Cov txheej txheem polishing piav qhia, kawm yuav ua li cas ua kom koj cov khoom ci

Lub sij hawm nyeem: 4 mins

Daim iav polishing

Txheej txheem cej luam ntawm Polishing

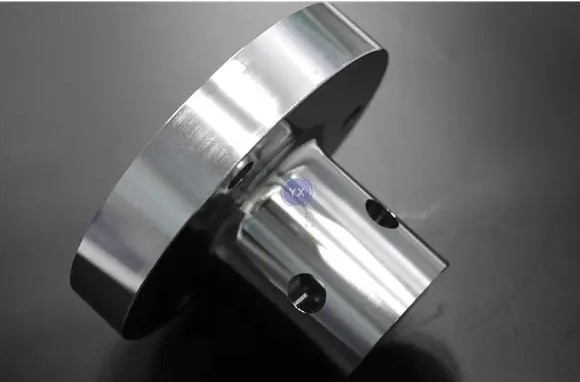

Polishing yog ib txoj kev ua haujlwm uas siv cov khoom siv kho tshuab, tshuaj lom neeg lossis hluav taws xob ua haujlwm los txo qhov roughness ntawm lub workpiece thiaj li yuav tau txais qhov kaj, tiaj tus.Feem ntau, nws yog txheej txheem ua tiav ntawm qhov chaw ua haujlwm siv cov cuab yeej polishing thiab cov khoom abrasive lossis lwm yam xov xwm polishing, feem ntau ua raws li kev tu kom zoo ntawm qhov chaw ua ntej txheej txheem.Qhov saum npoo ntawm polished yog du thiab me ntsis reflective.Qhov kawg tshwm sim ntawm polishing yog kev txhim kho gloss thiab luster ntawm qhov chaw.Daim iav zoo li ci ntsa iab tuaj yeem tau txais nrog polishing zoo.

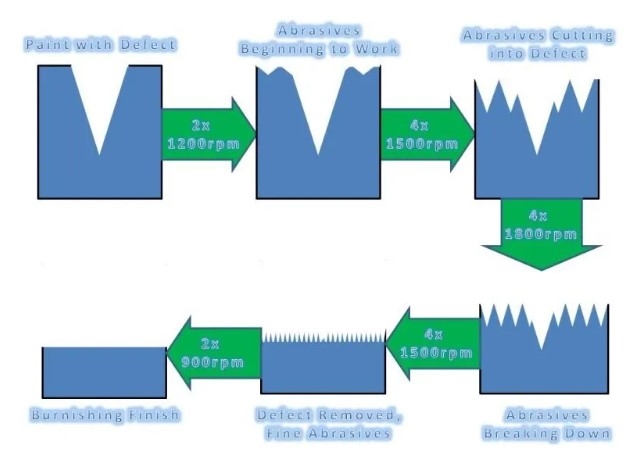

Polishing ua haujlwm li cas?

Polishing yog txoj cai ntawm kev tshem tawm cov txheej nyias nyias los ntawm qhov chaw polished siv cov khoom siv lub teeb.Polishing tshem tawm ib txheej nyias heev, uas ua rau saum npoo ntawm qhov ci thiab tiaj tus.Yog hais tias qhov defect ntawm qhov tob tob dua li qhov tuaj yeem raug tshem tawm los ntawm polishing, qhov tsis zoo ntawm qhov chaw tseem yuav pom, txawm hais tias qhov kev tshem tawm ib nrab ntawm qhov tsis xws luag yuav ua rau nws pom tsawg dua.Piv txwv li, yog tias qhov tsis xws luag yog 5 microns tuab thiab tsuas yog 3 microns tuaj yeem raug tshem tawm los ntawm polishing, tseem yuav muaj 2 microns sab laug.Txawm hais tias qhov tsis xws luag yog 3 microns tsawg dua thiab pom tsawg dua, nws tseem tuaj yeem pom.

Cov txiaj ntsig ntawm Polishing

- Muaj peev xwm kaw lub siab siab gases thiab kua

- Kev siv tshuaj pleev ib ce

- Muaj peev xwm siv cov cuab yeej kho qhov muag flatness ntsuas

- Txo tus nqi ntawm qhov chaw thiab sub-surface puas

- Muab qhov zoo sib xws rau qhov chaw uas xav tau cov txheej txheem epitaxial lossis cov khoom tso tawm

- Ua kom cov npoo ntawm cov cuab yeej txiav

Hom Polishing

Tshuab polishing

Txoj kev polishing no yog ua raws li cov yas deformation los yog txiav ntawm cov khoom nto kom tau ib tug du nto los ntawm kev tshem tawm cov polished convex nto.Mechanical polishing feem ntau siv abrasive rods, muaj lub log, thiab ntawv xuab zeb, thiab feem ntau yog phau ntawv.Kev sib hloov lub cev thiab lwm yam tshwj xeeb tuaj yeem siv cov cuab yeej pabcuam xws li turntables, thiab ultra-precision polishing tuaj yeem siv rau qhov kev xav tau zoo.

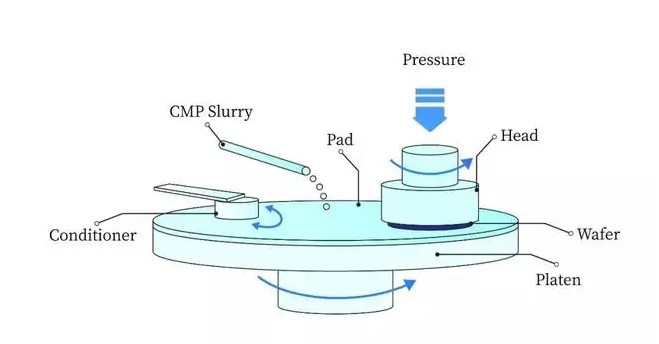

Ultra-precision polishing yog siv tshwj xeeb abrasives los tig cov txheej txheem ntawm lub workpiece ntawm kev kub ceev los ntawm nias rau hauv cov tshuaj polishing uas muaj cov abrasives.Qhov roughness ntawm 0.008μm tuaj yeem ua tiav siv cov txheej txheem no, uas yog qhov zoo tshaj plaws ntawm ntau txoj kev polishing.Txoj kev no feem ntau yog siv rau optical lens pwm.

Qhov zoo

High brightness

Zoo dua deg cleanability

Siab dua aesthetic thov

Txo cov khoom adhesion

Zoo dua nto tiav

Qhov tsis zoo

Tus nqi ua haujlwm siab

Tsis tuaj yeem tuav cov txheej txheem nyuaj

Ci tuaj yeem ua tau zoo ib yam thiab yuav tsis kav ntev

Tej zaum yuav raug rau corrosion

Tshuaj polishing

Tshuaj kho tshuab polishing

Hom polishing no siv lub hauv paus ntsiab lus hais tias cov khoom seem ntawm cov khoom nto yog qhov nyiam tshaj plaws nyob rau hauv cov tshuaj nruab nrab, yog li ua rau saum npoo ntawm lub workpiece smooth tom qab cov tshuaj tiv thaiv tiav.Lub hauv paus ntawm cov tshuaj polishing yog kev npaj cov tshuaj polishing, uas tuaj yeem ua tiav qhov roughness ntawm ob peb 10 μm, tab sis cov txiaj ntsig ncaj qha ntawm cov tshuaj polishing yog qhov smoothing thiab polishing ntawm micro- ntxhib qhov chaw.Nws kuj tseem ua rau kev sib xyaw ua ke ntawm cov txheej txheej sab saud.

Qhov zoo ntawm chemical polishing

Muaj peev xwm txhuam cov duab nyuaj vim tsis muaj kev koom tes ncaj qha yuav tsum tau ua

Kev ua haujlwm siab

Muaj peev xwm polish ntau qhov chaw tib lub sijhawm

Txo kev nqis peev hauv cov cuab yeej siv

Zoo corrosion kuj, tso cai rau tsim ib tug passivation txheej nyob rau saum npoo ntawm ib feem

Disadvantages ntawm tshuaj polishing

Tsis sib xws brightness

Tsis yooj yim rau kev kho cua sov

Gas yooj yim nchuav

Tsis yog ib puag ncig tus phooj ywg, tuaj yeem tso cov pa phem

Kev hloov kho nyuaj thiab rov tsim dua tshiab ntawm cov tshuaj polishing

Electrolytic polishing

Stainless hlau electrolytic polishing

Lub hauv paus ntsiab lus ntawm electrolytic polishing yog tib yam li tshuaj polishing, ob qho tib si siv cov kev daws teeb meem kom yaj cov me me rau ntawm qhov chaw thiab tau qhov chaw du.Txawm li cas los xij, piv nrog tshuaj polishing, cov nyhuv cathodic tuaj yeem raug tshem tawm thiab cov nyhuv polishing zoo dua.Electropolishing tshem tawm cov khoom los ntawm cov hlau ua haujlwm, txo qhov roughness ntawm qhov chaw thiab txhim kho qhov chaw tiav los ntawm smoothing tawm micro peaks thiab hav.Cov txheej txheem ntawm electrochemical polishing tuaj yeem muab faib ua ob kauj ruam, ua ntej, macro polishing, qhov twg cov khoom tawg tau diffuse rau hauv electrolyte, ua rau cov khoom nto roughness txo, es> 1μm, thiab tom qab ntawd anodic polarization, ua rau qhov ci ntsa iab.Ra <1 m.

Qhov zoo

Ntev ntev luster

Ib txwm xim sab hauv thiab tawm

Ntau yam khoom siv tuaj yeem kho tau

Tus nqi qis thiab lub sijhawm luv luv

Txhawb kom muaj kab mob tsawg

Siab corrosion kuj

Qhov tsis zoo

Siab ruaj khov peev

Complex pre-polishing txheej txheem

Cov cuab yeej thiab cov khoom siv hluav taws xob xav tau rau cov khoom siv

Tsis zoo versatility ntawm electrolyte

Polishing feem ntau yog txheej txheem kawg hauv kev tsim khoom thiab yog ib qho ntawm cov yuam sij kom ntseeg tau tias cov qauv tsim los yog cov khoom loj ua tau raws li cov qauv.Nws yog ib qho tseem ceeb heev rau peb cov neeg muas zaub uas nto ntawm ib feem yog ci thiab tiaj tus los ntawm meej thiab zoo polishing.Koj tuaj yeem tshawb xyuas pebcov kev pab kho saum npooyog xav paub ntxiv.

Prolean Tech cov kev pabcuam saum npoo av muaj cov qauv thiab nrov tiav rau qhov chaw.Peb cov tshuab CNC thiab lwm yam thev naus laus zis thev naus laus zis muaj peev xwm ua tiav kev ua haujlwm nruj thiab ua tau zoo, zoo ib yam rau txhua yam ntawm qhov chaw.Tsuas yogupload koj cov ntaub ntawv CADkom ceev, pub dawb hais thiab kev sab laj txog cov kev pabcuam cuam tshuam.

Post lub sij hawm: Apr-26-2022