An Bayyana Tsarin gogewa, koyi yadda ake sa sassan ku su haskaka

Lokacin karantawa: 4mins

Gyaran madubi

Bayanin Polishing

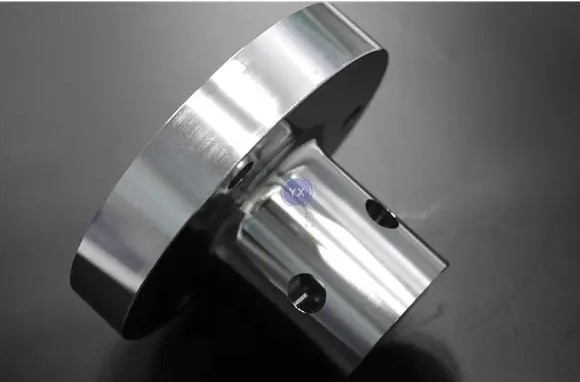

Polishing hanya ce ta sarrafawa wacce ke amfani da na'ura, sinadarai ko aikin electrochemical don rage ƙarancin saman kayan aikin don samun fili mai haske.Gabaɗaya, tsari ne na gamawa akan farfajiyar aikin aiki ta amfani da kayan aikin gogewa da ɓarna barbashi ko wasu kafofin watsa labarai na gogewa, yawanci ana biye da ingantaccen tsaftacewa na farfajiyar kafin aiwatarwa.Fuskar sashin da aka goge yana da santsi kuma yana nuna dan kadan.Sakamakon ƙarshe na gogewa shine ingantacciyar kyalli da kyalli na saman.Hakanan za'a iya samun saman haske mai kama da madubi tare da gogewa mai kyau.

Yaya Polishing Aiki?

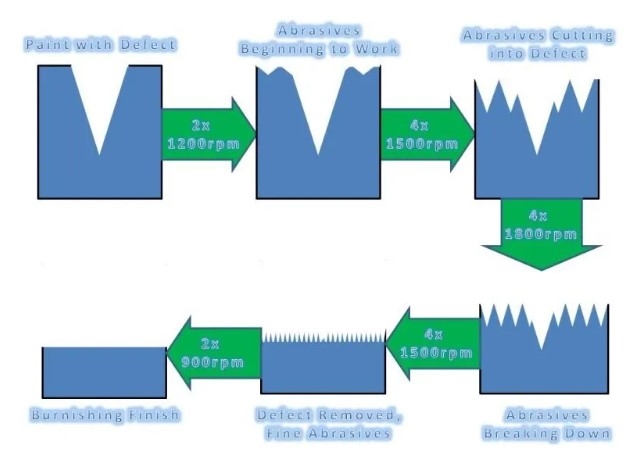

Gogewa shine aikin cire wani sirara mai bakin ciki daga saman da ake gogewa ta amfani da samfur mai kyalli.Gogewa yana kawar da wani ɗan ƙaramin bakin ciki sosai, wanda ke sa saman ɓangaren ya haskaka da lebur.Idan lahanin saman ya yi zurfi fiye da abin da za'a iya cirewa ta hanyar gogewa, lahani na saman zai kasance a bayyane, ko da yake cire wani ɓangare na lahani zai sa ya zama ƙasa.Misali, idan kauri na sama ya kai microns 5 kuma microns 3 kawai za'a iya cirewa ta hanyar goge baki, har yanzu akwai sauran microns 2.Ko da yake lahanin ba shi da zurfin 3 microns ƙasa da zurfi kuma yana iya zama ƙasa da bayyane, har yanzu ana iya gani.

Amfanin goge goge

- Ikon rufe manyan iskar gas da ruwaye

- Amfanin kwaskwarima

- Ikon amfani da na'urorin auna ma'auni

- Yana rage yawan lalacewar ƙasa da ƙasa

- Yana ba da ingantacciyar daidaituwa ga saman da ke buƙatar matakan epitaxial ko kayan ajiya

- Yana samar da fitattun gefuna akan kayan aikin yanke

Nau'in goge baki

Gyaran injina

Wannan hanyar goge goge ta dogara ne akan nakasar filastik ko yankan saman kayan don samun santsi mai santsi ta hanyar cire ƙoƙon filaye.Gyaran injina gabaɗaya yana amfani da sanduna masu ɓarna, ƙafafun ƙafafu, da takarda yashi, kuma galibi na hannu ne.Juyawa jiki da sauran sassa na musamman na iya amfani da kayan aikin taimako irin su turntables, kuma ana iya amfani da polishing mai madaidaici don buƙatun ingancin ƙasa.

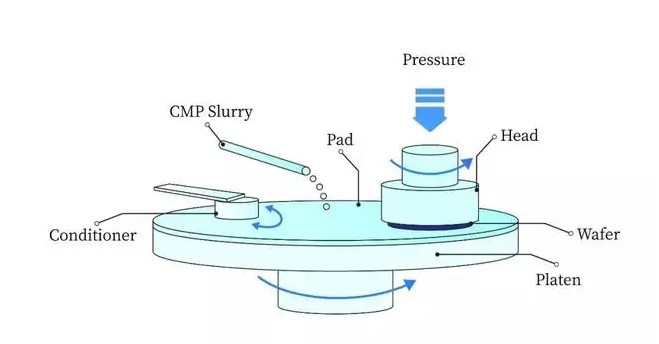

Ultra-daidaici polishing shine a yi amfani da abrasives na musamman don jujjuya saman da aka sarrafa na aikin a cikin babban sauri ta danna shi a cikin maganin polishing mai ɗauke da abrasives.Za'a iya samun rashin ƙarfi na 0.008μm ta amfani da wannan fasaha, wanda shine mafi kyau tsakanin hanyoyin gogewa daban-daban.Ana amfani da wannan hanyar sau da yawa don ƙirar ruwan tabarau na gani.

Amfani

Babban haske

Mafi kyawun tsaftar ƙasa

Mafi girman kyan gani

Rage manne samfurin

Mafi kyawun ƙarewa

Rashin amfani

Babban tsadar aiki

Ba za a iya sarrafa hadadden tsarin sassa ba

Haske na iya zama daidai kuma bazai daɗe ba

Zai iya zama mai saurin lalacewa

Chemical polishing

Chemical inji polishing

Irin wannan polishing yana amfani da ka'idar cewa sassan da ke fitowa daga cikin kayan sun fi dacewa a narkar da su a cikin matsakaicin sinadarai, don haka ya sa saman kayan aikin ya zama santsi bayan an kammala aikin sinadaran.Jigon gyaran gyare-gyaren sinadarai shine shirye-shiryen maganin polishing, wanda zai iya kaiwa ga rashin ƙarfi na 10 μm da yawa, amma sakamakon kai tsaye na gyaran gyare-gyaren sinadarai shine laushi da gogewa na ƙananan sassa.Har ila yau yana haifar da rushewar saman Layer na sashin.

Amfanin goge gogen sinadarai

Yiwuwar goge hadaddun sifofi kamar yadda ba a buƙatar sa hannun hannu kai tsaye ba

Babban inganci

Yiwuwar goge sassa da yawa a lokaci guda

Rage hannun jari a kayan aiki

Kyakkyawan juriya na lalata, ƙyale samuwar Layer passivation a saman sashin

Rashin hasara na gogewar sinadarai

Haske mara daidaituwa

Wuya don yin maganin zafi

Gas yana zubewa cikin sauki

Ba abokantaka da muhalli ba, na iya sakin iskar gas mai cutarwa

Wahalar daidaitawa da sabuntawar maganin goge baki

Electrolytic polishing

Bakin karfe electrolytic polishing

Mahimmin ka'ida na polishing electrolytic iri ɗaya ne da gogewar sinadarai, duka biyun suna amfani da maganin narkar da su don narkar da ƙananan ƙwanƙwasa a saman kuma samun wuri mai santsi.Duk da haka, idan aka kwatanta da sinadaran polishing, sakamakon cathodic dauki za a iya kawar da kuma polishing sakamako ne mafi alhẽri.Electropolishing yana cire kayan aiki daga kayan aiki na ƙarfe, yana rage ƙarancin ƙasa kuma yana haɓaka ƙarewar ƙasa ta hanyar daidaita ƙananan kololuwa da kwaruruka.Ana iya raba tsarin polishing electrochemical zuwa matakai biyu, na farko, macro polishing, inda samfuran narkar da su ke yaɗuwa a cikin electrolyte, suna sa ƙarancin kayan abu ya ragu, maimakon> 1μm, sa'an nan kuma anodic polarization, yana sa haske ya karu.Ra <1μm.

Amfani

Tsawon haske mai dorewa

Daidaitaccen launi ciki da waje

Za'a iya yin magani da yawa na kayan aiki

Ƙananan farashi da ɗan gajeren lokacin zagayowar

Yana ƙarfafa ƙarancin ƙazanta

Babban juriya na lalata

Rashin amfani

Babban kafaffen zuba jari

Rukunin tsari na riga-kafi

Kayan aiki da na'urorin lantarki da ake buƙata don hadaddun sassa

Rashin ƙarfi na electrolyte

Polishing yawanci tsari ne na ƙarshe a masana'anta kuma yana ɗaya daga cikin maɓallan don tabbatar da cewa samfura ko samarwa da yawa sun cika ƙa'idodi.Yana da matukar mahimmanci ga abokan cinikinmu cewa saman sashin yana da haske da lebur ta hanyar gogewa mai inganci da inganci.Kuna iya duba musaman jiyya ayyukadon ƙarin bayani.

Sabis na gamawa na Prolean Tech yana ba da daidaitattun kuma sanannen kammalawa ga sassa.Our CNC inji da sauran surface karewa fasahar ne iya cimma m tolerances da high quality, uniform saman ga kowane irin sassa.Kawailoda fayil ɗin CAD ɗin kudon faɗakarwa da sauri, kyauta da shawarwari akan ayyuka masu alaƙa.

Lokacin aikawa: Afrilu-26-2022