Iwo mashanu akajairika epurasitiki jekiseni ekuumba maitiro

1 Jekiseni Molding

Nheyo yekuumbwa kwejekiseni ndeyekuwedzera granular kana poda zvigadziriso muhopi yemuchina wejekiseni, uye zvigadzirwa zvinopisa uye zvinonyungudutswa kuita mvura, zvino kusundirwa nescrew kana piston yemuchina wejekiseni, pinda mukati memold mukati. iyo muromo uye yekudurura system ye mold, uye omesa uye uise mugomba rekuumba.Zvinhu zvinokanganisa kunaka kwejekiseni molding:jekiseni pressure, jekiseni nguva, jekiseni tembiricha.

Process Technology features.

Zvakanakira:

1, pfupi yekuumba kutenderera, yakakwira kugadzirwa kwakanaka, nyore kuita otomatiki

2, inogona kuumba chimiro chakaoma, saizi chaiyo, nesimbi kana isiri-simbi inopinza zvikamu zvepurasitiki

3, Yakagadzikana chigadzirwa chemhando

4, dzakasiyana siyana dzekushandisa.

Zvakaipa:

1, Jekiseni kuumba midziyo mutengo wakakwira

2, Complex chimiro chejekiseni mold

3, mitengo yakakwira yekugadzira, kutenderera kwenguva refu yekugadzira, isina kukodzera kugadzirwa kwebatch rimwe chete rezvikamu zvepurasitiki

Zvikumbiro:

Muzvigadzirwa zvemaindasitiri, zvigadzirwa zvakaumbwa nejekiseni zvinosanganisira kitchenware (magaba emarara, mbiya, migomo, jugs, tableware, uye midziyo yakasiyana-siyana), dzimba dzemidziyo yemagetsi (mabhomba, vacuum cleaners, musanganisi wechikafu, nezvimwewo), matoyi nemitambo, zvikamu zvakasiyana zvemagetsi. iyo indasitiri yemotokari, zvikamu zvezvimwe zvakawanda zvigadzirwa, nezvimwe.

2 Isa Molding

Isa molding application

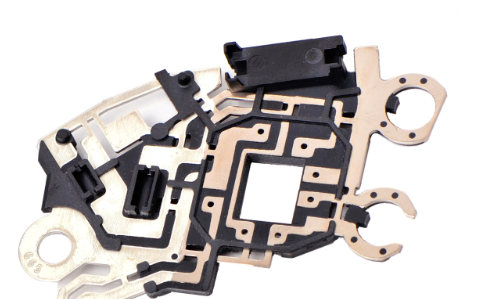

Insert molding inzira yekuumba iyo mold inozadzwa neyakafanogadzirirwa yekuisa yemidziyo yakasiyana yobva yabayiwa neresin, uye zvinhu zvakanyungudutswa zvinobatanidzwa nezvinoiswa uye zvinoporeswa kugadzira chigadzirwa chakabatanidzwa.

Process Technology maitiro

1, Kuiswa kwakawanda kunosanganiswa kumberi, zvichiita kuti post-engineering yechigadzirwa unit musanganiswa iwedzere kunzwisisika.

2, Iko kusanganiswa kwekureruka kweresin yekuumba, kupeta uye kusimba kwesimbi, simba uye kupisa kwekudzivirira kunogona kuwedzeredzwa kugadzira yakaoma uye yakapfava simbi-plastiki yakabatanidzwa zvigadzirwa.

3, Kunyanya, musanganiswa wekuisa resin uye simbi yemagetsi conductivity inogona kugadzira zvigadzirwa zvakaumbwa zvinogona kusangana nemabasa ekutanga ezvigadzirwa zvemagetsi.

4, Yezvigadzirwa zvakaomarara zvakaumbwa uye magasi erubha, kuumbwa kwejekiseni yezvigadzirwa zvakasanganiswa pane substrate kunobvisa basa rakaoma rekuronga zvisimbiso uye kunoita kuti zvive nyore kugadzira otomatiki musangano wepashure.

3 Jekiseni remavara maviri

Muenzaniso wejekiseni remavara maviri

Kaviri-ruvara jekiseni molding: Iyo inzira yekuumba iyo inopinza maviri akasiyana mavara epurasitiki muforoma imwechete.Inogona kuita kuti plastiki ionekwe mumarudzi maviri akasiyana uye inogona kuita kuti zvikamu zvepurasitiki zvivepo maitiro enguva dzose kana zvisingaenzaniswi nemakore-semaitiro ekuvandudza kushandiswa uye kunaka kwezvikamu zvepurasitiki.

Maitiro Technology maitiro.

1, Iyo yakakosha zvinhu inogona kushandisa yakaderera viscosity zvinhu kuderedza jekiseni kumanikidza.

2, Kubva pakufunga nezvekuchengetedzwa kwezvakatipoteredza, iyo yakakosha zvinhu inogona kushandisa yakadzokororwa yechipiri zvinhu.

3, tambo kune akasiyana maitiro ekushandisa, akadai sekushandiswa kwezvinhu zvakapfava kune gobvu rakapedzwa ganda, zvinhu zvakaomarara zvepakati zvinhu kana zvepakati zvinhu zvinogona kushandiswa kudzikisa huremu hwepurasitiki yefuro.

4, kushandisa yakaderera mhando musimboti zvinhu kuderedza mutengo.

5, zvinhu zveganda kana zvepakati zvinhu zvinogona kushandisa zvinodhura uye nehunyanzvi hwepamusoro zvivakwa.Zvakadai senge anti-electromagnetic kupindira, yakakwira magetsi conductivity, uye zvimwe zvinhu kuti uwedzere kuita kwechigadzirwa.

6, Yakakodzera ganda zvinhu uye yakakosha zvinhu zvinogona kuderedza kusara kunetseka kwezvigadzirwa zvakaumbwa, kuwedzera simba remakanika kana chigadzirwa pamusoro pezvivakwa.

4 Microcellular Foam Injection Molding (MFIM)

MFIM chimiro

Microcellular foam jekiseni molding process: Iyo innovative precision Injection molding tekinoroji, iyo inotsamira pakuwedzera kwepores kuzadza chigadzirwa, uye inopedzisa kuumbwa kwechikamu pasi pekudzvinyirira kwakaderera uye kweavhareji.Iyo nzira ye microcellular foam molding inogona kukamurwa kuita nhanho nhatu: yekutanga, iyo supercritical fluid (carbon dioxide kana nitrogen) inonyungudika mune inopisa melt glue kuti igadzire imwe-phase solution;ipapo mhango ye mold ine tembiricha yakaderera uye kudzvanywa inobayiwa kuburikidza neinochinja-mhando yemuromo, iyo inokonzeresa kusagadzikana kwemamorekuru nekuda kwekudzika kwetembiricha uye kumanikidza kuumba huwandu hukuru hwebubble nuclei muchigadzirwa, uye idzi bubble nuclei zvishoma nezvishoma zvinokura kusvika. gadzira maburi madiki.

Process Technology features

1, Precision jekiseni kuumba.

2, Kuburikidza nezvakawanda zvipimo zvechinyakare jekiseni molding, inogona kuderedza zvakanyanya huremu hwezvikamu, kupfupisa kutenderera kutenderera.

3, inovandudza zvakanyanya iyo warpage deformation uye dimensional kugadzikana kwezvikamu.

Applications

Motokari chiridzwa mapaneru, mapaneru emagonhi, madhiraivha emhepo, nezvimwe.

5 Nano Molding Technology(NMT)

NMT muenzaniso

NMT (Nano Molding Technology): Inzira yekubatanidza simbi nepurasitiki ne nanotechnology, kutanga, simbi inobatwa ne nanosize, uyezve purasitiki inobaiwa zvakananga uye inoumbwa pamusoro pesimbi, kuitira kuti simbi nepurasitiki zvigone. kuumbwa sechinhu chimwe.Nanomolding tekinoroji zvinoenderana nenzvimbo yepurasitiki yakakamurwa kuva marudzi maviri emaitiro.

1, ipurasitiki yekusaonekwa kwechiso chechimwe-chidimbu chekuumba

2, plastiki yekuonekwa kwechiso chekubatanidza kuumbwa

Process Technology features:

1, chigadzirwa chine chimiro chesimbi uye chimiro.

2, dhizaini yechigadzirwa chechigadzirwa inorerutswa, kuitira kuti chigadzirwa chireruke, chitete, chipfupi, chidiki, uye chinodhura-chinodhura kupfuura CNC kugadzirisa nzira.

3, kuderedza mari yekugadzira uye simba rekubatanidza, uye kuderedza zvakanyanya kushandiswa kwezvinhu zvine hukama

Inoshanda simbi uye resin zvinhu.

1, Aluminium, magnesium, mhangura, simbi isina tsvina, titanium, simbi, galvanized sheet, ndarira.

2, aluminium alloy inonyanya kuchinjika, kusanganisira 1000 kusvika 7000 akatevedzana.

3, resin zvinosanganisira PPS, PBT, PA6, PA66, PPA.

4, PPS ine yakanyanya kusimba yekubatanidza simba (3000N / c㎡).

Applications:

Cell phone casing, laptop casing, etc.

Jekiseni molding inoshandiswa zvakanyanya mumaindasitiri akasiyana siyana uye inokwanisa kuwana isina musono uye chaiyo misa kugadzirwa kwezvikamu munguva pfupi.Prolean Tech inopa majekiseni ekuumba masevhisi kune akawanda ezvigadzirwa, zvinosanganisira mapurasitiki uye elastomers.Simply upload yourCAD fairayekukurumidza, yemahara quote uye kubvunzana pane ane hukama masevhisi.

Nguva yekutumira: Kubvumbi-02-2022

.png)