5 feem ntau cov txheej txheem yas txhaj tshuaj molding

1 Txhaj Moulding

Lub hauv paus ntsiab lus ntawm kev txhaj tshuaj molding yog ntxiv granular lossis hmoov raw cov ntaub ntawv rau hauv lub hopper ntawm lub tshuab txhaj tshuaj, thiab cov ntaub ntawv raw yog rhuab thiab yaj mus rau hauv lub xeev ua kua, ces thawb los ntawm cov ntsia hlau los yog piston ntawm lub tshuab txhaj tshuaj, nkag mus rau hauv pwm kab noj hniav. lub nozzle thiab lub pouring system ntawm pwm, thiab harden thiab teem nyob rau hauv lub pwm kab noj hniav.Cov ntsiab lus cuam tshuam qhov zoo ntawm kev txhaj tshuaj molding:txhaj tshuaj, lub sijhawm txhaj tshuaj, txhaj tshuaj kub.

Txheej Txheem Technology nta.

Qhov zoo:

1, luv molding voj voog, siab ntau lawm efficiency, yooj yim rau automate

2, tuaj yeem pwm cov duab zoo, qhov loj me, nrog cov hlau lossis cov hlau tsis yog hlau ntxig cov khoom yas

3, ruaj khov khoom zoo

4, ntau yam kev siv.

Qhov tsis zoo:

1, Txhaj tshuaj molding khoom nqi yog siab

2, complex qauv ntawm kev txhaj tshuaj pwm

3, cov nqi tsim khoom siab, lub voj voog ntev ntev, tsis haum rau ib qho me me ntawm cov khoom yas

Daim ntawv thov:

Hauv cov khoom lag luam, cov khoom siv tshuaj molded muaj xws li cov khoom siv hauv chav ua noj (khoom khib nyiab, tais, thoob, jugs, tableware, thiab ntau lub thawv), vaj tse rau cov khoom siv hluav taws xob (blowers, nqus tsev vacuum, khoom noj khoom haus, thiab lwm yam), cov khoom ua si thiab kev ua si, ntau qhov chaw rau kev lag luam automotive, qhov chaw rau ntau yam khoom, thiab lwm yam.

2 Ntxig Moulding

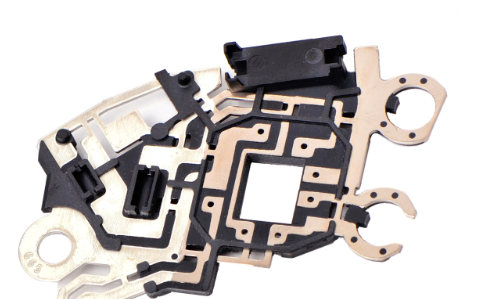

Insert molding daim ntawv thov

Ntxig molding yog txheej txheem molding nyob rau hauv uas lub pwm tau ntim nrog pre-npaj inserts ntawm cov khoom sib txawv thiab ces txhaj nrog resin, thiab cov ntaub ntawv molten tau koom nrog cov inserts thiab kho los ua ib qho khoom sib xyaw.

Txheej txheem Technoloy yam ntxwv

1, Ntau qhov ntxig ntxig ua ke ua ntej, ua rau kev tsim khoom tom qab kev tsim khoom ua ke kom tsim nyog.

2, Kev sib xyaw ntawm cov resin yooj yim ntawm molding, dabtsi yog khoov thiab hlau rigidity, lub zog thiab tshav kub kuj yuav supplemented los ua complex thiab ilv khoom hlau-yas integrated khoom.

3, tshwj xeeb tshaj yog, kev sib xyaw ua ke ntawm cov khoom siv hluav taws xob thiab cov hlau hluav taws xob tuaj yeem ua cov khoom molded uas tuaj yeem ua tau raws li cov haujlwm tseem ceeb ntawm cov khoom siv hluav taws xob.

4, Rau cov khoom siv molded nruj thiab cov roj hmab gaskets, kev txhaj tshuaj molding ntawm cov khoom sib xyaw ntawm cov khoom siv hauv lub substrate tshem tawm cov kev ua haujlwm nyuaj ntawm kev teeb tsa cov ntsaws ruaj ruaj thiab ua rau nws yooj yim rau automate tom qab txheej txheem sib dhos.

3 Ob chav xim txhaj tshuaj

Muab ob npaug rau xim txhaj tshuaj piv txwv

Muab ob npaug rau xim txhaj tshuaj molding: Nws yog ib txoj kev molding uas txhaj ob xim sib txawv ntawm cov yas rau hauv tib lub pwm.Nws tuaj yeem ua rau cov yas tshwm hauv ob xim sib txawv thiab tuaj yeem ua rau cov khoom yas tam sim no tsis tu ncua lossis cov qauv huab cua tsis zoo los txhim kho kev siv tau thiab kev zoo nkauj ntawm cov khoom yas.

Txheej txheem Technology yam ntxwv.

1, Cov khoom siv tseem ceeb tuaj yeem siv cov khoom viscosity tsawg los txo qhov kev txhaj tshuaj.

2, Los ntawm kev xav txog kev tiv thaiv ib puag ncig, cov khoom siv tseem ceeb tuaj yeem siv cov khoom siv thib ob.

3, cording rau cov yam ntxwv sib txawv ntawm kev siv, xws li kev siv cov khoom muag muag rau cov khoom siv tawv tawv tiav, cov khoom siv tawv tawv rau cov khoom siv los yog cov khoom siv tseem ceeb tuaj yeem siv los txo qhov hnyav ntawm cov yas ua npuas ncauj.

4, siv cov khoom siv qis dua kom txo tau cov nqi.

5, cov khoom siv tawv nqaij lossis cov khoom siv tseem ceeb tuaj yeem siv cov khoom kim thiab nrog cov khoom tshwj xeeb.Xws li kev tiv thaiv hluav taws xob cuam tshuam, hluav taws xob hluav taws xob siab, thiab lwm yam khoom siv los ua kom cov khoom ua tau zoo.

6 、 Cov khoom siv tawv nqaij tsim nyog thiab cov khoom siv tseem ceeb tuaj yeem txo qhov kev ntxhov siab ntawm cov khoom molded, ua kom cov khoom siv dag zog lossis cov khoom ntog.

4 Microcellular Foam Txhaj Moulding (MFIM)

MFIM structure

Microcellular foam txhaj tshuaj molding txheej txheem: Nws yog ib qho tshiab precision Txhaj molding tshuab, uas tso siab rau ntawm qhov nthuav dav ntawm qhov hws los sau cov khoom, thiab ua kom tiav cov molding ntawm ib feem nyob rau hauv ib tug tsawg thiab nruab nrab siab.Cov txheej txheem ntawm microcellular ua npuas ncauj molding tuaj yeem muab faib ua peb theem: ua ntej, cov kua dej supercritical (carbon dioxide lossis nitrogen) yog yaj rau hauv cov kua nplaum kub yaj los ua ib qho kev daws teeb meem;Tom qab ntawd cov pwm kab noj hniav nrog qhov kub thiab txias yog txhaj los ntawm lub tshuab hloov-hom nozzle, uas ua rau tsis muaj zog ntawm cov molecules vim qhov kub thiab txias thiab siab los tsim ntau cov npuas nuclei hauv cov khoom, thiab cov npuas nuclei maj mam loj tuaj. tsim cov qhov me me.

Txheej Txheem Technology nta

1, Precision txhaj tshuaj molding.

2, Kev tawg ntawm ntau qhov kev txwv ntawm kev txhaj tshuaj molding, tuaj yeem txo qhov hnyav ntawm qhov chaw, txo lub voj voog molding.

3, zoo heev txhim kho lub warpage deformation thiab seem stability ntawm qhov chaw.

Daim ntawv thov

Tsheb ntsuas vaj huam sib luag, qhov rooj vaj huam sib luag, cua txias ducts, thiab lwm yam.

5 Nano Moulding Technology(NMT)

NMT np

NMT (Nano Moulding Technology): Nws yog ib txoj hauv kev sib txuas cov hlau thiab yas nrog nanotechnology, ua ntej, cov hlau saum npoo yog kho nrog nanosize, thiab tom qab ntawd cov yas yog ncaj qha txhaj thiab molded ntawm cov hlau nto, kom cov hlau thiab yas tuaj yeem. raug tsim ua ib qho.Nanomolding tshuab raws li qhov chaw ntawm cov yas muab faib ua ob hom txheej txheem.

1, yas rau qhov tsis pom ntawm qhov chaw ntawm ib daim molding

2, yas rau qhov pom ntawm qhov chaw ntawm kev sib xyaw molding

Txheej Txheem Technology nta:

1, cov khoom muaj xim hlau zoo nkauj thiab kev ntxhib los mos.

2, tus tsim ntawm cov khoom mechanism yog yooj yim, yog li ntawd cov khoom yog sib dua, nyias, luv, me me, thiab ntau npaum li cas-zoo li CNC ua txoj kev.

3, txo cov nqi tsim khoom thiab kev sib koom ua ke siab, thiab txo qis kev siv cov khoom siv cuam tshuam

Siv tau cov ntaub ntawv hlau thiab resin.

1, Aluminium, magnesium, tooj liab, stainless hlau, titanium, hlau, galvanized ntawv, tooj dag.

2, aluminium alloy yog hloov tau ntau dua, suav nrog 1000 txog 7000 series.

3, resins suav nrog PPS, PBT, PA6, PA66, PPA.

4, PPS muaj lub zog tshwj xeeb ntawm kev sib txuas (3000N / c㎡).

Daim ntawv thov:

Cell phone casing, laptop casing, thiab lwm yam.

Kev txhaj tshuaj molding yog dav siv nyob rau hauv ntau yam kev lag luam thiab tuaj yeem ua tiav seamless thiab meej ntau lawm ntawm cov khoom hauv lub sijhawm luv luv.Prolean Tech muab kev txhaj tshuaj molding rau kaum ob ntawm cov ntaub ntawv, suav nrog cov yas thiab elastomers.Tsuas yog upload kojCAD cov ntaub ntawvkom ceev, pub dawb hais thiab kev sab laj txog cov kev pabcuam cuam tshuam.

Post lub sij hawm: Apr-02-2022

.png)