi Kuchepetsa Nthawi Yozungulira mu CNC Machine Shop.International Journal of Research in Engineering, Science and Management (IJRESM), 1-2.

2. Unit 5 Machining Time Kuwerengera.(2012).MuKukonzekera kwa Njira & Kuyerekeza Mtengo(masamba 2-3).siridyaengg.

3. Verma, E. (2022).Kumvetsetsa Nthawi ya TAKT ndi Nthawi Yozungulira vs. Nthawi Yotsogolera.Simplilearn.com.

Nthawi yotumiza: Dec-09-2022